Sustainability and Certifications to Require for Lab Countertops

- Sustainability and Certifications to Require for Lab Countertops

- Why sustainability matters for lab countertops

- Key sustainability goals to consider for Lab Countertops

- Common lab countertop materials and their sustainability profiles

- Certifications and standards to require (what they mean and why they matter)

- How certifications change procurement, risk and lifecycle cost

- Practical steps to verify supplier sustainability claims

- Specifying sustainability and certifications in RFPs and lab design specs

- Why choose Max Lab's Lab Countertops for sustainable labs

- Max Lab’s sustainability differentiators

- Implementation checklist and maintenance best practices

- Frequently Asked Questions (FAQ)

- Q1: Which certification is most important for indoor air quality?

- Q2: Should I prefer stainless steel or epoxy for a chemistry lab?

- Q3: Can a countertop with certifications still fail in a real lab?

- Q4: How do certifications affect LEED scores?

- Q5: What documentation should I ask for before purchase?

- Contact and product CTA

- Authoritative references and further reading

Sustainability and Certifications to Require for Lab Countertops

Why sustainability matters for lab countertops

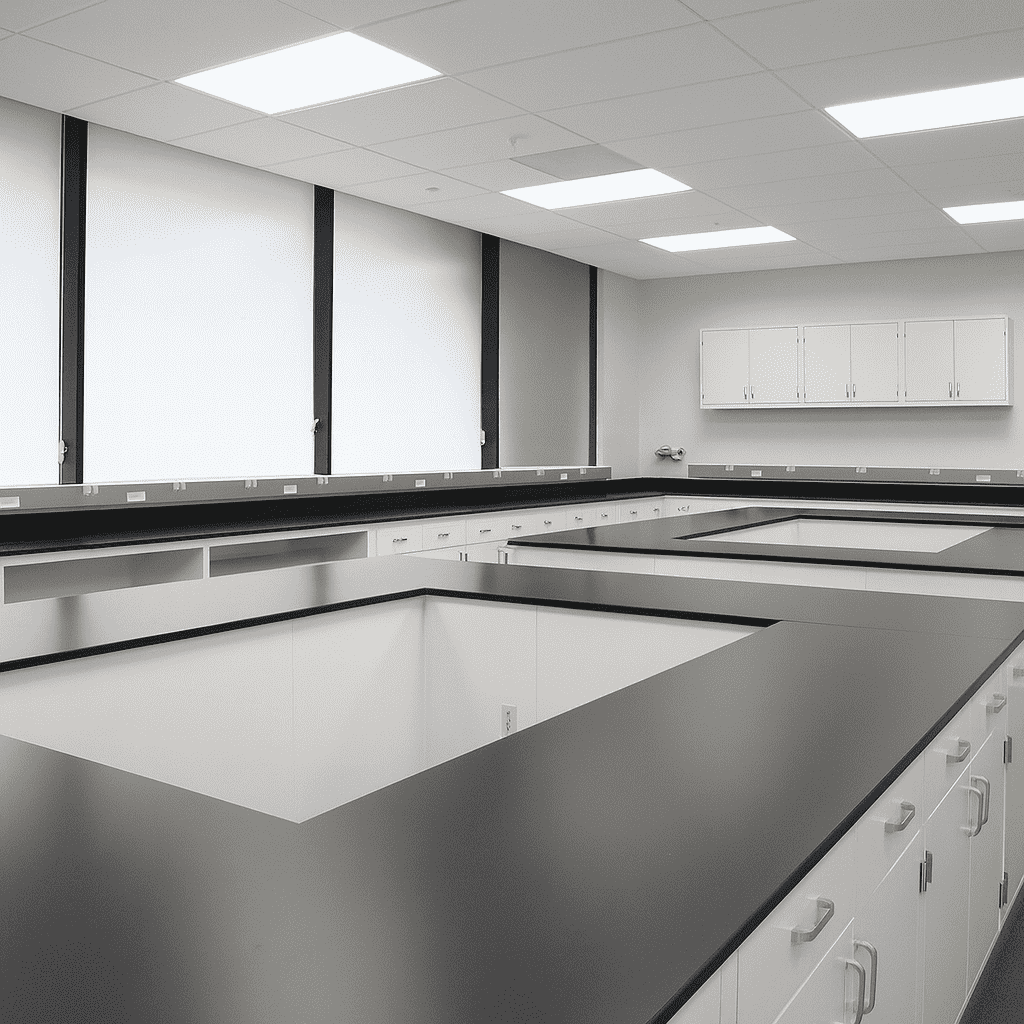

When designing or renovating laboratories, the choice of a lab countertop is not only a performance decision but also an environmental and health decision. A lab countertop sits at the interface of chemicals, biological agents, thermal loads and people — so material durability, emissions, recyclability and the manufacturer’s environmental practices matter. Specifying sustainable, certified lab countertops reduces long‑term cost through longevity, lowers indoor chemical exposure, helps meet institutional sustainability goals (LEED, WELL), and simplifies regulatory compliance for handling hazardous substances.

