Custom vs Standard Lab Furniture: Pros and Cons

- Choosing the Right Lab Furniture: What Every Lab Manager Should Evaluate

- What this article covers — lab furniture design with practical decision criteria

- Overview: Custom vs standard lab furniture in lab furniture design

- Comparison table: key differences in lab furniture design

- Cost, budget planning, and total cost of ownership in lab furniture design

- Compliance, safety, and materials selection

- Lead time, installation, and minimizing downtime

- Durability, maintenance, and lifecycle considerations

- When to choose custom — practical scenarios

- When to choose standard/modular — practical scenarios

- Decision checklist for lab furniture design

- Cost vs benefit: sample ROI comparison (illustrative)

- MAX LAB: manufacturing strength supporting both custom and standard lab furniture design

- Procurement tips when working with manufacturers

- Case example: choosing between custom and modular for a biotech R&D lab

- Final recommendations for lab furniture design selection

- Frequently Asked Questions (FAQ)

- 1. How much more does custom lab furniture cost compared to standard solutions?

- 2. Can standard lab furniture meet biosafety and chemical storage requirements?

- 3. What is the typical lead time difference between custom and modular lab furniture?

- 4. Are modular systems as durable as custom-built furniture?

- 5. How do I choose a supplier for lab furniture design and installation?

- 6. Can furniture be relocated or resold later?

- Contact and next steps

- References

Choosing the Right Lab Furniture: What Every Lab Manager Should Evaluate

Selecting the right laboratory furniture is one of the most consequential decisions for lab safety, workflow efficiency, and long-term operating costs. Whether you are planning a research lab, QA/QC facility, educational lab, or industrial testing center, understanding the trade-offs between custom and standard lab furniture will help you align your lab furniture design with budget, schedule, performance, and compliance goals.

What this article covers — lab furniture design with practical decision criteria

We compare custom and standard (also called modular or off-the-shelf) lab furniture across cost, lead time, compliance, flexibility, installation impacts, maintenance, and total cost of ownership. You’ll find side-by-side comparisons, procurement tips, and a checklist to help you choose the right approach. Recommendations reflect industry best practice, safety guidance, and manufacturing realities.

Overview: Custom vs standard lab furniture in lab furniture design

In lab furniture design, “custom” means furniture designed and built to unique dimensions, finishes, utilities, and workflows; it is typically manufactured to order. “Standard” or modular furniture consists of pre-designed modules or systems that can be configured on-site, often with a limited palette of sizes and finishes. Each approach has merits:

- Custom: Ideal for highly specialized workflows, unique space constraints, integration with unusual utilities, or when specific materials/finishes are required.

- Standard/Modular: Best when schedule, predictable cost, and scalability are priorities. Suited to many teaching labs, routine analytical labs, and phased builds.

Comparison table: key differences in lab furniture design

| Criteria | Custom Lab Furniture | Standard / Modular Lab Furniture |

|---|---|---|

| Design flexibility | High — tailored layouts, integrated utilities, bespoke materials | Moderate — configurable modules, limited customization of sizes/finishes |

| Upfront cost | Higher — design, prototyping, and bespoke fabrication add cost | Lower — economies of scale and repeatable production reduce price |

| Lead time | Longer — engineering and bespoke manufacturing add weeks/months | Shorter — stocked modules and standardized lines accelerate delivery |

| Installation impact | On-site adjustments may be needed; trades coordination more complex | Faster installation, less site disruption because modules fit together |

| Compliance & safety integration | Can be engineered to meet specific biosafety, ventilation, or chemical requirements | Meets common standards; special requirements may need add-ons or adaptations |

| Future adaptability | Depends on initial design; retrofits can be costly | High — modules can be reconfigured or reused across spaces |

| Resale & lifecycle | Lower resale potential; high asset-specific value for original owner | Higher reusability and resale value for standard modules |

Cost, budget planning, and total cost of ownership in lab furniture design

Upfront costs are only part of the picture. Consider total cost of ownership (TCO): installation, downtime during installation, energy and utility costs, maintenance, and eventual replacement. In many cases, modular lab furniture shows better TCO when you factor in:

- Lower initial capital outlay and shorter project financing periods.

- Faster installation and therefore less facility downtime.

- Ease of reconfiguration that delays full replacement.

