Maintenance Tips to Extend the Life of Your Lab Sink

- Daily Maintenance Practices for Lab Sinks

- 1. Daily cleaning and decontamination routine

- 2. Proper handling of chemicals and wastes

- 3. Preventing physical damage and surface abrasion

- Periodic and Preventive Maintenance Procedures

- 1. Weekly and monthly inspection checklist

- 2. Drain maintenance and clog prevention

- 3. Faucet and plumbing maintenance

- Material-Specific Care and Repair Guidance

- 1. Chemical-resistant resin sinks (epoxy, phenolic)

- 2. Stainless steel sinks

- 3. Polypropylene/HDPE and ceramic sinks

- Troubleshooting, Repairs and When to Replace

- 1. Common problems and quick fixes

- 2. Deciding between repair and replacement

- 3. Professional repair and regulatory considerations

- Material Comparison Table: Choosing the Right Lab Sink

- Operational Best Practices and Staff Training

- 1. Standard operating procedures (SOPs)

- 2. Staff training and signage

- 3. Inventory of spare parts and consumables

- Brand Advantages and Why Choose Our Lab Sink Cabinet

- FAQ — Maintenance and Use of Lab Sinks

- Q1: How often should I inspect the lab sink and cabinet?

- Q2: Can I pour acids or solvents down a lab sink?

- Q3: What cleaning products are safe for chemical-resistant lab sinks?

- Q4: How do I know when the lab sink needs replacement?

- Q5: Where can I find more technical guidance on laboratory furniture and safety?

Well-maintained lab sinks are critical components of modern laboratory workspaces. Regular cleaning, correct chemical handling, appropriate material selection and simple preventive measures can greatly extend the useful life of a lab sink and the supporting Lab Sink Cabinet while preserving laboratory safety and compliance. This article outlines practical maintenance routines, material-specific guidance, inspection checklists and troubleshooting tips tailored for chemistry labs, teaching labs, biopharmaceutical facilities and testing departments.

