How Variable Air Volume Fume Hoods Improve Lab Safety

- How Variable Air Volume Fume Hoods Work to Protect Personnel

- Fundamentals of containment and face velocity

- How VAV differs from constant air volume (CAV) systems

- Key components that enable safe VAV operation

- Technology and Controls: Why Venturi Valve Systems Matter

- What a Venturi valve does in a VAV fume hood

- Introducing the Variable Air Volume Fume Hood product

- Benefits of integrating advanced controls

- Safety, Compliance, and Performance: Evidence-Based Advantages

- Containment performance and standards

- Energy savings without compromising safety

- Improved indoor air quality (IAQ) and occupant safety

- Installation, Commissioning, and Maintenance Best Practices

- Commissioning for performance and safety

- Routine maintenance and testing

- Training and operational procedures

- Comparing VAV and CAV Hoods: Safety and Cost Considerations

- Real-World Implementation: Case Examples and Considerations

- Typical retrofit vs. new construction considerations

- Monitoring, alarms, and remote oversight

- When to choose a Venturi valve-based Variable Air Volume Fume Hood

- Frequently Asked Questions (FAQ)

- Q: Are variable air volume fume hoods safe for all types of laboratory work?

- Q: How much energy can a lab save by switching to VAV fume hoods?

- Q: What maintenance is required for VAV fume hoods and Venturi valves?

- Q: Do VAV systems affect building pressurization?

Variable air volume fume hoods (often referred to as VAV fume hoods) are a critical technology for modern laboratories seeking to balance occupant safety, contaminant containment, and energy efficiency. By automatically adjusting exhaust flow to sash position, face velocity, and duct static pressure, these systems reduce unnecessary make-up air, maintain stable containment, and integrate tightly with building HVAC controls. This article explains how Variable Air Volume Fume Hoods enhance lab safety, the technology behind them, best practices for commissioning and maintenance, and how integrating high-performance Venturi valve control systems such as the MAX LAB Venturi Valve Air Velocity Control System can deliver measurable safety and energy performance improvements.

How Variable Air Volume Fume Hoods Work to Protect Personnel

Fundamentals of containment and face velocity

Fume hood containment depends on maintaining a stable face velocity—the speed of air moving into the hood face—across the sash opening. For most chemistry and research labs, recommended design face velocities typically range around 80–120 ft/min (24–37 m/min), optimized to balance capture effectiveness and operator comfort. A fume hood that falls outside this range can either allow contaminants to escape (if too low) or create turbulence and wasted energy (if too high).

How VAV differs from constant air volume (CAV) systems

Traditional constant air volume (CAV) hoods run at a fixed exhaust rate regardless of sash position—this ensures steady face velocity only if the sash remains at the design height. VAV fume hoods, by contrast, modulate exhaust flow as the sash moves: when the sash is raised, exhaust increases to keep face velocity constant; when lowered, exhaust decreases. This demand-controlled ventilation model enhances safety by maintaining containment under dynamic use and reduces energy by not over-exhausting when full flow is unnecessary.

Key components that enable safe VAV operation

Core components include sash position sensors, airflow sensors or pressure transducers, control logic (local or building management system), and an actuator/valve assembly such as a Venturi valve or variable-speed fan. Advanced systems also include alarm setpoints, setback modes, and interlocks to prevent hazardous sash positions. Proper interplay between these components ensures the hood responds quickly to changes and preserves containment.

Technology and Controls: Why Venturi Valve Systems Matter

What a Venturi valve does in a VAV fume hood

The Venturi valve is a precision airflow control element that regulates exhaust velocity by varying flow through a fixed duct geometry. High-performance Venturi valve systems offer fast response, low hysteresis, and consistent face velocity even when duct static pressure changes—an important advantage over simpler dampers or throttling valves.

