Maintenance, Cleaning, and Longevity of Lab Furniture

- Optimizing Lab Environments for Performance

- Why lab furniture design influences maintenance and longevity

- Establishing a maintenance policy tied to lab furniture design

- Material selection: implications for cleaning and lifespan

- Cleaning best practices for different furniture types

- Compatibility checklist: avoid common cleaning mistakes

- Inspection, preventive maintenance, and repair protocols

- Common repairs and when to replace

- Designing for maintainability: lab furniture design principles

- Cost of ownership: estimating lifecycle costs

- Safe cleaning chemicals and decontamination strategies

- Decontamination case: formaldehyde and corrosive acids

- Manufacturer role and quality control—MAX LAB example

- Actionable checklist: implement today

- FAQ

- 1. How often should lab countertops be replaced?

- 2. What cleaning agents are safe for epoxy resin?

- 3. How often should fume hoods be certified?

- 4. Can powder-coated steel be used in corrosive labs?

- 5. What is the best strategy to minimize long-term cost?

- 6. How should I handle a chemical spill on a countertop?

- Contact and product information

- References

Optimizing Lab Environments for Performance

Effective maintenance and cleaning are essential components of any lab furniture design strategy. Well-designed lab furniture not only supports daily workflows but also determines long-term safety, contamination control, and total cost of ownership. This article explains how to clean, maintain, and extend the service life of common laboratory furniture—benches, countertops, storage cabinets, fume hoods, and specialized equipment—based on industry standards and practical field experience.

Why lab furniture design influences maintenance and longevity

Lab furniture design choices—materials, finishes, joinery, and hardware—directly affect how furniture responds to chemicals, heat, mechanical load, and routine cleaning. For example, an epoxy resin countertop resists most acids and solvents better than melamine, while stainless steel cabinets excel at corrosion resistance but may dent under impact. Selecting materials that align with the intended use reduces repair frequency and extends service life, lowering life-cycle costs.

Establishing a maintenance policy tied to lab furniture design

Every facility should create a written maintenance policy that considers the lab furniture design and the lab’s hazard profile. Key elements include: cleaning schedules, compatible cleaning agents, inspection frequency, preventive maintenance tasks, spare parts inventory, and escalation procedures for damage or contamination events. Policies reduce downtime and ensure compliance with safety and accreditation standards.

Material selection: implications for cleaning and lifespan

Material selection is the single most influential decision for longevity. Below is a concise comparison of common materials used in lab furniture design with regard to lifespan, chemical resistance, thermal resistance, and recommended cleaning agents.

| Material | Typical Lifespan (years) | Chemical Resistance | Recommended Cleaning Agents | Notes |

|---|---|---|---|---|

| Epoxy Resin Countertop | 15–25 | Excellent for acids, bases; poor against some solvents (ketones over long exposure) | Mild detergent, isopropyl alcohol (70%), neutral cleaners | Heat resistant to ~150°C; can yellow under UV |

| Phenolic Resin Countertop | 10–20 | Good for solvents; better thermal resistance | Neutral detergent, soft-bristle brush, mild solvents per manufacturer | Less impact-resistant than epoxy |

| Stainless Steel (304/316) | 20–40+ | Very good to excellent; 316 better in chloride environments | Non-chlorinated detergents, diluted bleach if required (with passivation), alcohol | Prone to scratches and dents; regular passivation advised in corrosive labs |

| Powder-coated Steel Casework | 8–15 | Moderate; chips expose substrate to corrosion | Mild detergent; avoid abrasive cleaners | Edge protection important to avoid rust |

| Laminate/Melamine | 5–12 | Low—vulnerable to solvents and moisture at seams | Mild cleaners; limit solvent exposure | Cost-effective for low-hazard labs only |

Data sources: manufacturer datasheets and industry guidance (see References).

Cleaning best practices for different furniture types

Cleaning frequency and methods should be tailored to the furniture type and lab activity. The following are evidence-based best practices:

- Countertops: Remove spills immediately, clean with neutral detergents for daily maintenance, and disinfect with appropriate agents (e.g., 70% isopropyl alcohol) depending on biological risk. Avoid acetone or prolonged exposure to strong solvents on epoxy surfaces.

