Specification Guide for a Variable Air Volume Fume Hood

- Key Performance Specifications for Lab Airflow Control

- Airflow and Face Velocity Requirements

- VAV Response Time and Stability

- Design Considerations for Variable Air Volume Fume Hoods

- Venturi Valve and Air Velocity Control System

- Integration with Building HVAC and Controls

- Testing, Compliance, and Maintenance

- Standards, Certification, and Performance Tests

- Maintenance, Commissioning, and Calibration

- Energy, Safety, and Operational Best Practices

- Energy Savings and Comparative Data

- Operational Safety and Training

- Selection Checklist and Specification Template

- Minimum Technical Checklist

- Sample Specification Snippet

- Frequently Asked Questions (FAQ)

- Q: How does a Variable Air Volume Fume Hood differ from a constant-volume hood?

- Q: Are Venturi valves reliable for long-term laboratory use?

- Q: What standards should be used for acceptance testing?

- Q: How often should velocity sensors be calibrated?

- Q: Can a VAV fume hood be retrofitted into an existing lab?

Optimize laboratory safety and energy performance by specifying the right Variable Air Volume Fume Hood. This guide details the critical airflow, control, integration, testing, and maintenance specifications you need to ensure consistent face velocity, fast response to duct static pressure changes, and compliance with laboratory ventilation standards.

Key Performance Specifications for Lab Airflow Control

Airflow and Face Velocity Requirements

Face velocity is the primary metric used to assess the containment performance of a variable air volume fume hood. Typical design face velocities range from 80 to 120 feet per minute (fpm) for general chemical fume hoods, with exact targets depending on laboratory processes and local regulations. When specifying a VAV fume hood, require the vendor to provide calibrated face velocity maps and acceptance criteria for sash positions (fully open, partially open, and closed). Include specifications for uniformity: face velocity variation across the sash opening should typically be within ±10–15%.

Because a VAV system dynamically changes supply/exhaust rates, specify how face velocity will be maintained when sash position is altered. The control system should compensate quickly to maintain target face velocity, ensuring contaminant capture even during sash movement.

VAV Response Time and Stability

Response time (the time to return to target face velocity after a disturbance) is critical for safety. Specify maximum acceptable response times: for example, less than 10–20 seconds for a 10% disturbance is a reasonable target for high-performance systems. Stability means the system should avoid overshoot and oscillation which could momentarily reduce containment.

Demand an air velocity control system with automatic duct static pressure compensation. Systems that use a Venturi valve or equivalent proportional control maintain air velocity more reliably under varying building conditions. Include maximum allowable deviations from setpoint (e.g., ±5 fpm) as part of the specification.

Design Considerations for Variable Air Volume Fume Hoods

Venturi Valve and Air Velocity Control System

Specify the control mechanism in detail. The Variable Air Volume Fume Hood must include a high-performance Venturi Valve Air Velocity Control System to optimize airflow regulation and ensure precise laboratory ventilation. For example, the product description below should be included in project submittals:

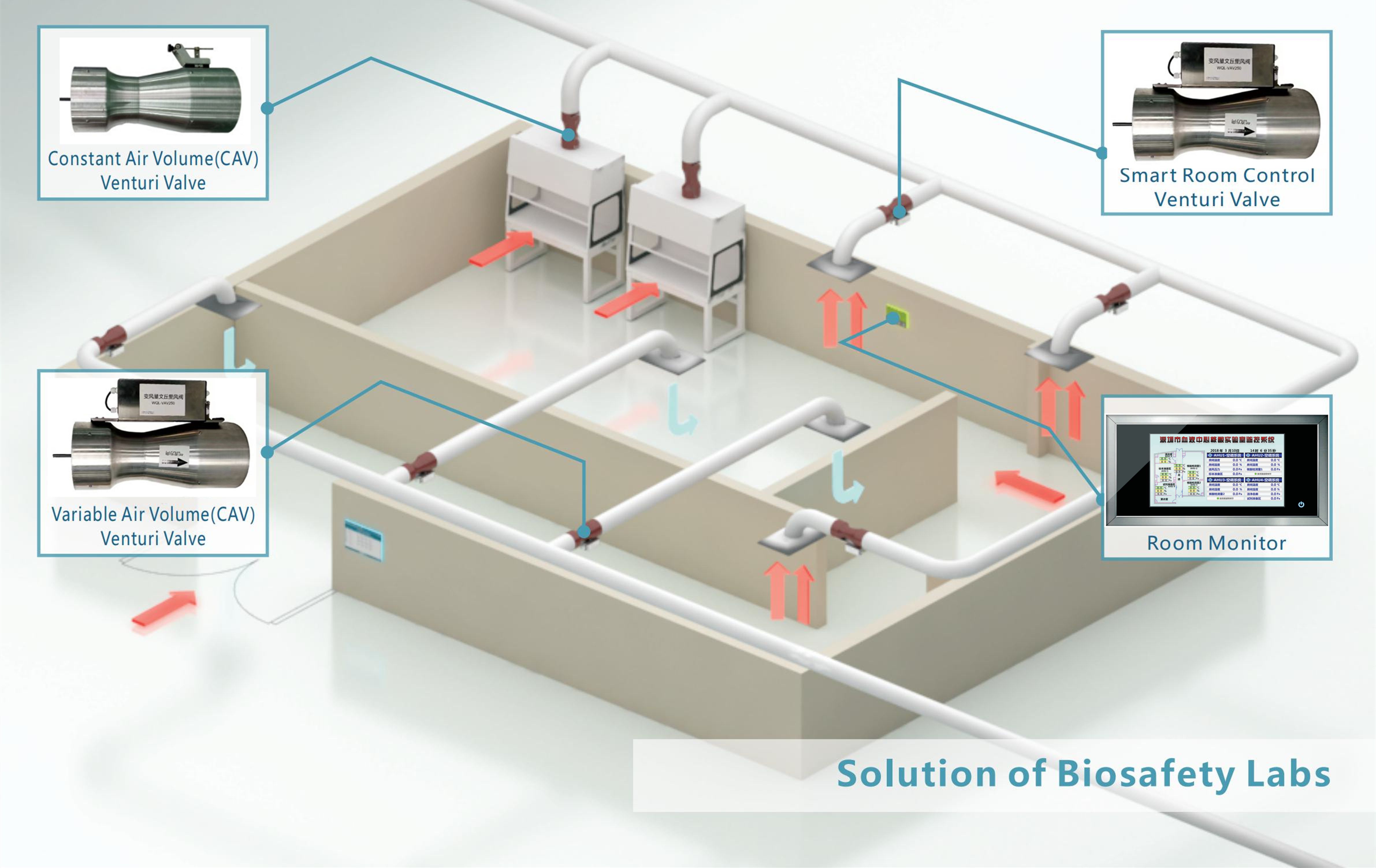

Optimize airflow regulation and ensure precise laboratory ventilation with MAX LAB Venturi Valve Air Velocity Control System. Designed for high-performance air pressure control, this system automatically adjusts to changes in duct static pressure, maintaining stable and energy-efficient air velocity management. Ideal for laboratories, cleanrooms, and healthcare facilities, it provides fast response times, low maintenance, and superior contaminant control. Our Venturi valve system enhances HVAC efficiency, improves air quality, and ensures compliance with critical environment safety standards.

The Venturi valve functions by modulating the effective cross-sectional flow area with minimal moving parts, enabling fast proportional control and low maintenance compared to mechanical dampers. When specifying, require the following Venturi valve attributes: proportional control range (e.g., 10–100% flow), leak-tight performance at closed positions, low pressure drop at full open, and materials compatible with the exhaust stream.

Integration with Building HVAC and Controls

VAV fume hoods must integrate with the Building Management System (BMS) and the laboratory HVAC design. Specify control signals (e.g., analog 0–10 V, 4–20 mA, or BACnet/IP), safety interlocks for sash positions, and BMS monitoring points (face velocity, sash position, valve position, duct static pressure, and alarm states).

Also specify requirements for setback and modes: night setback strategies should preserve negative pressure relationships while reducing flow safely, and the control logic must fail safe (e.g., sash closure or safe flow mode on loss of communication or power). Confirm required exhaust filtration (if any) and connection details such as duct orientation and access for service.

Testing, Compliance, and Maintenance

Standards, Certification, and Performance Tests

Include references to recognized test standards in your specification. Common references include ASHRAE Standard 110 (method of testing performance of laboratory fume hoods), and industry guidance such as the Fume hood overview on Wikipedia for background. ASHRAE Standard 110 provides an established protocol for tracer gas containment testing and should be used for acceptance testing. See ASHRAE's information on testing and standards for details: ASHRAE Standards.

