Product

Laboratory Air Scrubber

PP scrubber is a kind of waste gas treatment equipment, it not only deals with the industrial organic waste gas containing a small amount of soot has a good effect, but also can apply acid base neutralization method to treat acid and alkaline organic waste gas.

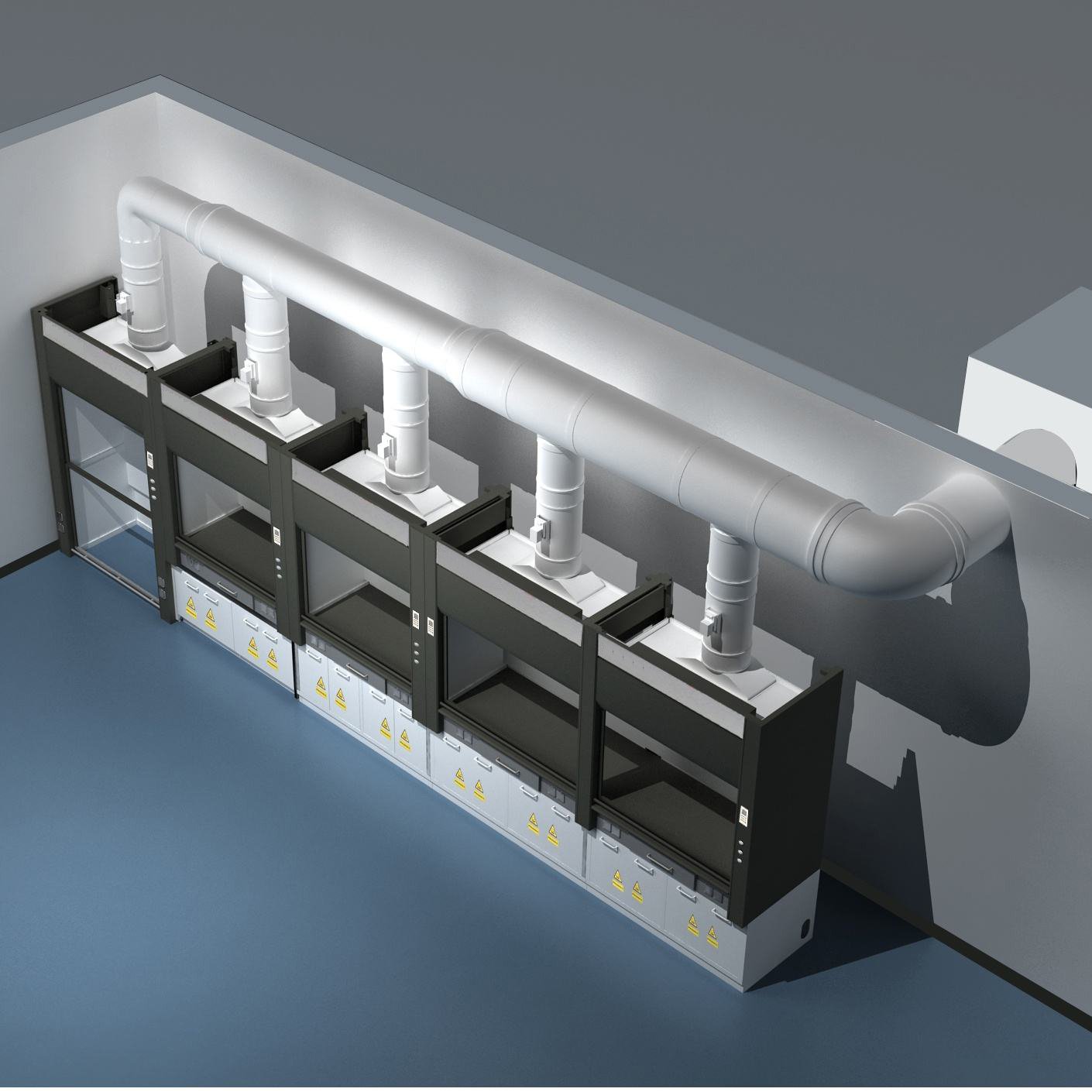

The perchloric acid fume hood is specially designed to handle the regular use of hot perchloric acid, hot nitric acid or perchloric acid. Does not handle sulfuric acid, acetic acid, organic solvents, or any combustible materials.