However, if your lab requires specialized containment, corrosion-resistant materials, or integrated equipment supports, custom solutions may reduce downstream retrofit costs and operational risk — sometimes justifying higher initial investment. To quantify, build a 5–10 year cash flow model that includes maintenance intervals, expected downtime for upgrades, and utility impacts. Use that model to estimate payback rather than relying on upfront price alone.

Compliance, safety, and materials selection

Regulatory compliance and safety are non-negotiable. Fume hoods, chemical-resistant countertops, storage for flammables and corrosives, and cleanability for contamination control must be embedded in lab furniture design. Key considerations:

- Fume hoods: Ensure furniture integrates with hood sash geometry, ductwork, and face velocity requirements set by safety authorities.

- Countertops: Select materials (e.g., epoxy resin, phenolic, stainless steel) based on chemical resistance and heat tolerance; verify against ASTM or equivalent chemical resistance testing.

- Storage: Cabinets for acids/bases require corrosion-resistant interiors and secondary containment; flammable storage must meet local fire codes.

Custom furniture allows specification of niche materials and containment features. Standard systems generally offer tested, code-compliant options but may limit material choices. In either case, verify supplier test data for chemical resistance, load ratings, and finishes before purchase.

Lead time, installation, and minimizing downtime

Project schedule often drives the decision. Standard/modular systems typically deliver and install faster because of stocked modules and repeatable assembly. If your project has tight milestones or you need phased installations (e.g., keep a portion of a facility operational), modular systems reduce disruption.

Custom furniture requires design validation, shop drawings, and potentially on-site mock-ups. Expect longer procurement cycles. However, if the custom approach saves time later by preventing utility relocations or rework, that time may be recovered. To mitigate schedule risk:

- Lock down lab furniture design and interface points early in construction documents.

- Use mock-ups for critical interfaces (hoods, service columns) to avoid late changes.

- Coordinate early with MEP and ventilation contractors.

Durability, maintenance, and lifecycle considerations

Think beyond aesthetics. Durable finishes, replaceable components, and standardized spare parts reduce maintenance costs. Standard systems make it easier to obtain replacement modules and parts years later. Custom systems can be built for extreme durability but may require custom spare parts and vendor support.

Ask suppliers for:

- Material datasheets and warranty terms.

- Maintenance manuals and recommended service intervals.

- Availability of spare parts and lead times.

When to choose custom — practical scenarios

- Unique workflows — specialized equipment loads, integration of vertical utilities, or atypical sample handling requiring bespoke layouts.

- Historic or constrained spaces where dimensions deviate from standard module sizes and modifications are impractical.

- High-spec materials needed for extreme chemical resistance, pharmaceutical cleanrooms, or high-temperature processes.

When to choose standard/modular — practical scenarios

- Education labs, general analytical labs, and QC labs where workflows use common benching and storage types.

- Phased facilities or multi-site rollouts that benefit from repeatable, reconfigurable systems.

- Projects with tight schedules and budgets where predictability and speed are priorities.

Decision checklist for lab furniture design

Use this checklist before selecting a path:

- Define workflows and critical equipment that affect furniture (sashes, ductwork, utilities).

- Specify required materials and test data (chemical resistance, load, fire rating).

- Set firm lead time and budget constraints.

- Assess future flexibility needs (reconfigurability, resale potential).

- Confirm supplier quality systems, warranties, and spare parts availability.

Cost vs benefit: sample ROI comparison (illustrative)

| Metric (5-year) | Custom | Standard/Modular |

|---|---|---|

| Initial capital | High | Low–Medium |

| Installation downtime | Longer | Shorter |

| Reconfiguration cost | High | Low |

| Maintenance predictability | Variable (depends on design) | High (standard parts) |

| Overall 5-year TCO | Can be lower for extremely specialized use cases | Often lower for general-use labs and phased projects |

MAX LAB: manufacturing strength supporting both custom and standard lab furniture design

Founded in 2000, Guangzhou Max Laboratory Equipment Co., Ltd. (MAX LAB) is a leading manufacturer that integrates the design, production, and sales of laboratory furniture and equipment. With over 15 years of export experience, our founder has led the company to serve clients in more than 60 countries and regions, earning a reputation for reliability and excellence. Guided by our core values—Quality First, Delivery First, Price First, and Service First—we are committed to delivering superior laboratory solutions that meet the highest global standards.

