Resource

- Introduction: Revolutionizing Lab Safety with Ductless Fume Hoods

- How Ductless Fume Hoods Work: A Deep Dive into Filtration Technology

- The Multi-Stage Filtration Process

- Key Advantages of Going Ductless

- Understanding the Limitations: When Ductless Might Not Be Right

- Critical Exclusion Criteria

- A Comprehensive Guide to Ductless Fume Hood Filters

- Ductless vs. Ducted Fume Hoods: A Detailed Comparison

- Selecting the Right Ductless Fume Hood for Your Needs

- Installation, Operation, and Maintenance Best Practices

- Regulatory Standards & Compliance for Ductless Fume Hoods

- The Future of Ductless Fume Hood Technology

- Conclusion: Empowering Safer, More Flexible Laboratories

- Frequently Asked Questions

- What is the primary difference between a ductless and a ducted fume hood?

- How often do I need to replace the filters in a ductless fume hood?

- Can ductless fume hoods handle all types of chemicals?

- Are ductless fume hoods truly energy efficient?

- What are the essential safety checks for operating a ductless fume hood?

- How do I know which filter type is best for my specific laboratory chemicals?

- Is a ductless fume hood suitable for highly hazardous or volatile compounds?

- What kind of maintenance is required for a ductless fume hood beyond filter replacement?

- References

Ultimate Guide to Ductless Fume Hoods: Selection, Safety, and Future Trends in 2026

A comprehensive guide for laboratory managers and safety officers on ductless fume hoods. This article covers advanced filtration mechanisms, SEFA 9 and ASHRAE 110 compliance, detailed cost-benefit analyses against ducted systems, and essential safety limitations. It provides actionable advice on filter selection and maintenance to ensure optimal laboratory safety and efficiency.

