Product

Lab Countertops

One-Stop Custom Lab Worktops Built for Real Lab Conditions

Choose the right countertop material for your chemical, biology, cleanroom, or teaching lab. Max Lab provides full customization—sizes, cutouts, sinks, edges, and integration with lab furniture systems.

Lab countertops are a critical component of laboratory workstations, directly affecting safety, durability, and daily operational efficiency. In modern laboratories, countertops must withstand chemical exposure, frequent cleaning, mechanical impact, and long-term use without compromising performance.

Well-specified lab countertops support consistent workflows across clinical, research, educational, and industrial laboratory environments.

Lab Countertop Materials Customization | Max Lab

Why Countertop Material Matters in Labs

Laboratory countertops are not ordinary work surfaces. They must withstand daily exposure to chemicals, heat, water, cleaning agents, and heavy instruments—while staying easy to sanitize and safe for staff. Max Lab helps you select and customize the best countertop based on your workflows, chemical exposure, cleaning frequency, safety requirements, and budget.

One-Stop Customization (What We Customize)

2.1 Dimensions (Standard + Non-Standard)

-

Custom length, depth, and thickness

-

Bench height options for ergonomics

-

Single-piece or multi-section solutions for long runs

2.2 Cutouts & Functional Openings

-

Sink and faucet cutouts

-

Drip rack openings

-

Instrument recesses (balances, analyzers, etc.)

-

Cable grommets and service penetrations (power/data/gas routing)

2.3 Edge & Spill Control Options

-

Rounded edges / chamfered edges

-

Raised lip, backsplash, and water stop edges

-

Seam and joint sealing for spill resistance

2.4 System Integration (Lab-Ready Delivery)

-

Match with base cabinets and frames

-

Optional water supply & drainage coordination

-

Interfaces for ventilation zones and workflow safety layout

ADVANTAGES

SAME-COLOR PENETRATING CORE

SAME-COLOR PENETRATING CORE

High-quality glaze, fired at high temperature, the same material and color inside and outside, the corners are cut at will, and the cut surface does not need post-glazing treatment, and the glaze is excellent.

FLATNESS

FLATNESS

Ceramics have an even and smooth surface finish. Usage of ceramic glue creates seamless joints and thus eliminating uneven installation issues.

GLAZING TECHNOLOGY

GLAZING TECHNOLOGY

The edges of Ceramics glazed as the top surface. Edges can resist 98% concentrated sulfuric acid, 40% sodium hydroxide and withstand high temperature of 400oC. This feature has been tested and certified by test authority. This is unique in the market and unparalleled.

HIGH ON MOHS HARDNESS SCALE

HIGH ON MOHS HARDNESS SCALE

Ceramics are level 7 on the Mohs hardness scale (diamond's Mohs hardness is 10, while stainless steel's is 5.5)

SCRATCH RESISTANCE

SCRATCH RESISTANCE

Ceramics achieved Class 1 surface scratch resistance in accordance to national standards. Together with its high Mohs hardness scale, it is resistance to scratches from high friction activities or accidental scratches.

CHEMICAL RESISTANCE

CHEMICAL RESISTANCE

Ceramics have passed the SEFA-3 tests standards which is tested against 49 different chemicals commonly used in laboratories.

HEAT RESISTANCE

HEAT RESISTANCE

Ceramics is classified as Class A non-combustible material. It is fire retarding and resistant to extreme temperature of 1350oC, which at present is the highest temperature testing limit in China.

HIGH LOADING-BEARING

HIGH LOADING-BEARING

Ceramics passed the static load test of load-bearing capacity of at least 450kg making it suitable for heavy laboratory equipment.

ANTI-BACTERIAL AND HYGIENIC

ANTI-BACTERIAL AND HYGIENIC

The smooth surface of Ceramics is non-porous and easy to clean. Used together with ceramic glue to create seamless joints, Ceramics does not promote growth of mold, mildew and bacteria. Its resistance to Escherichia coli, staphylococcus aureus and other bacteria ensures a hygienic environment for lab personnel and the accuracy of experiment results.

GLAZE CRACKIGN RESISTANCE

GLAZE CRACKIGN RESISTANCE

Ceramics imported glazing material ensures excellent quality and superior performance that prevents cracking.

EASY TO CLEAN

EASY TO CLEAN

The glaze of ceramics is excellent, leading in technology, hard to gather dirt and bacteria, and easy to clean.

