Choosing a Variable Air Volume Fume Hood: Buyer Checklist

- Why a Variable Air Volume Fume Hood Makes Sense

- What differentiates VAV from CAV fume hoods?

- Energy and environmental benefits

- Technical and Performance Checklist

- Containment performance and face velocity

- Control stability: Venturi valve vs. other actuators

- Airflow monitoring and alarms

- Controls, Integration and Installation Considerations

- HVAC and building integration

- Commissioning, testing and validation

- Physical installation and footprint

- Maintenance, Lifecycle Costs and ROI

- Operation and maintenance requirements

- Estimating lifecycle cost and payback

- Documentation and training

- Comparisons, Standards and Risk Management

- VAV vs CAV: quick comparison

- Applicable standards and guidance

- Risk assessment and emergency behavior

- Practical Buyer Checklist (Actionable Items)

- FAQs

- Q: Are variable air volume fume hoods safe for all lab applications?

- Q: How much energy can I realistically save with a VAV fume hood?

- Q: What maintenance is required for a Venturi valve-based system?

- Q: How do I verify containment after installation?

- Q: Can a VAV fume hood integrate with my building automation system?

Choosing a variable air volume fume hood is a critical decision for modern laboratories that must balance containment, occupant safety, and energy efficiency. This guide focuses on what buyers need to evaluate—performance metrics (face velocity, containment), control strategies (VAV with Venturi valve and pressure regulation), HVAC integration, maintenance needs, and compliance with standards—to ensure the selected Variable Air Volume Fume Hood meets operational requirements and reduces total cost of ownership.

Why a Variable Air Volume Fume Hood Makes Sense

What differentiates VAV from CAV fume hoods?