Our 5,000 m² factory in Guangzhou is equipped with advanced German-imported machinery and operates under modern management systems to ensure precision and consistency. With three standardized production lines and a well-stocked modular inventory, we achieve production efficiency and delivery times up to 30% faster than industry peers.

At MAX LAB, we insist on stringent quality control for every product before it leaves the factory. Using materials from leading global suppliers, we ensure that every item—from lab furniture and storage cabinets to fume hoods and countertops—meets international quality and environmental standards. Our dedication to innovation, efficiency, and customer satisfaction has made MAX LAB a trusted partner in laboratory projects worldwide.

MAX LAB’s core product strengths include lab storage cabinets, fume hoods, lab countertops, lab benches, purifying equipment, and anti-vibration tables. These products are available as prefabricated modular systems for rapid deployment and as bespoke solutions for unique lab furniture design challenges. The combination of modular inventory and custom engineering means MAX LAB can support projects that need fast delivery without compromising on the ability to supply customized, high-performance solutions when required.

Procurement tips when working with manufacturers

- Request detailed shop drawings and a clear scope of supply that lists utilities, finishes, anchors, and tolerances.

- Ask for chemical resistance and load-test data for materials used in countertops and cabinets.

- Require a project timeline with milestones and penalties for missed dates if schedule is critical.

- Inspect factory QA processes and ask about certifications (e.g., ISO 9001) and third-party testing.

- Confirm spare parts lead times and whether modules are stocked for future orders.

Case example: choosing between custom and modular for a biotech R&D lab

Scenario: A mid-size biotech firm needs benching for tissue culture, microscopy, and small synthesizers in a retrofit building with limited floor penetrations. They require chemical-resistant benches and integrated service columns but also want the ability to reconfigure in five years as projects change.

Recommended approach: Adopt a hybrid strategy — modular benching for general-purpose workstations (quick to install, reconfigurable) and custom-built sections for tissue-culture suites and integrated utility islands where containment and service integration are critical. This balances speed, cost, and performance.

Final recommendations for lab furniture design selection

Choose modular/standard systems when schedule, budget predictability, and future adaptability are top priorities. Choose custom furniture when you must meet unique process, containment, or spatial constraints that modular systems cannot satisfy. Frequently, a hybrid approach yields the best long-term value: standard modules for routine areas and custom pieces where functionality cannot be compromised.

If you are planning a lab fit-out, involve furniture manufacturers early, validate critical interfaces with mock-ups, and quantify TCO rather than judging solely on upfront cost.

Frequently Asked Questions (FAQ)

1. How much more does custom lab furniture cost compared to standard solutions?

Costs vary widely by materials and complexity. Custom furniture commonly costs more upfront — sometimes 15–50% higher — due to bespoke engineering and fabrication. However, accurate ROI depends on lifecycle needs; for highly specialized environments, custom may reduce retrofit costs and operational risk.

2. Can standard lab furniture meet biosafety and chemical storage requirements?

Yes. Many standard systems are designed to meet common biosafety and chemical storage needs. For higher biosafety levels or unusual hazardous material profiles, confirm that the system’s materials and containment options meet relevant codes and testing standards.

3. What is the typical lead time difference between custom and modular lab furniture?

Standard/modular systems can often be delivered and installed in weeks to a few months depending on stock and scope. Custom solutions typically take longer—often several months—because of design, approvals, and bespoke manufacturing. Early engagement with suppliers narrows schedule uncertainty.

4. Are modular systems as durable as custom-built furniture?

Modern modular systems are engineered for durability and easy maintenance; many use the same high-grade materials as custom furniture. Durability depends on material selection, fabrication quality, and maintenance—request datasheets and warranties to compare.

5. How do I choose a supplier for lab furniture design and installation?

Look for suppliers with verified quality systems, industry references, transparent lead times, factory inspection capability, and documented test data for materials. Prefer vendors who offer both modular stock and custom engineering experience so you can adopt hybrid strategies when needed.

6. Can furniture be relocated or resold later?

Standard modular furniture is designed for reconfiguration and resale; custom units are often site-specific and harder to relocate without modification. If asset mobility is important, favor modular systems or ensure custom designs include modular elements.