SAFETY

SAFETY

Ceramics contain no formalde and other noxious ingredients , have low heavy metal content. They are healthy and environmentally friendly.

Countertop Materials (6 Options)

Each lab is different. Below is a practical selection guide Max Lab uses for real projects.For Lab Benches, Lab Cabinets, Fume Hoods, Chemical Storage Cabinets, Cleanroom Solutions.

Ceramic Countertop

Best for: high heat resistance, scratch resistance, dense non-porous surface

Typical labs: high-temperature work areas, strong staining reagents, high-cleanliness zones

Highlights: excellent surface durability and easy cleaning

Epoxy Resin Countertop

Best for: chemical resistance and long-term durability lab bench

Typical labs: chemical labs, central islands, heavy daily chemical exposure

Highlights: stable thick slabs, supports complex cutouts and sink integration

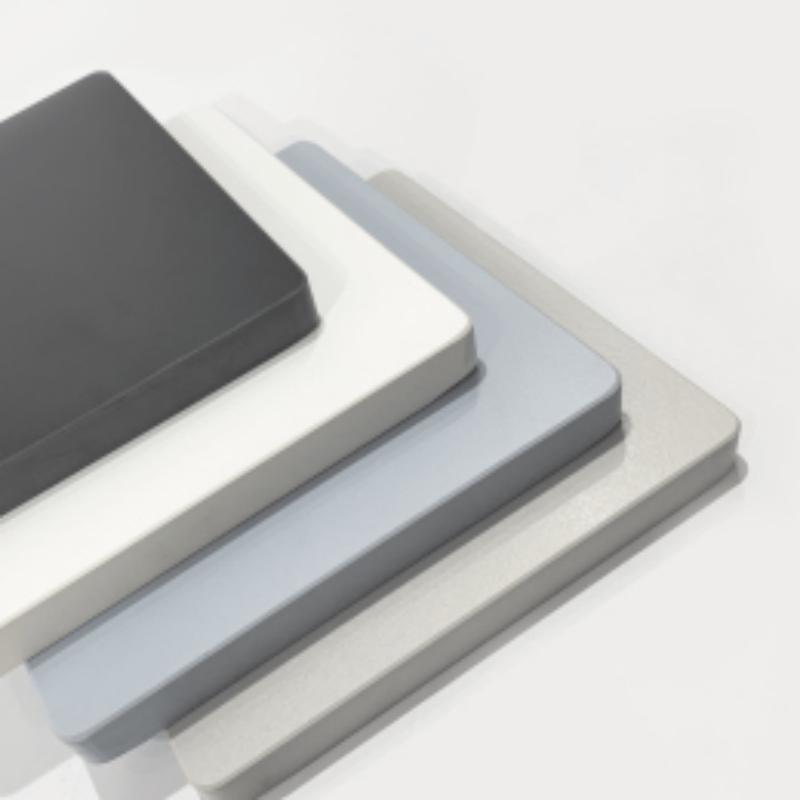

Trespa Countertop (HPL)

Best for: balanced durability + aesthetics, cost-effective options

Typical labs: teaching labs, general R&D labs, multi-purpose rooms

Highlights: many colors/finishes; recommended for light-to-medium chemical environments

