Resource

- Introduction

- The Mechanics of Protection

- Quick Summary: Key Takeaways for Class II BSCs

- Understanding the Different Types of Class II Biological Safety Cabinets

- 1. Class II Type A1

- 2. Class II Type A2 (The Industry Standard)

- 3. Class II Type B1

- 4. Class II Type B2 (Total Exhaust)

- 5. Class II Type C1 (Emerging Standard)

- How Class II BSCs Ensure Comprehensive Protection: Airflow and Filtration

- Key Applications and Biosafety Levels for Class II Biological Safety Cabinets

- Class II BSC vs. Other Lab Equipment: Fume Hoods and Laminar Flow Hoods

- Class II BSC vs. Laminar Flow Hood (Clean Bench)

- Class II BSC vs. Chemical Fume Hood

- Installation, Certification, and Maintenance Best Practices for 2026

- Installation and Site Assessment

- Annual Biological Safety Cabinet Certification

- Routine Maintenance

- Beyond 2025: Innovations and Future Trends in Class II Biological Safety Cabinets

- Choosing the Right Class II BSC: A Comprehensive Buying Guide

- Buying Checklist

- Expert Tips for Optimal Class II BSC Use and Common Mistakes to Avoid

- Frequently Asked Questions (FAQ)

- How do Class II A2 and B2 biological safety cabinets differ in operation?

- What biosafety levels are Class II cabinets designed for?

- Can Class II biosafety cabinets be used with volatile chemicals?

- How often should a Class II BSC be certified?

