Plumbing and Installation Considerations for Lab Sink Cabinets

- Key Plumbing Requirements for Lab Sink Cabinets

- Water supply and service valves

- Drainage, traps and waste lines

- Ventilation and fume considerations

- Installation Best Practices and Site Preparation

- Pre-installation site survey

- Rough-in and utility coordination

- Mounting types: C-type, floor-mounted and H-type

- Materials, Fixtures and Corrosion Resistance

- Sink and cabinet materials

- Faucets, lab fittings and safety fixtures

- Chemical waste management

- Maintenance, Compliance and Troubleshooting

- Routine maintenance checklist

- Common installation issues and fixes

- Regulatory compliance and documentation

- Practical Examples and Plumbing Scenarios

- Example 1: Teaching lab bench retrofit

- Example 2: Biopharmaceutical QC lab

- Example 3: Chemistry research lab

- Brand Advantages and Choosing the Right Lab Sink Cabinet

- Frequently Asked Questions (FAQ)

- Q1: Can I dispose of chemicals down the lab sink?

- Q2: What sink material is best for a chemistry lab?

- Q3: How do I prevent sink traps from drying out?

- Q4: What documentation should I keep after installation?

- Q5: How do I choose between C-type, floor-mounted and H-type cabinets?

- References and Authoritative Resources

Installing lab cabinets with integrated sinks requires careful coordination between laboratory planners, plumbing contractors and safety officers. This article explains practical plumbing and installation considerations for Lab Sink Cabinet units—covering water service connections, chemical-resistant drains, trap protection, ventilation interfaces, and site preparation—so your laboratory furniture integrates reliably with lab bench systems and meets safety and regulatory expectations. Proper installation must also support compliance, so reviewing safety features to look for in lab sink cabinets is essential.

Key Plumbing Requirements for Lab Sink Cabinets

Water supply and service valves

Reliable, clearly labeled water supply lines are essential for any lab cabinets that include a sink and faucet. Use dedicated cold and hot service valves with backflow prevention where required by local code. Service stops should be easily accessible above the sink or behind an access panel in the cabinet to allow quick isolation during maintenance or emergency shutoff. For labs handling hazardous chemicals, consider installing service valves with tamper-resistant handles and color-coded identification to align with chemical safety protocols.

Drainage, traps and waste lines

Proper drainage is critical to avoid leaks, corrosion and odors. Lab sinks must be connected to a waste system that accommodates the type of effluent (neutral, corrosive, or chemical). A P-trap is required at each sink to prevent sewer gas intrusion; in many installations, a trap primer may be recommended to prevent trap drying in intermittently used sinks. For corrosive waste, use acid-resistant waste lines and specify compatible traps (for example, polypropylene or CPVC components rather than standard galvanized steel).

Ventilation and fume considerations

While lab sink cabinets do not typically house fume hoods, the placement of sinks affects ventilation strategies. Sinks used for rinsing volatile solvents should be located away from open bench areas or under local exhaust ventilation (LEV). Consider positioning sinks near fume hoods or integrating bench-level extraction to capture vapors during operations that generate airborne hazards. Coordination with the lab ventilation engineer ensures sink placement does not disrupt airflows or contaminate adjacent work zones.

Installation Best Practices and Site Preparation

Pre-installation site survey

Before installing lab cabinets, perform a detailed site survey. Verify rough-in locations for domestic water, lab-grade water systems (if required), waste lines, and service chases. Confirm floor level and bench alignment to ensure modular bench systems mate correctly with the Lab Sink Cabinet. Document any deviations from the design drawings and coordinate adjustments with the bench fabricator and plumbing contractor.

Rough-in and utility coordination

Rough-in dimensions must be confirmed prior to cabinet installation. Typical checkpoints include the centerline of water inlets, height of shutoff valves, drain centerline and floor penetration locations. For integrated laboratory bench systems, follow the manufacturer's rough-in guide to ensure seamless integration. Use flexible connectors where slight misalignment is possible, but avoid excessive use as they can increase leak risk. Plan for adequate clearance for under-sink equipment such as neutralization tanks, pump systems or automatic valves.

Mounting types: C-type, floor-mounted and H-type

Lab Sink Cabinet units are available in several mounting/configuration types. Selecting the appropriate type affects plumbing routing and installation complexity.

| Type | Typical Use | Plumbing Considerations | Installation Complexity |

|---|---|---|---|

| C-type | Compact bench runs; integrates between two benches | Requires in-bench routing; water and drain stub-ups through bench panel | Moderate—requires careful alignment with adjacent benches |

| Floor-mounted | Standalone cabinets or islands with full service access | Floor penetrations for waste and water may be required; easier access to under-sink utilities | Lower—easier utility access and maintenance |

| H-type | High-capacity islands or paired sink stations | Often requires centralized plumbing runs and balanced drainage systems | Higher—may need coordination for symmetrical routing and venting |

Choosing between C-type, floor-mounted and H-type configurations affects plumbing access and the need for routing through benches or beneath the floor. Floor-mounted options often simplify maintenance access, while C-type units optimize continuous bench runs.

