Lifecycle Cost Analysis for Lab Countertops in Institutional Labs

- Lifecycle Cost Analysis for Lab Countertops in Institutional Labs

- Why lifecycle cost matters for your lab countertop

- Product overview: Lab Countertops for real lab conditions

- Defining lifecycle cost for lab countertops (TCO methodology)

- Common lab countertop materials and high-level comparison

- How to read this table

- Material-specific lifecycle considerations

- Epoxy resin countertops

- Phenolic resin countertops

- Stainless steel countertops

- Calculating TCO with an example (10-year horizon)

- Installation, cutouts, integration and customization costs

- Maintenance, cleaning protocols and decontamination

- Downtime, repair and contingency planning

- Sustainability, disposal and end-of-life considerations

- Choosing the right lab countertop for your facility

- Brand value — Why choose Lab Countertops from Max Lab

- Practical steps to perform your own lifecycle cost analysis

- Frequently Asked Questions (FAQ)

- Q: What is the single best countertop material for all labs?

- Q: How much more should I budget for customized cutouts and integrations?

- Q: How do I include downtime costs in the lifecycle calculation?

- Q: Can worn or damaged epoxy countertops be repaired in the field?

- Q: Are there standards or guidance for lab furniture and surfaces?

- Contact us / See product

- Authoritative references and further reading

Lifecycle Cost Analysis for Lab Countertops in Institutional Labs

Why lifecycle cost matters for your lab countertop

Choosing a lab countertop isn't just a purchase decision — it's a long-term capital and operational commitment. A lab countertop affects safety, functionality, cleaning protocols, equipment integration, and long-term budget planning. Lifecycle Cost Analysis (LCA) or Total Cost of Ownership (TCO) reveals the real expense of different materials and installation strategies over the useful life of a lab, helping facility managers, purchasing officers, and lab directors make defensible, cost-effective choices.