Key sustainability goals to consider for Lab Countertops

Before selecting material or vendor, clarify priorities. Typical goals include:

- Low indoor emissions (VOCs, residual monomers) to protect lab users and sensitive instruments.

- Durability and chemical resistance to avoid frequent replacement and prevent contamination.

- Recycled content and end‑of‑life recyclability to reduce embodied carbon.

- Manufacturer environmental management (ISO 14001) and supply‑chain chemical controls (REACH, RoHS).

- Third‑party certification to provide independent verification of claims.

Common lab countertop materials and their sustainability profiles

Different materials bring different tradeoffs between performance and sustainability. The following table summarizes typical characteristics for the materials most often specified for lab worktops.

| Material | Chemical resistance | Heat resistance | VOCs & emissions | Recyclability / End‑of‑life | Typical certifications / compliance |

|---|---|---|---|---|---|

| Epoxy resin (cast) | High (most acids, bases, solvents) | Moderate (can char at high temps) | Low after cure; some VOCs during manufacture/repair | Limited recyclability; long service life reduces lifetime impact | Manufacturer test data, sometimes GREENGUARD or internal QA |

| Phenolic resin (high‑pressure) | Very good to water/aqueous chemistry and cleaners | Good for moderate heat | Generally low emissions once fully cured | Limited; durable so fewer replacements | Often used in cleanrooms; supplier compliance to REACH/RoHS |

| Stainless steel (304/316) | Excellent (corrosion‑resistant grades for corrosive labs) | Very high | Zero VOCs in service; fabrication may involve coatings | Highly recyclable (high scrap value) | Recycled content documentation; material standards (ASTM) |

| Epoxy/engineered granite | High (abrasion & many chemicals) | High | Low after cure; manufacturing emissions vary | Limited recyclability; long life | Manufacturer test data; possible GREENGUARD/LEED credits |

| Ceramic / Vitrified surfaces | Excellent (inert to most chemicals) | Excellent | Very low emissions in use | Can be recycled as inert material; heavy to transport | Material standards; low‑emitting product claims |

| Solid surface / Quartz | Good, but some solvents can etch | Moderate | Variable; some products have low VOC certification | Challenging to recycle; some manufacturers offer take‑back | GREENGUARD, manufacturer lifecycle data |

Certifications and standards to require (what they mean and why they matter)

When evaluating suppliers, ask for documentation for the following certifications and standards. Each addresses a different sustainability or safety dimension.

- ISO 14001 — Environmental management system. Demonstrates the manufacturer has systematic processes to reduce environmental impacts across production and supply chain. Useful when an institution requires supplier EMS certification.

- GREENGUARD / UL GREENGUARD Gold — Certification for low chemical emissions (VOCs). Important for indoor air quality in labs, especially where sensitive instruments or long occupant exposure exist.

- LEED credits (USGBC) — While not a product certification, some countertop choices can help projects earn LEED points (low‑emitting materials, recycled content, regional materials). Suppliers should provide documentation to support LEED submissions.

- REACH / RoHS compliance — Chemical regulatory compliance (EU‑centric). REACH confirms restricted substances are managed; RoHS limits hazardous substances in materials and components. Useful for international procurement and for institutional policies that forbid certain chemicals.

- BIFMA e3 / Furniture sustainability standards — Though traditionally for office furniture, BIFMA’s e3 attributes can apply when countertops integrate with lab casework; they evaluate material sourcing, product life cycle and social responsibility.

- Cradle to Cradle (C2C) — Assesses material health, product circularity and manufacturing impacts. Relevant when institutions seek high circularity and safe material chemistry.

- ASTM & EN test standards — Look for third‑party test reports for chemical resistance, abrasion, flame spread, and mechanical properties to confirm manufacturer claims for lab conditions.

- Third‑party chemical resistance testing — Independent lab reports showing resistance to common reagents used in your lab (acids, bases, solvents) are critical, especially for chemistry labs.

How certifications change procurement, risk and lifecycle cost

Requiring certifications shifts procurement from price‑only decisions to risk‑informed lifecycle choices:

- Certified low‑emitting materials reduce indoor air quality risks and potential instrument interference, lowering health and maintenance costs.

- Environmental management certifications (ISO 14001) and regulatory compliance (REACH/RoHS) reduce supply‑chain risk, particularly for large facilities that must meet institutional procurement policies.

