Modular Lab Furniture Systems: Flexibility & Benefits

- Why Labs Are Moving to Modular Systems

- What is modular lab furniture design and why it matters

- Core benefits of modular lab furniture design

- Comparing modular vs. traditional lab furniture design

- Design considerations when specifying modular lab furniture design

- Laboratory safety and regulatory alignment with lab furniture design

- Performance metrics: durability, maintenance, and lifecycle costs in lab furniture design

- Technical features and innovations in modular lab furniture design

- How to evaluate modular lab furniture suppliers — procurement checklist

- Cost comparison example (illustrative)

- Industry example and manufacturer profile: MAX LAB

- Implementation roadmap for adopting modular lab furniture design

- FAQs — Frequently asked questions about modular lab furniture design

- 1. What is the difference between modular and fixed lab furniture?

- 2. How much faster is modular furniture to install?

- 3. Are modular benches as durable as traditional casework?

- 4. Can modular systems integrate with existing lab utilities and fume hoods?

- 5. What are the common pitfalls when choosing modular lab furniture?

- 6. How do I assess long-term value when selecting modular lab furniture?

- Contact and product inquiry

- References

- Notes on data and methodology

Why Labs Are Moving to Modular Systems

Modern laboratories need to evolve rapidly to support changing research priorities, safety regulations, and workflows. The trend toward modular lab furniture design reflects a shift from static, built-in fittings to adaptable systems that allow labs to reconfigure quickly, minimize downtime, and manage costs over the lifecycle. In this article I draw on industry research, design standards, and practical project experience to explain the benefits, technical considerations, specification guidance, and vendor selection criteria for modular lab furniture systems.

What is modular lab furniture design and why it matters

Lab furniture design that is modular uses pre-engineered units — benches, cabinets, service panels, and utilities modules — built to standardized dimensions and connection schemes. These modules can be combined, relocated, or replaced with minimal interruption to operations. For institutions that anticipate changes in research programs, frequent turnover of equipment, or phased construction, modular design reduces time and cost associated with change.

Core benefits of modular lab furniture design

Key benefits include:

- Flexibility: Rapid reconfiguration without demolition.

- Faster delivery and installation: Prefabrication shortens on-site time.

- Quality control: Factory-controlled production ensures consistency.

- Lower long-term disruption: Less downtime for renovations.

- Sustainability: Reusable modules reduce waste from demolition.

Comparing modular vs. traditional lab furniture design

Choosing modular furniture should be based on quantitative and qualitative criteria. The table below summarizes common performance areas and typical outcomes when using modular systems compared to fixed, site-built furniture.

| Metric | Modular Lab Furniture Design | Traditional Fixed Furniture |

|---|---|---|

| Lead time (procure + install) | Shorter — prefabrication reduces onsite time; industry reports show modular construction can cut schedules by up to 30–50% depending on scope* | Longer — custom site-built casework and finishes extend schedules |

| Reconfiguration speed | High — panels and benches can be reconfigured in days | Low — demolition and rebuild required |

| Initial cost | Comparable to slightly higher depending on finishes; lower soft costs | Variable — potentially lower materials cost but higher labor on site |

| Lifecycle cost | Often lower — reduced renovation frequency and downtime costs | Often higher — repeated remodels increase total cost |

| Quality & QA | High — factory-controlled QA and documented testing | Variable — dependent on site conditions and contractor skill |

*Sources: Modular Building Institute; manufacturer project data. See references.

Design considerations when specifying modular lab furniture design

Specifying modular lab furniture requires early coordination across disciplines. The following considerations will help you write clear requirements and avoid costly change orders.

- Space planning and module grid: Define a consistent module grid (e.g., 600/900/1200 mm widths) so benches, cabinets, and service carriers align. This simplifies future reconfiguration.

- Utility integration: Specify how gas, vacuum, compressed air, and electrical services are routed — underbench, through service columns, or via overhead service carriers. Modular systems must include standardized quick-connects or isolation valves accessible in reconfiguration.

- Countertop and bench loads: List expected static and dynamic loads (equipment weight, vibration-sensitive instruments) and select surfaces and mounting systems accordingly (e.g., epoxy resin, phenolic, stainless steel, or stone for heavy appliances).

- Ergonomics and human factors: Include adjustable-height benches or sit-stand options for tasks requiring long durations. Consider clearances for wheelchair access and compliance with accessibility rules where applicable.