For cleanroom-compatible installations, consider ISO 14644 requirements for environment classification: ISO 14644. For occupational safety and ventilation guidance, refer to CDC/NIOSH recommendations for laboratory ventilation controls: CDC NIOSH - Ventilation.

Maintenance, Commissioning, and Calibration

Specify a commissioning procedure that includes tracer gas or smoke testing, face velocity mapping at multiple sash positions, verification of BMS communication, and verification of the Venturi valve response. Commissioning reports should document baseline performance and any corrective actions.

Maintenance requirements must be explicit: annual calibration of velocity sensors, periodic inspection/cleaning of the Venturi valve orifice, verification of sash counterbalance and interlocks, and replacement intervals for any filters. For long-term reliability, specify spare parts availability and recommended preventive maintenance tasks and intervals.

Energy, Safety, and Operational Best Practices

Energy Savings and Comparative Data

One of the major advantages of a variable air volume fume hood is reduced energy consumption compared with constant air volume (CAV) systems. Below is a concise comparison to help quantify benefits when preparing specifications.

| Parameter | VAV Fume Hood (Venturi Valve) | CAV Fume Hood |

|---|---|---|

| Average Exhaust Flow per Hood | Variable; averages 40–60% of CAV during typical use | Constant high flow (design face velocity at full sash) |

| Estimated Energy Savings | 30–60% (typical, dependent on usage and HVAC) | Baseline (0% savings) |

| Control Accuracy | High — maintains face velocity across sash positions | Stable but may over-ventilate |

| Maintenance Needs | Moderate — requires sensor calibration and valve checks | Lower control complexity but higher HVAC load |

| Initial Cost | Higher (control hardware and commissioning) | Lower |

Note: Actual savings depend on lab occupancy patterns and the ability of the BMS to implement intelligent control strategies such as setback and demand-based scheduling. For energy calculation methodologies, consult building energy modeling resources and local code guidance.

Operational Safety and Training

Operational protocols are as important as hardware. Require that the vendor provide user training for laboratory staff covering sash operation, alarm response, and emergency procedures. Training should include how the Venturi valve-based control behaves during transient conditions and how to interpret BMS alarms.

Include interlocks for safe operation: audible/visual alarms for low face velocity, sash-open alarms when hazardous processes are underway, and automatic default modes for power or network failure. These safety measures must be defined in the specification and verified during commissioning.

Selection Checklist and Specification Template

Minimum Technical Checklist

- Target face velocity and allowable tolerance (e.g., 100 fpm ±10 fpm)

- Venturi valve control range, leak-tightness, and materials

- VAV control response time and stability criteria

- BMS integration protocol and required monitoring points

- Acceptance testing per ASHRAE 110 or equivalent

- Commissioning, warranty, and spare parts availability

Sample Specification Snippet

Provide a Variable Air Volume Fume Hood equipped with a Venturi Valve Air Velocity Control System capable of maintaining the specified face velocity within ±10% across all sash positions. The system shall automatically compensate for duct static pressure changes and communicate status via BACnet/IP (or other specified protocol). Acceptance testing shall be performed in accordance with ASHRAE Standard 110. Include vendor-supplied commissioning, training, and a two-year warranty on controls.

Frequently Asked Questions (FAQ)

Q: How does a Variable Air Volume Fume Hood differ from a constant-volume hood?

A: A variable air volume fume hood modulates exhaust flow to maintain target face velocity as sash position or building pressure changes, reducing overall exhaust airflow and HVAC energy use. A constant-volume (CAV) hood exhausts a fixed flow rate regardless of sash position, which is simpler but typically less energy efficient.

Q: Are Venturi valves reliable for long-term laboratory use?

A: Yes. Properly specified Venturi valves are robust, have few moving parts, and require minimal maintenance. Require vendor documentation for material compatibility with exhaust streams and scheduled maintenance tasks. Verify performance during commissioning and include periodic inspections.

Q: What standards should be used for acceptance testing?

A: ASHRAE Standard 110 is widely used for fume hood performance testing and should be included in the specification. Additional references include ISO 14644 for cleanroom-adjacent environments and national occupational safety guidance such as CDC/NIOSH ventilation recommendations: CDC NIOSH - Ventilation.

