2026 Master Guide: Perfecting Your Station Eye Wash Compliance Strategy

- Executive Summary: Key Takeaways for Safety Managers

- What is Required for Station Eye Wash Compliance?

- Navigating the Regulations: OSHA vs. ANSI Z358.1

- Selecting the Right Station: Plumbed vs. Self-Contained

- The Tepid Water Imperative: Preventing Thermal Injury

- Common Compliance Mistakes to Avoid (Expert Tips)

- Future-Proofing: Smart Monitoring and Budgeting for 2026

- Conclusion & Call to Action

Executive Summary: Key Takeaways for Safety Managers

Station eye wash compliance is a dual responsibility requiring adherence to federal mandates and technical performance standards. To effectively protect your workforce and avoid costly citations, safety managers must master both the legal requirements and the practical engineering of their safety systems.

In this guide, we break down the critical components of a compliant safety strategy:

- Regulatory Dualism: OSHA 1910.151(c) regulations mandate the provision of safety equipment, while ANSI Z358.1 dictates the specific performance metrics.

- The 10-Second Rule: Equipment must be accessible within 10 seconds (roughly 55 feet) of a hazard.

- Tepid Water: Maintaining fluid temperature between 60°F and 100°F is critical to prevent thermal shock during the 15-minute flush.

- Maintenance: Weekly activation is non-negotiable for preventing biofilm and ensuring mechanical function.

What is Required for Station Eye Wash Compliance?

To achieve compliance, a station eye wash must provide a controlled flow of fluid to both eyes simultaneously at a velocity low enough to be non-injurious. It must deliver at least 0.4 gallons per minute (1.5 liters) for a continuous 15-minute cycle.

Meeting emergency eyewash station requirements involves more than just installing a unit; it requires a holistic approach to location, flow rate, and temperature control. A compliant system must satisfy the following criteria:

- Accessibility: Located within 10 seconds of the hazard, on the same level, with an unobstructed path.

- Flow Rate: Minimum 0.4 GPM at 30 psi.

- Activation: Hands-free valve that activates in one second or less and stays open.

- Temperature: Fluid delivered between 60°F and 100°F (16°C - 38°C).

Navigating the Regulations: OSHA vs. ANSI Z358.1

OSHA 1910.151(c) regulations provide the federal mandate for "suitable facilities," while ANSI Z358.1 offers the detailed technical roadmap for achieving that suitability. In essence, OSHA provides the "what" and "why," while ANSI provides the "how."

It is crucial to understand that while OSHA is the enforcing body, they frequently reference ANSI standards during inspections to determine if a facility is compliant. According to the Occupational Safety and Health Administration (OSHA), employers must ensure that suitable facilities for quick drenching or flushing are provided within the work area for immediate emergency use.

Key Documentation Protocols:

- Weekly Checks: specific quick checks for flow and path clearance.

- Annual Inspections: Full ANSI Z358.1 compliance checklist audit.

- Log Retention: Keep records for at least 3 years to demonstrate a history of compliance.

Selecting the Right Station: Plumbed vs. Self-Contained

When choosing between portable vs plumbed eyewash stations, the decision depends heavily on your facility's infrastructure and the permanence of the hazard. Plumbed units offer unlimited water supply but require expensive piping, while portable units offer flexibility but require rigorous maintenance.

At Guangzhou Max Laboratory Equipment Co., Ltd. (MAXLAB), we have spent over 15 years advising clients in more than 60 countries on this exact decision. Our experience suggests that while plumbed units are standard for fixed labs, self-contained units are vital for dynamic industrial sites.

Comparison Guide:

- Plumbed Stations:

- Best For: Permanent laboratories, manufacturing lines.

- Pros: Unlimited water supply, lower daily maintenance.

- Cons: High installation cost, requires tepid water mixing valve.

- Self-Contained (Gravity Fed):

- Best For: Construction sites, remote areas, changing floor plans.

- Pros: Mobile, no plumbing required.

- Cons: Finite water supply (must be refilled), water preservative chemicals required.

Material Matters: For environments handling corrosive chemicals, standard ABS plastic may degrade. We often recommend stainless steel units from our 5,000 m² Guangzhou factory, ensuring durability against harsh vapors.

The Tepid Water Imperative: Preventing Thermal Injury

Tepid water, defined as 60°F to 100°F (16°C - 38°C), is a strict requirement because water outside this range can cause thermal shock or scalding, forcing the user to abort the flush early. A tepid water mixing valve is the engineering control used to blend hot and cold water to this safe range.

Physiological Risks:

- Hypothermia/Shock: Cold water (<60°F) triggers an immediate gasp reflex and eye closure, preventing effective rinsing.

