Case

Transforming a Material Testing Lab in Berlin, Germany

This project transformed a materials testing lab in Berlin into a modern research hub. Facing space, safety, and precision challenges, we designed a custom lab with vibration-resistant workstations, modular layouts, and safety upgrades. The result was improved testing accuracy, efficiency, and regulatory compliance, setting a new standard for materials research in Germany.

Case Study: Transforming a Material Testing Lab in Berlin, Germany

Time: 2018.8.3

Location: Berlin, Germany

Background:

Our client company, based in Germany, worked with a leading materials research institute in Berlin, Germany, to transform its aging materials testing laboratory into a modern research hub. The laboratory focuses on testing the mechanical, thermal and chemical properties of advanced materials, including metals, polymers and composites. The goal is to create a space capable of supporting high-precision testing while improving efficiency, safety and compliance with European and international standards.

The project presented several unique challenges:

Precision Requirements: Material testing demands extremely accurate measurements, requiring vibration-resistant and temperature-controlled environments.

Space Constraints: The lab had limited space but needed to accommodate large testing equipment like tensile testers, thermal analyzers, and spectroscopy instruments.

Safety Concerns: Handling high-strength materials and high-temperature testing posed significant safety risks.

Our Approach

Needs Assessment:

Our team conducted an in-depth consultation with the lab’s researchers and engineers to understand their workflows, equipment requirements, and pain points.

Custom Lab Design:

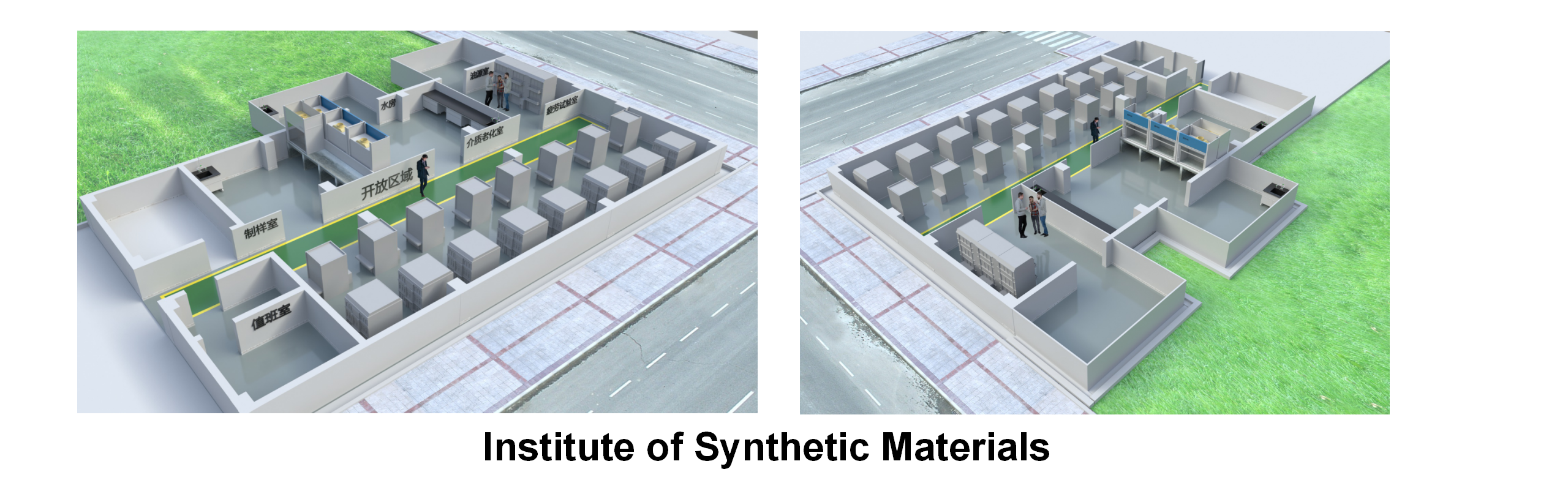

Using advanced 3D modeling, we designed a lab layout that maximized space utilization and workflow efficiency.

Key features included:

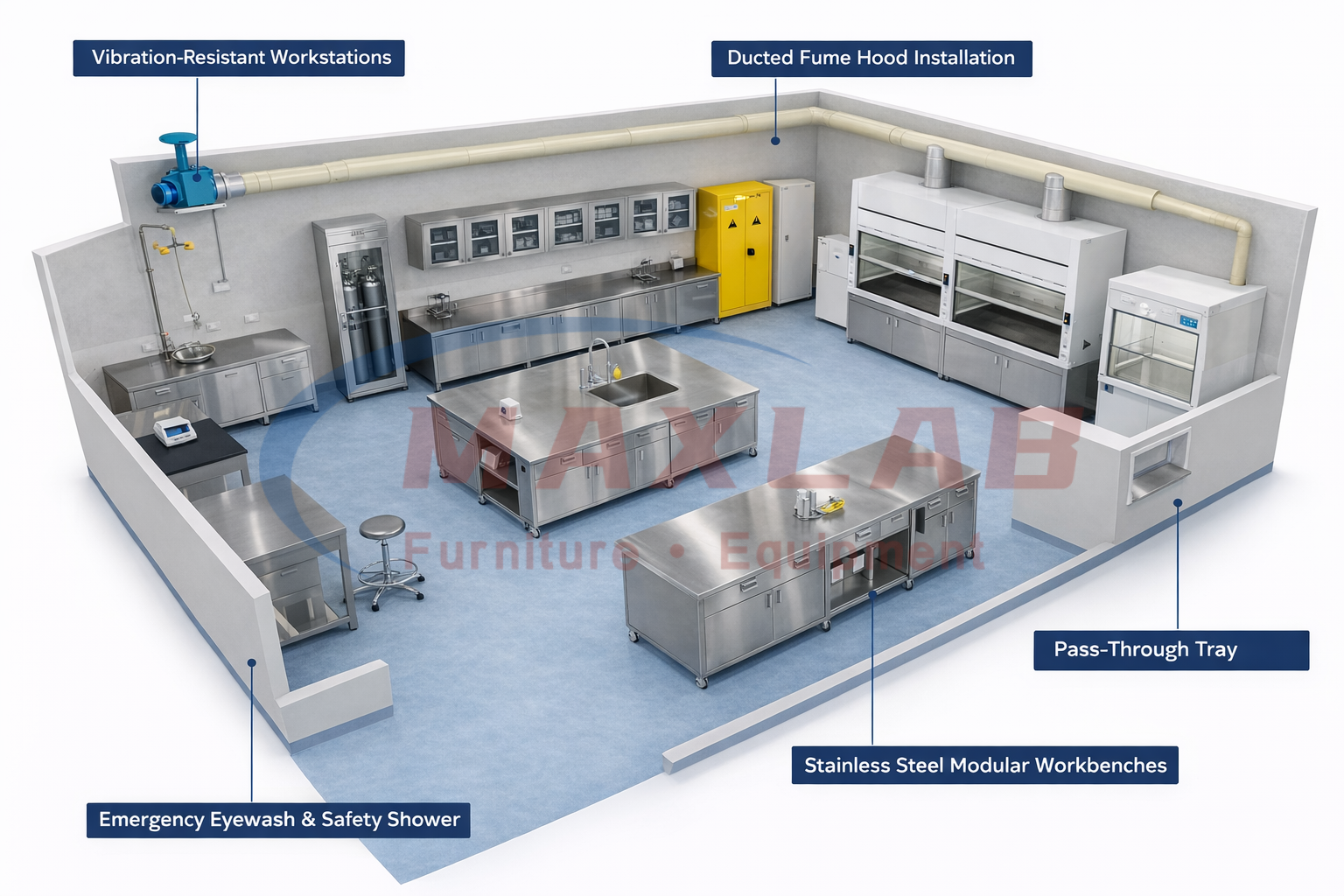

Vibration-Resistant Workstations: Designed to minimize interference with sensitive testing equipment.

Modular Workbenches: Allowed for easy reconfiguration to accommodate different testing setups. Custom made for the customer is stainless steel countertop. This laboratory makes heavy use of premium quality stainless steel work surfaces. Longevity and durability make stainless steel a preferred countertop material for heavy-use environments.

Specialized Equipment Stations: Space for large equipment. Improve the utilization rate of space and promote the efficiency of the experiment.

Safety Enhancements: Installed fire-resistant materials, emergency shut-off systems, and protective barriers for high-temperature testing.

Regulatory Compliance:

We ensured all designs and materials met DIN EN ISO/IEC 17025 standards, including proper calibration of testing equipment and documentation of procedures. We also adhered to German safety regulations, such as the German Equipment and Product Safety Act (GPSG).

Installation and Training:

Our team managed the installation process to minimize downtime and provided comprehensive training on the new equipment and safety protocols.

Case Result

The new lab has become a benchmark for material testing in Germany. Key outcomes include:

Enhanced Precision: The vibration-resistant workstations and temperature-controlled environment have significantly improved testing accuracy.

Increased Efficiency: The modular design allows researchers to quickly adapt the lab for different types of tests, reducing setup time.

Improved Safety: The new safety features have reduced risks associated with high-strength material testing.

Regulatory Approval: The lab successfully achieved DIN EN ISO/IEC 17025 certification, enhancing its credibility and marketability.

Client Feedback

Dr. Klaus Weber, the lab’s lead researcher, shared his thoughts:

The first impression the MAX LAB team gave us was one of great professionalism. They were able to grasp our ideas and intentions very well, and the design drawings they provided were very clear and easy to understand.

RELATED PRODUCTS

Contact us for a free consultation today!

Ready to revolutionize your laboratory? Contact us today to learn more about our products and how we can tailor them to meet your specific needs.

Pharmacy Lab in India

Flexible Modular Container Laboratory Case – Africa (40ft Cabinet Space)

Laboratory Solutions for Argentine Institute of Bacteriology

Private Biochemistry Research Laboratory in France

For Logistics

How are shipping costs calculated?

Shipping costs are calculated based on the size, weight, and destination of your order. We provide a detailed shipping quote during the ordering process.

For After-Sales Support

How about your after sale service?

We will reply you within 24 hours by email or phone.

If we have local agent,we will arrange him to your site within 24 hours to assist you to shoot the problem.

How can I get technical support for my equipment?

You can contact our technical support team via email or phone for assistance with installation, troubleshooting, or any issues you encounter with your laboratory equipment.

For Company

What types of companies do you work with?

We have worked with a wide range of companies, from small startups to large, multinational corporations. Our expertise in the laboratory furniture industry enables us to meet the needs of various sectors, including healthcare, research, education, pharmaceuticals, and industrial labs.

Customization

Does the customized equipment have a warranty?

Yes, all custom equipment comes with a warranty. Specific warranty terms are determined according to the type of equipment and customized content.

Get in touch with us

If you have any comments or good suggestions, please leave us a message; later our professional staff will contact you as soon as possible.

Scan QR Code

Scan QR Code

MaxLabFurniture

MaxLab Furniture

daihongada

Max Laboratory