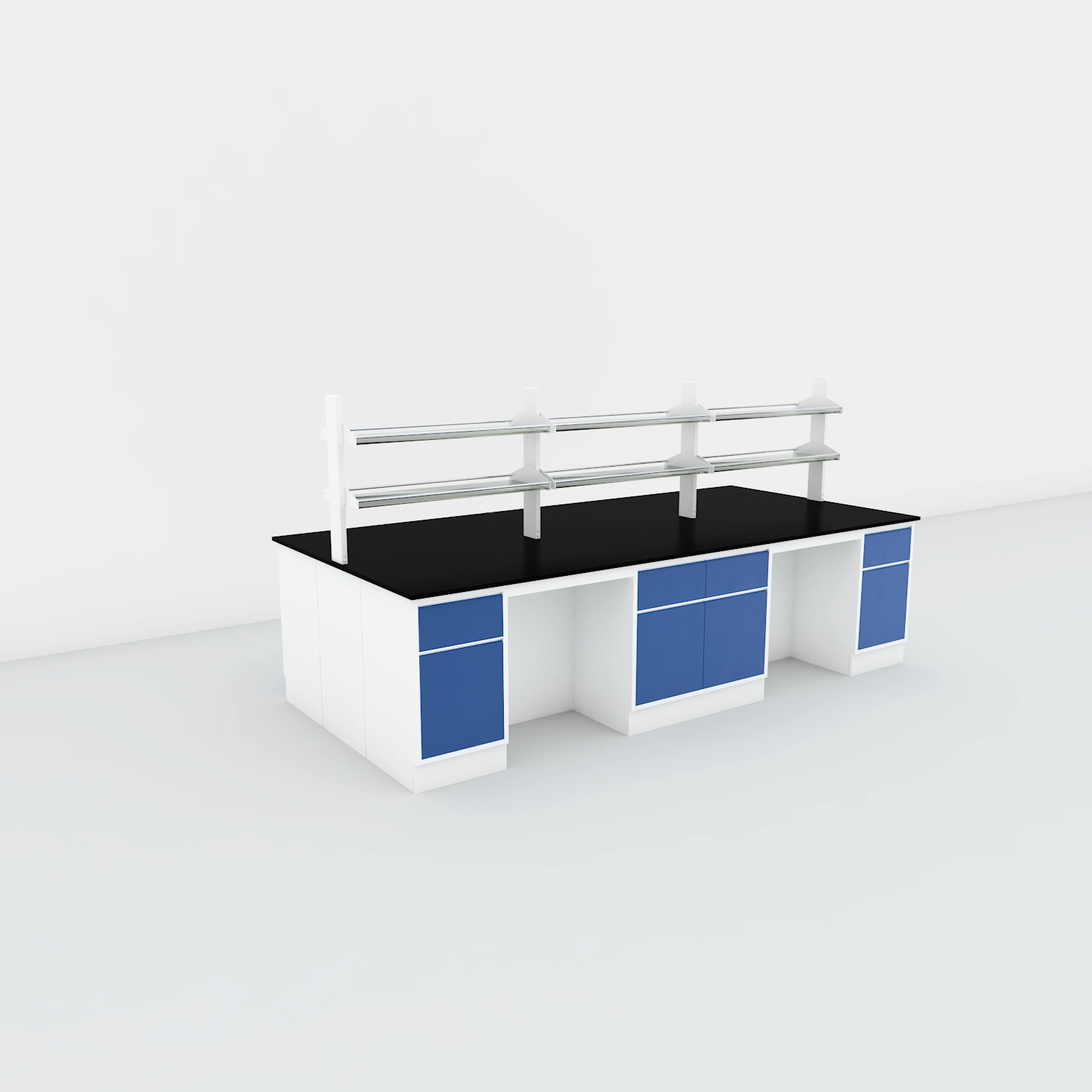

Product overview: Lab Countertops for real lab conditions

One-Stop Custom Lab Worktops Built for Real Lab Conditions

Choose the right countertop material for your chemical, biology, cleanroom, or teaching lab. Max Lab provides full customization—sizes, cutouts, sinks, edges, and integration with lab furniture systems.

Defining lifecycle cost for lab countertops (TCO methodology)

Lifecycle cost for a lab countertop includes more than initial purchase price. Use a structured TCO approach that sums:

- Initial cost: material, fabrication, edge treatments, cutouts, sinks, and delivery

- Installation cost: labor, site preparation, integration with casework, and utilities

- Maintenance and cleaning: routine cleaning supplies, labor, and periodic resealing or repairs

- Repair and downtime: costs when surfaces are taken out of service for restoration or replacement and lost productivity

- Replacement and disposal: end-of-life removal, disposal fees, and replacement installation

- Compliance and mitigation: costs to meet local codes, chemical compatibility testing, and cleanroom validation

Quantifying each component (annualized) over the expected service life yields a comparable annual cost for budgeting and ROI calculations.

Common lab countertop materials and high-level comparison

Selecting a material drives most lifecycle outcomes. The common options in institutional labs are epoxy resin, phenolic resin, stainless steel, solid surface/quartz/ceramic, and high-pressure laminate (limited use). The table below provides a compact comparison that helps identify which material fits a given lab mission.

| Material | Typical Initial Cost (relative) | Chemical Resistance | Maintenance | Typical Lifespan | Best Use |

|---|---|---|---|---|---|

| Epoxy Resin | Medium | Excellent (many acids/bases/solvents) | Low (periodic cleaning; can be repaired) | 15–25 years | Chemical labs, general-purpose labs |

| Phenolic Resin | Low–Medium | Good (especially to water and moderate chemicals) | Low | 10–20 years | Biology labs, wet labs with aqueous use |

| Stainless Steel (304/316) | Medium–High | Excellent (corrosion resistant; mechanical impact resistant) | Medium (polishing; weld repairs) | 20+ years | Food labs, cleanrooms, sterile environments |

| Quartz/Ceramic/Solid Surface | High | Good to excellent (chemical resistance varies) | Medium (stain repair; sealing for some materials) | 15–25 years | Teaching labs, labs needing aesthetics + durability |

| High-Pressure Laminate | Low | Poor (delaminates with solvents) | High (prone to damage) | 5–10 years | Non-chemical teaching benches, office-adjacent areas |

How to read this table

The table is a starting point. For institutional labs, chemical compatibility, cleanability, and downtime risk often matter more than initial unit cost. Epoxy and stainless steel frequently offer lower lifecycle cost in aggressive environments despite higher upfront investment.