- Cabinets and casework: Dust and wipe down weekly; inspect and clean hinges and locks every 3–6 months. For powder-coated steel, promptly repair chips to prevent corrosion.

- Fume hoods: Clean sash tracks and interior surfaces monthly; certified airflow testing annually (or per local regulations). Use compatible cleaners that do not leave residues affecting airflow sensors.

- Anti-vibration tables and precision equipment: Keep free from dust; avoid chemical sprays on sensitive electronics; perform calibration and mechanical checks per manufacturer intervals (commonly every 6–12 months).

Compatibility checklist: avoid common cleaning mistakes

Common errors accelerate wear or create hazards. Use this quick compatibility checklist when creating cleaning SOPs tied to lab furniture design:

- Never use abrasive pads on stainless steel—use soft cloths and non-scratch pads.

- Avoid high-concentration acids/solvents for routine cleaning—reserve for controlled decontamination.

- Do not pressure-wash casework seams; moisture intrusion is a leading cause of delamination and corrosion.

- Check manufacturer MSDS/TDS for chemicals used in cleaning; document compatibility.

Inspection, preventive maintenance, and repair protocols

Regular inspections detect small problems before they require costly replacement. Your inspection program should be risk-based and documented. Typical inspection intervals and tasks:

| Interval | Items to Inspect | Action |

|---|---|---|

| Daily | Surfaces for spills, contamination; sash position; obvious damage | Immediate cleaning; cordon off contaminated areas |

| Monthly | Hinges, drawer slides, seals, countertop joints | Lubricate moving parts; replace worn seals; touch-up paint |

| Quarterly | Electrical outlets, grounding connections on benches, anti-vibration mounts | Functional testing; retorque fasteners; service mounts |

| Annually | Fume hood certification, full inventory of consumables and spares, countertop integrity | Professional certification; plan replacements; order spare parts |

Document each inspection with date, inspector, findings, and corrective actions. This record is essential for audits and insurance claims.

Common repairs and when to replace

Minor repairs (re-sealing joints, replacing gaskets, touch-up painting, hinge replacement) often restore function quickly. Replacement should be considered when:

- Structural integrity is compromised (e.g., corroded support frames, delaminated countertops).

- Recurring contamination events occur due to design limitations (e.g., porous surfaces in high-hazard labs).

- Repair cost exceeds 40–60% of replacement value and impacts safety or compliance.

Designing for maintainability: lab furniture design principles

Design for maintainability reduces long-term costs. Key principles for lab furniture design include:

- Modularity: Use interchangeable parts and modular casework to simplify repairs and upgrades.

- Accessibility: Ensure access panels and removable sections for servicing mechanical and electrical components.

- Material zoning: Specify high-resistance materials (stainless, epoxy) in wet/chemical areas, and cost-effective finishes in low-risk zones.

- Standardization: Standard hardware and components across the facility streamline spare inventory and reduce downtime.

Adopting these principles helps labs respond to evolving needs without wholesale replacement.

Cost of ownership: estimating lifecycle costs

When comparing options, consider initial purchase price plus cleaning, maintenance, downtime, and disposal costs. A simple model compares two countertop choices (epoxy vs. laminate):

| Item | Epoxy Resin | Melamine Laminate |

|---|---|---|

| Initial cost (per linear meter) | $300–$500 | $80–$150 |

| Estimated lifespan | 15–25 years | 5–12 years |

| Annual maintenance & cleaning | Low–Moderate | Moderate–High (due to repairs/replace seams) |

| Replacement frequency (30-year horizon) | 1–2 times | 3–6 times |

Over 30 years, epoxy typically becomes more cost-effective for medium-to-high hazard labs despite higher upfront cost, due to reduced replacement and contamination risk.

Safe cleaning chemicals and decontamination strategies

Cleaning agents must be chosen for efficacy against contaminants while preserving surfaces. For biological decontamination, validated agents like 0.1%–0.5% sodium hypochlorite or 70% ethanol are commonly used, but check compatibility with surfaces—sodium hypochlorite can corrode metals and degrade some resins, so rinse thoroughly and follow with neutralizers if allowed. For chemical spills, refer to the chemical’s SDS for recommended neutralizers and cleanup procedures.