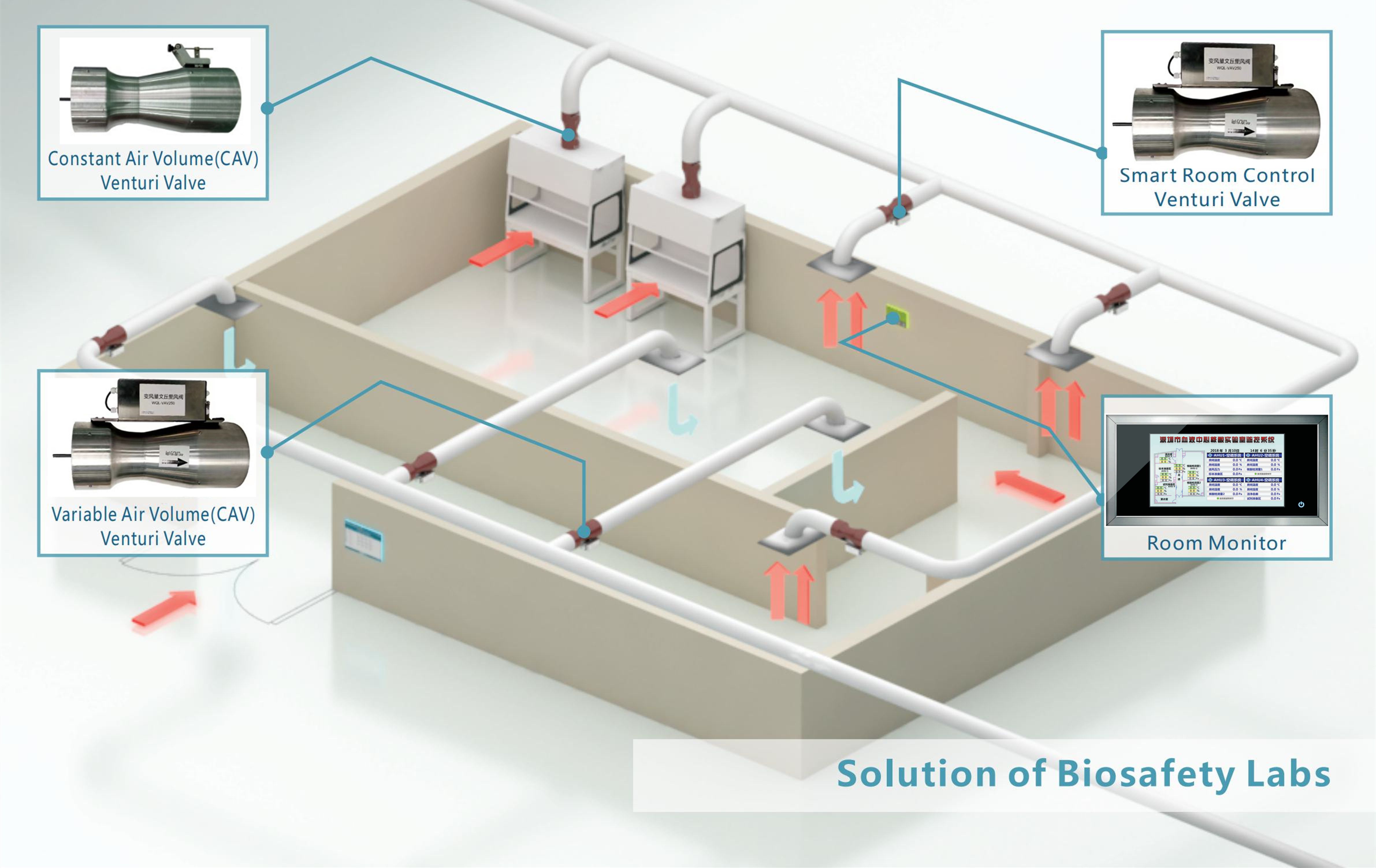

Introducing the Variable Air Volume Fume Hood product

Optimize airflow regulation and ensure precise laboratory ventilation with MAX LAB Venturi Valve Air Velocity Control System. Designed for high-performance air pressure control, this system automatically adjusts to changes in duct static pressure, maintaining stable and energy-efficient air velocity management. Ideal for laboratories, cleanrooms, and healthcare facilities, it provides fast response times, low maintenance, and superior contaminant control. Our Venturi valve system enhances HVAC efficiency, improves air quality, and ensures compliance with critical environment safety standards.

Benefits of integrating advanced controls

When VAV control logic is paired with a reliable Venturi valve, labs gain: rapid response to sash movement and transient events, consistent containment during duct pressure fluctuations, simplified balancing during commissioning, and reduced maintenance due to fewer moving parts under stress. These features are particularly important in multi-hood labs or facilities that operate under variable building loads.

Safety, Compliance, and Performance: Evidence-Based Advantages

Containment performance and standards

Performance testing standards such as ASHRAE/ANSI/AIHA Standard 110 define procedures for assessing fume hood containment and face velocity. VAV hoods that use precise airflow control and alarmed setpoints can consistently meet or exceed these containment test results by maintaining face velocity and minimizing turbulence during normal operation and sash adjustments.

Energy savings without compromising safety

Demand-controlled ventilation reduces total exhaust and conditioned makeup air, which is one of the largest energy consumers in lab buildings. Industry programs such as the U.S. EPA’s Labs21/Green Labs initiatives document significant energy savings when VAV systems and high-performance controls are implemented—typical case studies report substantial reductions in HVAC energy use while maintaining ventilation and containment standards. See EPA Labs resources for detailed guidance and case studies: Labs for the 21st Century.