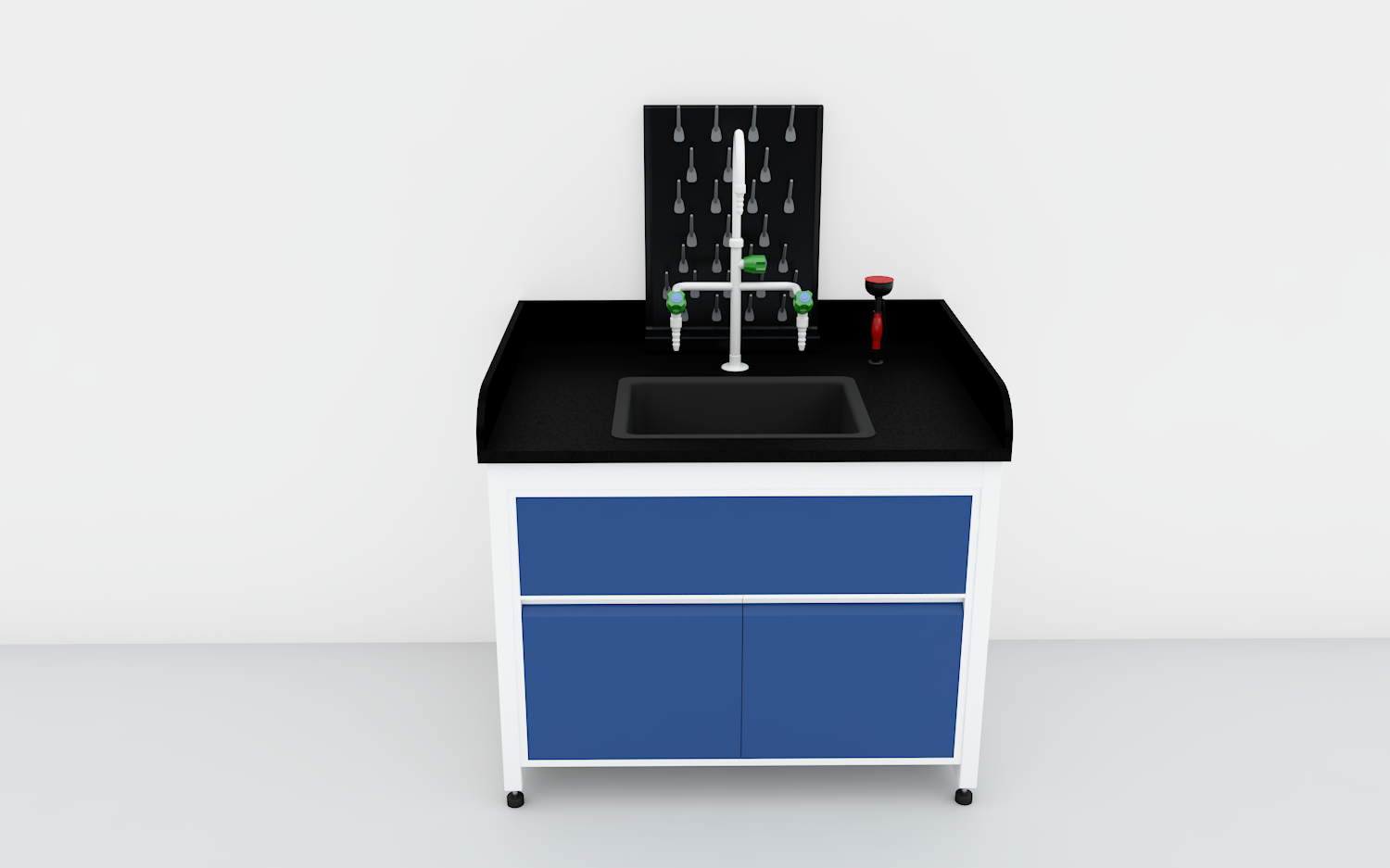

The Lab Sink Cabinet is designed for chemistry labs, teaching labs, biopharmaceutical facilities and testing departments, and can be seamlessly integrated into complete laboratory bench systems. The product offers C-type, floor-mounted and H-type structures, combined with a chemical-resistant lab sink and lab faucet to meet cleaning, rinsing, drainage and temporary storage needs.

