Resource

- What Furniture Does a Cleanroom Lab Need?

- 1. Cleanroom Workbenches & Laboratory Tables

- Why They Matter

- What to Look For

- Common Cleanroom Options

- 2. Fume Hoods & Laminar Flow Cabinets

- Why They Matter

- Key Equipment Types

- Selection Considerations

- 3. Cleanroom Storage Solutions

- Why They Matter

- Recommended Storage Types

- 4. Cleanroom Chairs & Seating

- Why They Matter

- Key Features to Consider

- 5. Cleanroom Sinks & Wash Stations

- Why They Matter

- Common Cleanroom Solutions

- 6. Pass-Through Chambers & Transfer Hatches

- Why They Matter

- Common Solutions

- Cleanroom Compliance Considerations

- Why Work With an Experienced Cleanroom Furniture Manufacturer?

- Conclusion: Building a Cleanroom That Performs

Essential Cleanroom Lab Furniture and Equipment Guide-What Lab Furniture Is Needed for a Cleanroom?

This guide is designed for laboratory planners, engineers, and procurement teams who need to understand what furniture and equipment are required in a cleanroom environment.

Rather than focusing on products alone, this guide explains why each type of cleanroom lab furniture matters, how it supports contamination control, and what to consider when selecting furniture for ISO and GMP-compliant cleanrooms.

What Furniture Does a Cleanroom Lab Need?

In cleanroom environments—such as pharmaceutical manufacturing, biotechnology laboratories, and semiconductor facilities—furniture selection directly impacts contamination control, safety, and compliance.

Unlike conventional laboratories, cleanrooms require furniture that:

-

Minimizes particle generation

-

Is easy to clean and disinfect

-

Supports controlled workflows

-

Meets ISO, GMP, and FDA requirements

This guide walks through the essential categories of cleanroom lab furniture and equipment, explaining their role and selection criteria.

1. Cleanroom Workbenches & Laboratory Tables

Why They Matter

Workbenches are the core working surface in any cleanroom. Poor material choices or design can become a major source of particle contamination.

What to Look For

-

Smooth, non-porous surfaces

-

Anti-static cleanroom tables

-

Minimal joints and seams

-

Easy access for cleaning

Common Cleanroom Options

-

Height-adjustable laboratory tables

These designs help maintain cleanliness while supporting long-term durability.

2. Fume Hoods & Laminar Flow Cabinets

Why They Matter

Airflow control is critical in cleanrooms to protect both personnel and sensitive samples.

Key Equipment Types

-

Ducted and ductless cleanroom fume hoods

Selection Considerations

-

HEPA filtration efficiency

-

Compatibility with cleanroom airflow design

-

Compliance with ISO and NSF standards

Proper airflow equipment helps maintain sterile conditions and regulatory compliance.

3. Cleanroom Storage Solutions

Why They Matter

Improper storage increases clutter, disrupts workflows, and raises contamination risks.

Recommended Storage Types

-

Stainless steel cleanroom cabinets (GMP-compliant)

-

Wall-mounted cleanroom shelving

-

Sealed drawer systems

-

Mobile cleanroom carts with anti-static wheels

Storage systems should be easy to clean and designed to reduce particle accumulation.

4. Cleanroom Chairs & Seating

Why They Matter

Personnel comfort affects productivity, but seating must not compromise cleanroom integrity.

Key Features to Consider

-

ESD-safe materials

-

Antimicrobial, non-porous surfaces

-

Height and tilt adjustability

-

Particle-resistant casters

Cleanroom chairs should balance ergonomics with contamination control.

5. Cleanroom Sinks & Wash Stations

Why They Matter

Hand hygiene is essential in maintaining cleanroom standards.

Common Cleanroom Solutions

-

Foot-operated wash stations

-

Touchless faucet systems

These designs help reduce cross-contamination and improve hygiene compliance.