- Chemical Interaction: Hot water (>100°F) can accelerate chemical reactions in the eye or cause scalding.

- Bacterial Growth: Stagnant water in pipes between 68°F and 120°F is a breeding ground for Legionella, making weekly flushing vital.

Strategies for retrofitting older facilities include installing point-of-use thermostatic mixing valves (TMVs) that cut off flow if the cold water supply fails, preventing scalding.

Common Compliance Mistakes to Avoid (Expert Tips)

The most frequent compliance failures are not regarding equipment purchase but regarding daily upkeep and accessibility. A blocked path or a dry pipe is just as dangerous as having no station at all.

Top Violations Checklist:

- Obstruction Hazards: Storing boxes, brooms, or machinery in the "path of travel." The University of Texas at Austin EHS notes that even temporary obstructions violate the 10-second rule.

- The 'Weekly Skip': Failing to activate plumbed units weekly. This leads to sediment buildup and brown water, which can discourage use during an emergency.

- Improper Signage: Relying on faded or small signs. The station must be identified with a highly visible sign recognizable to workers of any language.

- Dust Cover Failure: Leaving nozzles exposed. Airborne contaminants can clog nozzles or be blasted into the eye upon activation.

Future-Proofing: Smart Monitoring and Budgeting for 2026

As we approach 2026, the industry is shifting toward "smart" safety solutions and stricter biological standards. Preparing your budget now for IoT-enabled devices can save thousands in manual inspection costs later.

Trends to Watch:

- IoT Monitoring: New stations can send alerts to a central dashboard when activated or when tank levels are low.

- Biological Standards: Expect stricter regulations on water quality and biofilm prevention.

- Cost Analysis: Retrofitting a tepid water mixing valve is often cheaper than paying a single OSHA fine for non-compliance.

Conclusion & Call to Action

Ensuring your facility meets station eye wash standards is not just about avoiding fines; it is about preserving vision and ensuring workforce trust. From selecting the right ANSI-compliant hardware to implementing a robust weekly maintenance schedule, a proactive strategy is your best defense against injury liability.

With our "Quality First" and "Service First" values, MAXLAB is ready to help you navigate these complexities with our premium range of laboratory safety equipment.

Contact Guangzhou Max Laboratory Equipment Co., Ltd. today via email at ada@maxlabfurniture.com to discuss your specific needs and request a free consultation.

Laboratory Workbench Design: Layout and Workflow

How to Choose the Right Lab Benches for Your Laboratory

Cleaning and Decontamination Best Practices for Lab Benches

Chemical-Resistant Lab Sink Solutions for Safety and Durability

About Solution

What is the corrosion resistance of the laboratory furniture?

Our products are made of high quality corrosion-resistant materials, such as epoxy resin, PP board and stainless steel, which can resist the erosion of various chemicals and prolong the service life of the products.

What is the warranty policy of the product?

We provide 1-3 years warranty service, depending on the product type. Meanwhile, comprehensive after-sales support is provided, including repair and replacement services.

For Customization

Can I customize the size and configuration of my lab furniture?

Yes, we offer full customization for laboratory benches, modular systems, and storage units to meet your specific space and functional needs.

FAQS

How can I request a quote?

Simply contact us or fill out our online form with your project details. Our team will respond promptly with a free quote.

For Products

What are the payment terms?

T/T by our bank account directly, or by the West Union.

