Variable Air Volume Fume Hood Features That Buyers Prioritize

- Key Performance Features Buyers Seek in Variable Air Volume Fume Hoods

- Airflow precision and containment performance

- Energy efficiency and operational economics

- Safety, alarms, and fail-safe behaviour

- Design and Integration Considerations for Modern Labs

- Controls, automation, and BMS compatibility

- Ergonomics, sash design, and user experience

- Maintenance, accessibility, and longevity

- Compliance, Testing, and Verification Standards

- Relevant standards and test methods

- Commissioning, acceptance testing, and continuous verification

- Choosing the Right Variable Air Volume Fume Hood for Your Facility

- Comparing VAV and constant volume (CAV) hoods — performance and cost

- Procurement checklist and buyer priorities

- Implementation Advice, ROI, and Case Considerations

- Estimating energy savings and payback

- Case study highlights and real-world lessons

- Vendor selection and warranty considerations

- Frequently Asked Questions (FAQ)

- What is the main advantage of a variable air volume fume hood over a constant volume hood?

- How do Venturi valve systems improve VAV fume hood performance?

- Which standards should buyers reference when specifying a fume hood?

- How often should VAV fume hoods be re-certified?

- What are practical tips for maximizing energy savings from VAV hoods?

Variable air volume fume hoods are central to modern laboratory ventilation strategies because they balance containment performance with energy savings and HVAC efficiency. Buyers evaluating variable air volume fume hood solutions care most about precise airflow regulation, rapid response to duct static pressure changes, reliable contaminant control, integration with building automation systems, and low life-cycle costs. This article examines these priorities in depth and explains how systems such as the MAX LAB Venturi Valve Air Velocity Control System optimize airflow regulation and ensure precise laboratory ventilation. Designed for high-performance air pressure control, this system automatically adjusts to changes in duct static pressure, maintaining stable and energy-efficient air velocity management. Ideal for laboratories, cleanrooms, and healthcare facilities, it provides fast response times, low maintenance, and superior contaminant control. Our Venturi valve system enhances HVAC efficiency, improves air quality, and ensures compliance with critical environment safety standards.

Key Performance Features Buyers Seek in Variable Air Volume Fume Hoods

Airflow precision and containment performance

At the top of the priority list for buyers of a variable air volume fume hood is precise airflow control that maintains containment under changing conditions. The ability to hold a constant face velocity despite fluctuations in building pressure, extract demand, or adjacent door openings is essential to protect personnel and experiments. Buyers look for VAV fume hoods with active sensing and closed-loop control that continuously monitor face velocity and sash position, automatically compensating to maintain a preset capture velocity.

Advanced control methods, such as a Venturi valve with air velocity control, help stabilize airflow by responding to duct static pressure changes without requiring large fan speed adjustments. This minimizes transient leakage and prevents under- or over-ventilation events that could compromise containment or increase energy consumption.

Energy efficiency and operational economics

Energy considerations are a critical purchasing factor. Variable air volume fume hood systems that reduce exhaust volume during idle periods or when sash positions change can produce substantial HVAC energy savings over time. Buyers typically evaluate:

- Annual energy consumption estimates (kWh and cost)

- Potential HVAC load reduction and impact on building heating/cooling

- Payback period and total cost of ownership (TCO)

Solutions that provide accurate airflow control with minimal mechanical losses (for example, low-pressure-drop Venturi valves) are preferred because they maintain containment while lowering fan energy and conditioned air losses.

Safety, alarms, and fail-safe behaviour

Buyers also prioritize safety features: audible/visual alarms for low face velocity, automatic sash interlocks, and fail-safe modes that default to protective ventilation if a control component fails. Integration with building management systems (BMS) for remote monitoring and logging is increasingly expected in high-performance labs and regulated environments.

Design and Integration Considerations for Modern Labs

Controls, automation, and BMS compatibility

Modern labs demand fume hoods that communicate with building HVAC and automation systems. Buyers favor VAV fume hoods offering standard communication protocols (BACnet, Modbus) and open APIs for integration with a supervisory control platform. Seamless data exchange enables centralized monitoring of face velocity, sash position, and valve status — improving compliance documentation and facilitating predictive maintenance.

For example, variable air volume fume hood controllers can send event logs and trend data to a BMS to support continuous commissioning and energy optimization strategies, reducing unexpected downtime and operational risk.

