Product

PP Centrifugal Anti-corrosion Fans (Roof-mounted)

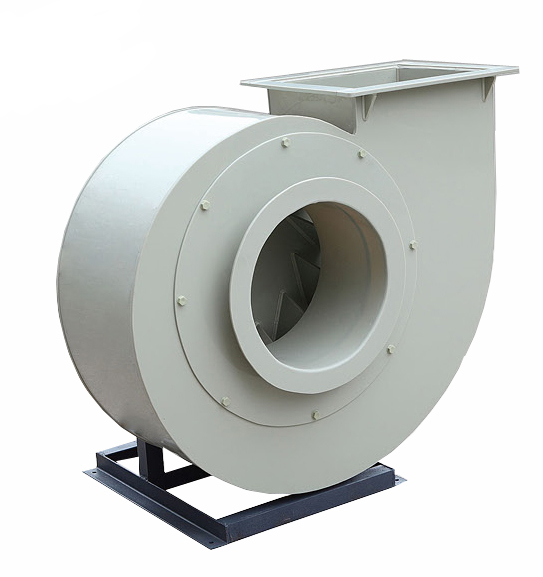

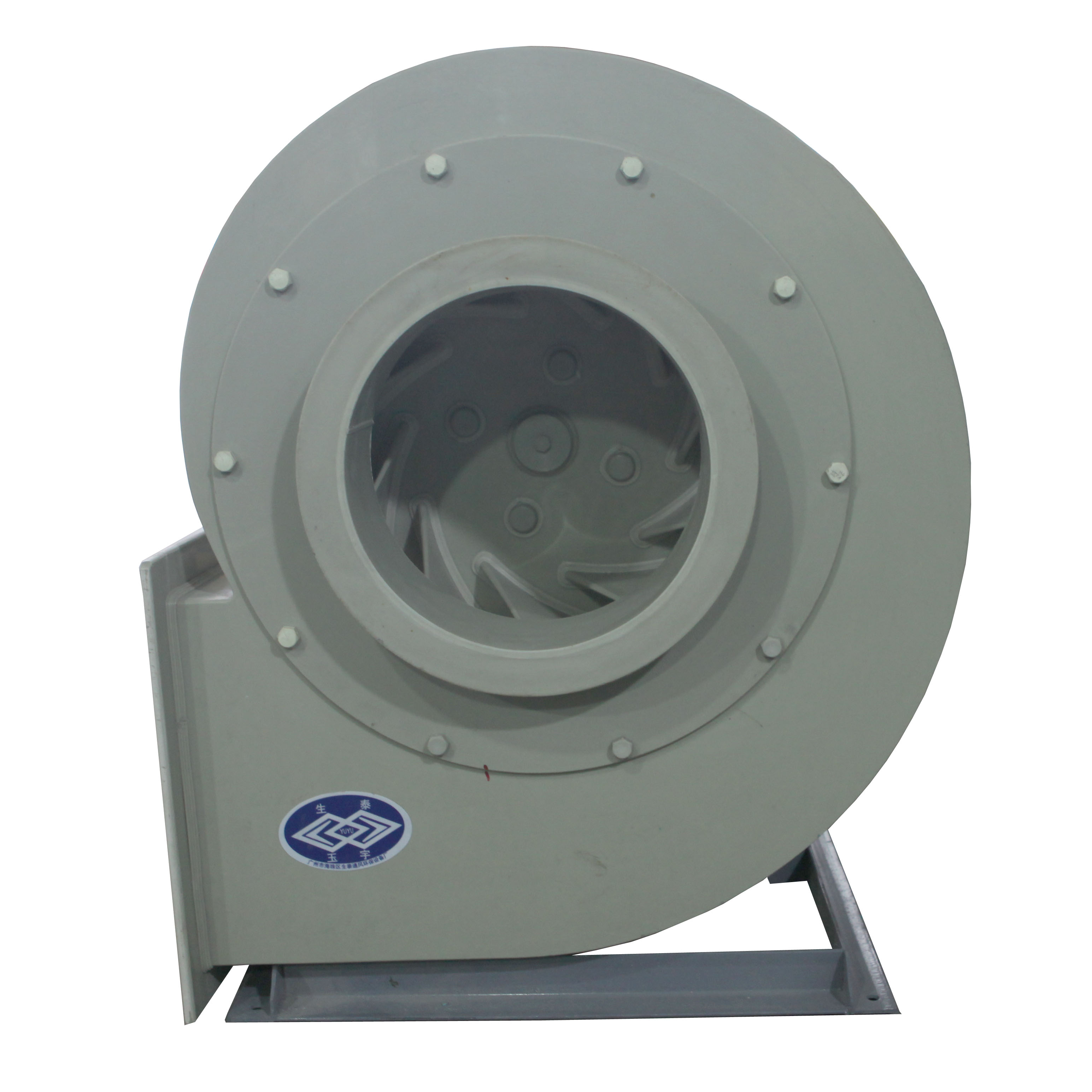

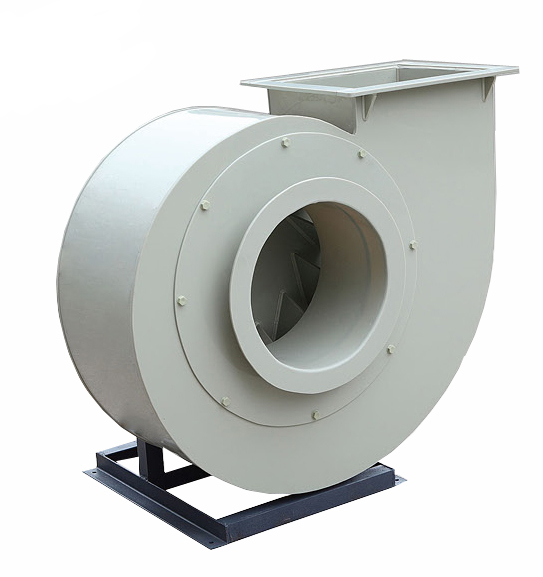

PP4-72 PP centrifugal blower. It has the characteristics of high strength, light weight, good corrosion resistance, not easy to age, and low noise. This series of blower blades using injection molding technology, the blower blades after injection molding are not only stronger and have higher anti-corrosion performance. Because the injection impeller achieves an effect that cannot be achieved by hand, the performance of the blower is more stable and the efficiency is higher.

PP Centrifugal Anti-corrosion Fans (Roof-mounted)

PP4-72 Anti-Corrosion Fan is a high-performance centrifugal blower made from PP (Polypropylene) material, a thermoplastic resin known for its excellent chemical stability. It is highly resistant to concentrated sulfuric acid and nitric acid, while being relatively stable against other chemical reagents. These fans operate efficiently in a temperature range from -10°C to 60°C and are designed to withstand corrosive environments, making them ideal for industrial applications requiring durable, corrosion-resistant ventilation systems.

PP Anti-Corrosion Fans are widely used in industries like chemical processing, laboratory ventilation, pickling, and other applications where corrosive or humid gases need to be extracted or ventilated. Available in centrifugal, axial, diagonal, and cabinet types, these fans are versatile and can handle various ventilation needs.

PP Anti-Corrosion Fan works by converting kinetic energy into potential energy (pressure) using a high-speed rotating impeller. In single-stage centrifugal blowers, gas enters the impeller axially, changes direction radially, and then flows into the diffuser, where it slows down and increases in pressure.

These fans are specifically designed for applications such as chemical laboratory ventilation, biological lab ventilation, odor purification systems, and exhaust systems in coastal or humid areas prone to corrosion. With features like high strength, lightweight, low noise, and resistance to aging, PP centrifugal blowers are ideal for extracting corrosive gases such as acid, alkali, and salts.

PP anti-corrosive centrifugal blower is suitable for discharging corrosive gases containing a certain concentration of acid, alkali, salt, etc. in chemical, textile, electroplating, laboratory and other places. It can also be used for ventilation of general factory buildings.

PP anti-corrosive centrifugal blowers are not allowed to be used to eliminate corrosive gases containing aromatic compounds, halogen derivatives of aliphatic and aromatic hydrocarbons, ketones and other corrosive gases. The use temperature of PP anticorrosive centrifugal blower is 0°C~40°C, and avoid sunlight exposure, and there should be no heat source near the site.

