Resource

- Introduction

- Understanding the Regulatory Landscape: OSHA and ANSI Z358.1 (2026 Update)

- Critical Performance Metrics for Every Lab Eye Wash Station

- The Evolution of Science Laboratory Furniture and Integrated Safety

- Deck-Mounted vs. Wall Mounted Eye Wash Station: Which is Best?

- Navigating Accessibility: ADA Compliance and Barrier-Free Design

- When to Choose an Eye Wash Station Portable: Flexibility in Dynamic Environments

- Eye Wash Station Installation: Best Practices for Casework Integration

- Key installation steps for a lab eye wash station include:

- The Future of Lab Safety: IoT-Enabled Smart Eye Wash Station Solutions

- Maintenance and TCO: Beyond the Initial Eye Wash Station Solution

- Conclusion

- FAQs

- Does a portable eye wash station meet OSHA requirements for corrosive chemicals?

- How far can the station eye wash be from the hazard?

- What is the required water temperature for a lab eye wash station?

- Can I install a station eye wash onto my existing lab furniture?

- How often must an emergency eye wash station be inspected?

2026 Laboratory Safety Compliance Guide: ANSI Z358.1 Station Eye Wash Integration in Modern Lab Furniture

Unlock the 2026 blueprint for laboratory safety. This guide explores ANSI Z358.1 compliance, seamless integration with science laboratory furniture, and IoT-driven maintenance to reduce TCO and audit risks.

Introduction

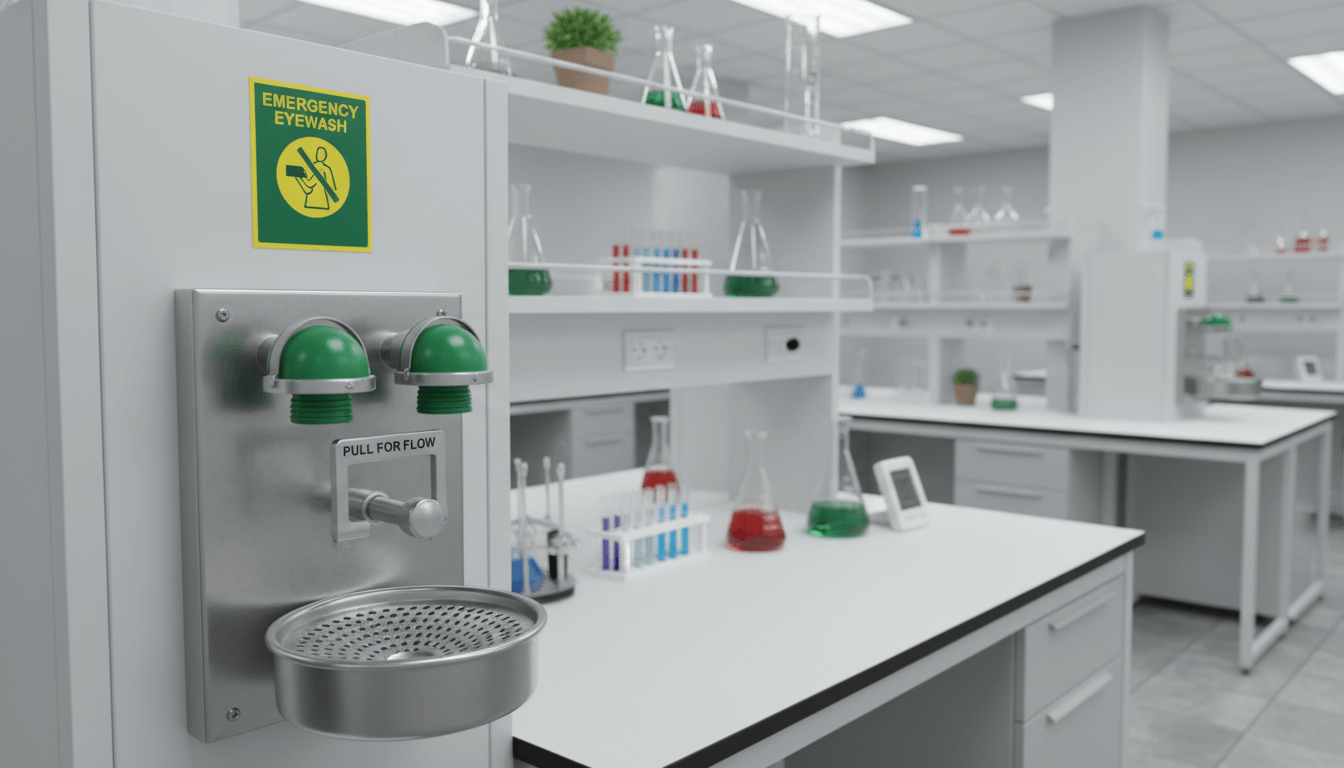

In the rapidly evolving world of scientific research, the integration of safety infrastructure within science laboratory furniture has moved from being a secondary consideration to a primary architectural requirement. As we look toward the 2026-2030 period, the "10-second rule" remains the gold standard for laboratory safety, but the way we implement a station eye wash has fundamentally changed. Modern facilities are moving away from bulky, obstructive fixtures in favor of sleek, integrated, and IoT-enabled solutions that prioritize both compliance and aesthetic harmony.