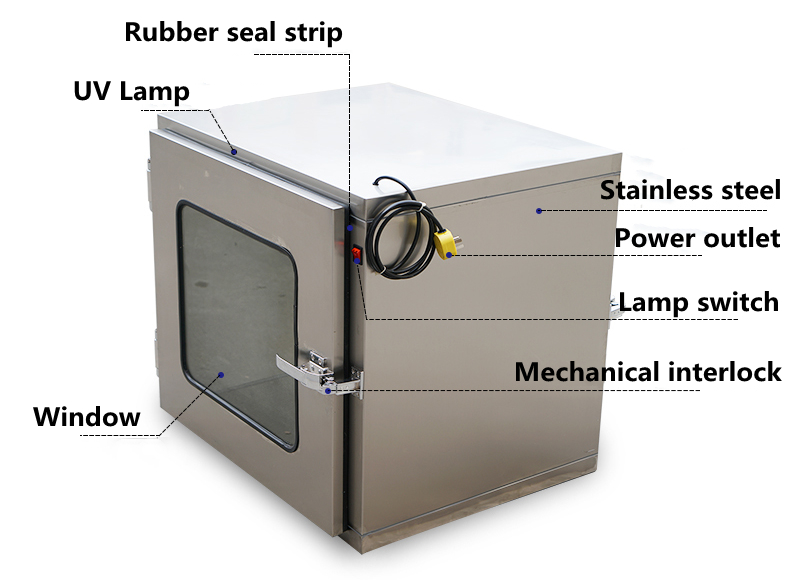

6. Pass-Through Chambers & Transfer Hatches

Why They Matter

Material transfer is a major contamination risk in cleanrooms.

Common Solutions

-

Stainless steel pass-through boxes

-

Static and dynamic pass boxes

-

Air shower transfer hatches

Pass-through systems reduce foot traffic and help maintain pressure differentials between clean zones.

Cleanroom Compliance Considerations

When selecting cleanroom lab furniture, always evaluate compatibility with:

-

ISO Cleanroom Class 3–8

-

GMP and FDA-regulated environments

-

ESD control requirements

-

Long-term cleaning and maintenance procedures

Furniture should support audit readiness, not just daily operation.

Why Work With an Experienced Cleanroom Furniture Manufacturer?

Choosing the right partner helps avoid:

-

Rework caused by non-compliant furniture

-

Delays from long lead times

-

Workflow inefficiencies due to poor layout design

An experienced manufacturer can provide:

-

Custom fabrication based on cleanroom class

-

Certified materials and finishes

-

Design consultation and layout planning

-

Installation support for global projects

Conclusion: Building a Cleanroom That Performs

Outfitting a cleanroom is not only about filling a space—it’s about creating a controlled environment that supports safety, efficiency, and compliance.

By understanding the role of each type of cleanroom lab furniture and equipment, laboratories can make informed decisions that reduce risk and support long-term performance.

For tailored cleanroom furniture solutions and technical guidance, working with a specialized cleanroom partner makes all the difference.

Need help selecting cleanroom lab furniture for your project?

Talk to a cleanroom specialist for layout advice and compliance support.

Why We Choose to Be Your Lab Furniture Solution Provider, Not Just a Manufacturer

Max Lab Introduction

Electronics Lab Bench vs Chemistry Lab Bench: What You Need to Know

What Is an Air Shower for Cleanroom?

For Products

Do you offer ergonomic solutions for lab furniture?

Yes, our laboratory furniture includes ergonomic designs such as height-adjustable lab benches and chairs that reduce strain during long hours of work.

Do you have certifications for your products?

Yes, We have CE, ISO9001, ISO14001, OHSASI18001 and so on.

Customization

What is the after-sales support for customized services?

We provide a full range of after-sales service, including equipment installation guidance, regular maintenance, troubleshooting, operation training, etc., to ensure the safe and efficient operation of equipment.

For Customization

Do you offer custom branding for laboratory furniture?

Yes, we can incorporate custom logos, colors, and branding into your lab furniture to make it unique to your organization.

For Logistics

What is the lead time?

We usually will start to work after receiving 50% deposit, and as for the exact lead time, it depends on quantity and detailed requirement. We can promise it will be shipped on time as we negotiated.

Get in touch with us

If you have any comments or good suggestions, please leave us a message; later our professional staff will contact you as soon as possible.

Scan QR Code

Scan QR Code

MaxLabFurniture

MaxLab Furniture

daihongada

Max Laboratory