- Durable materials with proven chemical resistance increase mean time between replacements; even if initial cost is higher, total cost of ownership (TCO) often falls.

- Documentation supporting LEED or sustainability reporting helps institutions meet carbon and ESG reporting goals.

Practical steps to verify supplier sustainability claims

Not all claims are equal. Follow a short verification checklist before contract award:

- Request copies of certifications (PDFs) and confirm they are current and issued to the manufacturing site that produces the countertops.

- Ask for independent third‑party test reports for chemical resistance, VOC emissions, and mechanical properties relevant to your lab use cases.

- Require an environmental product declaration (EPD) or product data sheet showing recycled content, material composition, and cradle‑to‑gate impacts where available.

- Confirm manufacturer quality controls — ISO 9001 and ISO 14001 are strong indicators of consistent production and environmental stewardship.

- Include warranty language specifying service life and performance under defined laboratory conditions to align incentives.

Specifying sustainability and certifications in RFPs and lab design specs

When writing specifications or RFPs, be explicit. Example specification items to include:

- Material performance requirements (list required chemical resistance testing, maximum surface absorption, thermal limits).

- Required certifications: e.g., manufacturer ISO 14001, product GREENGUARD Gold or equivalent, REACH/RoHS compliance statement, and any regional requirements.

- Documentation deliverables: EPD, material safety data sheets (MSDS/SDS) for components, third‑party test reports.

- Warranty expectations and acceptability criteria for discoloration, chemical attacks and delamination.

- Installation and maintenance requirements to maintain warranties and sustainable performance.

Why choose Max Lab's Lab Countertops for sustainable labs

One-Stop Custom Lab Worktops Built for Real Lab Conditions

Choose the right countertop material for your chemical, biology, cleanroom, or teaching lab. Max Lab provides full customization—sizes, cutouts, sinks, edges, and integration with lab furniture systems.

Max Lab’s Lab Countertops are designed for demanding lab environments and procurement processes that require documented sustainability. We supply material performance data, third‑party test reports, and compliance statements (REACH/RoHS) on request. Our manufacturing partners work under environmental management programs and can provide EPDs or GREENGUARD documentation where available. Because we fabricates to order, we reduce overproduction and can optimize material usage to minimize waste.

Max Lab’s sustainability differentiators

- Material expertise: recommendations matching lab chemistry to the correct countertop material to avoid early failures and replacements.

- Documentation and transparency: supply of test reports, certifications and lifecycle data to support procurement and LEED/WELL submissions.

- Customization and integration: precise cutouts and integrated sinks reduce secondary on‑site modifications (lower waste and risk).

- Warranty and support: performance warranties tied to correct maintenance routines, and guidance to extend service life.

Implementation checklist and maintenance best practices

Even the best countertop needs appropriate installation and care:

- Verify substrate support and leveling during installation to prevent stress and cracking.

- Use manufacturer‑approved adhesives and sealants with documented low emissions.

- Provide a maintenance schedule: approved cleaners, frequency, and guidance for spill response to extend life.

- Document repairs and chemical exposures during the warranty period to maintain coverage.

- Plan end‑of‑life: identify whether the manufacturer offers take‑back, or how the material should be disposed or recycled.

Frequently Asked Questions (FAQ)

Q1: Which certification is most important for indoor air quality?

A1: GREENGUARD or UL GREENGUARD Gold are widely used for low emissions and are directly relevant to indoor air quality. For labs with sensitive instruments or prolonged occupant exposure, require GREENGUARD documentation or equivalent low‑emitting product test reports.

Q2: Should I prefer stainless steel or epoxy for a chemistry lab?

A2: Both are valid choices depending on the chemistry and workflow. Stainless steel is highly heat resistant, recyclable and inert for many applications, but can corrode with halogenated acids and chlorides unless the correct grade is selected (e.g., 316). Epoxy cast tops offer excellent chemical resistance to a broad range of common reagents and are often preferred in educational and analytical labs. Review third‑party chemical resistance data for the exact reagents you use.

Q3: Can a countertop with certifications still fail in a real lab?

A3: Certifications reduce risk but do not guarantee infinite resistance under all conditions. Performance depends on correct material selection, installation, maintenance and how the material is used (chemical concentration, exposure time, heat spikes). Always match the supplier test matrix to lab reagents and operational conditions.

Q4: How do certifications affect LEED scores?

A4: Product certifications themselves do not automatically award LEED points, but documented low‑emitting materials, recycled content, regional sourcing and manufacturer environmental management systems can contribute to multiple LEED credits. Suppliers should provide documentation to support project submissions.

Q5: What documentation should I ask for before purchase?