For EHS managers and laboratory architects, selecting the right eye wash station solution is no longer just about meeting a checklist; it is about risk mitigation, space optimization, and long-term operational efficiency. This guide explores the critical factors of emergency eye wash station integration in the modern laboratory environment.

Understanding the Regulatory Landscape: OSHA and ANSI Z358.1 (2026 Update)

The foundation of any laboratory safety program is a deep understanding of the regulatory framework. While OSHA 29 CFR 1910.151(c) provides the legal mandate requiring "suitable facilities for quick drenching or flushing," it is the ANSI/ISEA Z358.1-2014 (R2020) standard that provides the technical specifications for what is considered "suitable".

In 2026, compliance is more than a legal hurdle—it is a data-driven process. OSHA continues to refer to ANSI standards to determine if an employer has provided an adequate lab eye wash station. Failure to comply can result in penalties that have increased by nearly $80\%$ in recent years, reaching thousands of dollars for a single serious violation. A compliant station eye wash must be accessible within 10 seconds (approximately 55 feet) of a hazard, located on the same level as the risk, and free of any obstructions.

Critical Performance Metrics for Every Lab Eye Wash Station

To ensure a station eye wash effectively prevents permanent ocular damage, it must meet rigorous performance metrics. These metrics are the difference between a successful emergency response and a life-altering injury.

-

Flow Rate: A plumbed station eye wash must deliver at least $0.4\text{ GPM}$ ($1.5\text{ L/min}$) of flushing fluid for a continuous 15-minute period.

-

Activation Time: The unit must activate in one second or less and feature a "stay-open" valve that allows for hands-free operation once triggered.

-

Tepid Water: The flushing fluid must be tepid, maintained between $60^\circ\text{F}$ and $100^\circ\text{F}$ ($16^\circ\text{C}$ to $38^\circ\text{C}$). This temperature range is critical; water that is too cold can cause thermal shock, while water that is too hot can accelerate chemical reactions or cause scalding.

-

Spray Pattern: Nozzles must be positioned between 33 and 53 inches from the floor and at least 6 inches away from the nearest obstruction.

The Evolution of Science Laboratory Furniture and Integrated Safety

The trend for 2026 is "invisible technology." Modern science laboratory furniture is designed to hide the complexity of safety systems until they are needed. Gone are the days of yellow pipes disrupting the clean sightlines of a modular R&D space.

Today’s integrated lab eye wash station is often deck-mounted or built directly into the casework. By using the existing plumbing and drainage of the laboratory sink, these units eliminate the need for dedicated floor drains, which significantly reduces eye wash station installation costs during laboratory renovations. High-end facilities are opting for neutral finishes—such as electropolished Type 316 stainless steel—that match the architectural hardware of the room, using high-visibility yellow only on the activation handles.

Deck-Mounted vs. Wall Mounted Eye Wash Station: Which is Best?

Choosing the mounting typology is a critical decision in the laboratory design phase. Each has its specific use case based on the hazard profile and the layout of the science laboratory furniture.

| Feature | Deck-Mounted (Swing-Away) | Wall Mounted Eye Wash Station |

| Best For | Island benches and modular labs | Perimeter walls and chemical storage |

| Drainage | Drains into the lab sink |

Dedicated wall drain or bowl |

| Aesthetics | Minimalist; hides when not in use |

Industrial; permanently visible |

| Installation | Medium complexity (integrated) |

Low complexity (standalone) |

A wall mounted eye wash station is ideal for heavy-duty chemical processing areas where workers need a fixed, unmistakable safety point. Conversely, deck-mounted units are the preferred eye wash station solution for biotech and pharmaceutical labs where flexibility and bench-top space are at a premium.

Navigating Accessibility: ADA Compliance and Barrier-Free Design

As laboratory inclusivity becomes a standard requirement, ensuring your emergency eye wash station is ADA-compliant is paramount. An accessible station must consider the "knee clearance" required for a wheelchair user to approach the unit. For a station to be fully barrier-free, the cabinetry beneath the sink or eyewash station must be replaced with suspended cabinetry or an open knee space. The minimum dimensional requirements are as follows:

-

Height clearance: 27 inches (685 mm)

-

Depth: 19 inches (485 mm)

-

Width: 30 inches (760 mm)

In addition, the activation handle must be positioned within a maximum forward reach of 48 inches (1,220 mm) to ensure accessibility for users with limited mobility.

When to Choose an Eye Wash Station Portable: Flexibility in Dynamic Environments

While plumbed units offer an unlimited water supply, there are scenarios where a portable eye wash station is the only practical option. These situations include temporary worksites, remote field laboratories, or locations where plumbing infrastructure is unavailable.

A high-quality portable eye wash station must still provide a full 15 minutes of flushing at 0.4 GPM to meet ANSI standards. For organizations seeking a portable eye wash station OSHA-approved (or, more accurately, ANSI-compliant as recognized by OSHA), gravity-fed or pressurized units are commonly used. However, these units require more rigorous maintenance, including the use of water preservatives every 3 to 6 months to prevent bacterial growth in stagnant water.

