Energy Savings with a Variable Air Volume Fume Hood

- How Variable Air Volume Fume Hoods Reduce Energy Use

- Principles of VAV airflow control

- Venturi valve and rapid response systems

- Comparison with Constant Air Volume (CAV) fume hoods

- Design and Installation Considerations for VAV Fume Hoods

- Sash position, setpoints and user interaction

- Ductwork, pressure control and HVAC integration

- Control strategies, monitoring and alarms

- Performance, Safety and Compliance

- Maintaining containment while saving energy

- Monitoring, validation and periodic re-commissioning

- Applicable regulations and standards

- Calculating Energy Savings and Return on Investment

- Typical savings and a simple case study

- ROI example table

- Maintenance, lifecycle and non-energy benefits

- Implementation Checklist for Facility Managers

- Procurement and specification tips

- Commissioning and validation

- User training and lab policies

- Frequently Asked Questions (FAQ)

- Will a Variable Air Volume Fume Hood compromise safety?

- How much energy can I expect to save?

- What is the role of the Venturi valve in a VAV system?

- How often should VAV hoods be re-commissioned?

- Can VAV hoods be retrofitted into existing labs?

Variable air volume fume hoods offer laboratories a proven path to reduce energy consumption while maintaining or improving occupant safety and contaminant containment. By actively adjusting exhaust flow to sash position and real-time duct static pressure, VAV fume hoods optimize HVAC load, lower fan energy, and cut conditioned makeup air costs—especially when combined with advanced control devices such as Venturi valve systems. Below we explain how a Variable Air Volume Fume Hood works, how to size and commission one, safety and compliance considerations, typical energy savings, and practical steps to maximize return on investment.

How Variable Air Volume Fume Hoods Reduce Energy Use

Principles of VAV airflow control

A variable air volume fume hood regulates exhaust flow to match real-time ventilation needs. When the hood sash is closed or partially open, the hood exhausts less air; when the sash is fully open, the exhaust increases to maintain containment. This contrasts with constant air volume (CAV) hoods that exhaust a fixed flow regardless of sash position. VAV control significantly reduces conditioned makeup air requirements and fan power, two of the largest energy consumers in lab HVAC systems. For background on fume hood function and laboratory ventilation, see the fume hood overview on Wikipedia.

