Resource

- Introduction: The Foundation of an Efficient Laboratory

- Why Investing in the Right Lab Cabinets Matters

- Types of Lab Cabinets: A Comprehensive Classification

- Specialized Function Cabinets

- Safety and Chemical Storage Cabinets

- Materials for Lab Cabinets: Durability, Resistance, and Aesthetics

- Metal Lab Cabinets

- Wood and Phenolic Resin

- Epoxy Resin

- Key Features and Specifications of High-Performance Lab Cabinets

- Selecting the Ideal Lab Cabinets: A Step-by-Step Buyer's Guide

- How to choose Lab Cabinet manufacturers?: key features

- Installation, Layout, and Optimizing Your Lab Workspace

- Maintenance and Longevity: Protecting Your Lab Cabinet Investment

- The Future of Lab Cabinets: Smart Technology and Sustainable Design

- Conclusion: Building a Safer, Smarter, and More Efficient Lab

- Frequently Asked Questions

- What are the primary types of lab cabinets based on function?

- How do I choose the right material for my lab cabinets?

- What essential safety features should I look for in lab cabinets?

- Can lab cabinets be customized to fit specific laboratory needs?

- What certifications or standards should lab cabinets meet?

- How often should lab cabinets be maintained for optimal performance?

- What is the key difference between a fume hood base cabinet and a biosafety cabinet?

- Are there eco-friendly or sustainable options available for lab cabinets?

- References

Ultimate Guide to Lab Cabinets 2026: Types, and Innovations

This authoritative guide explores the essential ecosystem of lab cabinets for 2026. It covers critical selection criteria including SEFA standards, material durability (epoxy vs. phenolic), and safety compliance (OSHA/NFPA). The article details various cabinet types—from biosafety to flammable storage—and looks ahead to smart lab innovations, offering a practical buyer's checklist for facility managers and lab directors.