Always label cleaning SOPs with:

- Type of contaminant

- Recommended cleaner and concentration

- Contact time

- Personal protective equipment (PPE) requirements

- Waste disposal method

Decontamination case: formaldehyde and corrosive acids

Formaldehyde requires specialized neutralization and ventilation during cleaning—typically neutralizing agents and HEPA-filtered vacuums for settled particulates. Strong acids (e.g., HCl, H2SO4) should be neutralized with appropriate bases, but not on sensitive countertops—contain the spill and replace or repair severely etched surfaces.

Manufacturer role and quality control—MAX LAB example

Partnering with a strong manufacturer reduces lifecycle risk. Founded in 2000, Guangzhou Max Laboratory Equipment Co., Ltd. (MAX LAB) is a leading manufacturer that integrates the design, production, and sales of laboratory furniture and equipment. With over 15 years of export experience, our founder has led the company to serve clients in more than 60 countries and regions, earning a reputation for reliability and excellence. Guided by our core values—Quality First, Delivery First, Price First, and Service First—we are committed to delivering superior laboratory solutions that meet the highest global standards.

Our 5,000 m² factory in Guangzhou is equipped with advanced German-imported machinery and operates under modern management systems to ensure precision and consistency. With three standardized production lines and a well-stocked modular inventory, we achieve production efficiency and delivery times up to 30% faster than industry peers.

At MAX LAB, we insist on stringent quality control for every product before it leaves the factory. Using materials from leading global suppliers, we ensure that every item—from lab furniture and storage cabinets to fume hoods and countertops—meets international quality and environmental standards. Our dedication to innovation, efficiency, and customer satisfaction has made MAX LAB a trusted partner in laboratory projects worldwide.

Brief summary of MAX LAB advantages and main products: MAX LAB specializes in lab storage cabinets, fume hoods, lab countertops, lab benches, purifying equipment, and anti-vibration tables. Competitive advantages include integrated design-to-manufacture capability, modern machinery, standardized production lines, fast delivery, and strict QC with High Quality material sourcing—yielding reliable, maintainable, and high-performance lab furniture design solutions.

If you need furniture specified for easy cleaning, high chemical resistance, or modular maintainability, choosing a manufacturer like MAX LAB helps ensure designs that reduce long-term maintenance and extend the useful life of your lab assets.

Actionable checklist: implement today

- Map lab zones by hazard and match materials: epoxy/phenolic for wet chemistry, stainless for wash areas, laminate for offices/meeting rooms.

- Create a cleaning SOP matrix listing agent compatibility per surface.

- Schedule inspections and log all maintenance (digital CMMS recommended).

- Stock common spares: gaskets, hinges, fasteners, touch-up paint, replacement filters for fume hoods.

- Partner with a manufacturer providing modular parts and technical support for at least 5–10 years.

FAQ

1. How often should lab countertops be replaced?

Replacement depends on material and use. Epoxy countertops typically last 15–25 years in active labs; phenolic 10–20 years; laminate 5–12 years. Replace sooner if structural damage, persistent contamination, or safety issues arise.

2. What cleaning agents are safe for epoxy resin?

Use mild detergent and water for routine cleaning. For disinfection, 70% isopropyl alcohol is commonly used. Avoid prolonged contact with ketones (e.g., acetone) and strong oxidizing acids unless guided by the manufacturer.

3. How often should fume hoods be certified?

Typically fume hoods require annual certification of airflow and containment per local regulations and standards (some high-risk labs may require more frequent testing). Document all certifications.

4. Can powder-coated steel be used in corrosive labs?

Powder-coated steel is suitable for low-to-moderate hazards but can chip and expose substrate to corrosion. For corrosive or chloride-rich environments, stainless steel (304 or 316) is preferred.

5. What is the best strategy to minimize long-term cost?

Select materials appropriate for the hazard level, design for modularity and maintainability, standardize components, enforce cleaning/inspection protocols, and partner with reputable manufacturers who provide spare parts and technical support.