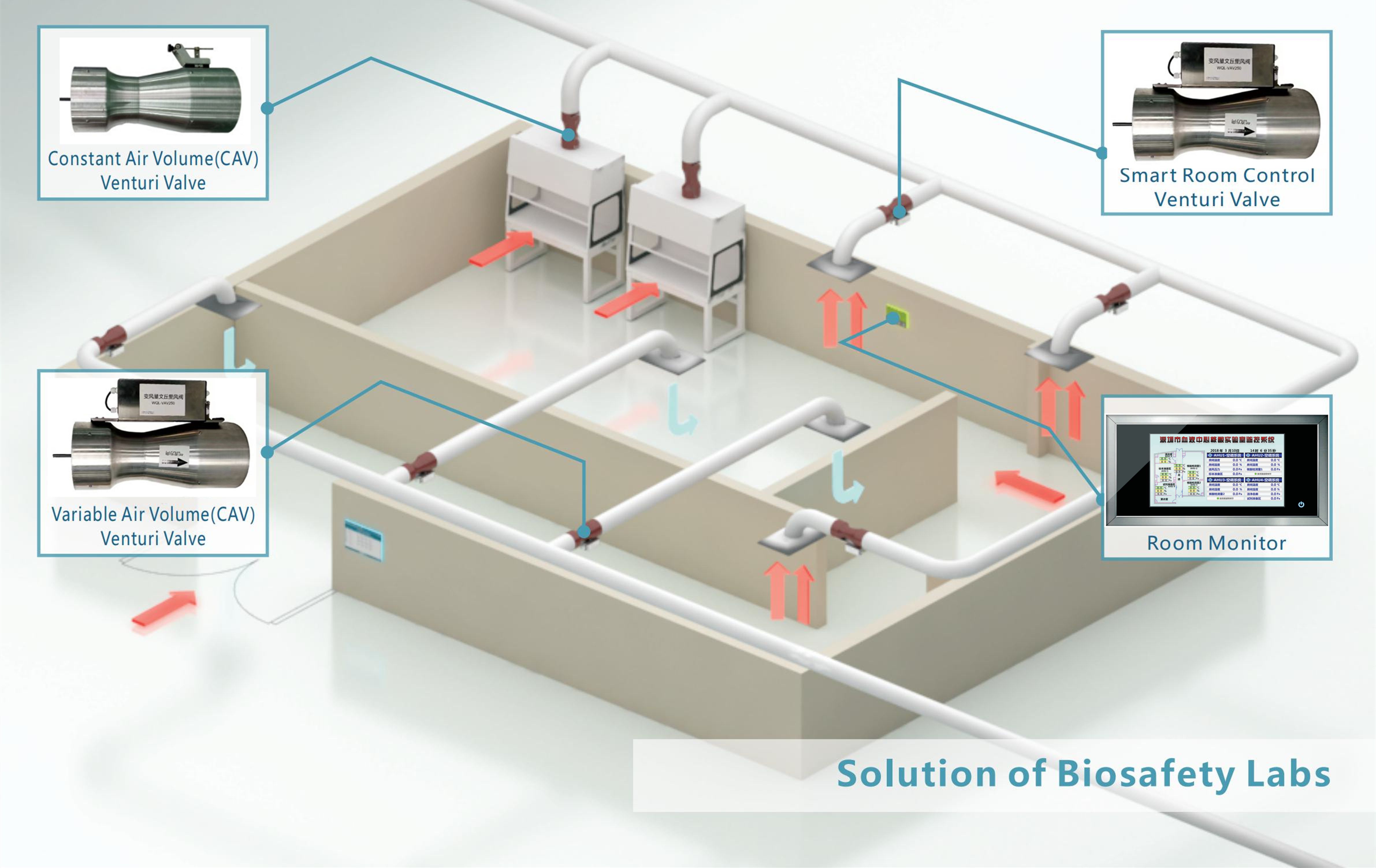

Venturi valve and rapid response systems

High-performance VAV hoods benefit from precise flow devices. The MAX LAB Venturi Valve Air Velocity Control System is designed to optimize airflow regulation and ensure precise laboratory ventilation. As described:

Optimize airflow regulation and ensure precise laboratory ventilation with MAX LAB Venturi Valve Air Velocity Control System. Designed for high-performance air pressure control, this system automatically adjusts to changes in duct static pressure, maintaining stable and energy-efficient air velocity management. Ideal for laboratories, cleanrooms, and healthcare facilities, it provides fast response times, low maintenance, and superior contaminant control. Our Venturi valve system enhances HVAC efficiency, improves air quality, and ensures compliance with critical environment safety standards.

Venturi valves provide fast, stable response to sash movement and duct pressure swings, reducing hunting and improving containment compared with some mechanical throttling devices.Comparison with Constant Air Volume (CAV) fume hoods

Compared to CAV hoods, a properly commissioned variable airflow fume hood can reduce exhaust volumes by 30–70% on average, depending on lab usage patterns. The immediate energy savings are in reduced exhaust fan power and lower heating/cooling loads for make-up air. Studies and guidance on laboratory ventilation and energy use from Lawrence Berkeley National Laboratory explain the magnitude of these savings and design strategies for labs: LBNL - Laboratory Ventilation and Energy Use.

Design and Installation Considerations for VAV Fume Hoods

Sash position, setpoints and user interaction

For a VAV fume hood to save energy while keeping users safe, sash control and setpoints must be clearly defined. Common setpoint strategies include:

- Fixed face velocity: keep a minimum face velocity (e.g., 80–120 ft/min) across opening;

- Occupied/unoccupied setpoints: drop to a low-flow standby when lab is unoccupied;

- Adaptive algorithms: use sash position sensors and predictive control to reduce overshoot.

Integrating clear sash markings and training reduces the risk of user behavior undermining energy savings (e.g., leaving sashes fully open unnecessarily).

Ductwork, pressure control and HVAC integration

VAV fume hoods interact tightly with building HVAC. Key design items include duct sizing for variable flows, plume capture considerations, and control coordination with building air handling units (AHUs). Venturi valve systems help by stabilizing hood flow despite static pressure changes in the duct, making the hood less sensitive to remote AHU operations. ASHRAE's resources and laboratory ventilation recommendations provide useful design guidance: ASHRAE.

Control strategies, monitoring and alarms

Robust control includes sash position sensors, flow measurement, local and building management system (BMS) integration, and alarms for low containment or flow loss. Continuous monitoring of face velocity and periodic containment testing (see ASHRAE 110 test methods) ensures ongoing performance. Automated alarming and remote dashboards improve safety and make energy savings visible to facilities teams.

Performance, Safety and Compliance

Maintaining containment while saving energy

Energy efficiency cannot compromise containment. Variable air volume fume hoods must be engineered and commissioned to maintain required face velocities and capture performance across sash positions. Containment testing during commissioning (such as tracer gas or ASHRAE 110 tests) validates that the VAV control strategy preserves user protection. For standards and laboratory biosafety ventilation guidance, refer to CDC resources: CDC ventilation guidance.