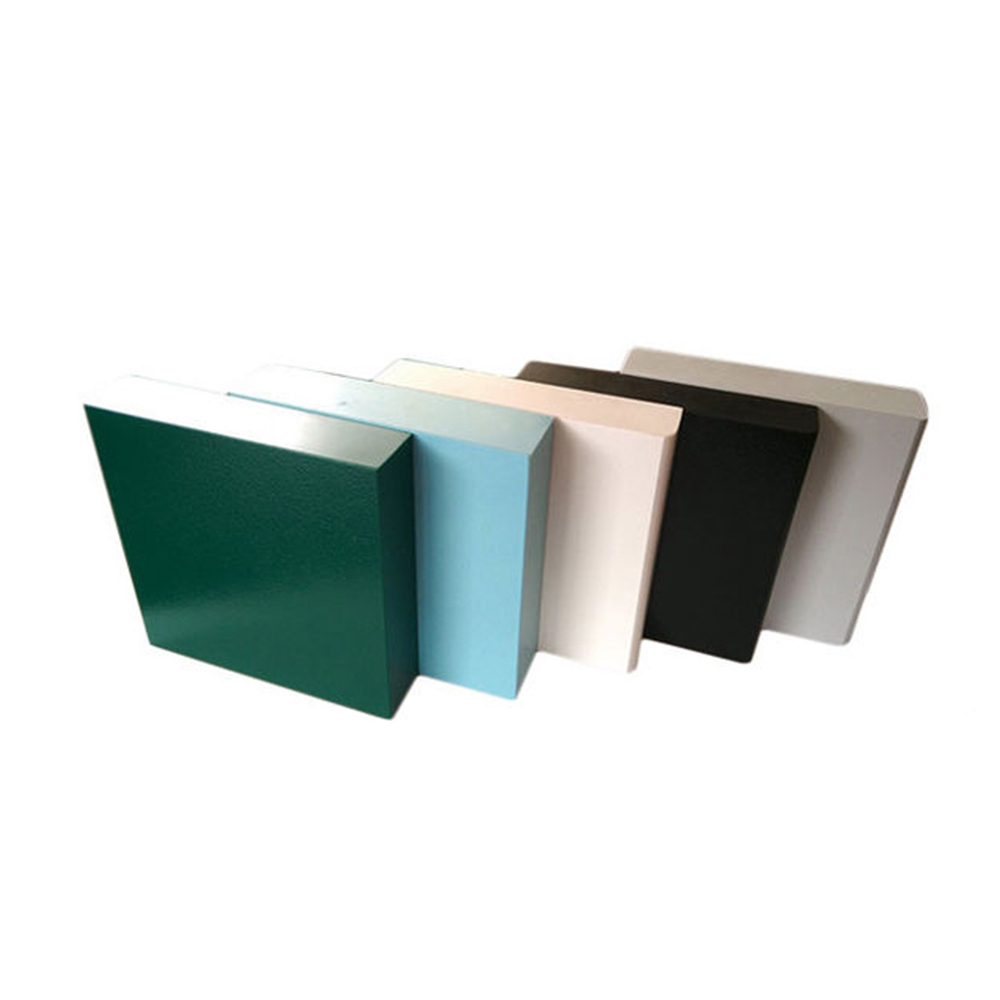

Phenolic Resin Countertop

Best for: all-around performance for general lab work

Typical labs: most standard labs (side benches, islands, instrument benches)

Highlights: good chemical resistance for typical lab use, strong value

Stainless Steel Countertop

Best for: wet areas, cleaning & disinfection, hygiene-focused zones

Typical labs: wash-up areas, sample prep, medical and clean environments

Highlights: can integrate welded sinks; reduces crevices and supports sanitation

PP Countertop (Polypropylene)