- References

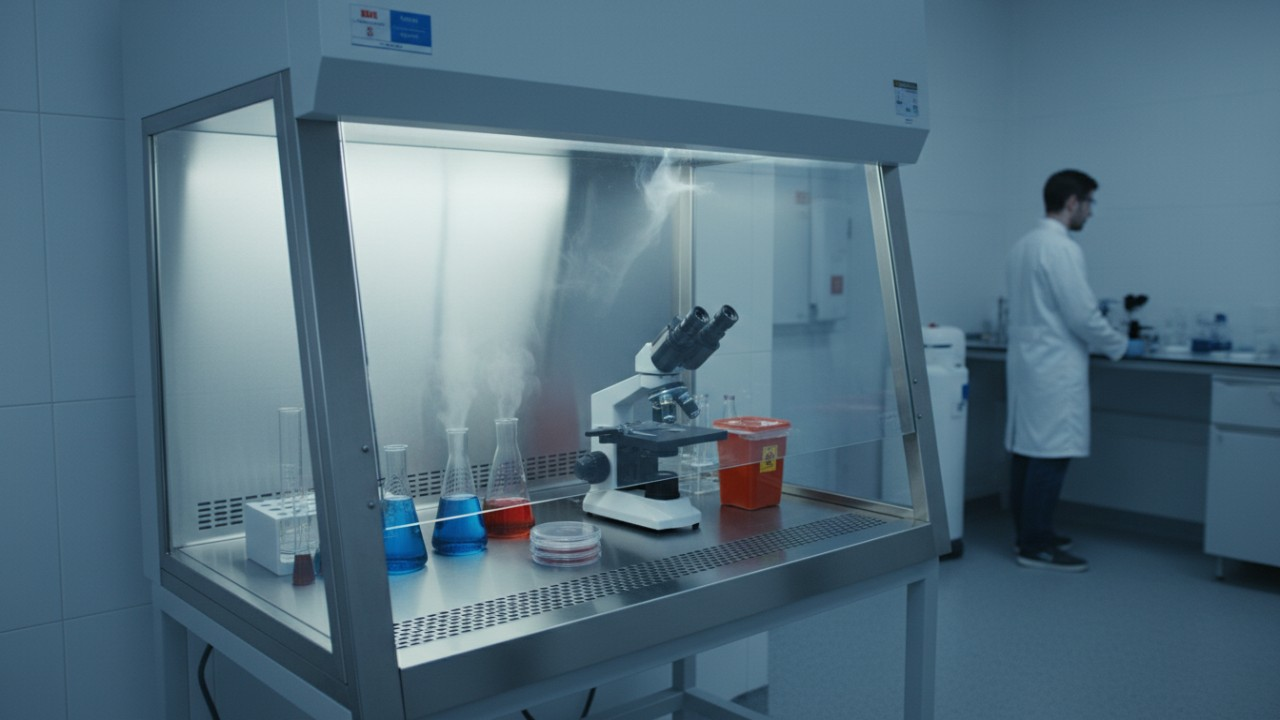

Ultimate Guide to Class II Biological Safety Cabinet for 2026

A comprehensive guide to Class II Biological Safety Cabinets for 2026. Covers Types A1, A2, B1, B2, and C1, new NSF/ANSI 49-2024 standards, energy-efficient innovations, and expert maintenance tips.

Introduction

A Class II biological safety cabinet is a primary containment device designed to protect laboratory personnel, the product, and the environment from hazardous biological agents by utilizing inward airflow and HEPA filtration. It is the standard-bearer for safety in microbiological and biomedical research, covering Biosafety Levels 1, 2, and 3.

The Mechanics of Protection

Understanding what is a biological safety cabinet requires looking at its airflow dynamics. Unlike a simple fume hood, a Class II BSC creates a dynamic air barrier. It employs an inward airflow at the front access opening to protect the operator, a downward HEPA-filtered laminar airflow to protect the sterile product on the work surface, and HEPA-filtered exhaust air to protect the laboratory environment.

According to 2024 market data, Class II cabinets dominate the global biosafety market, holding approximately 80% of the market share. This ubiquity underscores their critical role in preventing cross-contamination and ensuring user safety in pharmaceutical, clinical, and research settings.

Quick Summary: Key Takeaways for Class II BSCs

· Multi-Protection: Simultaneously safeguards the user, the product, and the room environment.

· Class Variations: Includes Types A1, A2, B1, B2, and the newer C1, each with specific airflow ratios.

· Filtration: Relies on High-Efficiency Particulate Air (HEPA) filters (99.97% efficiency at 0.3 microns) or ULPA filters.

· Standards: Must adhere to the recently updated NSF/ANSI 49-2024 standard for design and performance.

· Market Dominance: The biological safety cabinet class 2 is the preferred choice for over 90% of biomedical labs handling infectious agents.

Understanding the Different Types of Class II Biological Safety Cabinets

Class II biosafety cabinet models vary significantly in how they handle air recirculation and exhaust. Choosing the wrong type can compromise safety, especially when volatile chemicals are involved.

1. Class II Type A1

· Airflow: 70% recirculated, 30% exhausted.

· Velocity: Minimum inflow velocity of 75 fpm.

· Usage: Suitable for low-to-moderate risk agents. Not suitable for volatile toxic chemicals.

2. Class II Type A2 (The Industry Standard)

· Airflow: 70% recirculated, 30% exhausted.

· Velocity: Higher minimum inflow velocity of 100 fpm for better containment.

· Chemical Use: Can handle trace amounts of volatile toxic chemicals only if exhausted externally via a canopy connection.

3. Class II Type B1

· Airflow: 30% recirculated, 70% exhausted.

· Venting: Must be hard-ducted to an external exhaust system.

· Usage: Suitable for work with moderate amounts of volatile toxic chemicals and radionuclides.

4. Class II Type B2 (Total Exhaust)

· Airflow: 0% recirculation, 100% exhausted.

· Safety: The safest class 2 biological safety cabinet for volatile chemicals.

· Usage: Ideal for significant amounts of toxic chemicals and radionuclides as no air is reused within the cabinet.

5. Class II Type C1 (Emerging Standard)

· Flexibility: Can operate in either recirculating (A-mode) or exhausting (B-mode) configurations.

· Efficiency: Designed to reduce energy consumption and installation complexity while offering chemical protection similar to B-types in specific zoned areas.