Material-specific lifecycle considerations

Epoxy resin countertops

Epoxy resin is one of the most commonly specified materials for institutional lab countertops due to its strong chemical resistance and ease of fabrication. Key lifecycle points:

- Good resistance to most acids, bases and solvents; check chemical compatibility for concentrated reagents.

- Can be heat- and UV-sensitive; severe heat exposure leads to discoloration or loss of properties.

- Repairable: small chips and burns can be patched in the field, lowering replacement frequency.

- TCO advantage: longer lifespan and low maintenance given appropriate use.

Phenolic resin countertops

Phenolic is cost-effective and highly moisture-resistant, making it suitable for biology and teaching labs with frequent aqueous use. Considerations:

- Not as solvent-resistant as epoxy; avoid heavy organic solvents or concentrated acids.

- Excellent dimensional stability and lower thermal conductivity (comfortable for users).

- Lower upfront cost means faster payback for lower-stress environments.

Stainless steel countertops

Stainless steel (304, 316) excels in sterile, cleanroom, and food-related labs. Lifecycle notes:

- Highly durable; resists mechanical damage and many chemicals (316 is better against chlorides).

- Hygienic and easy to decontaminate; ideal for biosafety and GMP environments.

- Higher upfront cost but minimal replacement/repair frequency; polishing and weld integrity are maintenance tasks.

Calculating TCO with an example (10-year horizon)

Below is an illustrative TCO example using realistic, conservative assumptions. Numbers are exemplar and should be replaced with supplier quotes and local labor rates when making procurement decisions.

| Material | Initial Cost per m2 (USD) | Annual Maintenance Cost per m2 (USD) | Expected Lifespan (years) | Estimated 10-year Total Cost per m2 (USD) |

|---|---|---|---|---|

| Epoxy Resin | 350 | 10 | 20 | 450 (initial 350 + maintenance 100) |

| Phenolic Resin | 250 | 12 | 15 | 370 (initial 250 + maintenance 120) |

| Stainless Steel | 650 | 20 | 25+ | 850 (initial 650 + maintenance 200) |

| Quartz/Ceramic | 700 | 25 | 20 | 950 (initial 700 + maintenance 250) |

Interpretation: Even though stainless steel and quartz have higher upfront costs, their extended service life and predictable maintenance often yield competitive or favorable 10-year costs, especially when factoring downtime avoidance and compliance advantages.

Installation, cutouts, integration and customization costs

Customized Lab Countertops that include cutouts for sinks, instrumentation, gas and vacuum ports, and integrated backsplashes increase fabrication and installation costs but reduce long-term operational friction. Key points:

- Precision cutouts reduce retrofit downtime and prevent field modifications that can compromise chemical resistance.

- Edge treatments (e.g., coved backsplashes) and sealed seams minimize contamination and simplify cleaning.

- Integrated solutions that tie into bench systems reduce installation time and long-term service issues. Factor these benefits into TCO as lower downtime and reduced maintenance.

Maintenance, cleaning protocols and decontamination

Maintenance strategies dramatically affect lifecycle cost. A documented cleaning and decontamination protocol matched to material properties will:

- Extend usable life by preventing premature damage from incompatible cleaners.

- Reduce repair frequency and prevent chemical staining or delamination.

- Enable predictable budgeting for consumables and labor.

Recommendation: Maintain a compatibility matrix that maps commonly used chemicals and disinfectants to your specific countertop material. Train housekeeping and lab staff to follow product-specific procedures.

Downtime, repair and contingency planning

When a bench is out of service, laboratory throughput and schedules are affected. Include these in your LCA:

- Estimate the cost of lost productivity per bench-day (consider critical instruments and experiments).

- Plan for modular repairs and keep replacement panels or repair kits on hand for rapid fixes.

- Consider warranty and service agreements from suppliers to reduce unexpected repair costs.

Sustainability, disposal and end-of-life considerations

Increasingly, institutional procurement includes sustainability criteria. Consider:

- Recyclability: stainless steel is highly recyclable; some resin-based tops are harder to recycle and may require special disposal.