This professional fume hood has a PP liner surface (including work area) and a cleaning system, which is scattered throughout the fume hood. When heated, perchloric acid evaporates and condenses in the fume hood, air duct and fan assembly. In addition to being highly corrosive, the condensed steam can form explosive perchlorates and esters with fume hood gaskets, grease and other collected materials. Therefore, the PP surface improves cleanliness and the cleaning system can remove any explosive compounds that may be formed on the inner surface.

Product Details

Laboratory Air Scrubbers

Specification

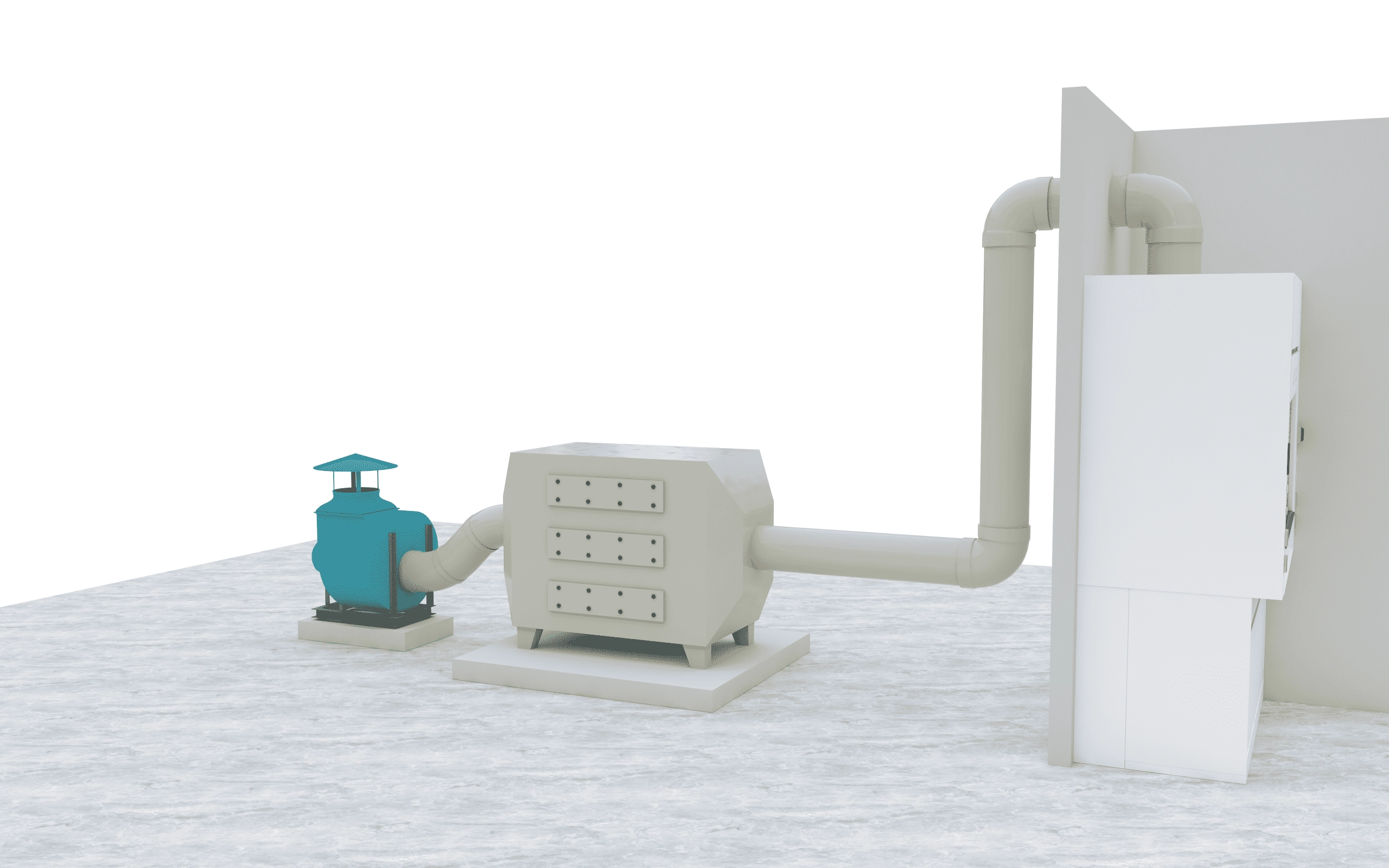

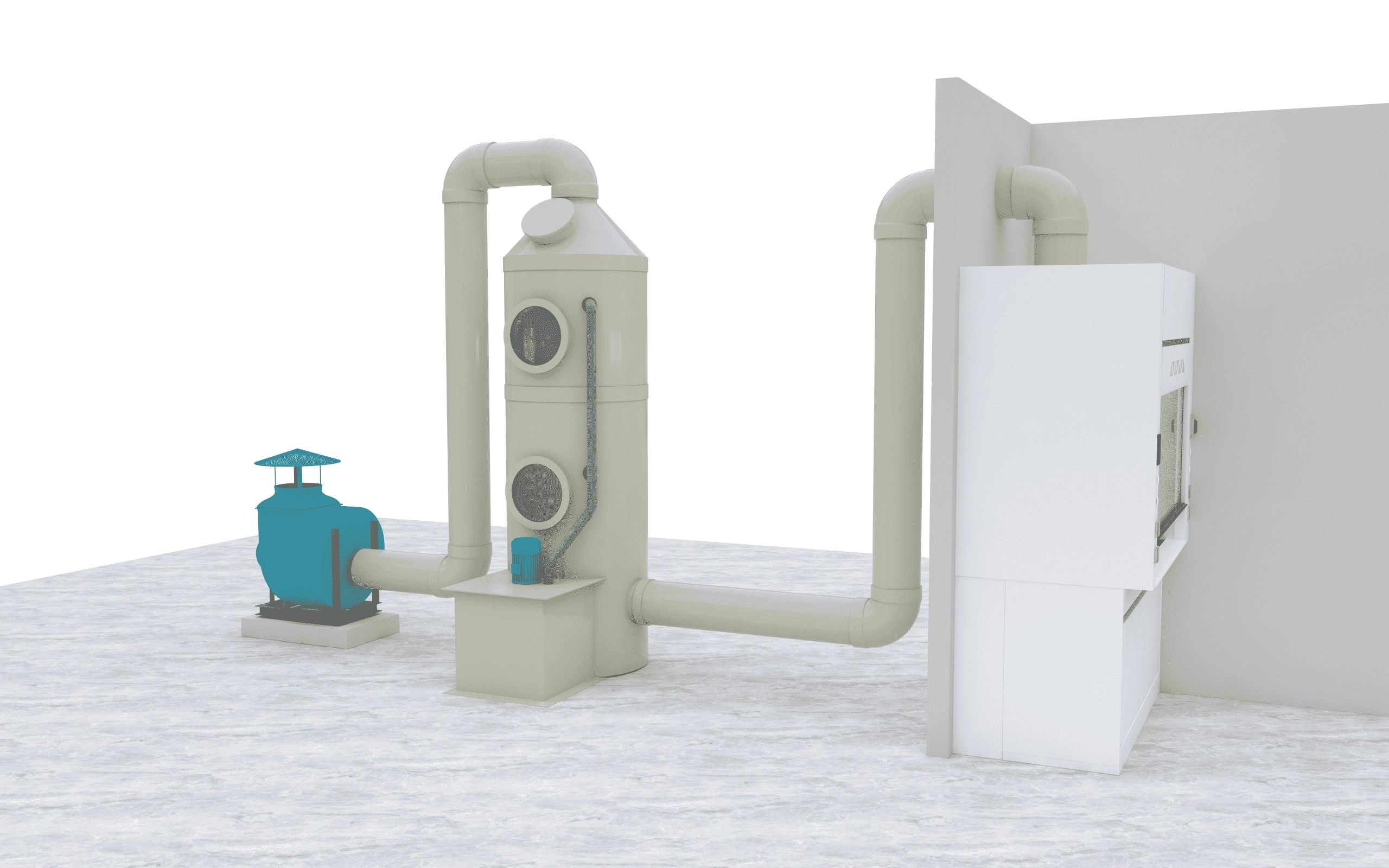

PP scrubber is a kind of waste gas treatment equipment, it not only deals with the industrial organic waste gas containing a small amount of soot has a good effect, but also can apply acid base neutralization method to treat acid and alkaline organic waste gas.It is usually used in combination with a fume hood.

