Laboratory Workbench Design: Layout and Workflow

- Smart Laboratory Bench Planning: Aligning Space, Safety, and Productivity

- Lab furniture design — what problem are we solving?

- Core principles of lab furniture design for workbench layout

- Workflow-based bench layouts: choosing the right configuration

- Ergonomics and safety — non-negotiable elements of lab furniture design

- Utilities and services: integrating gas, power, water and ventilation

- Materials and surfaces — matching durability to application

- Modularity, inventory and turnaround — manufacturing metrics that impact projects

- Selecting equipment: benches, storage cabinets, fume hoods and specialty items

- Quality assurance, installation and commissioning

- Why supplier selection matters: manufacturer capability and delivery performance

- Supplier profile — MAX LAB integration and strengths

- Practical checklist: specifying lab furniture design for a project

- Maintenance and lifecycle planning

- FAQs — Common questions about Laboratory Workbench Design and lab furniture design

- 1. What is the best bench layout for a teaching lab?

- 2. How do I decide between epoxy and phenolic countertops?

- 3. What are essential ergonomic features for laboratory benches?

- 4. How should I plan utilities for island benches?

- 5. Are ductless fume hoods safe?

- 6. How much extra budget should I plan for installation and commissioning?

- Contact and product inquiry

- References

Smart Laboratory Bench Planning: Aligning Space, Safety, and Productivity

Lab furniture design — what problem are we solving?

Laboratories succeed when space, equipment and people operate as a single system. Effective lab furniture design reduces wasted motion, prevents cross-contamination, and supports ergonomic, safe workflows. Whether you are renovating a teaching lab, designing an R&D bench, or specifying analytical workstations, the primary objective is to align bench layout with the lab’s core processes, safety needs and future adaptability.

Core principles of lab furniture design for workbench layout

Designing a workbench is not just about choosing materials or colors; it requires an integrated approach that balances four core principles:

- Workflow alignment: place frequent tasks and services in sequence to minimize travel and handoffs.

- Safety and containment: design to control hazards, provide clear segregation between clean and dirty zones, and ensure access to emergency services.

- Ergonomics: reduce repetitive strain through suitable bench heights, seating, reach zones and storage placement.

- Flexibility: use modular furniture so layouts can evolve with research programs or diagnostic volumes.

- Locate gas and vacuum lines along bench backs or through service troughs to keep benchtops clear.

- Plan power for benchtop instruments with dedicated circuits where necessary; include UPS for critical devices.

- Drainage and sinks must meet local plumbing codes and be chemically resistant to the reagents in use.