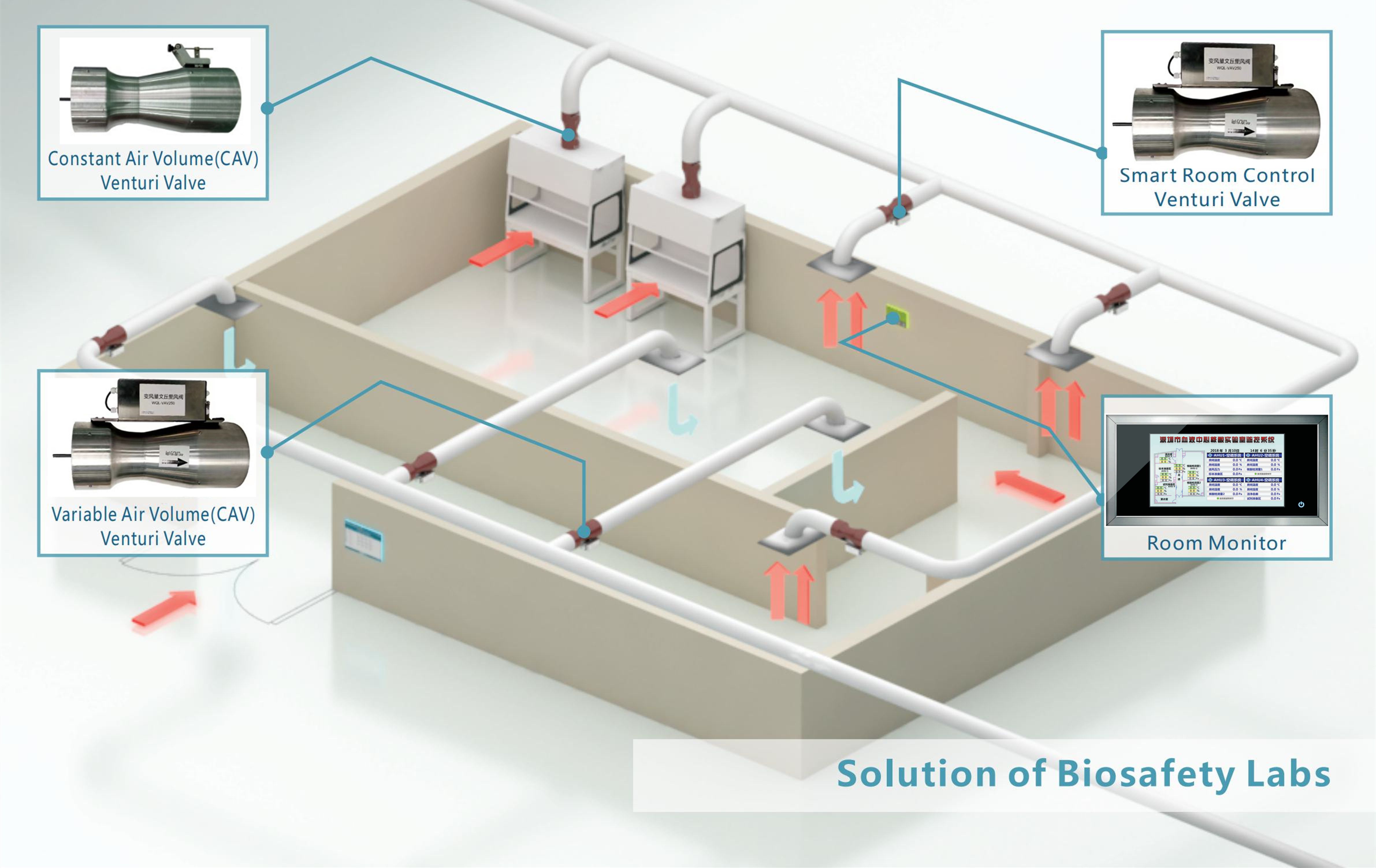

Variable air volume fume hoods (VAV fume hoods) adjust exhaust airflow in response to the sash position and disturbance conditions, unlike constant air volume (CAV) hoods that continually exhaust a fixed airflow. VAV control reduces fan energy and HVAC conditioning load when hoods are not fully open, enabling large energy savings in labs with intermittent use. For more on airflow control principles, see the VAV overview on Wikipedia.

Energy and environmental benefits

Because VAV systems reduce conditioned air being pulled from the lab and exhausted, they directly lower heating and cooling loads. When combined with efficient control devices such as Venturi valves, the system can maintain precise face velocity while minimizing power draw—improving sustainability and reducing facility operating costs.

Technical and Performance Checklist

Containment performance and face velocity

Containment is the top priority. Verify the hood achieves stable face velocity across sash positions and resists disturbances (walking by, doors opening). Typical target average face velocities are in the 80–120 fpm (0.4–0.6 m/s) range depending on local policy, but always follow your institution’s safety requirements. Performance should be validated per accepted test methods such as the ANSI/ASHRAE 110 test for fume hood performance; see ASHRAE resources.

Control stability: Venturi valve vs. other actuators

Venturi valve designs, like the MAX LAB Venturi Valve Air Velocity Control System, automatically adjust to duct static pressure changes and maintain stable air velocity. This reduces oscillation and hunting common with simple modulating dampers. Key control criteria to check:

- Fast response to sash movement and duct pressure change

- Minimal overshoot and steady-state error for face velocity

- Built-in fail-safe modes (closed sash, loss of signal)

Airflow monitoring and alarms

Ensure the hood includes or integrates with continuous airflow monitoring, local indicators (digital readouts), and remote alarms to notify lab personnel of low-flow or high-flow conditions. Look for features such as sash-position interlocks, calibration capability, and trend logging for audit and commissioning records.

Controls, Integration and Installation Considerations

HVAC and building integration

VAV fume hoods must be integrated into the building management system (BMS) for coordinated lab ventilation control. Confirm the hood's control outputs (analog/digital) and communication protocols (BACnet, Modbus, etc.) are compatible with your BMS. Also verify duct static pressure control strategies—Venturi valve systems automatically compensate for changes in duct static pressure, which simplifies commissioning and reduces rebalancing frequency.

Commissioning, testing and validation

Plan for commissioning using an ANSI/ASHRAE 110 test or your institution’s equivalent. Commissioning should include airflow balancing, face velocity mapping across sash positions, tracer gas or smoke containment checks, and verification of alarm limits and BMS integration. Reference authoritative lab safety guidance from the CDC and workplace safety expectations at OSHA Laboratory Safety.

Physical installation and footprint

Check ceiling height, duct routing, and make-up air supply capacity. Venturi valve systems reduce the need for frequent damper adjustments, but they still require appropriate duct sizes and backpressure allowances. Confirm clearances for maintenance access and whether the hood's casework and chemical-resistant finishes match your lab’s needs.