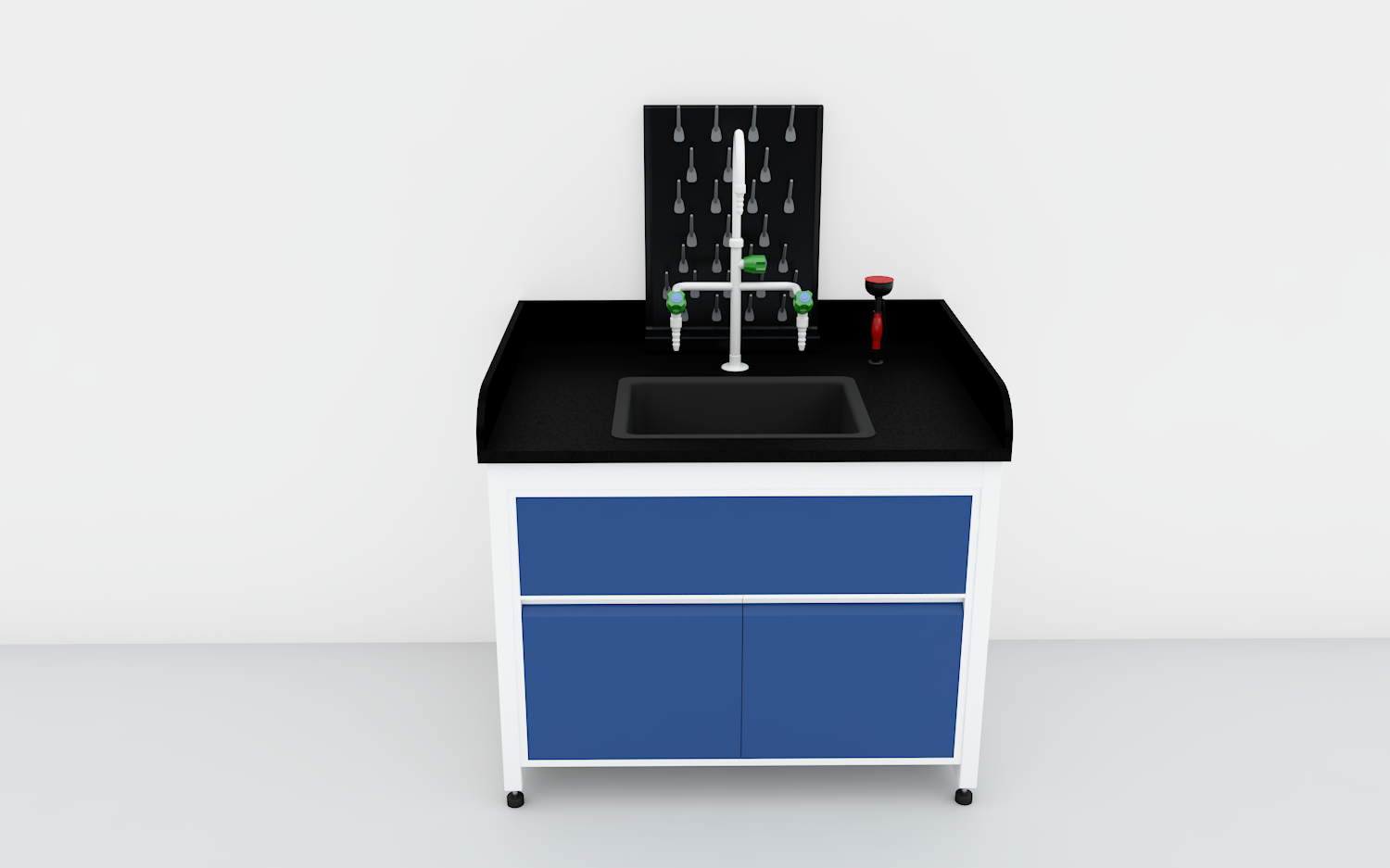

The Lab Sink Cabinet is designed for chemistry labs, teaching labs, biopharmaceutical facilities and testing departments, and can be seamlessly integrated into complete laboratory bench systems. The product offers C-type, floor-mounted and H-type structures, combined with a chemical-resistant lab sink and lab faucet to meet cleaning, rinsing, drainage and temporary storage needs.

Daily Maintenance Practices for Lab Sinks

1. Daily cleaning and decontamination routine

Establish a short, repeatable daily cleaning routine to remove residues and prevent accumulations that cause corrosion or staining. Use manufacturer-recommended cleaners compatible with the sink material. For chemical-resistant sinks, mild non-abrasive detergents are usually sufficient; for stainless steel, neutral pH cleaners help avoid pitting or discoloration. Always rinse thoroughly with water after cleaning to eliminate residues that can promote corrosion or biofilm formation.

2. Proper handling of chemicals and wastes

Never pour incompatible or concentrated corrosive chemicals down the lab sink. Many labs use designated chemical waste containers and fume hood sinks for strong acids, bases and solvents. Train personnel to use drainage controls (e.g., strainers, chemical traps) and to neutralize acids/bases per safety protocols. Refer to authoritative guidance on laboratory safety from the CDC Laboratory Safety for handling hazardous materials safely.

3. Preventing physical damage and surface abrasion

Avoid dropping heavy glassware or instruments into the sink. Use sink inserts or protective mats when handling delicate or heavy items. Do not use abrasive scrubbers on a chemical-resistant resin sink surface — these can scratch and reduce the sink's resistance to chemicals.

Periodic and Preventive Maintenance Procedures

1. Weekly and monthly inspection checklist

Create a simple inspection checklist to log condition and function. Key items include:

- Visual inspection of sink basin for cracks, discoloration or surface degradation.

- Check faucet operation, aerator condition and presence of leaks.

- Examine drain fittings, P-trap and joints for corrosion, blockages or leakage.

- Assess cabinet interiors for moisture, chemical stains or corrosion of supports.

Logging these checks helps detect problems early and supports lifecycle tracking for equipment.

2. Drain maintenance and clog prevention

Clogged drains cause backups and can lead to overflow or contamination incidents. Use strainers to capture solids, and employ sink-safe enzymatic drain cleaners on a monthly schedule where appropriate. Avoid frequent use of strong acids/alkalis for clearing clogs as they may damage some sink materials and plumbing. Mechanical cleaning (e.g., removal of P-trap for inspection) should be done using gloves and containment to prevent exposure to hazardous residues.

3. Faucet and plumbing maintenance

Faucets are high-use components and should be serviced periodically. Replace worn washers or cartridges, clean aerators to maintain flow, and check that chemical-resistant faucet seals remain intact. For labs using emergency eyewash or safety showers integrated near sinks, test flow and temperature controls according to ASSE/ANSI standards and institutional protocols.

Material-Specific Care and Repair Guidance

1. Chemical-resistant resin sinks (epoxy, phenolic)

Resin sinks offer excellent resistance to many chemicals but can be sensitive to prolonged contact with aggressive solvents or concentrated acids. Clean with non-abrasive cleaners and avoid organic solvents like acetone or methylene chloride directly in the basin. Small surface scratches can often be smoothed with manufacturer-recommended polishing kits; deeper cracks may require replacement to prevent leakage.