Ergonomics, sash design, and user experience

Ease of use affects daily compliance. Buyers evaluate sash types (vertical, horizontal, or combination), sash counterbalance, and clear sightlines. A well-designed sash and intuitive indicators (LED face velocity bars, color-coded alarms) encourage proper use and help lab personnel maintain correct sash positions, which directly impacts containment and energy performance.

Maintenance, accessibility, and longevity

Low-maintenance designs with accessible components reduce service costs and downtime. Buyers prefer systems with field-replaceable sensors, modular control units, and non-clogging valves. The MAX LAB Venturi Valve Air Velocity Control System, for instance, emphasizes low maintenance and fast response times, reducing the need for frequent adjustments or filter changes while maintaining consistent performance.

Compliance, Testing, and Verification Standards

Relevant standards and test methods

Compliance with established standards is non-negotiable in many institutions. Buyers must ensure the chosen variable air volume fume hood meets or is tested according to accepted standards such as ASHRAE 110 for fume hood performance testing and local regulatory requirements. For broader environmental control, ISO 14644 series addresses cleanroom and controlled environment classifications and testing methods. Referencing authoritative standards helps specifiers demonstrate conformity during audits and commissioning.

Useful references:

- Fume hood — Wikipedia (overview of types and testing)

- ISO 14644 — Cleanrooms and associated controlled environments (classification and testing)

- OSHA Laboratory Safety Guidance (worker protection and lab safety principles)

Commissioning, acceptance testing, and continuous verification

A rigorous commissioning and periodic re-certification program ensures a variable air volume fume hood continues to perform as intended. Buyers should require:

- Initial performance acceptance testing (face velocity, tracer gas containment where applicable)

- Commissioning documentation and baseline data

- Scheduled re-testing intervals and an approach for anomaly response

Tools for continuous monitoring integrated with the VAV controller can provide near-real-time alerts and trend analysis to catch performance degradation early.

Choosing the Right Variable Air Volume Fume Hood for Your Facility

Comparing VAV and constant volume (CAV) hoods — performance and cost

When choosing a hood type, buyers typically compare VAV fume hoods to constant volume alternatives. The table below summarizes key differences found in procurement evaluations. This comparison helps quantify potential energy savings and operational trade-offs.

| Characteristic | Variable Air Volume (VAV) Fume Hood | Constant Air Volume (CAV) Fume Hood |

|---|---|---|

| Energy use | Lower — adjusts exhaust to sash/usage; potential for large HVAC savings | Higher — runs at constant exhaust regardless of use |

| Containment control | High if properly controlled; requires accurate sensors and control strategy | Stable face velocity if properly designed; less responsive to building pressure changes |

| Initial cost | Moderate to high — additional controls and valves | Lower — simpler controls |

| Maintenance | Requires control calibration; modern designs emphasize low maintenance | Mechanically simpler but may cause higher HVAC wear/costs |

| Best use | Labs prioritizing energy savings and dynamic operation (multi-use spaces) | Environments requiring fixed airflow patterns or simple labs |

Procurement checklist and buyer priorities

To streamline selection, buyers can use this checklist during procurement:

- Verify compliant testing per ASHRAE/ISO/OSHA guidance and request test reports

- Confirm communication protocols and BMS integration (BACnet/Modbus/Open API)

- Request lifecycle cost analysis including energy modeling and payback

- Assess maintenance access, spare parts availability, and local service support

- Check for fail-safe behaviour, alarms, and commissioning support

Choosing a variable air volume fume hood with a tested valve system such as the MAX LAB Venturi Valve Air Velocity Control System can meet both containment and energy goals. Buyers should request demonstration data on response time to duct pressure transients, typical maintenance intervals, and expected energy reduction percentages.

Implementation Advice, ROI, and Case Considerations

Estimating energy savings and payback

Energy savings depend on usage patterns, sash management policies, and building HVAC design. Typical VAV deployments report energy reductions in exhaust heating/cooling loads of 30–70% compared to CAV installations for facilities with moderate to high idle periods. For accurate ROI figures, run an energy model incorporating sash position schedules, local energy prices, and HVAC efficiencies.

Case study highlights and real-world lessons

Successful implementations share common elements: strong commissioning, training for lab personnel on sash-use best practices, and ongoing monitoring. Facilities that pair a high-performance Venturi valve control with a BMS see faster stabilization of face velocities and fewer alarm events during building pressure fluctuations.