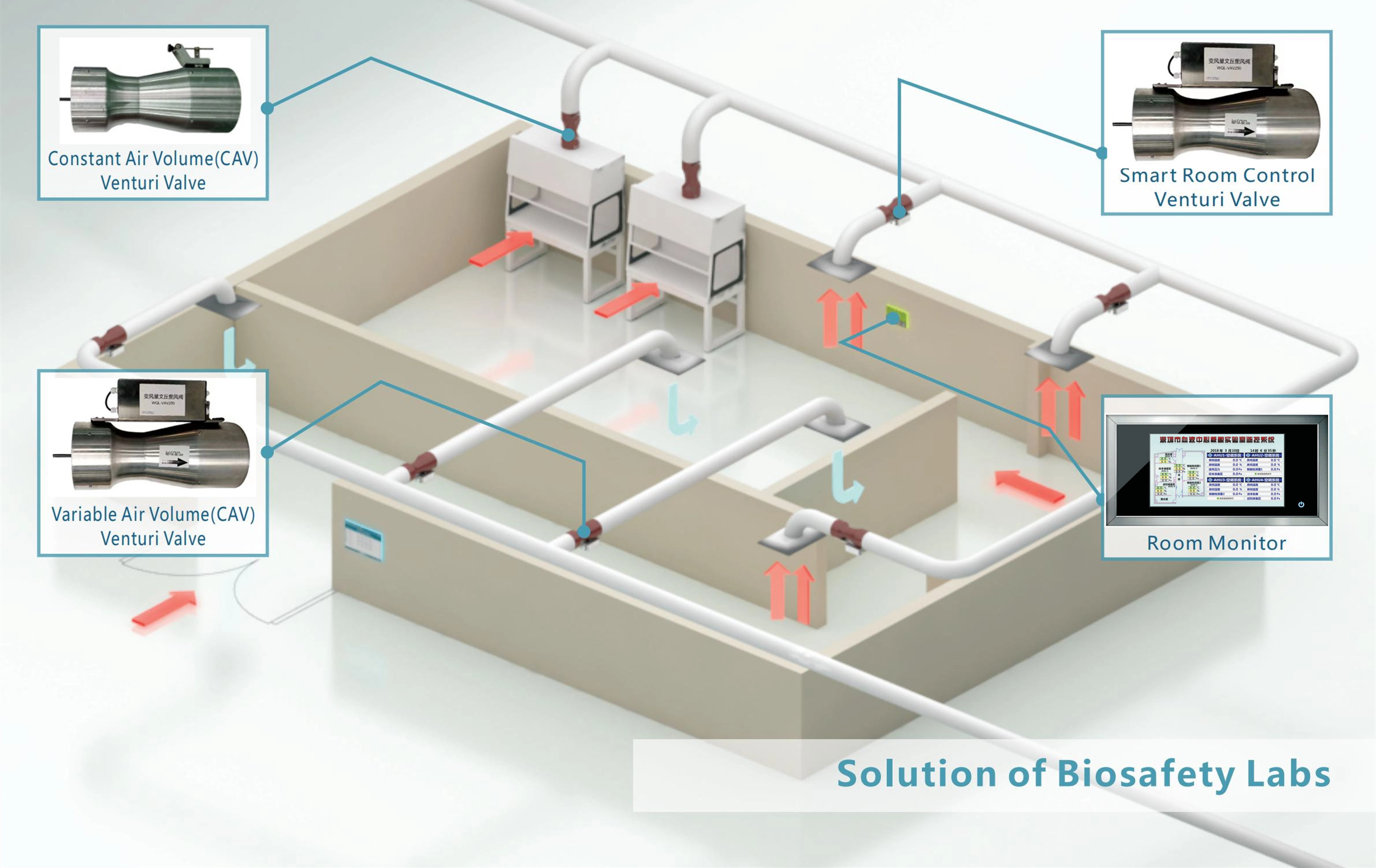

- Fire and ventilation integration: Ensure fume hoods and local ventilation modules meet local codes and coordinate with HVAC to avoid disrupting lab pressurization strategies.

- Material and finish standards: Specify chemical resistance, ease of cleaning, and environmental standards (low-VOC finishes; green certifications where required).

Laboratory safety and regulatory alignment with lab furniture design

Modular furniture must comply with applicable safety guidance for laboratory design and containment. Coordinate product selections with biosafety or chemical safety officers. Standards and guidance from bodies such as NIOSH/CDC and local building and fire codes should drive decisions for fume hoods, storage of hazardous chemicals, and airflow strategies.

Performance metrics: durability, maintenance, and lifecycle costs in lab furniture design

Procurement decisions should balance initial price with lifecycle costs. Consider:

- Expected lifespan of modules (10–20+ years depending on material and use).

- Ease and cost of replacing surfaces, shelving, or utilities.