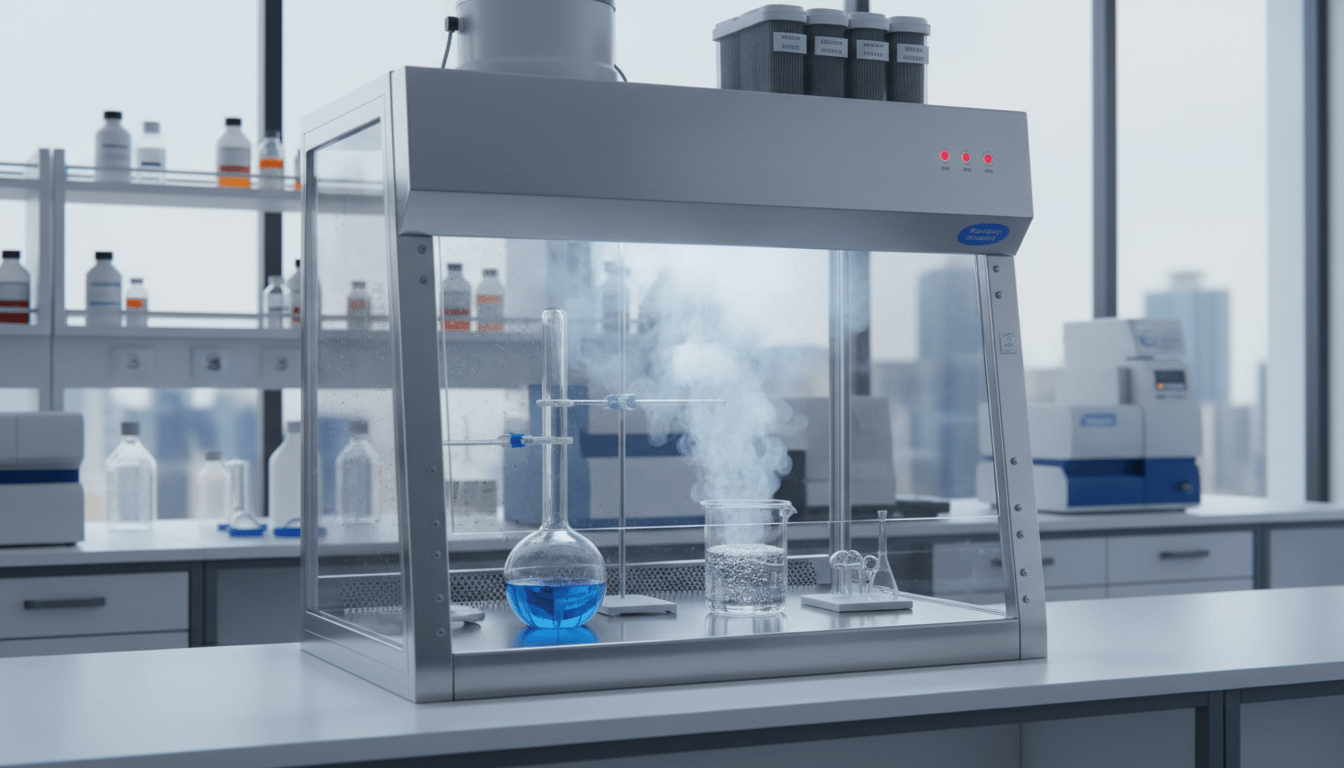

Introduction: Revolutionizing Lab Safety with Ductless Fume Hoods

The modern laboratory is evolving, shifting away from rigid infrastructure toward flexible, sustainable workspaces. At the forefront of this shift is the ductless fume hood (also known as a recirculating fume cupboard). Once considered a niche solution for light-duty applications, advancements in filtration technology have positioned ductless systems as a viable, safe, and energy-efficient alternative to traditional ducted hoods for a wide range of chemical processes.

Unlike their ducted counterparts, which exhaust conditioned air directly outside, ductless hoods function as self-contained air purification systems. They capture hazardous vapors and particulates, filter them through sophisticated media, and recirculate clean air back into the laboratory. This technology dates back to the introduction of HEPA filters in the 1950s, but recent innovations in molecular adsorption and detection sensors have significantly expanded their utility.

However, the adoption of ductless technology requires a higher level of vigilance regarding chemical compatibility and maintenance. This guide serves as a definitive resource for laboratory managers, procurement specialists, and safety officers, providing the deep technical insights needed to navigate the complexities of selection, compliance, and operation in 2025.

How Ductless Fume Hoods Work: A Deep Dive into Filtration Technology

To understand the safety profile of a ductless hood, one must understand the physics and chemistry occurring within the unit. The system relies on negative pressure aerodynamics to draw air away from the operator at a consistent face velocity (typically 60–100 fpm).

The Multi-Stage Filtration Process

1. Capture: The aerodynamic sash and baffles direct airflow to prevent turbulence and contain contaminants within the chamber.

2. Pre-Filtration: Air first passes through an electrostatic pre-filter, which traps large dust particles. This protects the main filter's lifespan by preventing physical clogging.

3. Main Filtration (The Core):

1. Molecular Filtration: For vapors, Activated Carbon filters utilize adsorption—a surface phenomenon where gas molecules adhere to the internal pore structure of the carbon granules. Chemical impregnation is often used to target specific non-organic hazards (e.g., acid gases).

2. Particulate Filtration: HEPA (High-Efficiency Particulate Air) or ULPA (Ultra-Low Particulate Air) filters use diffusion and interception mechanisms to capture aerosols and biological agents.

4. Sensing and Recirculation: Post-filtration sensors detect breakthrough (escaping chemicals). If the air is clean, it is returned to the room, eliminating the need for make-up air systems.

Key Advantages of Going Ductless

· Infrastructure Independence: Ductless units require no ductwork or roof penetrations. This allows for immediate installation and mobility, making them ideal for historic buildings or leased spaces where structural modifications are prohibited.

· Energy Efficiency & Cost Reduction: A single ducted fume hood can consume as much energy as three residential homes due to the exhaustion of tempered (heated or cooled) air. Ductless hoods eliminate this "energy penalty," potentially reducing HVAC load costs by thousands of dollars annually per unit.

· Sustainability: By filtering pollutants rather than diluting and ejecting them into the atmosphere, ductless hoods align with Green Lab initiatives and reduce the facility's overall carbon footprint.

Understanding the Limitations: When Ductless Might Not Be Right

Despite their benefits, ductless hoods are not universal replacements for ducted systems. Safety depends entirely on the filter's capacity to retain specific chemicals.

Critical Exclusion Criteria

According to industry safety guidelines, ductless hoods are generally unsuitable for:

· Perchloric Acid: Vapors can condense in the unit, forming explosive perchlorate salts.

· Radioisotopes: Standard carbon filters cannot effectively capture or contain radioactive particles/gases over time.

· High-Heat Acid Digestion: Extreme heat can degrade filter media and alter adsorption desorption kinetics.

· Unknown Chemical Processes: If the chemical byproducts are unknown, you cannot select the correct filter, posing an immediate breakthrough risk.

A Comprehensive Guide to Ductless Fume Hood Filters

Selecting the correct filter is the single most critical safety decision. Filters are not "one size fits all."