Monitoring, validation and periodic re-commissioning

Install continuous or periodic monitoring to track face velocity, sash position, and duct static pressure. Re-commissioning after changes in lab configuration, HVAC modifications, or observed performance drift is essential. Validation records are also important for regulatory compliance and internal audits.

Applicable regulations and standards

Relevant standards for fume hood performance and laboratory ventilation include ASHRAE publications and consensus test methods such as ASHRAE 110 (Method of Testing Performance of Laboratory Fume Hoods). Complying with local codes, institutional biosafety requirements, and national standards is required—aligning VAV hood design with those requirements ensures both safety and energy benefits. Consult your regulatory authority and applicable institutional policies when specifying equipment.

Calculating Energy Savings and Return on Investment

Typical savings and a simple case study

Energy savings from replacing a CAV hood with a variable air volume fume hood depend on number of hours of use, average sash position, climate (heating vs cooling load), and HVAC system efficiency. Below is a simplified example calculation for one hood.

| Parameter | CAV Hood | VAV Hood (Average) | Notes |

|---|---|---|---|

| Average exhaust flow (ft3/min) | 1,200 | 600 | Assumes 50% average reduction |

| Annual operating hours | 8,760 (continuous) | ||

| Fan power (kW) | 2.0 | 0.5 | Estimated: fan power scales cubically with flow, but real systems vary |

| Annual energy use (kWh) | 17,520 | 4,380 | Fan energy only |

| Annual fan energy savings (kWh) | 13,140 | ||

When conditioned makeup air is included (heating/cooling the makeup air), total HVAC energy savings can be 2–4 times the fan energy savings depending on climate and utility costs. The Lawrence Berkeley National Laboratory report linked earlier provides modeling details for labs and shows how makeup air typically dominates energy use in laboratory buildings: LBNL report.

ROI example table

| Item | Value |

|---|---|

| Incremental installed cost for VAV hood vs CAV | $5,000 |

| Annual HVAC energy savings (estimated) | $2,500 |

| Simple payback | 2 years |

Actual costs vary widely. Use site-specific measured sash-open profiles, local energy tariffs, and HVAC efficiencies to refine payback estimates. A conservative modeling approach and measured commissioning data will help validate performance and savings.

Maintenance, lifecycle and non-energy benefits

Maintenance for Venturi valve systems and modern VAV controllers tends to be low compared to mechanical dampers because there are fewer moving parts and the devices respond quickly to control inputs. Non-energy benefits include improved air quality, reduced noise, and better occupant comfort. Faster response times and stable control also reduce the risk of transient containment failures during HVAC pressure changes.

Implementation Checklist for Facility Managers

Procurement and specification tips

- Specify the face velocity setpoint range, sash sensor type, and BMS integration requirements.

- Require Venturi valve or equivalent stable flow control for hood banks subject to duct pressure fluctuations.

- Ask for factory pre-testing and site acceptance testing (including ASHRAE 110 or tracer gas tests).

Commissioning and validation

- Commission sash interlocks, flow control, and alarms. Document baseline and post-installation performance.

- Implement continuous or periodic monitoring of face velocity and sash position. Include a protocol for re-commissioning after lab changes.

User training and lab policies

- Train lab personnel on sash behavior for containment and energy savings.

- Post clear sash usage instructions and visible face velocity indicators where appropriate.

Frequently Asked Questions (FAQ)

Will a Variable Air Volume Fume Hood compromise safety?

No—when properly designed, commissioned, and maintained, VAV fume hoods maintain containment equivalent to CAV hoods. Validation through ASHRAE 110 testing or tracer gas testing and continuous monitoring ensures safety remains primary.

How much energy can I expect to save?

Savings vary by usage profile and climate. Typical savings range from 30% to 70% of exhaust-related energy compared to CAV hoods. Including makeup air savings, total HVAC energy reductions can be several times the fan energy savings. Use measured sash profiles and a site-specific energy model to estimate precise savings.

What is the role of the Venturi valve in a VAV system?

Venturi valves provide stable, fast-responding flow control that compensates for duct static pressure changes. They improve control stability and reduce hunting, which helps both safety and energy performance. The MAX LAB Venturi Valve Air Velocity Control System is an example of such a solution, delivering fast response times and low maintenance.

How often should VAV hoods be re-commissioned?

Re-commission after any major HVAC change, lab renovation, or if monitoring shows performance drift. As a best practice, perform routine verification annually and a full re-commissioning every 3–5 years or per institutional policy.