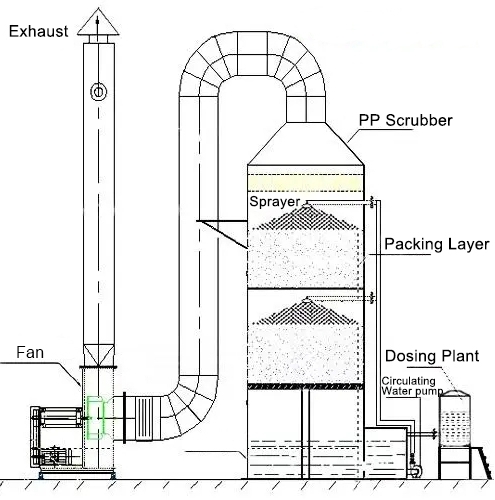

Operating Principle

The polluted waste gas is introduced into the scrubber by the air duct. Through the packing layer, the waste gas is fully absorbed by gas-liquid two phases from bottom to top and from liquid to bottom. After purification, the polluted waste gas is discharged into the atmosphere by the fan after dewatering and defogging by the defogging board. The absorbing liquid is pressurized by the water pump at the bottom of the scrubber and scrubber the top of the scrubber, and finally returned to the bottom of the scrubber for recycling.

Range Of Application

For corrosive gas (such as acid, alkaline waste gas) treatment, liquid absorption method is used at present. Using liquid absorption to manage the waste gas, the key lies in the selection of purification equipment. At present, our company independently developed the purification process and equipment of acid and alkaline waste gas with high purification efficiency, simple operation and management and long service life. The process and product have the characteristics of simple structure, low energy consumption, high purification efficiency and wide application range. It can effectively remove water soluble gases such as hydrogen chloride gas (HCl), hydrogen fluoride gas (HF), ammonia gas (NH3), sulfuric acid fog (H2SO4), chromic acid fog (CrO3), cyanuric acid gas (HCN), alkali vapor (NaOH), hydrogen sulfide gas (H2S), formalin (HCHO), etc.

Feature

Using packing scrubber to purify the waste gas, suitable for continuous and intermittent discharge of waste gas treatment; Simple process, management, operation and maintenance is quite convenient and simple, will not have any impact on the production of the laboratory;

Wide application range, can purify a variety of pollutants at the same time; The pressure drop is low, the operation flexibility is large, and has a good fog removal performance;

The scrubber body is made of PP (polypropylene) material; Packing with high efficiency, low resistance hollow ball, can completely remove the odor in the gas, harmful substances.

Construction

Standard components

▲ Equipment body: Intranet/skeleton, maintenance Windows, inlet/exhaust vents

▲ Packing layer: filler

▲ Defogging layer: filler

▲ Circulating water tank: automatic water supply control system, overflow drainage, liquid level pipe fittings, access port

▲ Circulating spray pipe: internal spiral nozzle spray atomization system, control valve, connection pipe fittings

Optional Components

▲ Water pump: pump body, rain cap

▲ Sampling platform: platform body and ladder

▲ Automatic dosing system: dispensing bucket, dosing pump, PH controller, electrode, control cabinet

▲ Induced draft fan: fan body, shock absorber system, foundation/support

▲ Power distribution control system: control probe, control cabinet, frequency conversion system, signal line/cable

Application

The process and equipment can be widely used in chemical industry, electronics, metallurgy, electroplating, textile (chemical fiber), food, machinery manufacturing and other industries in the process of acid, alkaline waste gas purification treatment. Such as flavored food, acid, pickling, electroplating, electrolysis, battery and so on.

Model

6.1 Key points of model selection: The selection of equipment determines the effect of exhaust gas treatment as well as the energy consumption load of equipment. In order to achieve the best selection, pay attention to the following points:

6.1.1 Source waste gas collection process: This part of the process determines the gas demand after collection, and also represents the size of equipment selection.

6.1.2 Pipeline wiring process design: This part of the process determines the pressure demand of the fan. Large pressure loss means large power, and small pressure loss means small power.

6.1.3 Exhaust gas composition and concentration: This part determines the size of the scrubber and the single or multi-stage equipment.

6.2 selection table: (note: air unit for the ㎥ / h "; The unit of scrubber diameter is "mm"; Pressure loss data is "±50Pa" deviation)

Note: The exhaust gas of easily soluble water component can be selected as the flow rate model of 2.0 ~ 2.5m/s, while the exhaust gas of insoluble water component can be selected as the flow rate model of 1.5 ~ 2.0ms.