Vendor selection and warranty considerations

Buyers should evaluate suppliers on technical documentation, warranty coverage for control electronics and valves, remote support capabilities, and references from similar facilities. A transparent service plan and clear escalation path ensure long-term performance and predictable costs.

Frequently Asked Questions (FAQ)

What is the main advantage of a variable air volume fume hood over a constant volume hood?

The main advantage is energy efficiency: VAV hoods adjust exhaust flow to actual usage (sash position and activity), reducing conditioned air loss and lowering HVAC energy consumption. When properly controlled, VAV hoods maintain equivalent containment while reducing operational costs.

How do Venturi valve systems improve VAV fume hood performance?

Venturi valve systems regulate air velocity by shaping and controlling flow with minimal pressure drop, enabling rapid response to duct static pressure changes. This stabilizes face velocity, reduces fan cycling, and lowers maintenance compared with some mechanical throttling devices.

Which standards should buyers reference when specifying a fume hood?

Buyers should reference performance and testing standards such as ASHRAE 110 for fume hood performance testing and ISO 14644 for cleanroom considerations, and follow applicable local OSHA or lab safety guidance available at OSHA.

How often should VAV fume hoods be re-certified?

Typical re-certification intervals range from annually to biannually depending on facility policy, the level of hazard, and regulatory requirements. Continuous monitoring reduces risk between formal tests and provides early warnings if performance degrades.

What are practical tips for maximizing energy savings from VAV hoods?

Enforce strict sash management policies (closed when not in use), enable automated setback modes for idle periods, ensure VAV controls are calibrated, and integrate hood controls with the building management system for coordinated HVAC responses.

If you would like to evaluate the Variable Air Volume Fume Hood with MAX LAB Venturi Valve Air Velocity Control System for your facility, request a datasheet, ROI analysis, or a demonstration. Contact our technical sales team or view the product to learn more.

Custom vs Standard Lab Furniture: Pros and Cons

Fume Hood Procurement Guide: Key Specs B2B Buyers Need

Fume Hood Maintenance Plans to Minimize Downtime

Installing Floor Mounted Lab Benches: What to Expect

For Customization

Can you create furniture for labs with special requirements?

Yes, we specialize in designing and manufacturing lab furniture for specialized environments, including clean rooms, bio labs, and industrial labs.

Can you create a lab design layout for us?

Yes, we'll provide preliminary layout, confirm 3D drawings and rendering drawings.

About Solution

Does your laboratory furniture support customization?

Yes, we provide fully customized services including size, material, color and functional design to meet customers' specific needs.

For After-Sales Support

How about your after sale service?

We will reply you within 24 hours by email or phone.

If we have local agent,we will arrange him to your site within 24 hours to assist you to shoot the problem.

For Company

Do you offer services internationally?

Yes, we serve clients around the world, including Europe, North America, and Asia. Our international experience enables us to provide solutions that meet local regulations and standards.

Variable Air Volume Fume Hood

Optimize airflow regulation and ensure precise laboratory ventilation with MAX LAB Venturi Valve Air Velocity Control System. Designed for high-performance air pressure control, this system automatically adjusts to changes in duct static pressure, maintaining stable and energy-efficient air velocity management. Ideal for laboratories, cleanrooms, and healthcare facilities, it provides fast response times, low maintenance, and superior contaminant control. Our Venturi valve system enhances HVAC efficiency, improves air quality, and ensures compliance with critical environment safety standards.