6. How should I handle a chemical spill on a countertop?

Immediately contain and neutralize based on the chemical’s SDS. Remove contaminated absorbents safely, clean the area with compatible cleaners, and inspect the surface for damage. If surface integrity is compromised, isolate and plan for repair or replacement.

Contact and product information

For tailored lab furniture design solutions, comprehensive product lines, and maintenance support, contact MAX LAB. Explore products including lab storage cabinets, fume hoods, lab countertops, lab benches, purifying equipment, and anti-vibration tables. Reach out for consultations, maintenance programs, and quotations to ensure your laboratory assets deliver long, safe, and cost-effective service lives.

Contact us to request product specifications, maintenance manuals, or a site assessment.

References

- U.S. Centers for Disease Control and Prevention (CDC) - Biosafety in Microbiological and Biomedical Laboratories (BMBL). https://www.cdc.gov/labs/BMBL. (accessed 2025-11-20)

- Occupational Safety and Health Administration (OSHA) - Laboratory Safety Guidance. https://www.osha.gov/laboratory (accessed 2025-11-20)

- NIH Office of Research Facilities - Laboratory Design and Materials. https://orf.od.nih.gov (accessed 2024-12-05)

- ASTM Standards and Manufacturer Technical Data Sheets for epoxy resin and phenolic countertops (representative manufacturer datasheets, various dates accessed 2025-10-10)

- International Organization for Standardization - ISO standards on lab equipment and material testing. https://www.iso.org (accessed 2025-01-15)

Plumbing and Installation Considerations for Lab Sink Cabinets

Safety and Compliance in Lab Furniture Design

2026 Master Guide: Perfecting Your Station Eye Wash Compliance Strategy

Cleaning and Decontamination Best Practices for Lab Benches

For Company

Where have you exported your equipment?

Do you offer services internationally?

Yes, we serve clients around the world, including Europe, North America, and Asia. Our international experience enables us to provide solutions that meet local regulations and standards.

FAQS

Do you export internationally?

Yes, we have over 15 years of export experience and have served clients in more than 60 countries and regions.

Do you offer custom design services?

Yes, we provide full design support tailored to your lab’s specific needs, including layout planning and furniture customization.

For After-Sales Support

What happens if my product is damaged during delivery?

If your product is damaged during shipping, please contact our customer service team immediately. We will arrange for a replacement or repair at no additional cost.