6.3 Standard Device Models and Processing Capabilities

|

Model |

External Size(mm) |

Power Pump kw |

Air Volume m³/h |

|||||

|

Φ |

211(H) |

221(H) |

1.0m/s |

1.5m/s |

2.0m/s |

2.5m/s |

||

|

PLT-WH2021PPL-D800 |

800 |

2550 |

3300 |

0.37 |

1755 |

2633 |

3510 |

4387 |

|

PLT-WH2021PPL-D1000 |

1000 |

2850 |

3350 |

0.75 |

2759 |

4138 |

5518 |

6897 |

|

PLT-WH2021PPL-D1200 |

1200 |

2950 |

3450 |

1.50 |

3962 |

5943 |

7924 |

9905 |

|

PLT-WH2021PPL-D1500 |

1500 |

3520 |

4270 |

2.20 |

6224 |

9336 |

12448 |

15559 |

|

PLT-WH2021PPL-D1800 |

1800 |

3620 |

4370 |

3.00 |

8995 |

13492 |

17989 |

22486 |

|

PLT-WH2021PPL-D2000 |

2000 |

3670 |

4670 |

4.00 |

11124 |

16686 |

22248 |

27810 |

|

PLT-WH2021PPL-D2200 |

2200 |

3770 |

4770 |

5.50 |

13480 |

20220 |

26960 |

33700 |

|

PLT-WH2021PPL-D2500 |

2500 |

3830 |

4830 |

7.50 |

17382 |

26072 |

34763 |

43453 |

|

PLT-WH2021PPL-D2800 |

2800 |

3870 |

5370 |

11.00 |

21841 |

32761 |

43681 |

54602 |

|

PLT-WH2021PPL-D3000 |

3000 |

3970 |

5470 |

11.00 |

25097 |

37645 |

50193 |

62741 |

Technological Process

|

Corollary Equipment |

Scrubber 1 |

Scrubber 2 |

Scrubber3 |

UV Photolysis |

Activated Carbon Absorber |

Ph Control System |

Fan |

|

General Acid Base Exhaust Gas |

√ |

|

|

|

|

√ |

√ |

|

High Concentration Acid Base Exhaust Gas |

√ |

√ |

|

|

|

√ |

√ |

|

Ammonia |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

Dust Exhaust Gas |

√ |

|

|

|

|

|

√ |

|

Organic Exhaust Gas |

√ |

|

|

√ |

√ |

|

√ |

Specification

Body material: PP (polypropylene)

Polypropylene (Polypropylene, short for PP) is a semi-crystalline thermoplastic. High impact resistance, strong mechanical properties, resistance to a variety of organic solvents and acid and alkali corrosion. It is widely used in industry and is one of the common polymer materials.

Packing Material: PP (Polypropylene)

The ball is made of polypropylene (PP) , and a ball is synthesized from two hemispheres. There are 8-12 semi-fan blades on each hemisphere according to the design needs, and the fan blades of the two hemispheres are staggered with each other.

The filler is characterized by large specific surface area and high voidage. However, due to the large number of blades, there is masking effect between each other, which is not conducive to liquid distribution and wetting.

Most liquids gather in the hollow column of the sphere, blocking the smooth flow of gas, so the resistance is larger. This kind of filler is used for waste gas treatment and water treatment engineering.

Model Specification:

|

Specification(mm) |

Specific Surface Area (m²/m³) |

Bulk Number (n/m³) |

Bulk Density (kg/m³) |

|

Φ25 |

460 |

85000 |

80 |

|

Φ38 |

300 |

22800 |

45 |

|

Φ50 |

236 |

11500 |

30 |

|

Φ76 |

110 |

3000 |

30 |

Pump Material: PP (Polypropylene)

Features: Minimum air mixing, large head

▲ Pump body using FRP, CFRPP and PVDF material, with high temperature resistance and corrosion resistance characteristics.

▲ Dry liquid seal (1-10HP) : can ensure to prevent the motor and bearing by chemical gas erosion, prolong the service life of the motor and pump.

▲ Suitable for etching spray washing equipment, waste gas washing scrubber, cooling cycle and matching filter use.

▲ pump can be used without water idling, never damage.

▲ Used in highly corrosive liquid medicine and environment, it is recommended to choose another titanium screw, motor to choose another epoxy coating treatment, enhance corrosion resistance and service life.

Automatic Dosing System:

The user only needs to install the combined dosing device in the dosing room. After the dosing pipe is connected and the power supply is switched on, the operation can be started. During the operation, the PH of the liquid and other indicators are automatically checked, and the corresponding agent is intelligently judged and added.

Get in touch with us

If you have any comments or good suggestions, please leave us a message, later our professional staff will contact you as soon as possible.

Scan QR Code

Scan QR Code

MaxLabFurniture

MaxLab Furniture

daihongada

Max Laboratory