Maintenance Protocols That Extend Lab Countertop Lifespan

- Maintenance Protocols That Extend Lab Countertop Lifespan

- Why proactive maintenance matters for your lab countertop

- Know your lab countertop material: why it changes the maintenance plan

- Daily maintenance checklist for lab countertop longevity

- Weekly and monthly inspections: catch small issues before they escalate

- Material-specific care protocols ( keyword: Lab Countertops maintenance)

- Epoxy resin countertops

- Phenolic resin countertops

- Stainless steel countertops

- Solid surface (e.g., Corian-style)

- Spill response protocols for chemical and biological agents

- Sealing, caulking, and edge protection

- Repair and restoration: when to DIY and when to call professionals

- Environmental controls and supporting furniture ( keyword: lab countertop integration)

- Inspection logs and lifecycle management

- Materials comparison: maintenance needs and expected lifespan

- Documented maintenance program example (Lab Countertops maintenance plan)

- Integrating Lab Countertops with furniture systems for longevity

- When replacement becomes the best option

- Brand advantages summary: Why choose Lab Countertops from Max Lab

- Frequently Asked Questions (FAQ)

- Contact Max Lab to review products or request a maintenance plan

- References and authoritative sources

- Call to action

Maintenance Protocols That Extend Lab Countertop Lifespan

Why proactive maintenance matters for your lab countertop

A well-maintained lab countertop is a foundational element of laboratory safety, efficiency, and long-term cost control. Whether you specify Lab Countertops for a chemical, biology, cleanroom, or teaching lab, routine care prevents premature deterioration, reduces downtime, and protects samples and personnel. This guide provides practical, material-specific maintenance protocols and checklists you can implement immediately to extend the usable life of any lab countertop. Finally, understanding maintenance ties back to the lab countertops spec sheet: must-have requirements for buyers, completing the loop from selection, material comparison, cost evaluation, inspection, customization, sustainability, and upkeep.

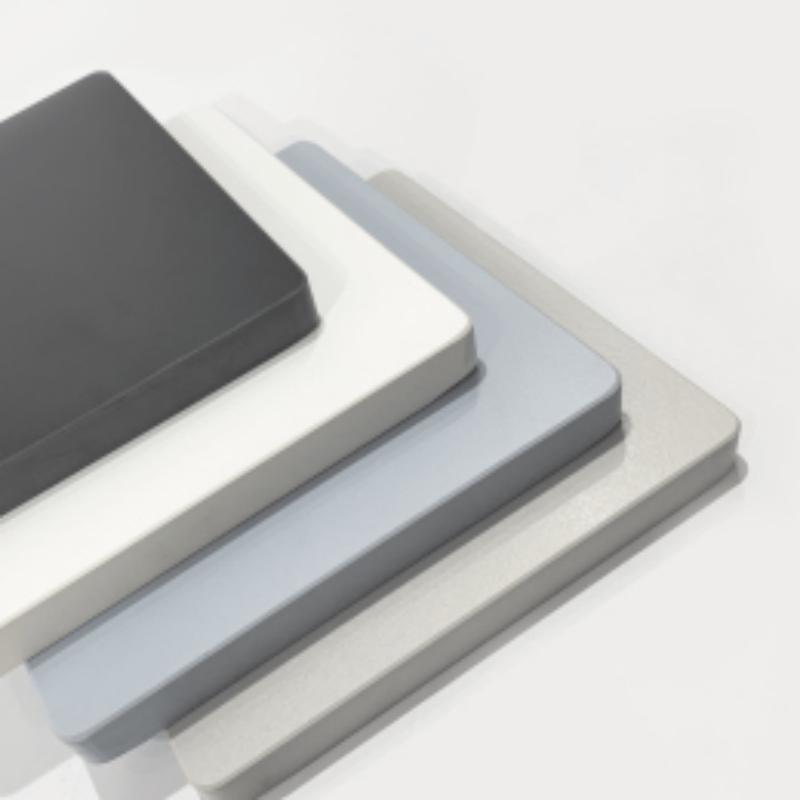

Know your lab countertop material: why it changes the maintenance plan

Different lab countertop materials — epoxy resin, phenolic resin, stainless steel, solid surface (acrylic/uncured polymer blends), and ceramic/tile — respond differently to chemicals, heat, abrasion, and moisture. Before setting protocols, identify the installed Lab Countertops material and note its chemical resistance, heat tolerance, and recommended cleaning agents. Maintenance frequency and allowed products will vary accordingly.