How Class II BSCs Ensure Comprehensive Protection: Airflow and Filtration

Biosafety cabinet class 2 systems utilize a sophisticated balance of air velocity and filtration to maintain a sterile and safe environment.

· Personnel Protection: An air barrier at the front sash (intake) travels at 100 fpm (for Types A2/B1/B2), preventing biohazards from escaping into the room.

· Product Protection: HEPA-filtered downflow air washes over the work surface, creating an ISO Class 5 clean zone that prevents room air from contaminating samples.

· Environmental Protection: All exhaust air passes through a HEPA filter before leaving the cabinet, trapping bacteria and viruses.

Data Insight: Recent studies on biological safety cabinet certification failures indicate that HEPA filter leaks and airflow pattern disruptions account for nearly 76% of containment failures, highlighting the need for rigorous testing.

Key Applications and Biosafety Levels for Class II Biological Safety Cabinets

These cabinets are the workhorses of the life sciences, critical for maintaining the integrity of the essential ecosystem of lab cabinets found in modern research facilities.

1. Microbiology & Virology: Essential for handling BSL-2 and BSL-3 agents like Salmonella, HIV, and SARS-CoV-2.

2. Pharmaceutical Compounding: Used extensively for sterile drug preparation. In fact, pharmaceutical companies account for over 50% of the end-user market share for these cabinets.

3. Cell Culture: Prevents cross-contamination in sensitive mammalian and insect cell lines.

4. Clinical Diagnostics: Protects technicians processing patient samples suspected of containing infectious pathogens.

Class II BSC vs. Other Lab Equipment: Fume Hoods and Laminar Flow Hoods

It is vital to distinguish between a biosafety cabinet vs fume hood or clean bench, as their purposes are diametrically opposed.

Class II BSC vs. Laminar Flow Hood (Clean Bench)

· Class II BSC: Protects User, Product, and Environment. Handles Biohazards.

· Laminar Flow Hood: Protects Product Only. Air blows towards the user. Dangerous for biohazards or hazardous chemicals.

Class II BSC vs. Chemical Fume Hood

· Class II BSC: Designed for Biological hazards (bacteria, viruses). HEPA filtered.

· Chemical Fume Hood: Designed for Chemical fumes and vapors. No HEPA filtration (usually). Protects the user from fumes but does not provide a sterile work area for the product.

Installation, Certification, and Maintenance Best Practices for 2026

Proper lifecycle management ensures your class ii biosafety cabinet remains compliant with the new NSF/ANSI 49-2024 standards.

Installation and Site Assessment

· Location: Place away from high-traffic areas, doors, and air vents to prevent airflow disruption.

· Exhaust: Type B1 and B2 units require a dedicated, hard-ducted exhaust system. Type A2 units can be thimble-connected.

Annual Biological Safety Cabinet Certification

Biological safety cabinet certification is mandatory annually. A qualified technician must perform:

· Downflow velocity tests.

· Inflow velocity measurements.

· HEPA filter integrity testing (leak scan).

· Smoke pattern visualization tests.

Routine Maintenance

· Daily: Surface disinfection and sash height checks.

· Weekly: UV light wiping (if installed) and drain pan checks.

· Filter Life: HEPA filters typically last 3-5 years depending on the cleanroom class and usage load.

Beyond 2025: Innovations and Future Trends in Class II Biological Safety Cabinets

The landscape of biological safety cabinet classes is evolving with technology. Manufacturers are prioritizing energy efficiency and smart integration for 2026 and beyond.

· Energy Efficiency: New DC ECM motors reduce energy consumption by up to 68% compared to traditional AC motors, lowering operating costs significantly.

· Smart Lab Integration: Modern cabinets feature IoT connectivity for real-time remote monitoring of airflow status and predictive maintenance alerts.

· AI Diagnostics: Advanced algorithms now detect subtle airflow drifts before they trigger a failure alarm, allowing for proactive servicing.

· Sustainable Design: The push for "Green Labs" is driving the use of recyclable materials and low-energy modes (Standby Mode) that maintain sterility while reducing power usage.