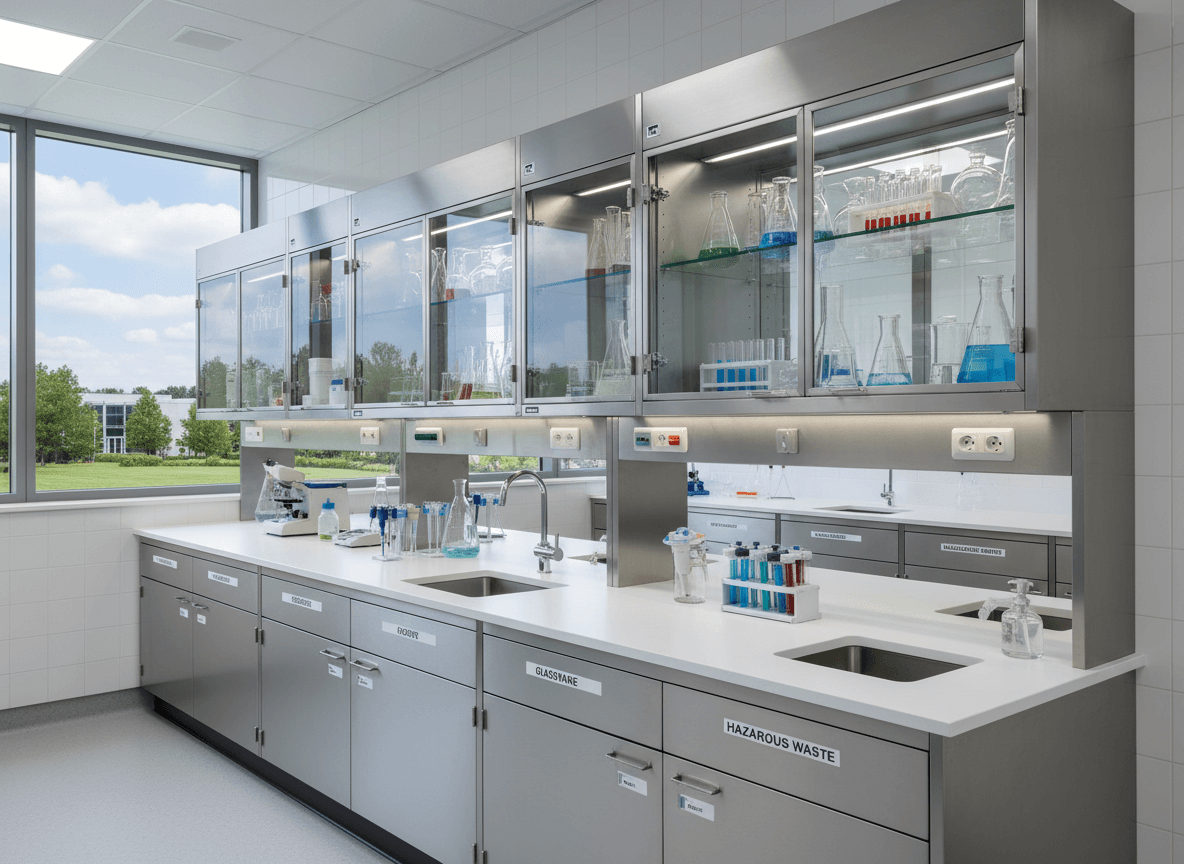

Introduction: The Foundation of an Efficient Laboratory

In the high-stakes environment of scientific research, lab cabinets are far more than simple storage units; they are the structural backbone of laboratory safety and efficiency. Whether housing volatile chemicals, sensitive biological samples, or expensive instrumentation, the quality and configuration of your laboratory storage solutions directly impact operational success.

Modern lab cabinets and countertops have evolved significantly from the wooden joinery of the 20th century. Today, they are engineered systems designed to meet rigorous international standards. As we approach 2026, the integration of cabinet lab infrastructure involves complex decisions regarding chemical resistance, load-bearing capacity, and ergonomic design. This guide provides an encyclopedic overview of lab cabinet technology, empowering facility managers and researchers to make informed decisions that ensure compliance and longevity.

Why Investing in the Right Lab Cabinets Matters

Selecting the correct lab storage cabinet is not merely an aesthetic choice; it is a critical safety protocol. According to OSHA regulations, improper storage of hazardous materials is a leading cause of laboratory citations.

· Safety & Compliance: Specialized cabinets prevent cross-contamination and contain fires. For instance, metal lab cabinets designed for flammables are engineered to withstand high temperatures, protecting the facility's structural integrity.

· Workflow Optimization: A well-planned lab cabinet layout minimizes movement, reducing the risk of spills and fatigue.

· Asset Protection: High-value reagents and equipment require protection from environmental factors like light, dust, and humidity, which standard cabinetry cannot provide.

Types of Lab Cabinets: A Comprehensive Classification

Understanding the distinct categories of cabinetry is essential for building a functional lab.

|

Cabinet Category |

Primary Function |

Typical Application |

|

General Storage |

Housing glassware, consumables, and non-hazardous equipment. |

Base units, wall-mounted, and tall storage in prep areas. |

|

Safety Storage |

Isolating hazardous chemicals (flammables, acids, corrosives). |

Chemical processing zones, waste collection areas. |

|

Specialized Containment |

Protecting samples or personnel from biohazards/particulates. |

Microbiology labs, tissue culture suites. |

Specialized Function Cabinets

For biological and clinical applications, distinguishing between containment devices is vital.

· Biological Safety Cabinets (BSCs): These are critical for working with infectious agents. A class ii biological safety cabinet is the workhorse of biomedical research, protecting the user, the environment, and the product (sample). As noted by the CDC, Class II cabinets utilize HEPA filtration to create a sterile work zone while exhausting filtered air, making them distinct from fume hoods which only protect the user from chemical vapors.

· Laminar Flow Cabinets: Often confused with BSCs, laminar flow cabinets provide a sterile environment for the sample but do not protect the user. A laminar flow cabinet blows HEPA-filtered air across the workspace toward the user, making it suitable only for non-hazardous materials like media preparation.

Safety and Chemical Storage Cabinets

Handling volatile substances requires adherence to NFPA 30 standards.

· Flammable Liquid Storage: These double-walled steel cabinets must be able to limit internal temperatures during a fire.

· Gas Cylinder Storage: Proper containment of compressed gases is non-negotiable. A gas cylinder storage cabinet with exhaust is essential for toxic or pyrophoric gases, ensuring that any minor leaks are vented safely out of the building. Advanced models may feature a gas cylinder storage cabinet with hose connection, allowing cylinders to remain safely secured while connected to a manifold system for active use.

Materials for Lab Cabinets: Durability, Resistance, and Aesthetics

The material chosen must match the laboratory's specific chemical and physical stressors.