Daily maintenance checklist for lab countertop longevity

Daily habits are the easiest way to prevent cumulative damage. Implement a short checklist for lab users and custodial staff that includes: wipe-down with manufacturer-approved cleaners, immediate neutralization and removal of small spills, inspection for new scratches or stains, and ensuring wet areas (sinks, faucets) are dried. Use soft, non-abrasive cloths and avoid strong solvents on surfaces not rated for them.

Weekly and monthly inspections: catch small issues before they escalate

Weekly tasks should include a more thorough cleaning of seams, cutouts, and sink junctions, plus a check of caulking and edge integrity. Monthly inspections should be documented in a log: note discoloration, deep scratches, edge lifting, or signs of chemical etching. Early detection allows targeted repairs (re-caulking, light sanding for some solid surfaces, or professional patching for epoxy) that are less costly than full surface replacement.

Material-specific care protocols ( keyword: Lab Countertops maintenance)

Below are recommended maintenance actions by common lab countertop material. Use these as baseline protocols and always cross-check with the manufacturer’s data sheet for your specific Lab Countertops product.

Epoxy resin countertops

Epoxy is widely used for chemical resistance. Daily cleaning with mild detergent and water is ideal. Avoid prolonged exposure to strong oxidizers (e.g., nitric acid) and high heat. For minor surface scratches, light buffing by a trained technician can restore appearance; deep cracks require professional repair. Annual inspection of seams and mechanical fasteners is recommended.

Phenolic resin countertops

Phenolic is moisture- and chemical-resistant when properly sealed. Keep phenolic tops dry at edges and joints; avoid strong alkaline cleaners that can degrade surface laminates. Replace damaged edge strips promptly and re-seal exposed core areas immediately to prevent swelling. Phenolic repairs are generally easier than epoxy but require rapid action when water intrusion occurs.

Stainless steel countertops

Stainless steel is durable and heat-resistant but vulnerable to pitting with chlorides. Daily wiping with a neutral cleaner and soft cloth prevents salt and chemical deposits. Use non-scratch pads for heavier cleaning and polish periodically. Check weld seams for corrosion and repair any breaches quickly to prevent underlying substrate issues.

Solid surface (e.g., Corian-style)

Solid surfaces are repairable by sanding and re-polishing. Use manufacturer-recommended cleaners and neutral pH solutions for daily care. For stains or burns, trained technicians can re-finish the area; replace only when damage is beyond repair. Re-sealing is generally not required, but careful cleaning on a schedule prevents buildup and discoloration.

Spill response protocols for chemical and biological agents

Rapid, documented spill response protects both the countertop and lab occupants. Create a spill-response SOP tied to the lab's chemical hygiene plan and biosafety procedures. For chemical spills: isolate and ventilate the area, consult the SDS for neutralization steps compatible with your Lab Countertops material, and remove residues with approved agents. For biological spills: follow established decontamination protocols (disinfectant contact time, PPE requirements) and verify the disinfectant is compatible with the countertop material to avoid surface degradation.

Sealing, caulking, and edge protection

Joints, sink cutouts, and exposed edges are the most vulnerable areas. Use compatible, laboratory-grade sealants and reapply them on a schedule (typically annually or as indicated by inspection). Ensure that edge treatments (e.g., bullnose or drip edge) are intact; damaged edges allow moisture ingress and delamination. For Lab Countertops integrated with furniture, verify the interface with cabinetry is sealed and mechanically supported to prevent stress fractures.

Repair and restoration: when to DIY and when to call professionals

Minor issues like surface stains, light scratches, or small chips can often be handled in-house with manufacturer-approved kits. However, structural damage, deep chemical etching, or widespread delamination require professional assessment. Reputable Lab Countertops manufacturers often provide repair services or certified contractors — use them to maintain warranty coverage and long-term performance.

Environmental controls and supporting furniture ( keyword: lab countertop integration)

Countertop lifespan is affected by the surrounding environment. Control humidity, temperature swings, and UV exposure where possible. Ensure cabinets and hardware provide even support; unsupported spans can cause sagging or cracking. When installing sinks, gas lines, or powered equipment, use proper cutout reinforcements and verify the countertop material is suitable for the load and thermal stress.

