Resource

- Key Benefits of Using a Pass Box

- Types of Pass Boxes

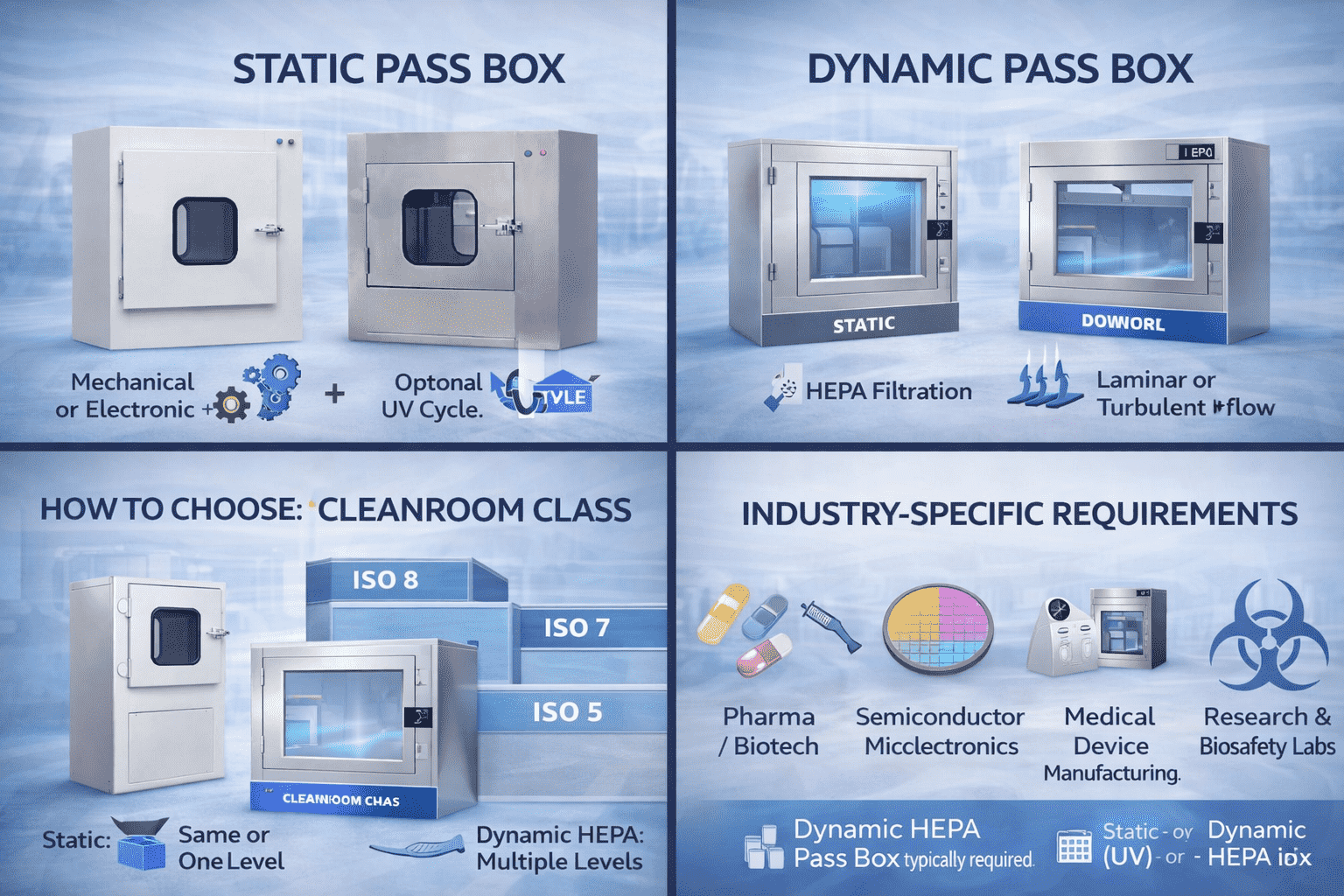

- 1) Static Pass Box (Non-HEPA / Non-ventilated)

- Static Interlocking Options

- UV Option (Common in Static Models)

- 2) Dynamic Pass Box (HEPA-Filtered / Ventilated)

- Common Dynamic Types

- How to Choose the Right Pass Box

- 1) Consider the Cleanliness Difference Between Rooms

- 2) Industry-Specific Requirements

- Recommended Material: Stainless Steel (304 / 316L)

- Why Choose MAX LAB Pass Boxes?