Q: How often should velocity sensors be calibrated?

A: At minimum, velocity sensors should be calibrated annually. High-use or critical environments may require more frequent checks (e.g., semi-annually). Calibration must be documented as part of maintenance records.

Q: Can a VAV fume hood be retrofitted into an existing lab?

A: Yes, in many cases. Retrofitting requires evaluation of existing ductwork capacity, AHU capability, and space for controls and sensors. A detailed site assessment and coordination with the HVAC engineer are essential to ensure proper integration and expected energy savings.

If you would like a specification template tailored to your project, commissioning support, or to view the Variable Air Volume Fume Hood product details and datasheet, please contact our team or view the product. Our specialists can provide BIM files, performance data, and help with ASHRAE 110 acceptance testing and commissioning plans.

References and further reading: ASHRAE Standards and guidelines (ASHRAE), Fume hood overview (Wikipedia), ISO cleanroom standards (ISO 14644), CDC/NIOSH ventilation guidance (CDC NIOSH), SEFA industry information (SEFA).

Modular Lab Sink Cabinets: Flexibility for Evolving Labs

Fume Hood Integration with HVAC and Laboratory Design

Choosing a laboratory table for precision balances: BT-03 insights

Anti-vibration Tables BT-03: Key specs for laboratory tables

For Products

What are the payment terms?

T/T by our bank account directly, or by the West Union.

Customization

How long does it take to customize the product?

The delivery time of the custom equipment depends on the specific customization program and production cycle, which generally takes 4 to 8 weeks. We will keep you updated during the production process.

What information do I need to provide to start a custom project?

In order to start a custom project, you need to provide information about the spatial layout of the laboratory, functional requirements, equipment quantity and specifications, budget, etc. If possible, you can also provide reference drawings or patterns so that we can better understand your needs.

Do you offer free design consultation?

Yes, we provide our clients with free preliminary design consulting services. Our design team will provide advice based on your needs and budget, and help you develop a laboratory layout and equipment plan that meets your requirements.

For After-Sales Support

Why choose your company?

We have been engaged in the manufacturing of various packing machines professionally over 15 years, and we can provide better after-sales service.

Variable Air Volume Fume Hood

Optimize airflow regulation and ensure precise laboratory ventilation with MAX LAB Venturi Valve Air Velocity Control System. Designed for high-performance air pressure control, this system automatically adjusts to changes in duct static pressure, maintaining stable and energy-efficient air velocity management. Ideal for laboratories, cleanrooms, and healthcare facilities, it provides fast response times, low maintenance, and superior contaminant control. Our Venturi valve system enhances HVAC efficiency, improves air quality, and ensures compliance with critical environment safety standards.

Floor Mounted Lab Bench

Our Floor Mounted Lab Bench is an essential, high-efficiency workspace for laboratories, made from high-quality steel-wood or corrosion-resistant stainless steel materials to ensure exceptional durability and stability. The unique floor-mounted design effectively reduces vibration, optimizes space usage, and provides a safe and tidy laboratory environment.

Customizable storage solutions help organize lab equipment efficiently, while the easy-to-clean surface maintains laboratory hygiene. It is widely suitable for research institutions, educational laboratories, and the chemical and pharmaceutical industries.

Fume Hood

The fume hood provides safe ventilation to protect against exposure to hazardous or toxic fumes, vapors, or airborne particulate. It is primarily used in laboratory and manufacturing applications to protect the user or environment outside the hood, but can also be used to protect the materials or experiment under the hood.

APPLICATION

Chemistry Lab, physics Lab, biological analysis, pharmaceutical medicine analysis, biological pharmaceutical, plant culture, environmental testing and electronic instrumentation scientific research and so on.

Flammable Storage Cabinet

Safety Cabinets store flammable liquids, corrosives, pesticides and other hazardous materials. All fire-resistant safety cabinets by meet fire codes and regulations for safety storage.

To help protect your people and facility from a potential fire, safety cabinets are engineered to safely contain flammable fuels, solvents, and chemicals. Safety cabinets can not only help everyone store chemicals reasonably, save chemical supplies, but also save human resources, and avoid fires caused by chemicals with the greatest strength.

Scan QR Code

Scan QR Code

MaxLabFurniture

MaxLab Furniture

daihongada

Max Laboratory