Metal Lab Cabinets

Metal lab cabinets are the industry standard for durability. Typically constructed from 18-gauge steel, they offer high load capacity and fire resistance.

· Stainless Steel: The gold standard for sterility. Essential in cleanrooms and clinical labs due to its non-porous nature and resistance to aggressive cleaning agents.

· Epoxy-Coated Steel: Offers excellent chemical resistance at a lower cost than stainless steel, making it ideal for general research environments.

Wood and Phenolic Resin

· Wood: While offering a warmer aesthetic, wood is increasingly reserved for educational or low-risk settings due to its porosity and lower chemical resistance compared to modern composites.

· Phenolic Resin: A composite material that is rapidly gaining popularity. It is impervious to moisture, highly resistant to chemicals, and does not delaminate, making it a superior choice for wet labs.

Epoxy Resin

Often used for countertops, epoxy resin is a monolithic material that is heat and chemically resistant, though it can be brittle under impact.

Key Features and Specifications of High-Performance Lab Cabinets

When evaluating a lab cabinet, look beyond the surface.

1. SEFA Compliance: The Scientific Equipment and Furniture Association (SEFA) sets the benchmark. Ensure cabinets meet SEFA 8 standards, which test for load-bearing capacity, chemical resistance, and hardware durability.

2. Ventilation Integration: Many safety cabinets require connection to external exhaust systems. A class ii biosafety cabinet must be properly ducted or thimble-connected depending on its type (A2 vs. B2) to function correctly.

3. Security: High-risk agents require cabinets with tamper-proof locking mechanisms.

4. Seismic Protection: In earthquake-prone zones, cabinets must feature lipped shelves and positive-latching doors to prevent content ejection.

Selecting the Ideal Lab Cabinets: A Step-by-Step Buyer's Guide

1. Conduct a Chemical Audit: List all chemicals to be stored. Acids require polyethylene-lined cabinets; flammables require grounded steel.

2. Determine Biosafety Level (BSL): If working with BSL-2 or BSL-3 agents, a class ii biosafety cabinet is mandatory.

3. Assess Space and Workflow: Use a "zones of usage" approach. Place general storage near entry points and safety cabinets away from exits and high-traffic areas.

4. Verify Standards: Request certifications. A reputable manufacturer will provide proof of UL listing for electrical components and FM Approvals for fire safety cabinets.

How to choose Lab Cabinet manufacturers?: key features

When vetting manufacturers, prioritize those who can deliver a complete lab furniture solution rather than just standalone cabinets, and who offer:

· Third-Party Testing: Documented evidence of SEFA 8 testing.

· Customization Capabilities: Ability to modify dimensions for specific equipment.

· Comprehensive Warranties: A minimum 5-10 year structural warranty suggests confidence in product longevity.

· Installation Support: Certified installers who understand local fire codes and union requirements.

Installation, Layout, and Optimizing Your Lab Workspace

Proper installation is as important as the product itself.

· Ergonomics and ADA Compliance: Ensure that a portion of your cabinetry meets Americans with Disabilities Act (ADA) guidelines. This includes maintaining accessible reach ranges (typically between 15 and 48 inches off the floor) and providing knee space under sinks and fume hoods.

· Clearance Zones: OSHA requires minimum aisle widths (usually 36-48 inches) to ensure safe egress. Do not block emergency eyewash stations or showers with tall cabinets.

· Ventilation Connections: For a gas cylinder storage cabinet with exhaust, ensure the ductwork is dedicated and provides sufficient negative pressure to prevent backflow.

Maintenance and Longevity: Protecting Your Lab Cabinet Investment

· Routine Inspections: Check shelf clips and hinges quarterly. For biological safety cabinets, annual certification by a qualified technician is mandatory to verify airflow velocity and filter integrity.

· Cleaning Protocols: Avoid abrasive cleaners on epoxy surfaces. For stainless steel, use non-chlorinated cleaners to prevent pitting corrosion.

· Spill Management: Immediate neutralization of spills is crucial. Prolonged exposure to acids can compromise even resistant finishes over time.

The Future of Lab Cabinets: Smart Technology and Sustainable Design

Looking toward 2026, the "Smart Lab" concept is transforming furniture.

· IoT Integration: Future cabinets will feature integrated sensors to monitor internal humidity, temperature, and VOC levels, alerting lab managers to potential hazards via mobile apps.