- FAQ 1: What is a pass box used for in a cleanroom?

- FAQ 2: What is the difference between a static pass box and a dynamic pass box?

- FAQ 3: When do you need a HEPA pass box for a cleanroom?

- FAQ 4: Is a UV pass box enough for sterile transfers?

- FAQ 5: Which is better—mechanical or electronic interlock for a pass box?

- FAQ 6: What material is best for pass boxes in cleanrooms (304 vs 316L)?

What Is a Pass Box? Types, Features, and How to Choose the Right Transfer Hatch

A pass box (transfer hatch) is a controlled enclosure that enables safe material transfer between cleanroom zones without compromising ISO-classified air quality. This guide explains what pass boxes are, compares static and dynamic models (including UV, laminar flow, and air shower types), and provides a practical selection framework based on cleanroom class differences, industry requirements, and compliance needs.

A pass box (also called a transfer hatch) is a contamination-controlled enclosure used to transfer materials between cleanroom areas of different cleanliness grades while maintaining ISO-classified air quality. It helps prevent cross-contamination when moving equipment, samples, components, or materials between Grade A/B/C/D environments in pharmaceutical, biotech, medical device, and electronics facilities.

If you’ve ever wondered how to transfer items between cleanroom zones—or between a cleanroom and a non-clean area—without compromising cleanliness, a pass box is the simplest and most effective solution.

Key Benefits of Using a Pass Box

-

Reduces contamination risk by creating a controlled transfer barrier

-

Improves workflow efficiency by minimizing personnel movement between rooms

-

Supports GMP/ISO compliance for controlled transfers and cleanroom integrity

-

Flexible configurations including static, dynamic (HEPA), laminar flow, air shower, and UV options

-

Types of Pass Boxes

Pass boxes are generally grouped into two categories: Static Pass Boxes and Dynamic Pass Boxes.

1) Static Pass Box (Non-HEPA / Non-ventilated)

A static pass box is a basic transfer chamber without an air filtration system. It is commonly used:

-

between similar or adjacent cleanroom classes

-

from a non-clean area to a lower-grade clean area (depending on process risk)

-

for facilities that need simple segregation + interlocking safety

Static pass boxes rely on door interlocking to prevent both doors from being opened at the same time.

Static Interlocking Options

Mechanical Interlock

-

Uses physical linkage between doors

-

No electricity required

-

Reliable during power outages

Electronic Interlock

-

Uses electromagnetic locks + sensors

-

Can support timers, alarms, status indicators

-

Often paired with an automatic UV cycle before unlocking the opposite door

UV Option (Common in Static Models)

UV pass boxes use UV-C (typically 254 nm) to reduce surface microbial contamination. Many systems run an automatic cycle (often 5–15 minutes) after the entry door is closed, then allow the opposite door to unlock.

Note: UV helps with surface decontamination but does not replace proper cleaning SOPs or HEPA-controlled environments for critical transfers.

2) Dynamic Pass Box (HEPA-Filtered / Ventilated)

A dynamic pass box includes a fan + HEPA filtration system that actively purifies chamber air during transfer. This is preferred for:

-

higher-grade cleanrooms

-

larger cleanliness gaps between rooms

-

processes sensitive to particles (and sometimes microbial contamination)

Dynamic systems generally create either:

-

Laminar (unidirectional) airflow: best for sweeping particles in one direction

-

Turbulent (mixed) airflow: improves overall mixing and filtration within the chamber

Common Dynamic Types

-

Provides stable, controlled airflow across the chamber

-

Ideal for high-cleanliness transfers and particle-sensitive processes

-

Uses high-velocity clean air jets to remove particles from item surfaces

-

Built-in door seals improve air tightness

-

Functions like a mini airlock during transfer

How to Choose the Right Pass Box

1) Consider the Cleanliness Difference Between Rooms

This is often the most important factor:

-

Same ISO class (e.g., ISO 7 → ISO 7):

Static pass box with interlock is often sufficient. -

One-class difference (e.g., ISO 6 → ISO 7):

Static with UV may be acceptable depending on risk assessment and SOPs. -

Multiple-level differences (e.g., unclassified → ISO 5):

Dynamic pass box with HEPA filtration is strongly recommended and may be required.