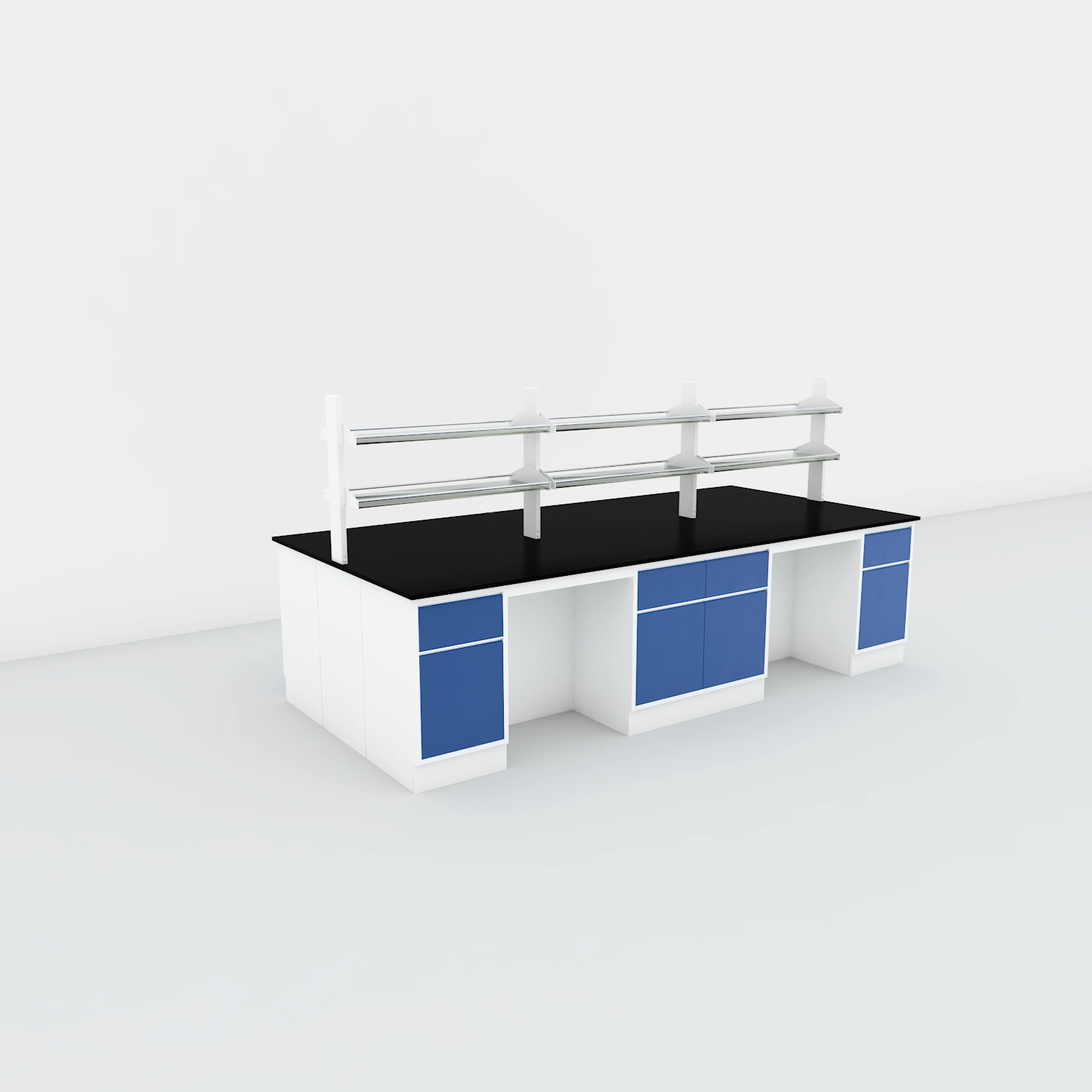

Floor Mounted Lab Bench

Our Floor Mounted Lab Bench is an essential, high-efficiency workspace for laboratories, made from high-quality steel-wood or corrosion-resistant stainless steel materials to ensure exceptional durability and stability. The unique floor-mounted design effectively reduces vibration, optimizes space usage, and provides a safe and tidy laboratory environment.

Customizable storage solutions help organize lab equipment efficiently, while the easy-to-clean surface maintains laboratory hygiene. It is widely suitable for research institutions, educational laboratories, and the chemical and pharmaceutical industries.

Fume Hood

The fume hood provides safe ventilation to protect against exposure to hazardous or toxic fumes, vapors, or airborne particulate. It is primarily used in laboratory and manufacturing applications to protect the user or environment outside the hood, but can also be used to protect the materials or experiment under the hood.

APPLICATION

Chemistry Lab, physics Lab, biological analysis, pharmaceutical medicine analysis, biological pharmaceutical, plant culture, environmental testing and electronic instrumentation scientific research and so on.

Flammable Storage Cabinet

Safety Cabinets store flammable liquids, corrosives, pesticides and other hazardous materials. All fire-resistant safety cabinets by meet fire codes and regulations for safety storage.

To help protect your people and facility from a potential fire, safety cabinets are engineered to safely contain flammable fuels, solvents, and chemicals. Safety cabinets can not only help everyone store chemicals reasonably, save chemical supplies, but also save human resources, and avoid fires caused by chemicals with the greatest strength.

Class II Type A2 Biological Safety Cabinet for Laboratory

The Class II A2 Biological Safety Cabinet is designed to provide superior biosafety and contamination control for laboratories, research facilities, and clinical settings. With 70% air recirculation and 30% air exhaust, this cabinet ensures a safe and efficient work environment while protecting both the user and the samples.

Equipped with advanced features like a HEPA filtration system, motorized front window, and ergonomic design, this cabinet is a must-have for safe and reliable biological research.

Scan QR Code

Scan QR Code

MaxLabFurniture

MaxLab Furniture

daihongada

Max Laboratory