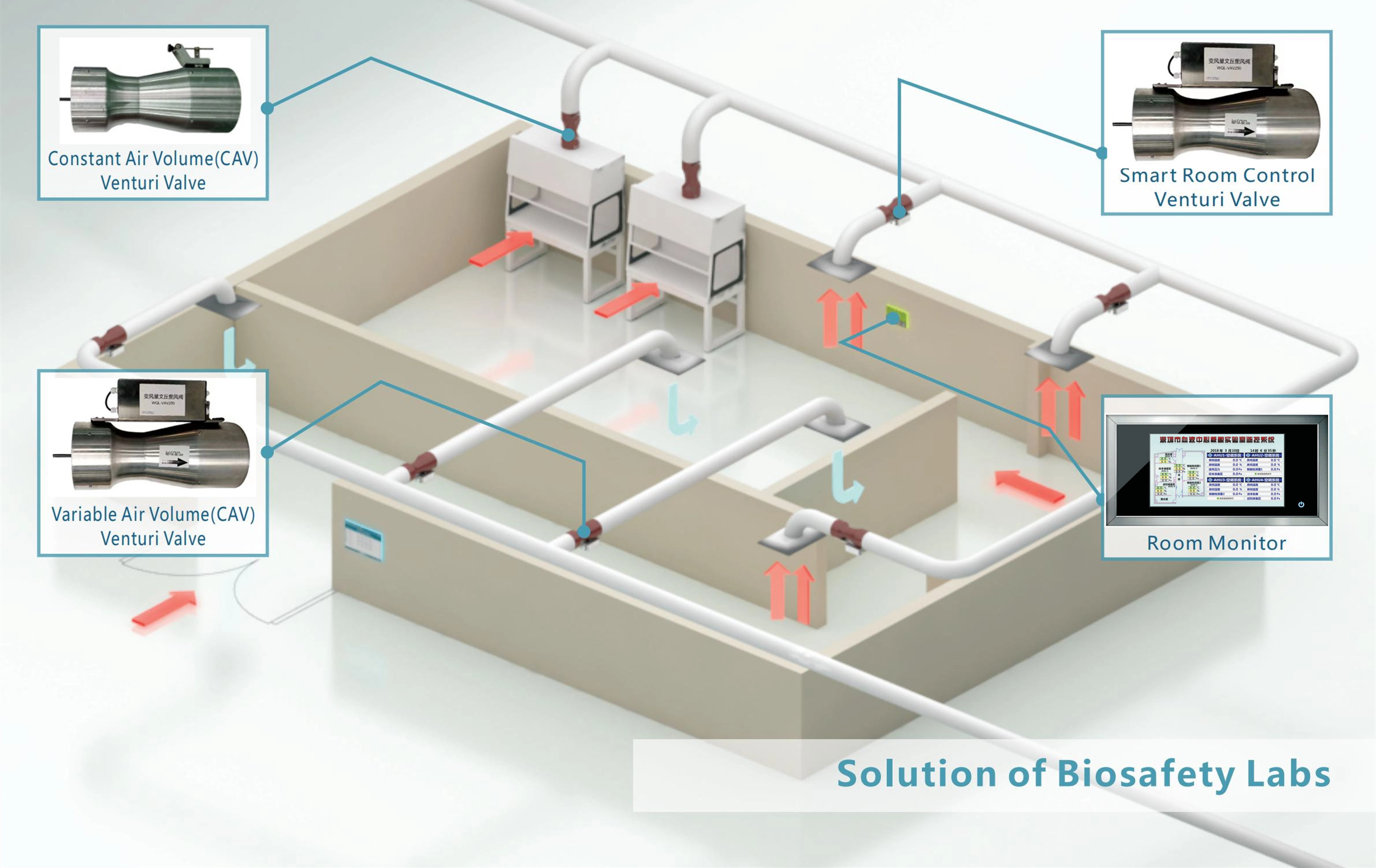

- Ventilation and exhaust for local containment (fume hoods, ductless hoods with certified filters) must comply with mechanical design and indoor air quality standards.

- Epoxy resin countertops — excellent chemical resistance and heat tolerance; standard for chemistry labs.

- Phenolic resin — moisture resistant and durable; often used in wet labs with heavy bench use.

- Stainless steel — preferred where sterilization, heat or sanitary processing is required.

- Laminate — cost-effective for low-chemical areas but less resistant to solvents and heat.

- Factory production capacity and standardized production lines.

- Availability of modular inventory for rapid shipments.

- Quality control processes and material traceability.

- Lab benches: choose bench height and load ratings to match tasks and equipment footprints.

- Lab storage cabinets: chemical-specific cabinets for flammables, corrosives and solvents; ensure venting and secondary containment as required by code.

- Fume hoods: specify type (ducted vs. ductless), face velocity, sash design and energy recovery options.

- Lab countertops: match material to chemical and thermal exposure profiles.

- Purifying equipment: bench-top water purification, HEPA/ULPA filtration for particle-sensitive work, ensure service access.

- Anti-vibration tables: required for precision balances, microscopy and certain analytical instruments; evaluate natural frequency and damping characteristics.

- Bench and cabinet dimensional verification against shop drawings.

- Material finish inspection and warranty documentation.

- Service connection tests (electrical, gas, water) and safety device verification.

- Training for facility staff on maintenance and safe use.

- Define core workflows and map tasks to bench zones.

- List all bench-mounted services required with locations and load specs.

- Specify countertop and cabinet materials based on chemical exposure and cleaning regime.

- Identify containment needs (fume hoods, BSCs) and their performance criteria.

- Insist on modular dimensions and spare parts availability.

- Require factory QC reports and pre-shipment images.

- Agree acceptance test plan and training schedule.

- CDC — Biosafety in Microbiological and Biomedical Laboratories (BMBL). https://www.cdc.gov/labs/BMBL. (accessed 2025-11-25)

- WHO — Laboratory Biosafety Manual, 4th Edition. https://www.who.int/publications/i/item/9789240011311 (accessed 2025-11-25)

- ISO 14644 — Cleanrooms and associated controlled environments. https://www.iso.org/standard/53394. (accessed 2025-11-25)

- NIOSH (CDC) — Ergonomics and Musculoskeletal Disorders. https://www.cdc.gov/niosh/topics/ergonomics/ (accessed 2025-11-25)

- ABSA International — Resources on laboratory design and biosafety. https://absa.org/ (accessed 2025-11-25)

Embedding the primary keyword lab furniture design into specifications helps procurement and contractors understand the scope and intent when bidding or advising.

Workflow-based bench layouts: choosing the right configuration

Common bench configurations include linear (single-wall), peninsula/island and modular cluster layouts. Each supports different workflows and scales. Below is a concise comparison to guide selection.

| Layout Type | Best for | Pros | Cons |

|---|---|---|---|

| Linear (single-wall) | Teaching labs, small analytical benches | Low cost, clear sightlines, easy services along wall | Limited collaborative space; less flexible |

| Island / Peninsula | Collaborative R&D, synthesis labs | Centralized services, team visibility, multi-access | Requires more floor space; service routing complex |

| Modular clusters | Dynamic labs, mixed-method facilities | Highly reconfigurable, supports sequential workflows | Initial cost higher; requires planning for utilities |

Choosing a layout should start from a process map: list tasks, frequency, personnel, and required services (gas, vacuum, power, data). Map those tasks physically to minimize person-to-person handoffs and instrument transit.