Inspection logs and lifecycle management

Implement an equipment lifecycle and inspection log for each lab countertop run. Record installation date, material type, cleaning products used, incidents (spills, impacts), and repair actions. Data-driven maintenance enables budgeting for replacement and helps identify systemic issues tied to laboratory processes.

Materials comparison: maintenance needs and expected lifespan

Use this table to compare typical maintenance frequency and realistic lifespan ranges for common lab countertop materials. Values are approximate and depend on lab conditions and maintenance quality.

| Material | Chemical Resistance | Maintenance Frequency | Typical Lifespan (with good maintenance) | Repairability |

|---|---|---|---|---|

| Epoxy Resin | High (except strong oxidizers) | Daily cleaning; monthly inspection | 10–20 years | Moderate (professional patching) |

| Phenolic Resin | Good (moisture-sensitive at edges) | Daily cleaning; monthly edge checks | 8–15 years | Moderate (edge replacement) |

| Stainless Steel | Very high (avoid chlorides) | Daily wipe; periodic polish | 15–30+ years | High (weld repairs possible) |

| Solid Surface | Good; repairable | Daily cleaning; annual re-finishing as needed | 10–20 years | High (sanding/polishing) |

| Ceramic/Tile | Very high; grout vulnerable | Daily cleaning; grout sealing periodically | 15–30 years | Moderate (tile replacement, grout repair) |

Documented maintenance program example (Lab Countertops maintenance plan)

Example quick program to adopt across a lab facility:

- Daily: Wipe with neutral cleaner; record any spills or visible damage.

- Weekly: Clean junctions and hardware; check for loose fasteners and water pooling.

- Monthly: Detailed inspection, photo-documentation, and minor repairs (re-caulk, replace gaskets).

- Quarterly: Review logs, order replacement parts, schedule professional inspection if recurring issues appear.

- Annually: Full condition assessment and lifecycle review; budget for replacement if >70% of surface area shows irreversible damage.

Integrating Lab Countertops with furniture systems for longevity

Choose countertop-to-furniture integration that minimizes stress and movement. For example, full-length supports, appropriate fasteners, and flexible sealants reduce point loads and allow thermal expansion without cracking. Max Lab Lab Countertops are designed for full customization — sizes, cutouts, sinks, edges, and integration with lab furniture systems — which simplifies specifying compatible supports and reduces installation mistakes that shorten service life.

Product Brief:

One-Stop Custom Lab Worktops Built for Real Lab Conditions

Choose the right countertop material for your chemical, biology, cleanroom, or teaching lab. Max Lab provides full customization—sizes, cutouts, sinks, edges, and integration with lab furniture systems.

When replacement becomes the best option

Even with excellent maintenance, some countertops reach the end of usable life due to cumulative chemical etching, structural failure, or repeated mechanical damage. Use your inspection logs and the 70% damage rule (or a manufacturer-recommended threshold) to make replacement decisions proactively — replacing early can be cheaper than frequent repairs and lost productivity.

Brand advantages summary: Why choose Lab Countertops from Max Lab

Max Lab Lab Countertops are tailored for real lab conditions with options across epoxy, phenolic, stainless, and solid surfaces. Key benefits include full customization (sizes, cutouts, sinks, and edge profiles), engineered integration with lab furniture systems to reduce stress and improve longevity, and technical support for maintenance and repair. Choosing a countertop designed for your specific chemistry and workflow reduces long-term maintenance costs and extends service life.

Frequently Asked Questions (FAQ)

Q: How often should I reseal countertops around sinks and cutouts?

A: Inspect seals monthly; reseal proactively at the first sign of cracking or water intrusion — typically annually in high-use areas.

Q: Are disinfectants safe for all lab countertop materials?

A: No. Some disinfectants (strong oxidizers or high-alkaline formulas) can damage certain materials. Always consult the countertop manufacturer’s chemical resistance table and the disinfectant SDS before routine use.

Q: My epoxy countertop has a deep chemical stain — can it be repaired?

A: Minor etching and stains may be improved by professional surface restoration. Deep chemical damage that alters material chemistry may require section replacement or full countertop replacement.

Q: What cleaning products are recommended for Lab Countertops?