- Warranty and spare-part support from the manufacturer.

- Downtime costs during refit — modular systems typically reduce business interruption.

Technical features and innovations in modular lab furniture design

Recent advances enhance modularity and integration:

- Pre-piped utility columns with rapid-connect fittings for safer, faster installation.

- Integrated anti-vibration modules for analytical instruments.

- Service panels with plug-and-play electrical modules and data/AV conduits.

- Quick-release bench tops and adjustable support frames for flexible bench heights.

- Modular fume hood interfaces that allow hoods to be relocated without heavy structural work.

How to evaluate modular lab furniture suppliers — procurement checklist

When assessing vendors for modular lab furniture design, use this checklist:

- Proven track record in lab projects similar in scope and complexity.

- Factory-controlled QA processes and documented testing procedures.

- Clear documentation for modular grids, utility schematics, and installation manuals.

- Spare parts policy and modular inventory availability.

- Local or regional installation support and warranty service.

- References and case studies highlighting delivery times, reconfiguration examples, and lifecycle outcomes.

Cost comparison example (illustrative)

Example lifecycle comparison for a mid-size research lab (10-year horizon): initial modular High Quality may be offset by reduced reconfiguration costs and downtime. For specific projects, request a TCO analysis from suppliers including downtime and renovation frequency assumptions.

Industry example and manufacturer profile: MAX LAB

Founded in 2000, Guangzhou Max Laboratory Equipment Co., Ltd. (MAX LAB) is a leading manufacturer that integrates the design, production, and sales of laboratory furniture and equipment. With over 15 years of export experience, our founder has led the company to serve clients in more than 60 countries and regions, earning a reputation for reliability and excellence. Guided by our core values—Quality First, Delivery First, Price First, and Service First—we are committed to delivering superior laboratory solutions that meet the highest global standards.

Our 5,000 m² factory in Guangzhou is equipped with advanced German-imported machinery and operates under modern management systems to ensure precision and consistency. With three standardized production lines and a well-stocked modular inventory, we achieve production efficiency and delivery times up to 30% faster than industry peers.

At MAX LAB, we insist on stringent quality control for every product before it leaves the factory. Using materials from leading global suppliers, we ensure that every item—from lab furniture and storage cabinets to fume hoods and countertops—meets international quality and environmental standards. Our dedication to innovation, efficiency, and customer satisfaction has made MAX LAB a trusted partner in laboratory projects worldwide.

MAX LAB advantages and main products: lab storage cabinets, fume hoods, lab countertop, lab benches, purifying equipment, anti-vibration table. MAX LAB differentiates through integrated design and manufacturing, fast lead times supported by modular inventory, German-imported machinery for precision, and rigorous QC that aligns with international standards.

Implementation roadmap for adopting modular lab furniture design

Follow these steps for a successful modular deployment:

- Define program needs: workflows, equipment lists, and reconfiguration frequency.

- Establish a module grid and utility backbone concept early in design.

- Engage a modular furniture supplier during schematic design for coordination.

- Develop detailed utility and sequencing drawings for prefabrication.

- Plan for spare parts and training for in-house maintenance teams.

- Track performance post-occupancy and adjust specifications for future phases.

FAQs — Frequently asked questions about modular lab furniture design

1. What is the difference between modular and fixed lab furniture?

Modular furniture consists of prefabricated units with standardized interfaces that can be reconfigured, whereas fixed furniture is custom-built onsite and is difficult and costly to alter. Modular systems emphasize interchangeability and faster installation.

2. How much faster is modular furniture to install?

Installation time depends on project scope. Industry data and supplier experience commonly report schedule reductions ranging from 20% to 50% for modular construction activities. Individual manufacturers may report different figures; for example, MAX LAB cites delivery and production efficiencies that can make delivery times up to 30% faster than peers.

3. Are modular benches as durable as traditional casework?

Yes — when specified with appropriate materials (e.g., chemical-resistant countertops, corrosion-resistant frames) and manufactured under proper QA, modular benches can have equivalent or superior durability to site-built casework.

4. Can modular systems integrate with existing lab utilities and fume hoods?

Most modular systems are designed for utility integration via service columns, quick-connect fittings, and standard interface heights. Integration with existing fume hoods and building services requires early coordination with mechanical and electrical engineers to ensure compatibility.

5. What are the common pitfalls when choosing modular lab furniture?

Pitfalls include late supplier engagement, undefined utility routing, mismatched module grids, insufficient spare parts, and failure to plan for instrument-specific anchoring or loads. Early coordination and clear technical specifications mitigate these risks.