Maintenance, Lifecycle Costs and ROI

Operation and maintenance requirements

Review maintenance schedules for mechanical valves, sensors, and actuators. A well-designed Venturi valve system typically offers lower maintenance than complex variable-speed fans because it provides simple mechanical regulation with fewer moving parts in the fan train. Confirm spare parts availability and whether local service providers are trained on the specific control system.

Estimating lifecycle cost and payback

When evaluating procurement, consider total cost of ownership (TCO): initial equipment cost, HVAC energy savings, maintenance, and facility retrofit expenses. Typical energy savings for VAV fume hoods versus CAV can range from 30% to 70% of hood-related HVAC load depending on lab usage patterns. Use actual local energy costs and usage schedules to model payback.

Documentation and training

Require complete documentation (operation manuals, control diagrams), training for facilities staff, and commissioning reports. Check warranty terms and service level agreements for remote or on-site support.

Comparisons, Standards and Risk Management

VAV vs CAV: quick comparison

| Feature | Variable Air Volume (VAV) | Constant Air Volume (CAV) |

|---|---|---|

| Energy efficiency | High — reduces flow when unused | Low — constant exhaust regardless of use |

| Control complexity | Higher — requires sophisticated control & commissioning | Lower — simpler controls |

| Containment stability | Dependent on control quality; Venturi valves improve stability | Generally stable if properly balanced |

| Maintenance | Moderate — sensors and actuators to maintain | Low — fewer control components |

Applicable standards and guidance

Design and acceptance should reference relevant standards and best practices—include ANSI/ASHRAE test methods (e.g., ASHRAE), laboratory biosafety guidance from the CDC, and OSHA laboratory safety guidance at OSHA. Adhering to recognized standards helps demonstrate compliance during audits and inspections.

Risk assessment and emergency behavior

Ensure the VAV hood has defined fail-safe states (e.g., default to safe maximum flow or shut sash interlock) and that emergency response integrates with building safety procedures. Check how the system behaves during power loss, fire alarm activation, or duct blockage scenarios.

Practical Buyer Checklist (Actionable Items)

- Performance: Confirm ANSI/ASHRAE 110 or equivalent containment test results for multiple sash positions.

- Control: Require Venturi valve or equivalent pressure-compensating device and verify response time and stability.

- Monitoring: Include continuous airflow monitoring, digital readouts, BMS integration, and alarm thresholds.

- Compatibility: Ensure communication protocols and signal types match your BMS (BACnet, Modbus, 0–10 V, etc.).

- Maintenance: Obtain maintenance schedule, spare parts list, and local service capability.

- Documentation: Verify operation manuals, calibration procedures, and commissioning reports will be provided.

- Standards: Request documentation of compliance testing and reference to ASHRAE/ANSI methods and OSHA/CDC guidance.

- Lifecycle Costing: Run a TCO model including energy savings projections, using local energy tariffs and typical hood duty cycles.

Product snapshot: include the following introductory product description in your procurement specifications to communicate the expected control performance and capabilities:

Optimize airflow regulation and ensure precise laboratory ventilation with MAX LAB Venturi Valve Air Velocity Control System. Designed for high-performance air pressure control, this system automatically adjusts to changes in duct static pressure, maintaining stable and energy-efficient air velocity management. Ideal for laboratories, cleanrooms, and healthcare facilities, it provides fast response times, low maintenance, and superior contaminant control. Our Venturi valve system enhances HVAC efficiency, improves air quality, and ensures compliance with critical environment safety standards.

FAQs

Q: Are variable air volume fume hoods safe for all lab applications?

A: VAV fume hoods can be safe and effective across many lab environments when properly specified, commissioned, and maintained. Certain high-risk or continuously used processes might still favor constant flow systems or require additional containment strategies. Risk assessment and adherence to standards such as ANSI/ASHRAE test methods are essential.

Q: How much energy can I realistically save with a VAV fume hood?

A: Savings depend on usage patterns. Labs with intermittent or part-time sash use typically see the largest reductions—30% to 70% reduction in hood-related HVAC energy is possible. Model with actual local energy costs and duty cycles for accurate payback estimates.