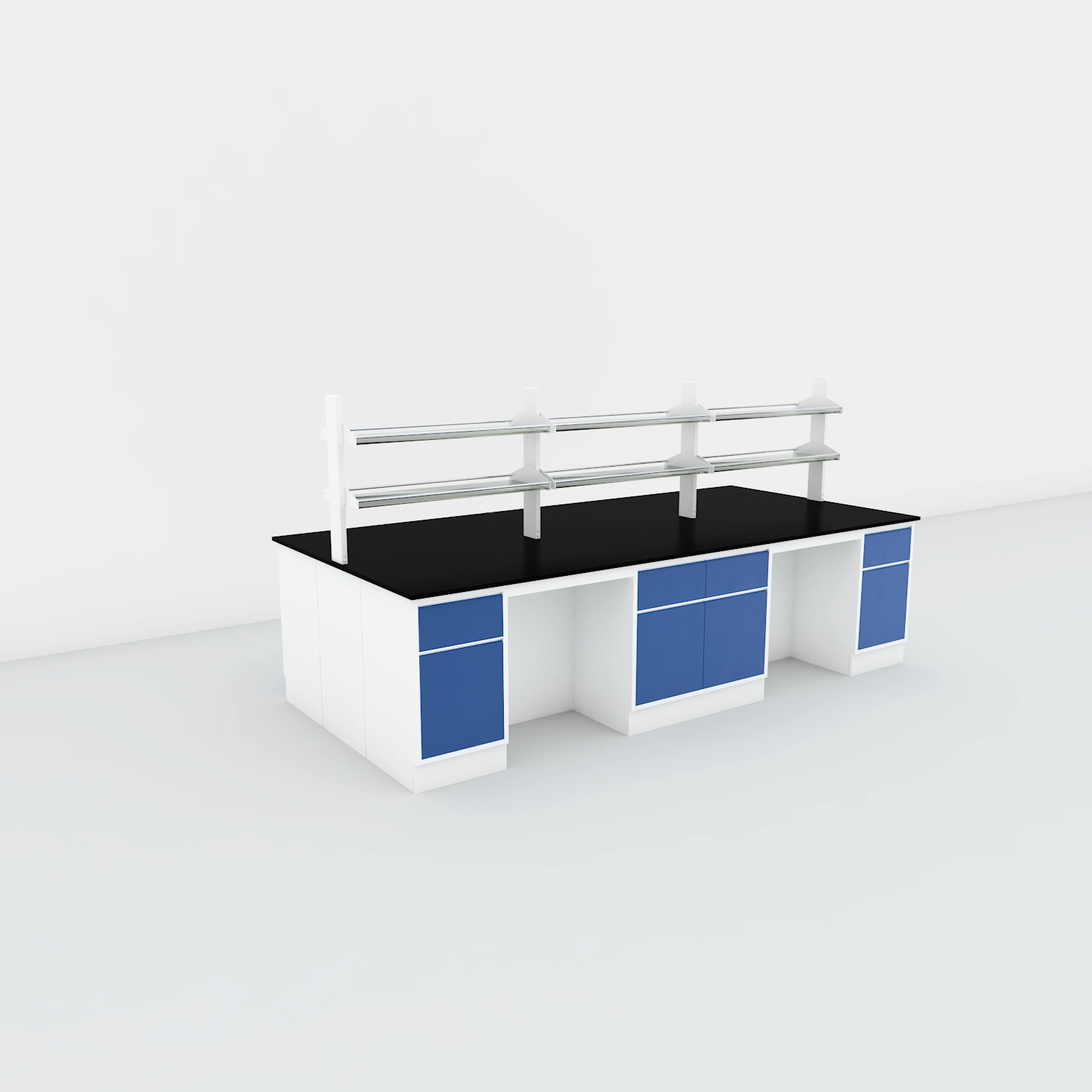

Floor Mounted Lab Bench

Our Floor Mounted Lab Bench is an essential, high-efficiency workspace for laboratories, made from high-quality steel-wood or corrosion-resistant stainless steel materials to ensure exceptional durability and stability. The unique floor-mounted design effectively reduces vibration, optimizes space usage, and provides a safe and tidy laboratory environment.

Customizable storage solutions help organize lab equipment efficiently, while the easy-to-clean surface maintains laboratory hygiene. It is widely suitable for research institutions, educational laboratories, and the chemical and pharmaceutical industries.

Fume Hood

The fume hood provides safe ventilation to protect against exposure to hazardous or toxic fumes, vapors, or airborne particulate. It is primarily used in laboratory and manufacturing applications to protect the user or environment outside the hood, but can also be used to protect the materials or experiment under the hood.

APPLICATION

Chemistry Lab, physics Lab, biological analysis, pharmaceutical medicine analysis, biological pharmaceutical, plant culture, environmental testing and electronic instrumentation scientific research and so on.

Flammable Storage Cabinet

Safety Cabinets store flammable liquids, corrosives, pesticides and other hazardous materials. All fire-resistant safety cabinets by meet fire codes and regulations for safety storage.

To help protect your people and facility from a potential fire, safety cabinets are engineered to safely contain flammable fuels, solvents, and chemicals. Safety cabinets can not only help everyone store chemicals reasonably, save chemical supplies, but also save human resources, and avoid fires caused by chemicals with the greatest strength.

Scan QR Code

Scan QR Code

MaxLabFurniture

MaxLab Furniture

daihongada

Max Laboratory