Ergonomics and safety — non-negotiable elements of lab furniture design

Ergonomics reduces fatigue and injury; safety prevents incidents that disrupt operations. Key design measures include adjustable bench heights (or varied fixed heights for sitting/standing tasks), correct monitor placement for computer work, and reachable storage locations for frequently used items. For safety, ensure chemical work is handled in appropriate containment (fume hoods, biosafety cabinets) and that benches near hazardous operations have clear spill containment measures.

Standards and guidance such as CDC’s Biosafety in Microbiological and Biomedical Laboratories (BMBL) and WHO biosafety documents provide requirements for containment and layout that should influence bench placement and furniture specification (see References).

Utilities and services: integrating gas, power, water and ventilation

Utility planning should be done early. Retrofitting services after furniture is installed adds cost and schedule risk. Typical considerations:

Materials and surfaces — matching durability to application

Countertop and cabinet material selection affects longevity, maintenance and safety. Common choices:

Specify surface seams, backsplash details and edge profiles to minimize places where spills can travel or microbes can accumulate. Where contamination control is critical (cleanrooms, PCR labs) follow ISO 14644 recommendations for surface finish and cleaning protocols.

Modularity, inventory and turnaround — manufacturing metrics that impact projects

Modular casework enables faster installation and future reconfiguration. Manufacturers with standardized modules and an inventory of common components reduce lead times and on-site adjustments. When evaluating suppliers, inquire about:

Below is a sample procurement comparison to illustrate typical lead-time drivers:

| Factor | Impact on Lead Time | Mitigation |

|---|---|---|

| Custom vs modular | Custom: +6–12 weeks; Modular: +2–6 weeks | Specify modular modules where possible |

| Material availability | Backorders add 2–8 weeks | Use common commodity materials or confirm supplier stock |

| Quality inspection cycles | Can add 1–3 weeks if rework required | Factory QC & pre-shipment checks |

Selecting equipment: benches, storage cabinets, fume hoods and specialty items

Selection depends on process needs. Common product categories and selection notes:

Quality assurance, installation and commissioning

Effective commissioning includes pre-delivery factory checks, on-site verification of utilities and a staged acceptance testing protocol. Documented procedures should cover:

Why supplier selection matters: manufacturer capability and delivery performance

Manufacturers vary in how they combine design, production and logistics. Key differentiators include modern production equipment, standardized production lines, modular inventory and rigorous QC. Suppliers that integrate these elements typically deliver consistent quality, predictable lead times and better after-sales service.

Supplier profile — MAX LAB integration and strengths

Founded in 2000, Guangzhou Max Laboratory Equipment Co., Ltd. (MAX LAB) is a leading manufacturer that integrates the design, production, and sales of laboratory furniture and equipment. With over 15 years of export experience, our founder has led the company to serve clients in more than 60 countries and regions, earning a reputation for reliability and excellence. Guided by our core values—Quality First, Delivery First, Price First, and Service First—we are committed to delivering superior laboratory solutions that meet the highest global standards.

Our 5,000 m² factory in Guangzhou is equipped with advanced German-imported machinery and operates under modern management systems to ensure precision and consistency. With three standardized production lines and a well-stocked modular inventory, we achieve production efficiency and delivery times up to 30% faster than industry peers.

At MAX LAB, we insist on stringent quality control for every product before it leaves the factory. Using materials from leading global suppliers, we ensure that every item—from lab furniture and storage cabinets to fume hoods and countertops—meets international quality and environmental standards. Our dedication to innovation, efficiency, and customer satisfaction has made MAX LAB a trusted partner in laboratory projects worldwide.

MAX LAB main advantages and products: lab storage cabinets, fume hoods, lab countertop, lab benches, purifying equipment, anti-vibration table. The company emphasizes competitive delivery, modern production technology, modular solutions and stringent quality control as core differentiators.

Practical checklist: specifying lab furniture design for a project

Use this checklist when preparing documents for procurement or review with a supplier:

Maintenance and lifecycle planning

Design for maintainability—select finishes that survive aggressive cleaners and allow component replacement without wholesale demolition. Establish a preventive maintenance schedule for moving parts (sash counterweights, drawer slides, hinges) and for specialty equipment such as fume hood airflow systems and purified water units.