6. How do I assess long-term value when selecting modular lab furniture?

Ask suppliers for a total cost of ownership (TCO) analysis that includes expected reconfiguration frequency, downtime costs, replacement parts, warranties, and maintenance. Compare that to projected costs for repeated traditional remodels.

Contact and product inquiry

If you are planning a laboratory fitout or considering transitioning to modular lab furniture design, contact our team to request product specifications, case studies, or a project consultation. To view modular lab furniture products including lab storage cabinets, fume hoods, lab countertops, lab benches, purifying equipment, and anti-vibration tables, request a catalog or an on-site assessment from our sales engineers.

References

- Modular Building Institute — Benefits of Modular Construction. https://www.modular.org/ (accessed 2025-11-24)

- Centers for Disease Control and Prevention (NIOSH) — Laboratory Safety Guidance and Resources. https://www.cdc.gov/niosh/topics/labs/ (accessed 2025-11-24)

- ISO — ISO 9001: Quality Management. https://www.iso.org/iso-9001-quality-management. (accessed 2025-11-24)

- MAX LAB company materials and product literature — internal manufacturer data and production claims (accessed 2025-11-24)

Notes on data and methodology

Performance and schedule claims in this article are drawn from industry publications (Modular Building Institute) and manufacturer-reported data. Project-specific outcomes vary with scope, site conditions, and contract strategy. For verifiable, project-level metrics ask suppliers for documented case studies and on-site references.

Choosing a Variable Air Volume Fume Hood: Buyer Checklist

6 Tips to Select the Right Laboratory Furniture

Cost Estimating for Lab Furniture Projects

Comparing Chemical Resistance: Phenolic vs Epoxy vs Stainless

About Solution

How about your after sale service?

We will reply to you within 24 hours by email or phone.

If we have a local agent, we will arrange for him to be at your site within 24 hours to assist you in shooting the problem.

Do you provide laboratory layout design service?

Yes, we provide professional laboratory layout design service to optimize space utilization and workflow according to customer's site and usage requirements.

What is the warranty policy of the product?

We provide 1-3 years warranty service, depending on the product type. Meanwhile, comprehensive after-sales support is provided, including repair and replacement services.

For After-Sales Support

What do I do if I am not satisfied with my purchase?

We strive to ensure customer satisfaction. If you are not happy with your purchase, please contact us, and we will do our best to resolve any concerns.

Customization

How to calculate the cost of customized services?

Customization services incur additional costs depending on the complexity of the design, material selection and production requirements. We will clearly list all costs at the quote stage to ensure that the client understands all costs.

Floor Mounted Lab Bench

Our Floor Mounted Lab Bench is an essential, high-efficiency workspace for laboratories, made from high-quality steel-wood or corrosion-resistant stainless steel materials to ensure exceptional durability and stability. The unique floor-mounted design effectively reduces vibration, optimizes space usage, and provides a safe and tidy laboratory environment.

Customizable storage solutions help organize lab equipment efficiently, while the easy-to-clean surface maintains laboratory hygiene. It is widely suitable for research institutions, educational laboratories, and the chemical and pharmaceutical industries.

Fume Hood

The fume hood provides safe ventilation to protect against exposure to hazardous or toxic fumes, vapors, or airborne particulate. It is primarily used in laboratory and manufacturing applications to protect the user or environment outside the hood, but can also be used to protect the materials or experiment under the hood.

APPLICATION

Chemistry Lab, physics Lab, biological analysis, pharmaceutical medicine analysis, biological pharmaceutical, plant culture, environmental testing and electronic instrumentation scientific research and so on.

Flammable Storage Cabinet

Safety Cabinets store flammable liquids, corrosives, pesticides and other hazardous materials. All fire-resistant safety cabinets by meet fire codes and regulations for safety storage.

To help protect your people and facility from a potential fire, safety cabinets are engineered to safely contain flammable fuels, solvents, and chemicals. Safety cabinets can not only help everyone store chemicals reasonably, save chemical supplies, but also save human resources, and avoid fires caused by chemicals with the greatest strength.

Class II Type A2 Biological Safety Cabinet for Laboratory

The Class II A2 Biological Safety Cabinet is designed to provide superior biosafety and contamination control for laboratories, research facilities, and clinical settings. With 70% air recirculation and 30% air exhaust, this cabinet ensures a safe and efficient work environment while protecting both the user and the samples.

Equipped with advanced features like a HEPA filtration system, motorized front window, and ergonomic design, this cabinet is a must-have for safe and reliable biological research.

Scan QR Code

Scan QR Code

MaxLabFurniture

MaxLab Furniture

daihongada

Max Laboratory