Choosing the Right Class II BSC: A Comprehensive Buying Guide

Selecting the right unit is about more than just price; it's about finding a trusted lab furniture solution that fits your safety profile.

Buying Checklist

1. Risk Assessment: Define your BSL level (1, 2, or 3) and chemical requirements.

2. Type Selection: Use Type A2 for standard bio-work; use Type B2 if working with significant volatile chemicals.

3. Facility Constraints: Do you have the ductwork for a biosafety cabinet class 3 or Class II Type B? If not, A2 is your only option.

4. Ergonomics: Look for motorized stands, angled sashes, and low-noise models (< 60 dBA) to reduce user fatigue.

5. Cost of Ownership: Factor in filter replacement costs and energy consumption (DC motors save money long-term).

Expert Tips for Optimal Class II BSC Use and Common Mistakes to Avoid

Even the best class i biosafety cabinet or Class II unit fails if used incorrectly. Follow these rules for safety.

· Tip: Purge Cycles. Run the cabinet for 5 minutes before beginning work to purge contaminated air.

· Tip: Work Zone Splitting. Keep clean items on one side (left), work in the center, and dirty items on the other side (right) to prevent cross-contamination.

· Mistake: Blocking Grilles. Never cover the front or rear air grilles with equipment or absorbent pads. This disrupts the air barrier and compromises safety.

· Mistake: Sash Alarms. Never mute the sash alarm. If the sash is too high, the inflow velocity drops, and containment is lost.

Frequently Asked Questions (FAQ)

How do Class II A2 and B2 biological safety cabinets differ in operation?

Class II Type A2 BSCs recirculate 70% of their air and exhaust 30%, making them energy-efficient but limited to trace volatile chemicals. Class II Type B2 BSCs are "total exhaust" systems (0% recirculation), making them the only choice for significant amounts of volatile toxic chemicals.

What biosafety levels are Class II cabinets designed for?

Class II cabinets are designed for Biosafety Level 1 (BSL-1), Biosafety Level 2 (BSL-2), and Biosafety Level 3 (BSL-3). They are not suitable for BSL-4, which typically requires a biosafety cabinet class 3 (Glove Box).

Can Class II biosafety cabinets be used with volatile chemicals?

Yes, but with restrictions. Type A2 can handle minute traces if ducted. Type B1 can handle moderate amounts. Type B2 is designed for significant chemical work. Standard lab cabinets or laminar hoods should never be used for chemicals.

How often should a Class II BSC be certified?

According to NSF/ANSI 49, a class 2 biological safety cabinet must be certified annually by a qualified field certifier. Certification is also required upon installation and after any relocation.

References

· Biological Safety Cabinet Market Size & Share Report 2025-2032

Why We Choose to Be Your Lab Furniture Solution Provider, Not Just a Manufacturer

Max Lab Introduction

Electronics Lab Bench vs Chemistry Lab Bench: What You Need to Know

What Is an Air Shower for Cleanroom?

Customization

Are customized services suitable for small laboratories?

Yes, our customized services are suitable for all types of laboratories, including small ones. We are able to provide customized solutions according to the actual needs of the laboratory.

What information do I need to provide to start a custom project?

In order to start a custom project, you need to provide information about the spatial layout of the laboratory, functional requirements, equipment quantity and specifications, budget, etc. If possible, you can also provide reference drawings or patterns so that we can better understand your needs.

For Logistics

How do you ensure the safety of items during shipping?

We have 15 years of experience in loading, fragile goods are packed in plywood boxes to ensure that they will not be damaged during transportation.

Do you offer express shipping options?

Yes, we offer express shipping for urgent orders. Please contact our sales team to inquire about availability and additional costs.

Get in touch with us

If you have any comments or good suggestions, please leave us a message; later our professional staff will contact you as soon as possible.

Scan QR Code

Scan QR Code

MaxLabFurniture

MaxLab Furniture

daihongada

Max Laboratory