2. Stainless steel sinks

Stainless steel is durable and easy to clean but susceptible to pitting and crevice corrosion if exposed to chlorides or left wet. Use neutral pH cleaners and avoid bleach or strong chlorinated cleaners. For persistent mineral deposits, a vinegar solution can be used to dissolve scale, followed by rinsing. For guidance on corrosion prevention and stainless steel properties, see Stainless steel — Wikipedia.

3. Polypropylene/HDPE and ceramic sinks

Thermoplastic sinks like polypropylene and HDPE provide good chemical resistance to many acids and alkalis but have lower heat resistance. Avoid high-temperature spills and sharp instrument impacts. Ceramic sinks resist scratching and staining but can crack under impact; repair usually requires professional replacement of the basin.

Troubleshooting, Repairs and When to Replace

1. Common problems and quick fixes

Leaks: Identify source (faucet, drain, P-trap). Tighten fittings and replace gaskets if necessary. Persistent leaks often indicate failing seals requiring parts replacement.

Clogs: Remove strainers and mechanically clean the P-trap. Use sink-safe enzymatic drain cleaners as a preventive measure.

Surface damage: For minor scratches in resin sinks, consult the manufacturer's repair kit. For stainless steel pitting, surface polishing may help, but deep pits reduce structural life.

2. Deciding between repair and replacement

Replace the sink or cabinet if the basin has an unrecoverable crack, if structural supports of the cabinet are compromised by corrosion, or if frequent repairs exceed a cost threshold (commonly 40–50% of replacement cost). Regular lifecycle cost accounting helps determine the best timing for replacement to avoid unexpected downtime.

3. Professional repair and regulatory considerations

For plumbing work connected to laboratory drains that handle hazardous wastes, use licensed contractors familiar with laboratory codes and local environmental discharge regulations. Maintain records of repairs and inspections for compliance with institutional safety audits.

Material Comparison Table: Choosing the Right Lab Sink

| Material | Chemical Resistance | Typical Lifespan | Maintenance Intensity | Best Use Cases |

|---|---|---|---|---|

| Epoxy/Phenolic Resin | High for many acids and bases; sensitive to strong solvents | 10–20 years (with proper care) | Moderate — avoid abrasives/solvents | Chemistry labs, general-purpose cleaning |

| Stainless Steel (304/316) | Good; 316 better for chlorides/stronger environments | 15–30+ years | Low — regular cleaning, avoid chlorides | Wash stations, aqueous processes, autoclave prep |

| Polypropylene / HDPE | Good for many acids and bases; limited heat resistance | 10–20 years | Low — avoid hot spills | Schools, teaching labs, light chemical use |

| Ceramic | Excellent for staining and acids; brittle | 15–25 years | Low — avoid impacts | Specialized uses where chemical staining is a concern |

Operational Best Practices and Staff Training

1. Standard operating procedures (SOPs)

Develop SOPs that define acceptable sink use, prohibited discharges, cleaning schedules and emergency procedures for spills and overflows. Make SOPs visible in lab areas and include sink maintenance in routine lab audits.

2. Staff training and signage

Train all users on proper disposal, daily cleaning tasks and how to report faults. Use clear signage above sinks explaining what may not be disposed of via the drainage system (solvents, heavy metals, biological wastes, etc.).

3. Inventory of spare parts and consumables

Keep common spare parts (aerators, seals, strainers, P-trap assemblies) on hand to enable quick repairs. Track usage of consumables like cleaning products and replace them according to manufacturer recommendations.

Brand Advantages and Why Choose Our Lab Sink Cabinet

Our Lab Sink Cabinet integrates design choices that simplify maintenance and extend service life. Key advantages include:

- Flexible configurations (C-type, floor-mounted, H-type) to suit diverse lab layouts and to enable efficient drainage routing.

- Chemical-resistant sink materials selected for laboratory compatibility and reduced maintenance needs.

- Robust cabinet construction with moisture-resistant interiors and accessible plumbing chase for quick servicing.

- Compatibility with standard lab faucets and safety fixtures to meet institutional requirements.

These design choices reduce downtime, lower total cost of ownership and make routine maintenance easier for facilities teams.

FAQ — Maintenance and Use of Lab Sinks

Q1: How often should I inspect the lab sink and cabinet?

A1: Perform a quick visual check daily, a more detailed inspection weekly, and a formal logged inspection monthly. Adjust frequency based on usage intensity and the types of chemicals used in the sink.

Q2: Can I pour acids or solvents down a lab sink?