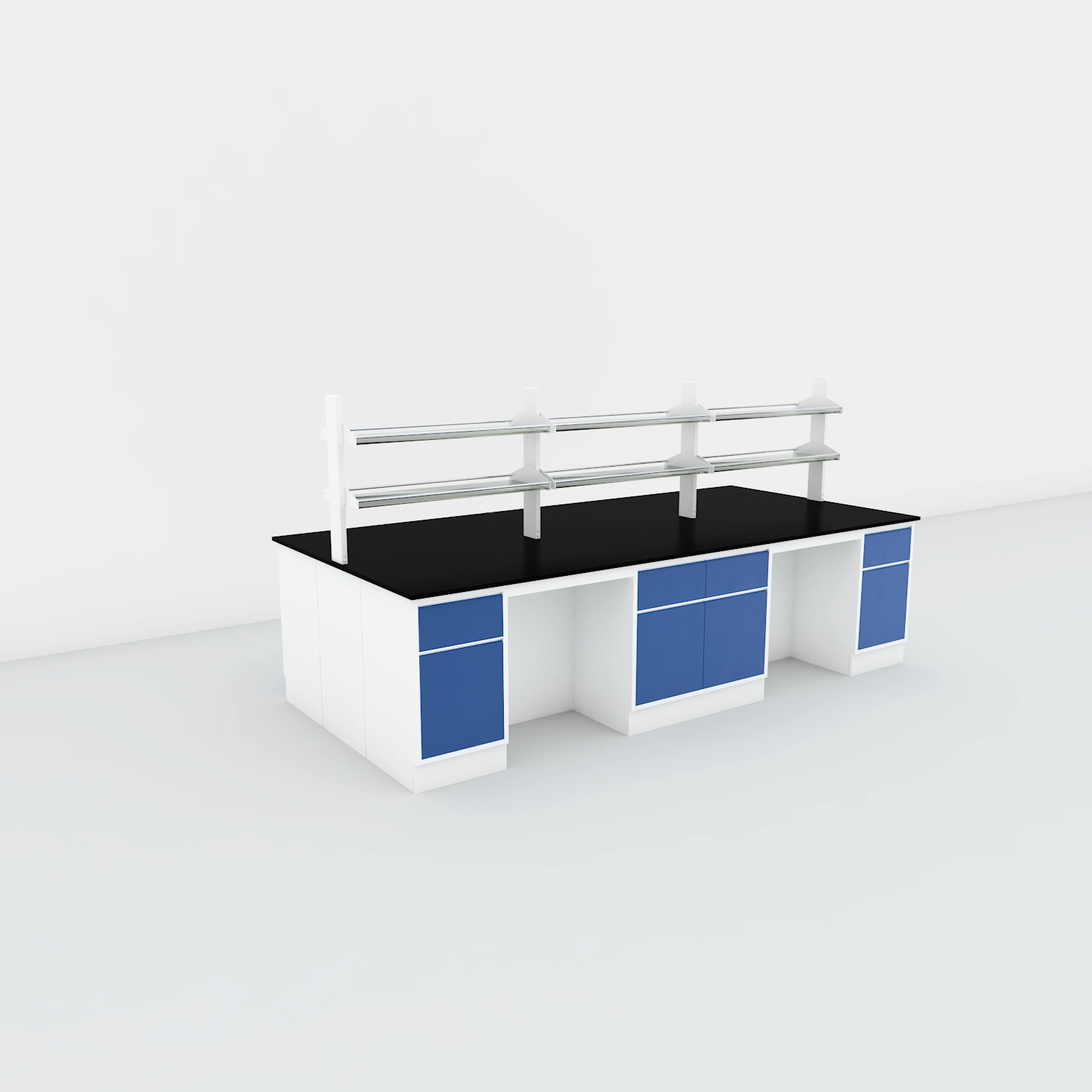

Floor Mounted Lab Bench

Our Floor Mounted Lab Bench is an essential, high-efficiency workspace for laboratories, made from high-quality steel-wood or corrosion-resistant stainless steel materials to ensure exceptional durability and stability. The unique floor-mounted design effectively reduces vibration, optimizes space usage, and provides a safe and tidy laboratory environment.

Customizable storage solutions help organize lab equipment efficiently, while the easy-to-clean surface maintains laboratory hygiene. It is widely suitable for research institutions, educational laboratories, and the chemical and pharmaceutical industries.

Fume Hood

The fume hood provides safe ventilation to protect against exposure to hazardous or toxic fumes, vapors, or airborne particulate. It is primarily used in laboratory and manufacturing applications to protect the user or environment outside the hood, but can also be used to protect the materials or experiment under the hood.

APPLICATION

Chemistry Lab, physics Lab, biological analysis, pharmaceutical medicine analysis, biological pharmaceutical, plant culture, environmental testing and electronic instrumentation scientific research and so on.

Flammable Storage Cabinet

Safety Cabinets store flammable liquids, corrosives, pesticides and other hazardous materials. All fire-resistant safety cabinets by meet fire codes and regulations for safety storage.

To help protect your people and facility from a potential fire, safety cabinets are engineered to safely contain flammable fuels, solvents, and chemicals. Safety cabinets can not only help everyone store chemicals reasonably, save chemical supplies, but also save human resources, and avoid fires caused by chemicals with the greatest strength.

Class II Type A2 Biological Safety Cabinet for Laboratory

The Class II A2 Biological Safety Cabinet is designed to provide superior biosafety and contamination control for laboratories, research facilities, and clinical settings. With 70% air recirculation and 30% air exhaust, this cabinet ensures a safe and efficient work environment while protecting both the user and the samples.

Equipped with advanced features like a HEPA filtration system, motorized front window, and ergonomic design, this cabinet is a must-have for safe and reliable biological research.

Scan QR Code

Scan QR Code

MaxLabFurniture

MaxLab Furniture

daihongada

Max Laboratory