· Activated Carbon (General Purpose): Optimized for organic solvents (e.g., Acetone, Xylene, Toluene). The carbon is activated with steam to create a vast network of pores.

· Impregnated Carbon (Specialized):

o Acid Gas Filters: Treated with alkalis to neutralize inorganic acids (e.g., HCl, HF).

o Ammonia/Amine Filters: Impregnated to chemically bind basic vapors.

o Formaldehyde Filters: Specifically designed to bond with aldehydes.

· HEPA/ULPA Filters:

o HEPA: 99.97% efficiency at 0.3 microns. Essential for powders and biological safety.

o ULPA: 99.999% efficiency at 0.12 microns. Used for nanoparticles.

· Life Expectancy & Saturation: Filter life is finite and governed by the retention capacity. Factors reducing life include high chemical concentration, high temperature, and high humidity. Modern units feature PID sensors (Photoionization Detectors) to alarm when the filter is nearing saturation.

Ductless vs. Ducted Fume Hoods: A Detailed Comparison

|

Feature |

Ductless Fume Hood |

Ducted Fume Hood |

|

Installation |

Plug-and-play; no ductwork required. |

Complex; requires HVAC integration, ductwork, and exhaust fans. |

|

Initial Cost |

Lower (equipment only). |

Higher (equipment + construction + HVAC upgrades). |

|

Operating Cost |

Higher (periodic filter replacement). |

High (constant energy loss from exhausting tempered air). |

|

Flexibility |

High; can be moved easily. |

Low; fixed in place. |

|

Chemical Range |

Limited to filter compatibility. |

Almost universal (with appropriate scrubber/materials). |

|

Safety |

Relies on sensor/filter integrity. |

Relies on mechanical exhaust integrity. |

Decision Framework: If your lab performs high-volume, high-heat, or extremely toxic (unknown) chemistry, ducted is mandatory. For specific, low-to-medium volume tasks with known chemicals, ductless offers superior ROI.

Selecting the Right Ductless Fume Hood for Your Needs

1. Chemical Assessment: You must list every chemical, concentration, and temperature used. Manufacturers utilize this data to guarantee filter performance (often called a "Validation" or "Application Review").

2. SEFA 9 Classification: Ensure the unit meets SEFA 9 standards for ductless enclosures:

o DH I: For nuisance odors/particulates only (non-toxic).

o DH II: For toxic chemicals (requires continuous monitoring and stops at filter breakthrough).

o DH III: Features a secondary "backup" safety filter to allow safe shutdown after primary breakthrough.

3. Face Velocity: The unit should maintain 60–100 fpm face velocity to ensure containment, verified against ASHRAE 110 testing protocols.

Installation, Operation, and Maintenance Best Practices

· Site Preparation: Place the hood away from cross-drafts (doors, air vents, heavy traffic) that could disrupt the protective air barrier.

· Daily Pre-Checks:

o Check the airflow monitor/alarm.

o Verify the sash is at the indicated safe working height.

o Ensure the baffle area is not blocked by equipment.

· Filter Maintenance: Do not rely solely on your nose. Use the electronic saturation alarm. When replacing filters, treat the saturated filter as hazardous chemical waste and dispose of it according to local environmental regulations.

Regulatory Standards & Compliance for Ductless Fume Hoods

Adhering to standards is non-negotiable for E-E-A-T compliance and personnel safety.

· SEFA 9 (Scientific Equipment and Furniture Association): The specific standard defining the design, testing, and classification (DH I, II, III) of ductless enclosures.

· ANSI/ASSP Z9.5 (Laboratory Ventilation): The overarching US standard. It explicitly states that ductless hoods must have a manufacturer-approved chemical assessment and a reliable breakthrough monitoring system.

· ASHRAE 110: The method for testing the performance of the hood (containment ability), typically using a tracer gas (SF6) to detect leaks.

· OSHA 1910.1450: The "Laboratory Standard" requiring a Chemical Hygiene Plan (CHP) that ensures fume hoods are functioning properly.

The Future of Ductless Fume Hood Technology

As we move through 2025, technology is making these units smarter and safer:

· IoT & Smart Monitoring: Next-gen hoods integrate with Building Management Systems (BMS), sending real-time alerts to facility managers regarding airflow drops or filter saturation.

· Green Chemistry: As labs push for "Net Zero," the energy savings of ductless hoods (eliminating makeup air requirements) are driving massive adoption.

· Advanced Sorbents: Research into new porous materials (like Metal-Organic Frameworks or MOFs) promises filters with vastly higher retention capacities and specificity than traditional activated carbon.

