Product

Intelligence Hazardous Chemical Cabinet

Featuring cutting-edge technology, this cabinet includes built-in sensors for real-time monitoring of temperature, humidity, and air quality, ensuring optimal storage conditions for volatile substances. With automatic alerts for any deviations, it allows you to proactively manage risks and maintain compliance with safety regulations. Constructed from robust, corrosion-resistant materials, the cabinet offers secure locking, ventilation, and spill containment features. Ideal for laboratories, industrial facilities, and chemical storage rooms, our Intelligent Hazardous Chemical Cabinet brings smart solutions to your chemical safety needs.

The MAX LAB Flammable & Poison Storage Cabinets range is designed to provide a safe, organized and compliant solution for storing hazardous chemicals in laboratories, universities, hospitals and industrial facilities.

Our cabinets are built from heavy-duty steel with durable powder coating and configured with spill-containment sumps, secure locking systems and optional ventilation ports.

By separating flammable liquids and toxic/poisonous chemicals into clearly labeled, dedicated cabinets, you can reduce risk, support safety inspections and create a safer working environment for your staff.

This product line includes:

-

Flammable Storage Cabinets – for storing flammable and combustible liquids

-

Poison Storage Cabinets – for storing toxic or harmful chemicals

Product Details

Intelligence Hazardous Chemical Cabinets

SPECIFICATION

1.

External construction:

The cabinet is made of 1.2mm high-quality cold-rolled steel sheet, and the base is made of 2.0mm cold-rolled steel sheet. After pickling and phosphating, it is electrostatically sprayed and cured at high temperature. There are four Φ60mm moving wheels at the bottom of the cabinet, which is convenient for the storage cabinet to move.

2.

Internal construction:

The inner tank of the cabinet (upper, lower, left and right lining boards) are all made of pp sheet; the interior is equipped with a three-layer stepped pp movable shelf, and the board has a 5MM ventilation hole. The bottom layer of the inside of the cabinet is left with a leaking canal that can store no less than 120mm thick yellow sand, which is used for burying flammable items.

3.

Hinge:

Continuous smooth piano hinge, 180° opening. A fireproof expansion seal is installed between the cabinet door and the cabinet, and the cabinet is filled with special fireproof materials with thermal insulation effect.

4.

Door locks:

mechanical locks, anti-theft locks and LCD electronic code locks, to meet the requirements of double double lock management.

5.

Air exhaust:

There is a Φ110mm air outlet on the top of the cabinet, and an AC220V, 50HZ, 0.18A axial flow fan is built in the air outlet on the top of the cabinet, the maximum air volume is 300m3/h, the speed is 2550 rpm/min, and the ambient temperature is (-10~+70)°C. There is an adjustable air inlet on the right side of the bottom of the cabinet, and the stainless steel adjustable air valve of corrosion-resistant material is set to open before the fan is turned on.

6.

Controller:

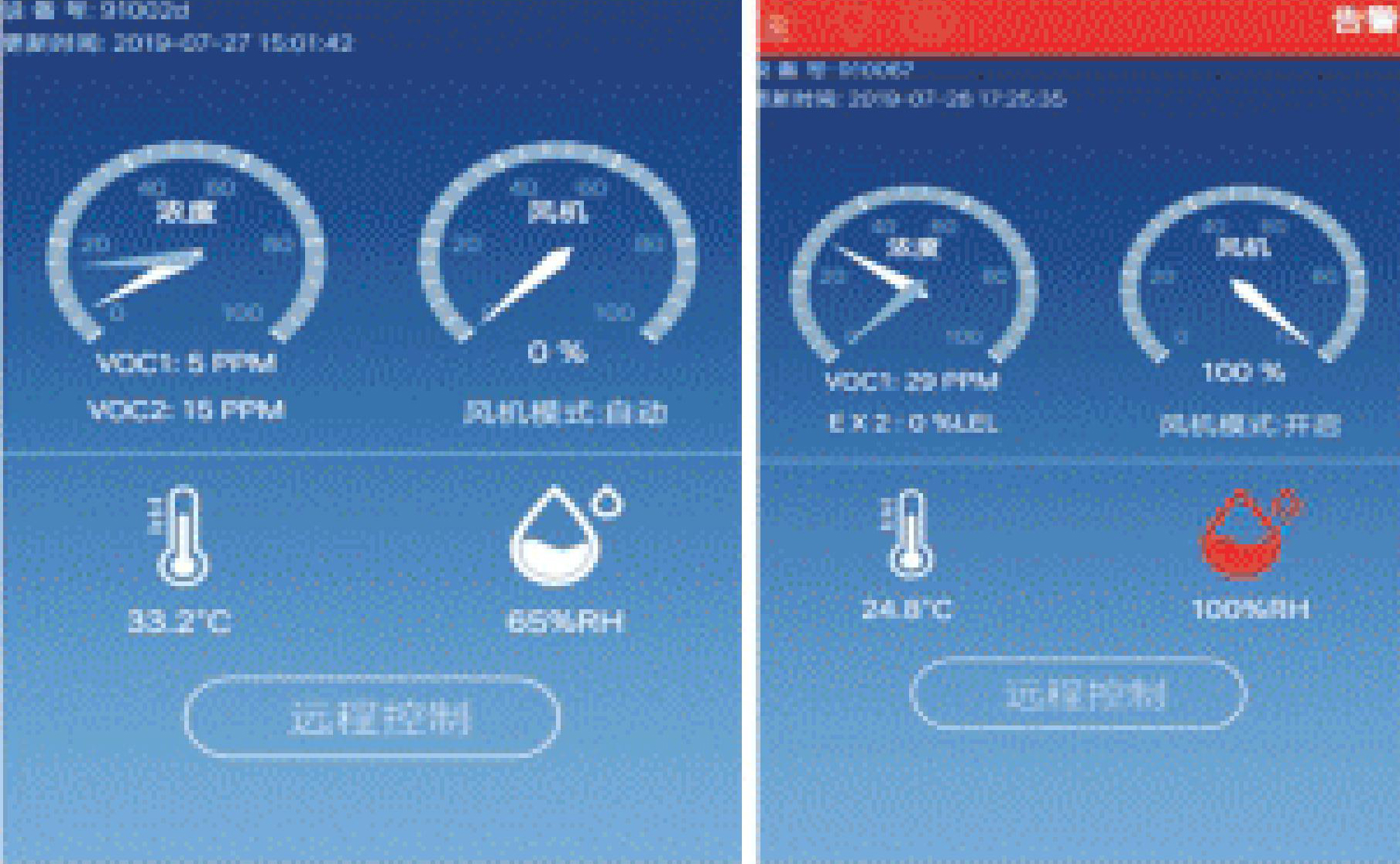

five-inch button display temperature, humidity, VOC value, real-time monitoring. At the same time, multiple time periods can be set for exhaust ventilation. You can check the temperature, humidity, and VOC values inside the storage cabinet in the past 30 days.

7.

Remote control:

Support online viewing of temperature, humidity, VOC concentration and other values inside the storage cabinet through mobile phone and computer, and can be controlled remotely.

8.

Alarm automatic exhaust:

When the temperature, humidity and VOC concentration exceed the set value, the sound and light alarm will give an alarm and the automatic exhaust device will be activated to reduce the temperature, humidity and VOC concentration inside the storage cabinet in time. The alarm prompt information will be continuously sent to the laboratory management personnel and users (the number of users is not limited) within minutes, until the complete report status is lifted.

|

MODEL |

DIMENSION (W*D*H)MM |

COLOR |

SPECIFICATION |

|

IHC-01 |

900*510*1860 |

Yellow/Blue/Red |

3 shelves, double doors, password lock, 5-inch LCD button-type controller, fan |

-

-

-

-

-

Key Features

-

-

-

-

Typical Applications

The Intelligent Hazardous Chemical Cabinet is suitable for:

-

University and research laboratories requiring strict chemical management

-

Pharmaceutical, biotechnology and medical laboratories

-

Quality control labs in chemical, electronics and semiconductor industries

-

Government or third-party testing laboratories

-

Laboratories using toxic, highly hazardous or strictly controlled chemicals

-

Smart monitoring system

Built-in intelligent controller with real-time monitoring of key parameters (such as temperature, humidity, gas concentration, door status – according to configuration). -

Multi-level access control

Supports IC/ID card, password or combination access (optional), allowing different permission levels for administrators, operators and visitors. -

Event logging & traceability

Automatically records door opening time, user ID, alarm events and parameter changes, helping build a complete audit trail of hazardous chemical storage. -

Visual touch screen interface

Front LCD / touch screen (according to model) displays real-time data, alarm status and cabinet operating conditions; easy to view and operate. -

Alarm & interlock functions

When gas concentration, temperature or other monitored parameters exceed preset limits, the cabinet can trigger sound/light alarms, display messages and optionally link to ventilation or other safety systems. -

Ventilation connection

Equipped with ventilation ports; can be connected to laboratory exhaust system or independent ventilation unit to dilute harmful vapors inside the cabinet. -

Robust and safe structure

Heavy-duty steel construction with corrosion-resistant coating and integrated spill containment sump, supporting safe storage of various hazardous chemicals (according to compatibility). -

Flexible internal layout

Adjustable shelves, trays and partitions help organize bottles, cans and reagent boxes by category, hazard level or user group. -

Networking & data output

Optional Ethernet / RS485 / Modbus communication interface for connection to lab management systems (LIMS/BMS) or data recording software.

Advantages Compared with Traditional Chemical Cabinets

From “static storage” to “smart management”

Not only stores chemicals, but also monitors, records and controls usage in real time.

Reduced human error

Access control and monitoring reduce risks caused by improper storage, forgotten door closing or incorrect personnel access.

Improved safety and compliance

Real-time alarms and traceable data help laboratories meet internal safety policies and external audit requirements.

Better visibility and management

Managers can quickly check cabinet status, operating history and alarm records, making chemical management more transparent.

Customization Options

MAX LAB can provide custom intelligent hazardous chemical cabinets based on your project:

Different cabinet sizes and capacities

Customized internal layouts (shelves, trays, partitions, drawers)

Selection of sensors (temperature, humidity, VOC, specific gases, etc.)

Different access control methods (card, password, fingerprint – if required)

Integration with existing LIMS/BMS or central monitoring systems

Multi-language interface and custom branding

Matching flammable, corrosive, toxic and gas cylinder cabinets to build a complete safety cabinet system

Get in touch with us

If you have any comments or good suggestions, please leave us a message, later our professional staff will contact you as soon as possible.

Scan QR Code

Scan QR Code

MaxLabFurniture

MaxLab Furniture

daihongada

Max Laboratory