Best for: strong acid/alkali resistance and corrosion-heavy environments

Typical labs: corrosive chemical handling, acid/alkali intensive processes

Highlights: excellent corrosion resistance; ideal for functional chemical zones

Surface Treatment

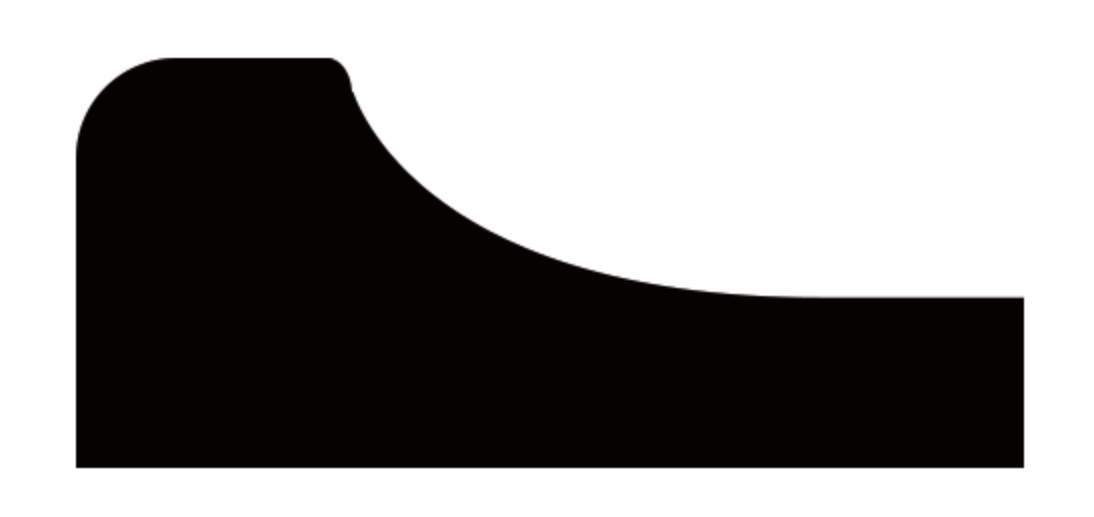

R3 Chamfer

Dish-shaped Integral

Laboratory Countertop Comparison Chart

|

Countertop |

Phenolic Resin |

Trespa |

Epoxy Resin |

Ceramic |

PP |

SS |

|

Dimension(MM) |

1525*3050 |

1525*3050 |

1500*3000 |

1800*900 |

1500*3000 |

1500*3000 |

|

Thickness(MM) |

12.7/16/19/25 |

13/16/20 |

15/16/19/25 |

15/20/25 |

8/10/12/15 |

20 |

|

Chemical Resistance |

Very Good |

Excellent |

Excellent |

Excellent |

Excellent |

Very Good |

|

Abrasive Resistance |

Good |

Good |

Excellent |

Excellent |

Fair |

Excellent |

|

Max Heat Resistance |

150°C |

150°C |

200°C |

1000°C |

100°C |

800°C |

|

Impact Resistance |

Good |

Good |

Good |

Good |

Fair |

Excellent |

|

Moisture Resistance |

Excellent |

Excellent |

Excellent |

Excellent |

Excellent |

Excellent |

|

Bacteria |

Good |

Good |

Excellent |

Excellent |

Excellent |

Excellent |

|

Application |

General Lab |

High-Standard Lab |

High-Temperature&Corrosion Lab |

High-Temperature&Corrosion Lab |

Strong Acid And Strong Base Lab |

High-Temperature Lab, Clean Room |

|

Type Of Use |

Very Diverse |

Very Diverse |

Very Diverse |

Selective |

Selective |

Selective |

Documentation & Lab Project Submittals (Available Upon Request)

For lab projects, safety and compliance documentation matters. Max Lab can provide documentation upon request based on your project scope and local requirements, such as:

-

Material datasheets and specifications

-

SDS / MSDS (where applicable)

-

Third-party test reports (project-based)

-

Project submittals: shop drawings, cut sheets, installation & maintenance guidance

-

Acceptance checklist support for commissioning and handover

-

Quality & Build Details (What Clients Care About)

-

Sealed seams and protected cutout edges to reduce spill infiltration

-

Precision cutouts for sinks, fixtures, and service penetrations

-

Consistent production for multi-room projects (color, thickness, fit)

-

Practical maintenance planning for high-frequency cleaning environments

-

Customization Process (From Layout to Installation)

-

Share your layout, room list, and workflow requirements

-

Max Lab recommends material + configuration + integration plan

-

Confirm dimensions, cutouts, edges, accessories, and quantities

-

Production + QC inspection

-

Packing, shipping (as required)

CTA line: Send your plan to

FAQ

What is the best lab countertop material for chemical resistance?

It depends on the chemicals used. Epoxy resin and PP are common choices for chemical-intensive environments, while ceramic performs well for heat and surface durability. Max Lab helps select the best fit based on your chemical list and workflow.

Can Max Lab do non-standard sizes and custom cutouts?

Yes. We support standard and fully customized dimensions, including sink cutouts, instrument openings, cable routing, and service penetrations.

Do you offer one-stop lab furniture + countertop integration?

Yes. Max Lab provides one-stop customization for lab benches, cabinets, and countertops so the system fits your space and workflow.

Can you provide documentation for lab projects?

Documentation such as datasheets, SDS, test reports, and project submittals can be provided upon request depending on your project requirements.

Which countertop is best for wet areas and easy disinfection?

Stainless steel is commonly selected for wash-up zones and hygiene-focused areas due to easy cleaning and the option for welded sink integration.

get a countertop recommendation within your project scope.

-

-

Get in touch with us

If you have any comments or good suggestions, please leave us a message, later our professional staff will contact you as soon as possible.

Scan QR Code

Scan QR Code

MaxLabFurniture

MaxLab Furniture

daihongada

Max Laboratory