A: Use neutral pH cleaners and manufacturer-recommended solutions. Avoid abrasive powders, concentrated solvents (unless specified), and household bleach on materials not rated for it.

Q: How do I document maintenance to preserve warranty and extend lifespan?

A: Keep a dated log recording daily/weekly cleaning, spills/incidents, repairs, and annual inspections. Photograph damage and repairs. Many manufacturers require evidence of proper care for warranty claims.

Contact Max Lab to review products or request a maintenance plan

If you need tailored maintenance protocols, inspection services, or a quote for Lab Countertops that match your lab’s chemistry and workflows, contact our technical team or view product options. Our specialists can provide SDS-based compatibility checks, recommended cleaning agents, and certified repair services to maximize your countertop lifespan.

References and authoritative sources

- Laboratory bench — Wikipedia

- CDC — Laboratory Safety

- OSHA — Laboratory Safety Guidance

- ASTM D543 — Standard Practices for Evaluating the Resistance of Plastics to Chemical Reagents

- NSF International — Standards and Certification

Call to action

Ready to extend the life of your lab countertop? Contact Max Lab for product details, maintenance plans, or to schedule an on-site assessment. View our Lab Countertops product range to choose the optimal material and customization for your lab.

How to Choose the Right Lab Sink for Your Facility

Laboratory table guide: Benefits of Anti-vibration Tables BT-03

Fume Hood Integration with HVAC and Laboratory Design

Fume Hood Lifecycle Costs: Total Cost of Ownership Guide

For Customization

Can you create a lab design layout for us?

Yes, we'll provide preliminary layout, confirm 3D drawings and rendering drawings.

About Solution

What is the warranty policy of the product?

We provide 1-3 years warranty service, depending on the product type. Meanwhile, comprehensive after-sales support is provided, including repair and replacement services.

FAQS

Do you offer custom design services?

Yes, we provide full design support tailored to your lab’s specific needs, including layout planning and furniture customization.

For Products

What products does MAX LAB offer?

We specialize in laboratory furniture and equipment, including lab benches, fume hoods, storage cabinets, lab accessories, and custom lab solutions.

For After-Sales Support

What do I do if I am not satisfied with my purchase?

We strive to ensure customer satisfaction. If you are not happy with your purchase, please contact us, and we will do our best to resolve any concerns.

Floor Mounted Lab Bench

Our Floor Mounted Lab Bench is an essential, high-efficiency workspace for laboratories, made from high-quality steel-wood or corrosion-resistant stainless steel materials to ensure exceptional durability and stability. The unique floor-mounted design effectively reduces vibration, optimizes space usage, and provides a safe and tidy laboratory environment.

Customizable storage solutions help organize lab equipment efficiently, while the easy-to-clean surface maintains laboratory hygiene. It is widely suitable for research institutions, educational laboratories, and the chemical and pharmaceutical industries.

Fume Hood

The fume hood provides safe ventilation to protect against exposure to hazardous or toxic fumes, vapors, or airborne particulate. It is primarily used in laboratory and manufacturing applications to protect the user or environment outside the hood, but can also be used to protect the materials or experiment under the hood.

APPLICATION

Chemistry Lab, physics Lab, biological analysis, pharmaceutical medicine analysis, biological pharmaceutical, plant culture, environmental testing and electronic instrumentation scientific research and so on.

Flammable Storage Cabinet

Safety Cabinets store flammable liquids, corrosives, pesticides and other hazardous materials. All fire-resistant safety cabinets by meet fire codes and regulations for safety storage.

To help protect your people and facility from a potential fire, safety cabinets are engineered to safely contain flammable fuels, solvents, and chemicals. Safety cabinets can not only help everyone store chemicals reasonably, save chemical supplies, but also save human resources, and avoid fires caused by chemicals with the greatest strength.

Class II Type A2 Biological Safety Cabinet for Laboratory

The Class II A2 Biological Safety Cabinet is designed to provide superior biosafety and contamination control for laboratories, research facilities, and clinical settings. With 70% air recirculation and 30% air exhaust, this cabinet ensures a safe and efficient work environment while protecting both the user and the samples.

Equipped with advanced features like a HEPA filtration system, motorized front window, and ergonomic design, this cabinet is a must-have for safe and reliable biological research.

Scan QR Code

Scan QR Code

MaxLabFurniture

MaxLab Furniture

daihongada

Max Laboratory