Eye Wash Station Installation: Best Practices for Casework Integration

The success of an eye wash station installation depends on the precision of the integration with the lab casework. For deck-mounted units, the countertop material—whether epoxy resin, phenolic resin, or stainless steel—must be professionally drilled to avoid cracking or structural failure.

Key installation steps for a lab eye wash station include:

-

Zoning: Placing the unit at the end of island benches to ensure it is on an unobstructed path.

-

Pressure Regulation: Incorporating a flow-control valve to ensure the stream is non-injurious, even with fluctuating building water pressure.

-

Tepid Water Supply: Installing a concealed thermostatic mixing valve (TMV) that blends hot and cold water to the precise $60-100^\circ\text{F}$ range.

The Future of Lab Safety: IoT-Enabled Smart Eye Wash Station Solutions

By 2026, the "Smart Lab" is no longer a concept but a reality. The latest emergency eye wash station models are equipped with IoT sensors that monitor readiness in real-time. These sensors can track:

-

Water Temperature: Alerting the EHS team if the water drops below the tepid range.

-

Activation Alerts: Instantly notifying the safety office when a unit is activated, allowing for an immediate emergency response.

-

Weekly Compliance Tracking: Automated logging of the required weekly activation tests, significantly reducing the administrative burden on lab managers.

These smart station eye wash systems reduce downtime and ensure that the equipment is always functional when seconds count.

Maintenance and TCO: Beyond the Initial Eye Wash Station Solution

The total cost of ownership (TCO) for a station eye wash includes more than just the purchase price. Maintenance is the most significant long-term expense. ANSI requires a weekly visual inspection and a 1-second activation to clear sediment from the lines.

For a portable eye wash station, the fluid must be changed and the tank disinfected regularly. In contrast, a plumbed emergency eye wash station is more expensive to install but offers lower ongoing labor costs, especially when integrated with automated reporting software. Investing in durable materials like 316 stainless steel prevents corrosion from the harsh chemical vapors common in chemistry labs, extending the lifespan of the hardware to 10-15 years.

Conclusion

The 2026 landscape of laboratory safety is defined by the seamless integration of high-performance safety equipment into a well-designed work environment. By choosing a station eye wash that balances ANSI Z358.1 compliance with the ergonomic and aesthetic needs of science laboratory furniture, organizations can foster a culture of safety that actually enhances research productivity. Whether you opt for a fixed wall mounted eye wash station or a flexible eye wash station portable, the goal remains the same: immediate, reliable protection for the laboratory's most valuable asset—its people. For a detailed reference on selection, installation, and maintenance, see the Master Guide for Station Eye Wash.

FAQs

Does a portable eye wash station meet OSHA requirements for corrosive chemicals?

Yes, provided the portable eye wash station OSHA approved (complying with ANSI Z358.1) can deliver at least 15 minutes of continuous, tepid flushing fluid at a rate of 0.4 GPM. Personal wash bottles do not meet this requirement and are considered supplemental only.

How far can the station eye wash be from the hazard?

The emergency eye wash station must be located within a 10-second walking distance (approx. 55 feet) on the same level as the hazard, with an unobstructed path.

What is the required water temperature for a lab eye wash station?

The water must be "tepid," which is defined as being between 60°F and 100°F (16°C to 38°C).

Can I install a station eye wash onto my existing lab furniture?

Yes, many deck-mounted and swing-away units are designed for eye wash station installation on existing benches. However, you must ensure the plumbing can support the required flow and that the furniture layout maintains an ADA-compliant path.

How often must an emergency eye wash station be inspected?

ANSI Z358.1 requires a weekly functional test (activation) to verify flow and clear the pipes, along with a more comprehensive annual inspection to ensure full compliance with the standard.

Why We Choose to Be Your Lab Furniture Solution Provider, Not Just a Manufacturer

Max Lab Introduction

Electronics Lab Bench vs Chemistry Lab Bench: What You Need to Know

Why a Fume Extractor is a Must-Have for Your Lab? How to choose fume extractor?

For Company

Where have you exported your equipment?

What types of companies do you work with?

We have worked with a wide range of companies, from small startups to large, multinational corporations. Our expertise in the laboratory furniture industry enables us to meet the needs of various sectors, including healthcare, research, education, pharmaceuticals, and industrial labs.

For Customization

What is the process for requesting a custom quote?

To request a custom quote, please provide us with details about your lab’s size, needs, and desired specifications.

Customization

What is the after-sales support for customized services?

We provide a full range of after-sales service, including equipment installation guidance, regular maintenance, troubleshooting, operation training, etc., to ensure the safe and efficient operation of equipment.

FAQS

Do you export internationally?

Yes, we have over 15 years of export experience and have served clients in more than 60 countries and regions.

Get in touch with us

If you have any comments or good suggestions, please leave us a message; later our professional staff will contact you as soon as possible.

Scan QR Code

Scan QR Code

MaxLabFurniture

MaxLab Furniture

daihongada

Max Laboratory