A5: Ask for current copies of certifications (ISO 14001, GREENGUARD, etc.), third‑party chemical resistance and VOC test reports, an EPD if available, SDS for constituent materials, and warranty terms. If you have a formal procurement process, require these as mandatory attachments to bids.

Contact and product CTA

Even with proper material and certification, longevity depends on care. Following maintenance protocols that extend lab countertop lifespan helps labs maximize performance and reduce replacement frequency.Ready to specify Lab Countertops that meet your performance and sustainability goals? Contact Max Lab for material recommendations, third‑party test reports, and a customized quotation. Reach our sales and technical team to review chemistry compatibility and documentation requirements.

Authoritative references and further reading

- ISO 14001 — Environmental management systems: https://www.iso.org/iso-14001-environmental-management.

- UL GREENGUARD Certification Program: https://www.ul.com/resources/ul-greenguard-certification-program

- USGBC — LEED rating system: https://www.usgbc.org/leed

- European Chemicals Agency — REACH: https://echa.europa.eu/regulations/reach/understanding-reach

- European Commission — RoHS Directive: https://ec.europa.eu/environment/topics/waste-and-recycling/rohs-directive_en

- BIFMA e3 — Furniture sustainability standard: https://www.bifma.org/standards/e3/

- Cradle to Cradle Certified: https://www.c2ccertified.org/

- ASTM International — Standards: https://www.astm.org/

- OSHA Laboratory Safety Guidance — Chemical Hygiene: https://www.osha.gov/laboratory-safety

- U.S. EPA — Green Building: https://www.epa.gov/greenbuilding

Fume Hood Airflow Testing: Critical Checks Buyers Should Require

Custom Lab Sink Cabinet Features That Improve Workflow

Lab Sink Cabinet Buying Guide: Materials, Sizes, and Features

How to Choose the Right Lab Sink for Your Facility

For After-Sales Support

How about your after sale service?

We will reply you within 24 hours by email or phone.

If we have local agent,we will arrange him to your site within 24 hours to assist you to shoot the problem.

For Customization

Can I make changes to my order once it has been placed?

We offer limited flexibility to make changes to your order after it has been placed. Contact our sales team as soon as possible if you need to make modifications.

For Products

Do you have certifications for your products?

Yes, We have CE, ISO9001, ISO14001, OHSASI18001 and so on.

For Company

Do you offer services internationally?

Yes, we serve clients around the world, including Europe, North America, and Asia. Our international experience enables us to provide solutions that meet local regulations and standards.

Are you a factory or trade company?

Direct factory. We also have our sales and design team to offer better service to our valued customers.

Floor Mounted Lab Bench

Our Floor Mounted Lab Bench is an essential, high-efficiency workspace for laboratories, made from high-quality steel-wood or corrosion-resistant stainless steel materials to ensure exceptional durability and stability. The unique floor-mounted design effectively reduces vibration, optimizes space usage, and provides a safe and tidy laboratory environment.

Customizable storage solutions help organize lab equipment efficiently, while the easy-to-clean surface maintains laboratory hygiene. It is widely suitable for research institutions, educational laboratories, and the chemical and pharmaceutical industries.

Fume Hood

The fume hood provides safe ventilation to protect against exposure to hazardous or toxic fumes, vapors, or airborne particulate. It is primarily used in laboratory and manufacturing applications to protect the user or environment outside the hood, but can also be used to protect the materials or experiment under the hood.

APPLICATION

Chemistry Lab, physics Lab, biological analysis, pharmaceutical medicine analysis, biological pharmaceutical, plant culture, environmental testing and electronic instrumentation scientific research and so on.

Flammable Storage Cabinet

Safety Cabinets store flammable liquids, corrosives, pesticides and other hazardous materials. All fire-resistant safety cabinets by meet fire codes and regulations for safety storage.

To help protect your people and facility from a potential fire, safety cabinets are engineered to safely contain flammable fuels, solvents, and chemicals. Safety cabinets can not only help everyone store chemicals reasonably, save chemical supplies, but also save human resources, and avoid fires caused by chemicals with the greatest strength.

Class II Type A2 Biological Safety Cabinet for Laboratory

The Class II A2 Biological Safety Cabinet is designed to provide superior biosafety and contamination control for laboratories, research facilities, and clinical settings. With 70% air recirculation and 30% air exhaust, this cabinet ensures a safe and efficient work environment while protecting both the user and the samples.

Equipped with advanced features like a HEPA filtration system, motorized front window, and ergonomic design, this cabinet is a must-have for safe and reliable biological research.

Scan QR Code

Scan QR Code

MaxLabFurniture

MaxLab Furniture

daihongada

Max Laboratory