FAQs — Common questions about Laboratory Workbench Design and lab furniture design

1. What is the best bench layout for a teaching lab?

Linear bench layouts along walls with island benches for demonstrations balance visibility and supervision. Prioritize durability, easy-clean surfaces and integrated power for student equipment.

2. How do I decide between epoxy and phenolic countertops?

Choose epoxy for aggressive chemical resistance and heat tolerance (chemistry labs). Choose phenolic for excellent moisture resistance and durability in wet biology or general-purpose labs. Consider lifecycle cost and repairability.

3. What are essential ergonomic features for laboratory benches?

Adjustable or mixed-height benches, proper knee clearance, reachable storage (within 15–30 cm for frequent items), anti-fatigue mats for standing work and correct monitor placement for computer tasks are core ergonomic features.

4. How should I plan utilities for island benches?

Route utilities through raised service troughs, floor service columns or overhead service carriers planned in the mechanical design stage. Avoid running multiple critical services under benches without access panels.

5. Are ductless fume hoods safe?

Ductless hoods can be safe for specific, low-toxicity applications when fitted with certified filters and used for materials the filter media can capture. For volatile organic solvents, acid fumes or high-risk chemistries, ducted hoods remain the standard.

6. How much extra budget should I plan for installation and commissioning?

Plan 10–20% of furniture and equipment cost for installation, services connection and commissioning. Complex utility routing or custom fabrication can increase this percentage.

Contact and product inquiry

If you want help translating your laboratory workflow into an optimized bench design, or to view modular workbench and equipment options such as lab storage cabinets, fume hoods, lab countertops, lab benches, purifying equipment and anti-vibration tables, contact MAX LAB for a tailored proposal and factory lead-time estimates. Our team can provide drawings, material samples and a staged installation plan to fit your schedule and compliance needs.

References

Retrofit Strategies for Installing Variable Air Volume Fume Hoods

How to Choose the Right Lab Benches for Your Laboratory

Fume Hood Maintenance Plans to Minimize Downtime

Variable Air Volume Fume Hood Sash Design Buyer Guide

Customization

What is the after-sales support for customized services?

We provide a full range of after-sales service, including equipment installation guidance, regular maintenance, troubleshooting, operation training, etc., to ensure the safe and efficient operation of equipment.

For Company

Do you provide installation services?

Yes, we offer professional installation services to ensure your laboratory furniture and equipment are set up properly and safely.

For Products

Are your products customizable?

Absolutely! We offer customized solutions for laboratory benches, lab tables, and furniture systems to meet the specific requirements of your workspace.

Can I change the size and color?

Yes, of course. Custom-made items are welcome, if you have any need, please feel free to contact us at anytime.

For Customization

Do you offer custom branding for laboratory furniture?

Yes, we can incorporate custom logos, colors, and branding into your lab furniture to make it unique to your organization.

Floor Mounted Lab Bench

Our Floor Mounted Lab Bench is an essential, high-efficiency workspace for laboratories, made from high-quality steel-wood or corrosion-resistant stainless steel materials to ensure exceptional durability and stability. The unique floor-mounted design effectively reduces vibration, optimizes space usage, and provides a safe and tidy laboratory environment.

Customizable storage solutions help organize lab equipment efficiently, while the easy-to-clean surface maintains laboratory hygiene. It is widely suitable for research institutions, educational laboratories, and the chemical and pharmaceutical industries.

Fume Hood

The fume hood provides safe ventilation to protect against exposure to hazardous or toxic fumes, vapors, or airborne particulate. It is primarily used in laboratory and manufacturing applications to protect the user or environment outside the hood, but can also be used to protect the materials or experiment under the hood.

APPLICATION

Chemistry Lab, physics Lab, biological analysis, pharmaceutical medicine analysis, biological pharmaceutical, plant culture, environmental testing and electronic instrumentation scientific research and so on.

Flammable Storage Cabinet

Safety Cabinets store flammable liquids, corrosives, pesticides and other hazardous materials. All fire-resistant safety cabinets by meet fire codes and regulations for safety storage.

To help protect your people and facility from a potential fire, safety cabinets are engineered to safely contain flammable fuels, solvents, and chemicals. Safety cabinets can not only help everyone store chemicals reasonably, save chemical supplies, but also save human resources, and avoid fires caused by chemicals with the greatest strength.

Class II Type A2 Biological Safety Cabinet for Laboratory

The Class II A2 Biological Safety Cabinet is designed to provide superior biosafety and contamination control for laboratories, research facilities, and clinical settings. With 70% air recirculation and 30% air exhaust, this cabinet ensures a safe and efficient work environment while protecting both the user and the samples.

Equipped with advanced features like a HEPA filtration system, motorized front window, and ergonomic design, this cabinet is a must-have for safe and reliable biological research.

Scan QR Code

Scan QR Code

MaxLabFurniture

MaxLab Furniture

daihongada

Max Laboratory