Q: What maintenance is required for a Venturi valve-based system?

A: Maintenance is usually periodic inspection, cleaning, and sensor calibration. Venturi valves are mechanically simple compared with variable-speed fan trains, often resulting in lower maintenance overhead. Confirm manufacturer-recommended intervals and local service capability.

Q: How do I verify containment after installation?

A: Commissioning should include face velocity checks at multiple sash positions, tracer gas or smoke testing per ANSI/ASHRAE 110, and verification of alarm setpoints and BMS interlocks. Retesting frequency should be defined in your lab management plan.

Q: Can a VAV fume hood integrate with my building automation system?

A: Yes. Most modern VAV systems provide BACnet, Modbus, or analog outputs. Confirm compatibility during procurement and include required communication protocols in the specification.

If you would like detailed specifications, a site evaluation, or to see how the Variable Air Volume Fume Hood with MAX LAB Venturi Valve system performs in comparable facilities, contact our sales and technical team or view the product datasheet. Request a demo, commissioning support, or an energy-savings analysis to evaluate ROI for your facility.

Contact us: For pricing, specifications, or to schedule a consultation, please contact our sales team or visit the product page.

References:

Reduce measurement errors with laboratory table BT-03 solutions

Top 10 Laboratory furniture Manufacturers and Supplier Brands in 2026

Lab Bench Configurations Ideal for Chemistry and Biology Labs

Ergonomic Considerations for Lab Benches to Reduce Fatigue

Customization

Can equipment be customized to specific experimental safety standards?

Yes. We offer customized equipment to specific safety standards, such as ANSI/ASHRAE standards, UL certification and ISO safety standards.

FAQS

Do you offer custom design services?

Yes, we provide full design support tailored to your lab’s specific needs, including layout planning and furniture customization.

For Company

About Solution

Do you have certifications for your products?

Yes, We have CE CERTIFICATIONS, Quality Management Systems Certificate ISO9001:2008 and Environmental Management Systems Certificate ISO14000:2004, etc.

Variable Air Volume Fume Hood

Optimize airflow regulation and ensure precise laboratory ventilation with MAX LAB Venturi Valve Air Velocity Control System. Designed for high-performance air pressure control, this system automatically adjusts to changes in duct static pressure, maintaining stable and energy-efficient air velocity management. Ideal for laboratories, cleanrooms, and healthcare facilities, it provides fast response times, low maintenance, and superior contaminant control. Our Venturi valve system enhances HVAC efficiency, improves air quality, and ensures compliance with critical environment safety standards.

Floor Mounted Lab Bench

Our Floor Mounted Lab Bench is an essential, high-efficiency workspace for laboratories, made from high-quality steel-wood or corrosion-resistant stainless steel materials to ensure exceptional durability and stability. The unique floor-mounted design effectively reduces vibration, optimizes space usage, and provides a safe and tidy laboratory environment.

Customizable storage solutions help organize lab equipment efficiently, while the easy-to-clean surface maintains laboratory hygiene. It is widely suitable for research institutions, educational laboratories, and the chemical and pharmaceutical industries.

Fume Hood

The fume hood provides safe ventilation to protect against exposure to hazardous or toxic fumes, vapors, or airborne particulate. It is primarily used in laboratory and manufacturing applications to protect the user or environment outside the hood, but can also be used to protect the materials or experiment under the hood.

APPLICATION

Chemistry Lab, physics Lab, biological analysis, pharmaceutical medicine analysis, biological pharmaceutical, plant culture, environmental testing and electronic instrumentation scientific research and so on.

Flammable Storage Cabinet

Safety Cabinets store flammable liquids, corrosives, pesticides and other hazardous materials. All fire-resistant safety cabinets by meet fire codes and regulations for safety storage.

To help protect your people and facility from a potential fire, safety cabinets are engineered to safely contain flammable fuels, solvents, and chemicals. Safety cabinets can not only help everyone store chemicals reasonably, save chemical supplies, but also save human resources, and avoid fires caused by chemicals with the greatest strength.

Scan QR Code

Scan QR Code

MaxLabFurniture

MaxLab Furniture

daihongada

Max Laboratory