Conclusion: Empowering Safer, More Flexible Laboratories

Ductless fume hoods have graduated from temporary solutions to permanent, essential fixtures in the modern laboratory. They offer unmatched flexibility and sustainability but demand a disciplined approach to chemical management. By strictly adhering to standards like SEFA 9 and ANSI Z9.5, and conducting rigorous chemical assessments, laboratory leaders can deploy ductless technology to create safer, greener, and more efficient research environments.

Frequently Asked Questions

What is the primary difference between a ductless and a ducted fume hood?

Ducted hoods vent hazardous fumes outside the building through a physical duct and exhaust system, expelling conditioned air. Ductless hoods capture contaminants using activated carbon or HEPA filters and recirculate the purified air back into the laboratory, requiring no external venting infrastructure.

How often do I need to replace the filters in a ductless fume hood?

Filter life varies significantly based on chemical usage, concentration, and evaporation rates. While it can range from 6 months to 2 years, you should never guess. Always rely on the unit's chemical sensor alarms and conduct manual colorimetric tube testing if recommended by the manufacturer.

Can ductless fume hoods handle all types of chemicals?

No. They are highly effective for specific families of chemicals (organics, acids, bases) but have strict limitations. They are generally not suitable for perchloric acid, radioisotopes, high-heat acid digestion, or unknown chemical mixtures.

Are ductless fume hoods truly energy efficient?

Yes. Because they recirculate air rather than exhausting expensive heated or cooled air outside, they significantly reduce the facility's HVAC load. This can result in energy savings of up to 96% compared to a standard constant volume ducted hood.

What are the essential safety checks for operating a ductless fume hood?

Before every use, verify the airflow monitor is reading within the safe range (usually 60-100 fpm) and that the filter saturation alarm is active. Ensure the sash is at the correct certified height and that the hood location is free from cross-drafts.

How do I know which filter type is best for my specific laboratory chemicals?

You must perform a chemical assessment listing every chemical name, volume, and temperature. Submit this to the manufacturer's chemical specialists. They will recommend specific filter types (e.g., ACI for acid, ORG for organics, AMM for amines) based on retention capacity databases.

Is a ductless fume hood suitable for highly hazardous or volatile compounds?

Suitability depends on the specific toxicity and the filter's retention capacity. For extremely toxic chemicals with low exposure limits, a Class DH III ductless hood (with backup safety filters) or a traditional ducted hood is preferred. Always consult your Safety Officer and the manufacturer's validation report.

What kind of maintenance is required for a ductless fume hood beyond filter replacement?

Regular maintenance includes annual certification of face velocity (airflow testing), sensor calibration (for saturation alarms), sash mechanism inspection, and cleaning the electrostatic pre-filters to ensure optimal airflow.

References

· AIHA: The New Laboratory Ventilation Standard (ANSI/ASSP Z9.5)

· ANSI: ANSI/ASHRAE 110: Laboratory Fume Hoods Performance Testing

· Princeton EHS: Fume Hood Common Misuses & Limitations

· University of Minnesota: Fume Hoods - Fact Sheet (Limitations)

Why We Choose to Be Your Lab Furniture Solution Provider, Not Just a Manufacturer

Max Lab Introduction

Electronics Lab Bench vs Chemistry Lab Bench: What You Need to Know

What Is a Pass Box? Types, Features, and How to Choose the Right Transfer Hatch

For After-Sales Support

How about your after sale service?

We will reply you within 24 hours by email or phone.

If we have local agent,we will arrange him to your site within 24 hours to assist you to shoot the problem.

Do you offer training for using your products?

Yes, we offer training for your staff on how to properly use and maintain the laboratory equipment we provide. Contact us to schedule a training session.

Why choose your company?

We have been engaged in the manufacturing of various packing machines professionally over 15 years, and we can provide better after-sales service.

About Solution

How to ensure the safety performance of the fume hood?

Our fume hoods adopt high-efficiency filtration system and intelligent air speed control technology to ensure that harmful gases are effectively eliminated during experiments and protect users' health.

Customization

What information do I need to provide to start a custom project?

In order to start a custom project, you need to provide information about the spatial layout of the laboratory, functional requirements, equipment quantity and specifications, budget, etc. If possible, you can also provide reference drawings or patterns so that we can better understand your needs.

Get in touch with us

If you have any comments or good suggestions, please leave us a message; later our professional staff will contact you as soon as possible.

Scan QR Code

Scan QR Code

MaxLabFurniture

MaxLab Furniture

daihongada

Max Laboratory