Materials, Fixtures and Corrosion Resistance

Sink and cabinet materials

Material selection is driven by the chemicals used in your lab. Common sink materials include stainless steel (304 or 316), epoxy resin, polypropylene and ceramic. For aggressive acids, bases or solvents, epoxy resin or polypropylene sinks offer superior chemical resistance compared to standard stainless steel. Cabinet bodies should be constructed from corrosion-resistant materials or coated with chemical-resistant finishes. Consider internal liners or removable trays for under-sink storage to protect cabinetry from spills.

Faucets, lab fittings and safety fixtures

Lab faucets should be high-quality, durable fixtures rated for lab use. Features to consider include gooseneck vs. swing spout, lever or knee-operated handles for hands-free operation, integrated vacuum breakers and separate service fittings for DI (deionized) water or gas where needed. Emergency fixtures—such as splash shields, eyewash stations near sink areas, and eyewash drench hoses—should be included in the overall lab safety plan and located per regulatory guidance.

Chemical waste management

When sinks will receive chemical waste, coordinate with your environmental health & safety (EHS) team. Many institutions prohibit disposing of hazardous chemicals down lab sinks. Provide neutralization tanks, dedicated chemical waste piping or separate containment systems. Where permitted, use labeled, corrosion-resistant piping and secondary containment under the sink for potential leaks.

Maintenance, Compliance and Troubleshooting

Routine maintenance checklist

Maintain sink function and safety with a routine schedule:

- Inspect under-sink plumbing and connections monthly for leaks and corrosion.

- Test shutoff valves and emergency fixtures quarterly.

- Clean and inspect P-traps and strainers to prevent clogs and chemical buildup.

- Replace worn gaskets, flexible connectors and seals promptly.

Common installation issues and fixes

Typical problems include misaligned rough-ins, slow drainage, and chemical corrosion. Fixes include:

- Use flexible connectors or coupling adjustments to correct minor misalignments.

- Install larger-diameter waste piping or add accessible cleanouts to resolve slow drainage.

- Retrofit under-sink liners or change to corrosion-resistant piping when early corrosion is observed.

Regulatory compliance and documentation

Keep records of installation, manufacturer manuals, and maintenance logs. Follow local plumbing code and laboratory safety requirements. Refer to authoritative guidance such as the Laboratory furniture overview on Wikipedia for general concepts and consult the CDC laboratory biosafety guidance and OSHA laboratory safety standards for safety practices. For plumbing-specific code, check with the International Code Council (ICC) or your local authority having jurisdiction (AHJ) to ensure compliance with the International Plumbing Code or local amendments.

Practical Examples and Plumbing Scenarios

Example 1: Teaching lab bench retrofit

Scenario: A university retrofits a row of benches with C-type Lab Sink Cabinets to add multiple sinks for teaching sections. Requirements include quick shutoffs, durable sinks for frequent student use, and minimal downtime during semester breaks. Solution: Use floor-mounted service manifolds with clearly labeled shutoffs above bench height, epoxy resin sinks for chemical resistance, and removable sink strainers for easy cleaning.

Example 2: Biopharmaceutical QC lab

Scenario: A QC lab requires sinks for instrument rinses and limited solvent cleanup. Because volatile solvents are present, ventilation and waste handling are critical. Solution: Place sinks adjacent to a local exhaust hood, use stainless steel 316 sinks for solvent compatibility, and provide designated solvent waste containers rather than routing solvents to sink drains.

Example 3: Chemistry research lab

Scenario: Research lab requires multiple corrosive waste sinks. Solution: Use polypropylene sinks, corrosion-resistant P-traps and dedicated chemical waste lines to a neutralization system. Provide secondary containment and continuous monitoring for leaks.

Brand Advantages and Choosing the Right Lab Sink Cabinet

When selecting a Lab Sink Cabinet, consider the following brand advantages that impact long-term value:

- Customization: Ability to deliver C-type, floor-mounted and H-type configurations that match your bench systems and lab layout.

- Chemical resistance: Sinks and cabinet finishes engineered to resist common lab reagents and solvents, reducing downtime and replacement costs.

- Compliance support: Documentation and rough-in guides that help meet local plumbing codes and laboratory safety standards.

- Service network: Local partners and technical support to assist with installation, maintenance and spare parts.

- Integrated design: Seamless integration with laboratory bench systems for consistent ergonomics and utility management.

Our Lab Sink Cabinet line emphasizes durable construction, configurable layouts and clear rough-in documentation to simplify installation and ensure that facilities teams and contractors can implement plumbing and drainage systems correctly the first time.