SPECIFICATION

|

Model (NO) |

Power (KW) |

RPM |

Air volume (M³/H) |

Total Pressure Pt (Pa) |

|

2.8A |

0.75 |

1450 |

565-1178 |

288-126 |

|

1.5 |

2900 |

1131-2356 |

994-606 |

|

|

3.2A |

0.75 |

1450 |

844-1758 |

324-198 |

|

2.2 |

2900 |

1688-3517 |

1300-792 |

|

|

3.6A |

0.75 |

1450 |

1332-2634 |

393-247 |

|

3 |

2900 |

2664-5268 |

1578-989 |

|

|

4A |

1.1 |

1450 |

2006-3700 |

501-329 |

|

4.5A |

1.5 |

1450 |

2856-5281 |

634-416 |

|

5A |

2.2 |

1450 |

3864-7728 |

790-502 |

|

3 |

1450 |

3864-7728 |

790-502 |

|

|

6A |

1.5 |

960 |

4420-8841 |

498-317 |

|

4 |

1450 |

6677-13353 |

1139-724 |

|

|

5.5 |

1450 |

7010-14020 |

1196-760 |

|

|

7A |

3 |

960 |

7312-14523 |

736-468 |

|

7.5 |

1450 |

10602-21204 |

1550-984 |

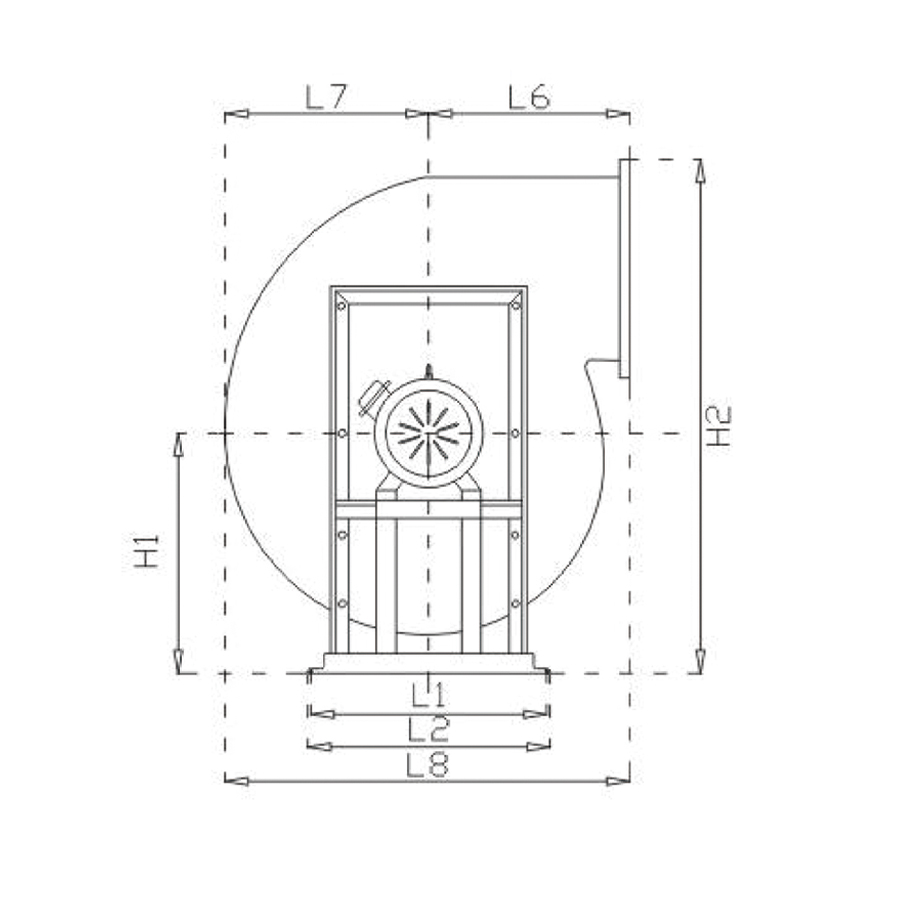

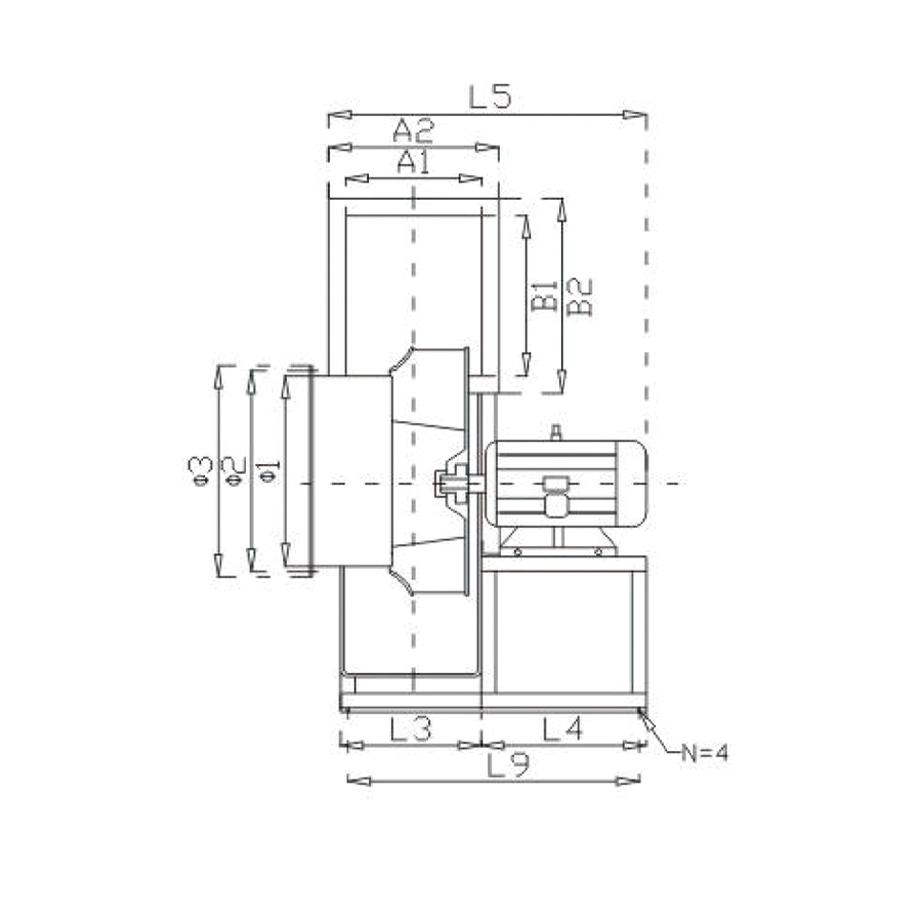

DIMENSION( (Unit: mm))

|

Model |

Air Inlet |

Air outlet |

External dimensions |

Frame dimensions |

|||||||||||||||

|

NO |

Φ1 |

Φ2 |

Φ3 |

A1 |

A2 |

B1 |

B2 |

H1 |

H2 |

L5 |

L6 |

L7 |

L8 |

L1 |

L2 |

L3 |

L4 |

L9 |

N |

|

2.8A |

178 |

223 |

273 |

187 |

264 |

215 |

281 |

293 |

633 |

510 |

214 |

290 |

504 |

325 |

367 |

207 |

219 |