Contact and next steps

Need help evaluating options for your next lab fit-out or retrofit? Contact us to discuss your layout, workflow requirements, and schedule. Explore MAX LAB’s product range (lab storage cabinets, fume hoods, lab countertops, lab benches, purifying equipment, anti-vibration tables) or request a tailored quote and factory inspection to see how our modular inventory and custom engineering can meet your project goals.

Request a consultation / View products: Contact MAX LAB sales to schedule a project review and receive shop drawings and lead-time estimates.

References

- OSHA — Laboratory Safety: https://www.osha.gov/laboratory-safety (accessed 2025-11-25)

- CDC — Laboratory Safety Guidance and Resources: https://www.cdc.gov/labsafety/index. (accessed 2025-11-25)

- ASTM International — D1308 Standard Test Method for Effect of Household Chemicals on Clear and Pigmented Organic Finishes: https://www.astm.org/Standards/D1308.htm (accessed 2025-11-25)

- Grand View Research — Laboratory Furniture Market Size, Share & Trends Analysis: https://www.grandviewresearch.com/industry-analysis/laboratory-furniture-market (accessed 2025-11-25)

- WHO — Laboratory biosafety manual (4th ed.): https://www.who.int/publications/i/item/9789240011311 (accessed 2025-11-25)

Top 10 Laboratory furniture Manufacturers and Supplier Brands in 2026

How to Choose the Right Lab Sink for Your Facility

Variable Air Volume Fume Hood Airflow Balancing Tips

Selecting Chemical-Resistant Worktops for Lab Benches

For Products

Are your products customizable?

Absolutely! We offer customized solutions for laboratory benches, lab tables, and furniture systems to meet the specific requirements of your workspace.

For Company

What types of companies do you work with?

We have worked with a wide range of companies, from small startups to large, multinational corporations. Our expertise in the laboratory furniture industry enables us to meet the needs of various sectors, including healthcare, research, education, pharmaceuticals, and industrial labs.

FAQS

What products does Max Lab offer?

We specialize in laboratory furniture and equipment, including lab benches, fume hoods, storage cabinets, and custom lab solutions.

Where are your products manufactured?

All products are manufactured in our advanced facility—the largest laboratory furniture factory in Guangzhou—ensuring strict quality control.

Customization

What information do I need to provide to start a custom project?

In order to start a custom project, you need to provide information about the spatial layout of the laboratory, functional requirements, equipment quantity and specifications, budget, etc. If possible, you can also provide reference drawings or patterns so that we can better understand your needs.