· RFID Inventory Management: Smart shelves will automatically track reagent usage, reordering supplies when stock runs low.

· Sustainability: The push for "Green Labs" is driving the use of powder-coated steel (which emits zero VOCs during manufacturing) and cabinets made from post-consumer recycled content.

Conclusion: Building a Safer, Smarter, and More Efficient Lab

Investing in high-quality lab cabinets is an investment in the validity of your research and the safety of your personnel. By prioritizing SEFA-tested materials, selecting a properly designed laboratory table to support daily workflows, understanding the distinction between a laminar flow cabinet and a biosafety cabinet, and planning for future technologies, you build a laboratory infrastructure that endures. Whether retrofitting a university lab or designing a commercial R&D facility, the principles of durability, compliance, and adaptability remain paramount.

Frequently Asked Questions

What are the primary types of lab cabinets based on function?

Lab cabinets can be categorized into general storage (e.g., base, wall, tall units), specialized function (e.g., fume hood bases, biological safety cabinets), and safety/chemical storage (e.g., flammable, corrosive cabinets).

How do I choose the right material for my lab cabinets?

Material selection depends on factors like chemical exposure (e.g., polypropylene for corrosives, metal lab cabinets for general use), required durability, aesthetics, budget, and specific laboratory environment (e.g., cleanroom).

What essential safety features should I look for in lab cabinets?

Key safety features include secure locking mechanisms, fire-resistant construction (double-wall steel), spill containment sumps, proper ventilation integration, and compliance with NFPA 30 and OSHA standards.

Can lab cabinets be customized to fit specific laboratory needs?

Yes, lab cabinets offer extensive customization options, including specific dimensions, material choices, internal configurations (adjustable shelving, specialized drawers), integrated utilities, and unique finishes to match lab requirements.

What certifications or standards should lab cabinets meet?

Look for certifications from organizations like SEFA (Scientific Equipment and Furniture Association) for performance, BIFMA for furniture standards, and compliance with OSHA, NFPA, and local building codes.

How often should lab cabinets be maintained for optimal performance?

Routine maintenance, including daily cleaning and weekly inspections for wear, damage, or spills, is crucial. Detailed quarterly or annual checks should be performed on structural integrity, hinges, locks, and specialized functions like the airflow in a class ii biosafety cabinet.

What is the key difference between a fume hood base cabinet and a biosafety cabinet?

A fume hood base cabinet typically houses the support structure and utilities for a chemical fume hood. A biosafety cabinet, however, is a self-contained unit that protects the user, product, and environment from biohazardous aerosols using HEPA filtration.

Are there eco-friendly or sustainable options available for lab cabinets?

Yes, sustainable options include cabinets made from recycled materials, those with low VOC finishes (like powder coating), and designs promoting energy efficiency. Many manufacturers now adhere to SEFA's sustainability practices.

References

· SEFA 8 Testing Standards for Metal Lab Casework

· OSHA 1926.152 - Flammable liquids

· Compressed Gas Cylinder Storage Requirements - Datacor

Top IoT Trends in 2026 and What the Future of IoT Looks Like

Why We Choose to Be Your Lab Furniture Solution Provider, Not Just a Manufacturer

Max Lab Introduction

Electronics Lab Bench vs Chemistry Lab Bench: What You Need to Know

What Is a Pass Box? Types, Features, and How to Choose the Right Transfer Hatch

For Customization

Can you create furniture for labs with special requirements?

Yes, we specialize in designing and manufacturing lab furniture for specialized environments, including clean rooms, bio labs, and industrial labs.

Can you create a lab design layout for us?

Yes, we'll provide preliminary layout, confirm 3D drawings and rendering drawings.

FAQS

Where are your products manufactured?

All products are manufactured in our advanced facility—the largest laboratory furniture factory in Guangzhou—ensuring strict quality control.

For Products

Are your products customizable?

Absolutely! We offer customized solutions for laboratory benches, lab tables, and furniture systems to meet the specific requirements of your workspace.

For After-Sales Support

What happens if my product is damaged during delivery?

If your product is damaged during shipping, please contact our customer service team immediately. We will arrange for a replacement or repair at no additional cost.

Get in touch with us

If you have any comments or good suggestions, please leave us a message; later our professional staff will contact you as soon as possible.

Scan QR Code

Scan QR Code

MaxLabFurniture

MaxLab Furniture

daihongada

Max Laboratory