405 |

M12 |

|

3.2A |

197 |

247 |

297 |

212 |

301 |

240 |

330 |

313 |

707 |

512 |

236 |

304 |

540 |

335 |

367 |

225 |

219 |

414 |

M12 |

|

3.6A |

216 |

271 |

321 |

240 |

338 |

273 |

372 |

348 |

781 |

545 |

272 |

342 |

631 |

389 |

427 |

246 |

227 |

464 |

M12 |

|

4A |

245 |

295 |

345 |

267 |

375 |

304 |

413 |

383 |

855 |

610 |

308 |

380 |

686 |

443 |

487 |

260 |

235 |

464 |

M12 |

|

4.5A |

274 |

319 |

369 |

294 |

402 |

345 |

457 |

428 |

982 |

643 |

343 |

417 |

760 |

483 |

525 |

260 |

242 |

514 |

M12 |

|

5A |

330 |

375 |

421 |

321 |

429 |

385 |

500 |

467 |

1065 |

620 |

374 |

466 |

987 |

498 |

548 |

260 |

360 |

588 |

M12 |

|

6A |

395 |

458 |

480 |

408 |

520 |

463 |

574 |

548 |

1267 |

705 |

443 |

482 |

1025 |

535 |

585 |

280 |

425 |

673 |

M12 |

|

7A |

443 |

498 |

553 |

406 |

519 |

478 |

584 |

629 |

1469 |

790 |

512 |

498 |

1063 |

587 |

645 |

320 |

490 |

758 |

M12 |

Get in touch with us

If you have any comments or good suggestions, please leave us a message, later our professional staff will contact you as soon as possible.

Scan QR Code

Scan QR Code

MaxLabFurniture

MaxLab Furniture

daihongada

Max Laboratory