Frequently Asked Questions (FAQ)

Q1: Can I dispose of chemicals down the lab sink?

A1: In most cases, hazardous chemicals should not be disposed of via lab sinks. Consult your environmental health & safety (EHS) team and local regulations. When limited disposal is permitted, use designated neutralization systems and corrosion-resistant piping.

Q2: What sink material is best for a chemistry lab?

A2: It depends on the chemicals used. Epoxy resin or polypropylene sinks offer excellent chemical resistance for many reagents. Stainless steel 316 is suitable for many solvents and general-purpose use. Choose materials based on a chemical compatibility assessment.

Q3: How do I prevent sink traps from drying out?

A3: Install trap primers or ensure periodic water flow through infrequently used sinks. Trap primers automatically replenish trap water to maintain the seal against sewer gases.

Q4: What documentation should I keep after installation?

A4: Keep as-built drawings showing plumbing connections, manufacturer installation guides, test certificates for backflow preventers, maintenance logs, and any compliance certifications required by your AHJ.

Q5: How do I choose between C-type, floor-mounted and H-type cabinets?

A5: Choose based on lab layout and access needs. C-type fits seamlessly within bench runs, floor-mounted units provide easier under-sink access, and H-type suits islands or paired sink stations requiring balanced plumbing. Consider maintenance access and plumbing routing when deciding.

If you have specific project requirements or need a quotation, please contact our sales team or view the Lab Sink Cabinet product page for technical datasheets and rough-in guides.

References and Authoritative Resources

Maintenance Tips to Extend the Life of Your Lab Sink

Maintenance, Cleaning, and Longevity of Lab Furniture

Best Materials for Lab Sink Cabinets: Chemical Resistance

Custom Lab Sink Cabinet Features That Improve Workflow

For Products

Do you offer ergonomic solutions for lab furniture?

Yes, our laboratory furniture includes ergonomic designs such as height-adjustable lab benches and chairs that reduce strain during long hours of work.

May I have my own design?

Yes, welcome. If you have your own design, please kindly send the Layout or plan to us. The designer team will make 3D drawings and Rendering drawings.

For Customization

Can I make changes to my order once it has been placed?

We offer limited flexibility to make changes to your order after it has been placed. Contact our sales team as soon as possible if you need to make modifications.

About Solution

Does your laboratory furniture support customization?

Yes, we provide fully customized services including size, material, color and functional design to meet customers' specific needs.

For After-Sales Support

How about your after sale service?

We will reply you within 24 hours by email or phone.

If we have local agent,we will arrange him to your site within 24 hours to assist you to shoot the problem.

Floor Mounted Lab Bench

Our Floor Mounted Lab Bench is an essential, high-efficiency workspace for laboratories, made from high-quality steel-wood or corrosion-resistant stainless steel materials to ensure exceptional durability and stability. The unique floor-mounted design effectively reduces vibration, optimizes space usage, and provides a safe and tidy laboratory environment.

Customizable storage solutions help organize lab equipment efficiently, while the easy-to-clean surface maintains laboratory hygiene. It is widely suitable for research institutions, educational laboratories, and the chemical and pharmaceutical industries.

Fume Hood

The fume hood provides safe ventilation to protect against exposure to hazardous or toxic fumes, vapors, or airborne particulate. It is primarily used in laboratory and manufacturing applications to protect the user or environment outside the hood, but can also be used to protect the materials or experiment under the hood.

APPLICATION

Chemistry Lab, physics Lab, biological analysis, pharmaceutical medicine analysis, biological pharmaceutical, plant culture, environmental testing and electronic instrumentation scientific research and so on.

Flammable Storage Cabinet

Safety Cabinets store flammable liquids, corrosives, pesticides and other hazardous materials. All fire-resistant safety cabinets by meet fire codes and regulations for safety storage.

To help protect your people and facility from a potential fire, safety cabinets are engineered to safely contain flammable fuels, solvents, and chemicals. Safety cabinets can not only help everyone store chemicals reasonably, save chemical supplies, but also save human resources, and avoid fires caused by chemicals with the greatest strength.

Class II Type A2 Biological Safety Cabinet for Laboratory

The Class II A2 Biological Safety Cabinet is designed to provide superior biosafety and contamination control for laboratories, research facilities, and clinical settings. With 70% air recirculation and 30% air exhaust, this cabinet ensures a safe and efficient work environment while protecting both the user and the samples.

Equipped with advanced features like a HEPA filtration system, motorized front window, and ergonomic design, this cabinet is a must-have for safe and reliable biological research.

Scan QR Code

Scan QR Code

MaxLabFurniture

MaxLab Furniture

daihongada

Max Laboratory