A2: Generally no. Concentrated acids, bases and organic solvents should be disposed of through designated chemical waste procedures. Consult your institution's hazardous waste guidelines and local regulations. CDC and institutional lab safety guidelines provide additional direction: CDC Laboratory Safety.

Q3: What cleaning products are safe for chemical-resistant lab sinks?

A3: Use non-abrasive, manufacturer-recommended detergents. Avoid strong organic solvents on resin sinks and avoid chlorinated bleaches on stainless steel. If unsure, consult the sink material data sheet or the manufacturer.

Q4: How do I know when the lab sink needs replacement?

A4: Replace the sink if there are unrecoverable cracks, persistent leaks after repairs, structural cabinet corrosion, or when repairs exceed roughly 40% of the replacement cost. Regular lifecycle reviews will help plan replacements proactively.

Q5: Where can I find more technical guidance on laboratory furniture and safety?

A5: Trusted sources include institutional safety offices, national public health bodies like the CDC, and equipment standards references. For general background on lab equipment and furniture, see Laboratory equipment — Wikipedia.

As maintenance routines are established, many facilities look to enhance productivity through custom lab sink cabinet features that improve workflow.If you have specific questions about installing, maintaining or upgrading your Lab Sink Cabinet, please contact our technical team or view the product details. Our specialists can recommend the best sink materials and maintenance plans for your laboratory needs.

Fume Hood Lifecycle Costs: Total Cost of Ownership Guide

How Anti-vibration Tables & Balance Tables BT-03 improve accuracy

Lab Sink Cabinet Size and Layout Tips for Efficient Workflows

Top 10 Laboratory furniture Manufacturers and Supplier Brands in 2026

For Logistics

What is the lead time?

We usually will start to work after receiving 50% deposit, and as for the exact lead time, it depends on quantity and detailed requirement. We can promise it will be shipped on time as we negotiated.

For Products

What materials do you use for your furniture?

We use a variety of durable materials such as stainless steel, steel wood, PP and wood composites. Our countertop materials are phenolic resin, epoxy resin, ceramic, trespa and granite, depending on your lab’s needs.

For Company

Do you offer our design service from scratch?

Yes, we provide full design support tailored to your lab’s specific needs, including layout planning and furniture customization.

How long has your company been in business?

Our company has been in the laboratory furniture and equipment business for over 15 years, during which we have gained extensive experience and built a solid reputation in the industry. We specialize in serving a variety of industries, including academic research labs, pharmaceutical labs, healthcare, manufacturing, and more.

FAQS

How can I request a quote?

Simply contact us or fill out our online form with your project details. Our team will respond promptly with a free quote.

Lab Sink LS-08

The LS-08 Round Cup / Funnel Sink is a small-diameter, deep cup sink designed as a funnel-type drain point on laboratory worktops. Constructed from chemical-resistant black PP, it features an extended threaded outlet that connects directly to drain piping.

This design is perfect for apparatus drain lines, RO reject water, condensate and other continuous or intermittent discharges where an open, funnel-like inlet is required.

Floor Mounted Lab Bench

Our Floor Mounted Lab Bench is an essential, high-efficiency workspace for laboratories, made from high-quality steel-wood or corrosion-resistant stainless steel materials to ensure exceptional durability and stability. The unique floor-mounted design effectively reduces vibration, optimizes space usage, and provides a safe and tidy laboratory environment.

Customizable storage solutions help organize lab equipment efficiently, while the easy-to-clean surface maintains laboratory hygiene. It is widely suitable for research institutions, educational laboratories, and the chemical and pharmaceutical industries.

Fume Hood

The fume hood provides safe ventilation to protect against exposure to hazardous or toxic fumes, vapors, or airborne particulate. It is primarily used in laboratory and manufacturing applications to protect the user or environment outside the hood, but can also be used to protect the materials or experiment under the hood.

APPLICATION

Chemistry Lab, physics Lab, biological analysis, pharmaceutical medicine analysis, biological pharmaceutical, plant culture, environmental testing and electronic instrumentation scientific research and so on.

Flammable Storage Cabinet

Safety Cabinets store flammable liquids, corrosives, pesticides and other hazardous materials. All fire-resistant safety cabinets by meet fire codes and regulations for safety storage.

To help protect your people and facility from a potential fire, safety cabinets are engineered to safely contain flammable fuels, solvents, and chemicals. Safety cabinets can not only help everyone store chemicals reasonably, save chemical supplies, but also save human resources, and avoid fires caused by chemicals with the greatest strength.

Scan QR Code

Scan QR Code

MaxLabFurniture

MaxLab Furniture

daihongada

Max Laboratory