Improved indoor air quality (IAQ) and occupant safety

By controlling exhaust to match actual need, VAV hoods reduce the risk of pressure imbalances, cross-contamination, and the entrainment of contaminants into occupied zones. Integration with building automation systems enables real-time monitoring, user alarms, and automated safe states if sensors indicate loss of containment or inadequate airflows—key elements in biosafety and chemical safety programs such as those outlined in the WHO Laboratory Biosafety Manual.

Installation, Commissioning, and Maintenance Best Practices

Commissioning for performance and safety

Proper commissioning must include face velocity verification across sash positions, smoke visualization tests, and AHU/duct static pressure profiling. Commissioning should follow recognized standards and involve calibration of sash sensors and airflow control loops. Documentation of test results and setting alarm thresholds are essential to demonstrate performance and to comply with safety audits.

Routine maintenance and testing

Scheduled maintenance should include calibration checks, inspection of Venturi valve or actuator components, sash mechanics lubrication, and verification of alarm and interlock functions. Periodic containment re-testing (e.g., annual or as required by facility policy) ensures the hood continues to perform under real-world conditions.

Training and operational procedures

Even the best-engineered VAV hood requires consistent user behavior to maintain containment: keep the sash at the recommended working height, avoid rapid sash movement when possible, and follow procedures for cross-drafts. Training should emphasize how the Variable Air Volume Fume Hood responds to sash changes and when to act on alarms.

Comparing VAV and CAV Hoods: Safety and Cost Considerations

The table below summarizes typical differences between Variable Air Volume (VAV) and Constant Air Volume (CAV) fume hoods. Values are representative ranges and should be validated for each project.

| Feature | VAV Fume Hood (Variable Air Volume) | CAV Fume Hood (Constant Air Volume) |

|---|---|---|

| Typical face velocity control | Maintains target face velocity across sash positions (e.g., ~80–120 ft/min) | Maintains face velocity only at design sash height; variable when sash moved |

| Energy use | Lower overall energy use due to demand-based exhaust (often large HVAC savings) | Higher energy use because exhaust and makeup air run at full rate |

| Containment consistency | Higher—if properly commissioned and controlled | Variable—can be unsafe if sash moved from design height |

| Control complexity | Higher (requires sensors, controls, valves/fan VFDs) | Lower (simpler controls) |

| Initial cost | Higher due to advanced controls and valves | Lower upfront cost |

| Lifecycle cost | Typically lower due to energy savings | Often higher due to ongoing energy expense |

For practitioners seeking deeper guidance on lab ventilation design and standards, the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) publishes standards and guidance relevant to HVAC design for labs, and testing protocols such as ASHRAE/ANSI/AIHA Standard 110 support rigorous verification of hood performance.

Real-World Implementation: Case Examples and Considerations

Typical retrofit vs. new construction considerations

In retrofit projects, space constraints and existing ductwork can limit options. Venturi valve solutions are often attractive for retrofits because they can provide precise control without requiring large fan system changes. For new construction, VAV strategies should be integrated into the HVAC design early to optimize airflow distribution, AHU sizing, and controls integration.

Monitoring, alarms, and remote oversight

Networked controls and BAS integration enable centralized monitoring of multiple VAV hoods, alarm aggregation, and trend analysis. This capability helps facilities detect performance drift (e.g., due to filter loading or duct leaks) before it impacts containment or IAQ.

When to choose a Venturi valve-based Variable Air Volume Fume Hood

Choose a Venturi valve approach when you need fast, accurate face velocity control in the presence of variable duct pressures, multi-hood central exhaust systems, or where low maintenance and long-term stability are priorities. The MAX LAB Venturi Valve Air Velocity Control System is designed specifically to meet these needs with automatic adjustment, fast response, and low upkeep.

Frequently Asked Questions (FAQ)

Q: Are variable air volume fume hoods safe for all types of laboratory work?

A: Yes, when properly specified, installed, and commissioned. VAV hoods are widely used for chemistry, research, and biosafety applications. They must meet containment test standards (e.g., ASHRAE 110) and be integrated with building alarms and interlocks for hazardous operations. Refer to operational policies and safety assessments for tasks involving particularly hazardous substances.

Q: How much energy can a lab save by switching to VAV fume hoods?

A: Savings vary by facility and usage patterns but are often substantial because VAV systems reduce both exhaust and conditioned makeup air. Industry resources and case studies—such as those documented by the EPA Labs21 program—show meaningful HVAC energy reductions when demand-based ventilation is implemented. See EPA Labs publications for examples: Labs21.

Q: What maintenance is required for VAV fume hoods and Venturi valves?