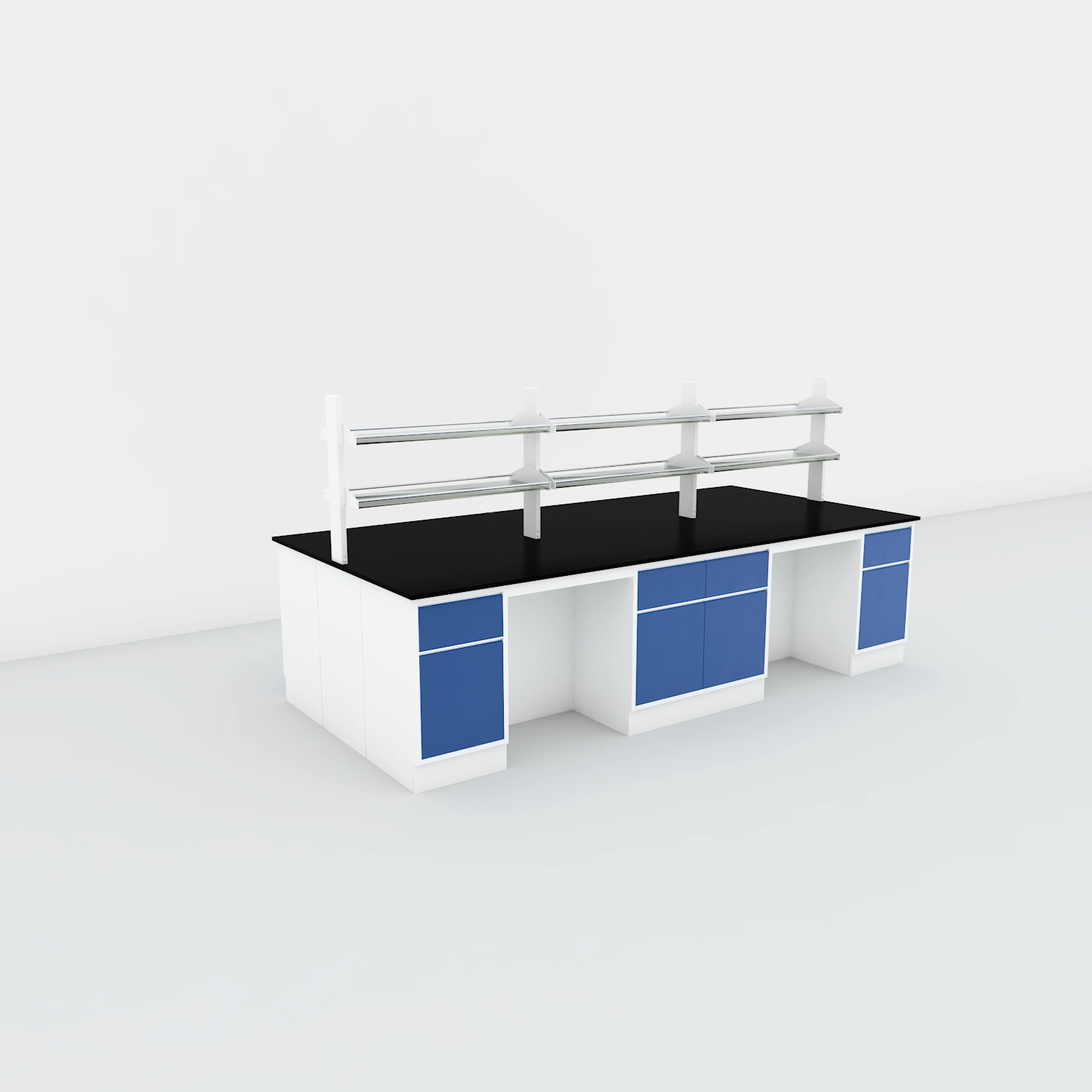

Floor Mounted Lab Bench

Our Floor Mounted Lab Bench is an essential, high-efficiency workspace for laboratories, made from high-quality steel-wood or corrosion-resistant stainless steel materials to ensure exceptional durability and stability. The unique floor-mounted design effectively reduces vibration, optimizes space usage, and provides a safe and tidy laboratory environment.

Customizable storage solutions help organize lab equipment efficiently, while the easy-to-clean surface maintains laboratory hygiene. It is widely suitable for research institutions, educational laboratories, and the chemical and pharmaceutical industries.

Fume Hood

The fume hood provides safe ventilation to protect against exposure to hazardous or toxic fumes, vapors, or airborne particulate. It is primarily used in laboratory and manufacturing applications to protect the user or environment outside the hood, but can also be used to protect the materials or experiment under the hood.

APPLICATION

Chemistry Lab, physics Lab, biological analysis, pharmaceutical medicine analysis, biological pharmaceutical, plant culture, environmental testing and electronic instrumentation scientific research and so on.

Flammable Storage Cabinet

Safety Cabinets store flammable liquids, corrosives, pesticides and other hazardous materials. All fire-resistant safety cabinets by meet fire codes and regulations for safety storage.

To help protect your people and facility from a potential fire, safety cabinets are engineered to safely contain flammable fuels, solvents, and chemicals. Safety cabinets can not only help everyone store chemicals reasonably, save chemical supplies, but also save human resources, and avoid fires caused by chemicals with the greatest strength.

Class II Type A2 Biological Safety Cabinet for Laboratory

The Class II A2 Biological Safety Cabinet is designed to provide superior biosafety and contamination control for laboratories, research facilities, and clinical settings. With 70% air recirculation and 30% air exhaust, this cabinet ensures a safe and efficient work environment while protecting both the user and the samples.

Equipped with advanced features like a HEPA filtration system, motorized front window, and ergonomic design, this cabinet is a must-have for safe and reliable biological research.

Scan QR Code

Scan QR Code

MaxLabFurniture

MaxLab Furniture

daihongada

Max Laboratory