2) Industry-Specific Requirements

-

Pharmaceutical (aseptic/sterile operations):

Dynamic HEPA pass boxes are typically required to meet GMP expectations. -

Semiconductor / Microelectronics:

Dynamic systems are preferred for strict particle control; materials should be low-shedding and chemical resistant. -

Medical Device Manufacturing:

Static (with UV) may fit ISO 7–8 zones; ISO 5 zones usually require dynamic HEPA systems. -

Research / Biosafety Labs:

Requirements vary widely; higher-risk workflows often require dynamic HEPA and may add UV for added control.

Recommended Material: Stainless Steel (304 / 316L)

Stainless steel is the preferred material for pass boxes because it is:

-

non-porous and easy to clean

-

corrosion-resistant and compatible with disinfectants

-

durable under frequent cleaning cycles

-

low particle generation during use

For most cleanrooms, 304 or 316L stainless steel is the standard choice.

Why Choose MAX LAB Pass Boxes?

-

Quiet operation (<60 dB)

-

Easy integration with existing cleanroom walls and workflows

Contact MAX LAB today for a free consultation to match your pass box to your cleanroom class, process risk, and facility layout.

FAQ 1: What is a pass box used for in a cleanroom?

A pass box is used to transfer materials between cleanroom zones (or between clean and non-clean areas) while reducing cross-contamination and helping maintain ISO-classified air cleanliness.

FAQ 2: What is the difference between a static pass box and a dynamic pass box?

A static pass box has no filtration system and relies on interlocked doors for isolation. A dynamic pass box includes a fan + HEPA filtration (often with laminar airflow) to actively remove particles inside the chamber during transfers.

FAQ 3: When do you need a HEPA pass box for a cleanroom?

A HEPA (dynamic) pass box is recommended when transferring across multiple cleanliness levels (e.g., unclassified to ISO 5), for high-risk or particle-sensitive processes, and in many GMP-controlled pharmaceutical applications.

FAQ 4: Is a UV pass box enough for sterile transfers?

UV pass boxes can reduce surface contamination, but UV alone does not replace HEPA-controlled airflow for critical transfers. For stricter sterile or high-grade cleanroom workflows, a dynamic HEPA pass box is typically preferred.

FAQ 5: Which is better—mechanical or electronic interlock for a pass box?

Mechanical interlocks are simple and work without power, making them reliable during outages. Electronic interlocks offer more control (status indicators, alarms, timed UV cycles, access control) and are often chosen for higher compliance needs.

FAQ 6: What material is best for pass boxes in cleanrooms (304 vs 316L)?

Stainless steel is the industry standard because it is non-porous, durable, and easy to disinfect. 304 stainless steel works for most cleanrooms, while 316L offers better corrosion resistance for harsher disinfectants or higher corrosion-risk environments.

Why We Choose to Be Your Lab Furniture Solution Provider, Not Just a Manufacturer

Max Lab Introduction

Electronics Lab Bench vs Chemistry Lab Bench: What You Need to Know

Lab Safety 101 Best Practices for Storing Chemical Reagents

For Products

What are the payment terms?

T/T by our bank account directly, or by the West Union.

About Solution

What is the warranty policy of the product?

We provide 1-3 years warranty service, depending on the product type. Meanwhile, comprehensive after-sales support is provided, including repair and replacement services.

Customization

Are customized services suitable for small laboratories?

Yes, our customized services are suitable for all types of laboratories, including small ones. We are able to provide customized solutions according to the actual needs of the laboratory.

How to calculate the cost of customized services?

Customization services incur additional costs depending on the complexity of the design, material selection and production requirements. We will clearly list all costs at the quote stage to ensure that the client understands all costs.

For Customization

Can you create a lab design layout for us?

Yes, we'll provide preliminary layout, confirm 3D drawings and rendering drawings.

Get in touch with us

If you have any comments or good suggestions, please leave us a message; later our professional staff will contact you as soon as possible.

Scan QR Code

Scan QR Code

MaxLabFurniture

MaxLab Furniture

daihongada

Max Laboratory