A: Routine maintenance includes periodic calibration of sensors, inspection of valve actuators, verification of alarm setpoints, sash hardware checks, and annual containment retesting. Venturi valves are generally low-maintenance compared to complex mechanical throttles, but they should still be included in preventive maintenance schedules.

Q: Do VAV systems affect building pressurization?

A: Yes—VAV hoods change exhaust quantities dynamically, so the building HVAC must be designed to handle variable makeup. Proper AHU controls, makeup air systems, and pressure control strategies are necessary to avoid unintended building pressurization impacts. Coordination between lab and central HVAC teams during design and commissioning is essential.

If you’d like to evaluate how a Variable Air Volume Fume Hood with a MAX LAB Venturi Valve Air Velocity Control System can improve safety and efficiency in your facility, contact our sales and technical team for a consultation and site assessment. View product details or request a quote: Variable Air Volume Fume Hood.

References: ASHRAE and testing standards (https://www.ashrae.org/), ASHRAE/ANSI/AIHA Standard 110 (https://en.wikipedia.org/wiki/ASHRAE_Test_Standard_110), Fume hood overview (https://en.wikipedia.org/wiki/Fume_hood), WHO Laboratory Biosafety Manual (https://www.who.int/publications/i/item/9789240011311), EPA Labs21 resources (https://www.epa.gov/labs/labs-21st-century-publications).

2026 Master Guide: Perfecting Your Station Eye Wash Compliance Strategy

Customizing Floor Mounted Lab Benches: Modules and Accessories

Comparing Chemical Resistance: Phenolic vs Epoxy vs Stainless

Cleaning and Decontamination Best Practices for Lab Benches

For Logistics

How are shipping costs calculated?

Shipping costs are calculated based on the size, weight, and destination of your order. We provide a detailed shipping quote during the ordering process.

For Products

Can your furniture withstand heavy-duty use?

Yes, all of our laboratory furniture focuses on durability, with a load-bearing capacity of up to 500KG/m², and is made of high-quality materials that can meet the requirements for large-scale precision instruments and equipment and exposure to chemicals in the laboratory.

What materials do you use for your furniture?

We use a variety of durable materials such as stainless steel, steel wood, PP and wood composites. Our countertop materials are phenolic resin, epoxy resin, ceramic, trespa and granite, depending on your lab’s needs.

Customization

How long does it take to customize the product?

The delivery time of the custom equipment depends on the specific customization program and production cycle, which generally takes 4 to 8 weeks. We will keep you updated during the production process.

FAQS

What products does Max Lab offer?

We specialize in laboratory furniture and equipment, including lab benches, fume hoods, storage cabinets, and custom lab solutions.

Variable Air Volume Fume Hood

Optimize airflow regulation and ensure precise laboratory ventilation with MAX LAB Venturi Valve Air Velocity Control System. Designed for high-performance air pressure control, this system automatically adjusts to changes in duct static pressure, maintaining stable and energy-efficient air velocity management. Ideal for laboratories, cleanrooms, and healthcare facilities, it provides fast response times, low maintenance, and superior contaminant control. Our Venturi valve system enhances HVAC efficiency, improves air quality, and ensures compliance with critical environment safety standards.

Floor Mounted Lab Bench

Our Floor Mounted Lab Bench is an essential, high-efficiency workspace for laboratories, made from high-quality steel-wood or corrosion-resistant stainless steel materials to ensure exceptional durability and stability. The unique floor-mounted design effectively reduces vibration, optimizes space usage, and provides a safe and tidy laboratory environment.

Customizable storage solutions help organize lab equipment efficiently, while the easy-to-clean surface maintains laboratory hygiene. It is widely suitable for research institutions, educational laboratories, and the chemical and pharmaceutical industries.

Fume Hood

The fume hood provides safe ventilation to protect against exposure to hazardous or toxic fumes, vapors, or airborne particulate. It is primarily used in laboratory and manufacturing applications to protect the user or environment outside the hood, but can also be used to protect the materials or experiment under the hood.

APPLICATION

Chemistry Lab, physics Lab, biological analysis, pharmaceutical medicine analysis, biological pharmaceutical, plant culture, environmental testing and electronic instrumentation scientific research and so on.

Flammable Storage Cabinet

Safety Cabinets store flammable liquids, corrosives, pesticides and other hazardous materials. All fire-resistant safety cabinets by meet fire codes and regulations for safety storage.

To help protect your people and facility from a potential fire, safety cabinets are engineered to safely contain flammable fuels, solvents, and chemicals. Safety cabinets can not only help everyone store chemicals reasonably, save chemical supplies, but also save human resources, and avoid fires caused by chemicals with the greatest strength.

Scan QR Code

Scan QR Code

MaxLabFurniture

MaxLab Furniture

daihongada

Max Laboratory