Can VAV hoods be retrofitted into existing labs?

Yes—many existing systems can be upgraded to VAV control with minimal disruption, especially when Venturi-based flow control and modern sash sensors are used. A site survey and HVAC impact analysis are required to determine feasibility and estimated savings.

For more detailed product information, commissioning guidance, or a custom ROI analysis for your facility, contact our lab solutions team or view the Variable Air Volume Fume Hood product page. Our experts can provide specification templates, integration support, and commissioning packages tailored to your laboratory's needs.

References: ASHRAE (for standards and guidance) https://www.ashrae.org/; LBNL laboratory ventilation and energy use report https://eta-publications.lbl.gov/sites/default/files/lbnl-44061.pdf; CDC ventilation guidance https://www.cdc.gov/coronavirus/2019-ncov/community/ventilation.; Fume hood overview on Wikipedia https://en.wikipedia.org/wiki/Fume_hood.

Contact us to schedule a demo or request technical specifications for the Variable Air Volume Fume Hood with MAX LAB Venturi Valve Air Velocity Control System—email sales@yourlabcompany.com or call +1-800-555-0199.

Sustainability and Certifications to Require for Lab Countertops

Ergonomic Principles in Lab Furniture Design

Custom Fume Hood Configurations for Specialized Laboratory Needs

Lab Sink Cabinet Buying Guide: Materials, Sizes, and Features

For Products

Do you offer ergonomic solutions for lab furniture?

Yes, our laboratory furniture includes ergonomic designs such as height-adjustable lab benches and chairs that reduce strain during long hours of work.

Can your furniture withstand heavy-duty use?

Yes, all of our laboratory furniture focuses on durability, with a load-bearing capacity of up to 500KG/m², and is made of high-quality materials that can meet the requirements for large-scale precision instruments and equipment and exposure to chemicals in the laboratory.

Customization

What is the after-sales support for customized services?

We provide a full range of after-sales service, including equipment installation guidance, regular maintenance, troubleshooting, operation training, etc., to ensure the safe and efficient operation of equipment.

Does the customized equipment have a warranty?

Yes, all custom equipment comes with a warranty. Specific warranty terms are determined according to the type of equipment and customized content.

About Solution

Do you have certifications for your products?

Yes, We have CE CERTIFICATIONS, Quality Management Systems Certificate ISO9001:2008 and Environmental Management Systems Certificate ISO14000:2004, etc.

Variable Air Volume Fume Hood

Optimize airflow regulation and ensure precise laboratory ventilation with MAX LAB Venturi Valve Air Velocity Control System. Designed for high-performance air pressure control, this system automatically adjusts to changes in duct static pressure, maintaining stable and energy-efficient air velocity management. Ideal for laboratories, cleanrooms, and healthcare facilities, it provides fast response times, low maintenance, and superior contaminant control. Our Venturi valve system enhances HVAC efficiency, improves air quality, and ensures compliance with critical environment safety standards.

Floor Mounted Lab Bench

Our Floor Mounted Lab Bench is an essential, high-efficiency workspace for laboratories, made from high-quality steel-wood or corrosion-resistant stainless steel materials to ensure exceptional durability and stability. The unique floor-mounted design effectively reduces vibration, optimizes space usage, and provides a safe and tidy laboratory environment.

Customizable storage solutions help organize lab equipment efficiently, while the easy-to-clean surface maintains laboratory hygiene. It is widely suitable for research institutions, educational laboratories, and the chemical and pharmaceutical industries.

Fume Hood

The fume hood provides safe ventilation to protect against exposure to hazardous or toxic fumes, vapors, or airborne particulate. It is primarily used in laboratory and manufacturing applications to protect the user or environment outside the hood, but can also be used to protect the materials or experiment under the hood.

APPLICATION

Chemistry Lab, physics Lab, biological analysis, pharmaceutical medicine analysis, biological pharmaceutical, plant culture, environmental testing and electronic instrumentation scientific research and so on.

Flammable Storage Cabinet

Safety Cabinets store flammable liquids, corrosives, pesticides and other hazardous materials. All fire-resistant safety cabinets by meet fire codes and regulations for safety storage.

To help protect your people and facility from a potential fire, safety cabinets are engineered to safely contain flammable fuels, solvents, and chemicals. Safety cabinets can not only help everyone store chemicals reasonably, save chemical supplies, but also save human resources, and avoid fires caused by chemicals with the greatest strength.

Scan QR Code

Scan QR Code

MaxLabFurniture

MaxLab Furniture

daihongada

Max Laboratory