- Embodied carbon and manufacturing footprint: choose suppliers with transparent environmental reporting if that aligns with institutional policy.

- Safe disposal of chemically contaminated tops: contaminated countertops may be regulated as hazardous waste depending on use; plan for decontamination or certified disposal in lifecycle costs.

Choosing the right lab countertop for your facility

Match material selection to lab mission and risk profile:

- Chemical research labs: epoxy resin or specialty phenolic where chemical resistance and reparability are critical.

- Biology and wet labs: phenolic for cost-sensitive installations; stainless steel where sterilization and contamination control are priorities.

- Cleanrooms and sterile processing: stainless steel or compatible solid surface with validated cleaning protocols.

- Teaching labs: balance cost and durability — epoxy or phenolic with sacrificial surfaces for heavy student use.

Brand value — Why choose Lab Countertops from Max Lab

Max Lab’s Lab Countertops combine material selection expertise, full customization, and institutional installation experience to reduce lifecycle cost and operational risk. Key advantages:

- One-stop customization: precise cutouts, integrated sinks, and edge treatments reduce on-site modifications and downtime.

- Material guidance: recommendations tailored to chemical, biological, cleanroom, and teaching lab needs supporting long-term TCO optimization.

- Warranty and service: installation and after-sales support that helps keep maintenance predictable and costs controllable.

- Design for compliance and cleanability: options to meet SEFA and lab safety standards.

Practical steps to perform your own lifecycle cost analysis

- Inventory requirements: list bench area, expected loads, and chemical usage.

- Request supplier quotes including fabrication, installation, and service agreements.

- Estimate maintenance and downtime costs based on historical data or conservative assumptions.

- Calculate 5- and 10-year TCO scenarios for each material option.

- Factor in soft benefits: compliance, staff safety, and ease of cleaning.

- Make a decision matrix that weights cost, performance, safety, and sustainability.

Frequently Asked Questions (FAQ)

Q: What is the single best countertop material for all labs?

A: No single material fits every lab. Epoxy and stainless steel are versatile for many institutional environments; phenolic is cost-effective for aqueous work. Material choice should align with chemicals used, cleaning protocols, and operational priorities.

Q: How much more should I budget for customized cutouts and integrations?

A: Customizations typically add 10–30% to fabrication costs depending on complexity (sinks, plumbing, gas ports, electrical cutouts). However, they often reduce long-term retrofit costs and downtime, improving lifecycle value.

Q: How do I include downtime costs in the lifecycle calculation?

A: Estimate the value of lost lab work per day (based on staff salaries, instrument time, and project deadlines). Multiply by expected downtime days for repairs or replacement, and add to the TCO as an operational cost.

Q: Can worn or damaged epoxy countertops be repaired in the field?

A: Yes. Epoxy is commonly repaired on-site for chips and burns, which lowers replacement frequency and overall lifecycle cost compared to materials that require full panel replacement.

Q: Are there standards or guidance for lab furniture and surfaces?

A: Yes. Industry groups like SEFA publish guidelines for lab furniture; regulatory bodies like OSHA and CDC provide laboratory safety guidance that affects surface selection and cleaning protocols.

Contact us / See product

To evaluate lifecycle costs for your facility and get a tailored quote for Lab Countertops, contact Max Lab sales for a free site assessment or request product specifications and case studies. Our experts will help you model TCO, choose the right material, and plan installation with minimal downtime.

Authoritative references and further reading

- Scientific Equipment and Furniture Association (SEFA): https://www.sefa.org

- CDC Laboratory Framework and Design Guidance: https://www.cdc.gov/labs/framework

- OSHA Laboratory Safety Guidance: https://www.osha.gov/laboratory-safety

- Epoxy resin (Wikipedia): https://en.wikipedia.org/wiki/Epoxy

- Phenolic resin (Wikipedia): https://en.wikipedia.org/wiki/Phenolic_resin

- Stainless steel (Wikipedia): https://en.wikipedia.org/wiki/Stainless_steel

Installing Floor Mounted Lab Benches: What to Expect

6 Tips to Select the Right Laboratory Furniture

Customizing Floor Mounted Lab Benches: Modules and Accessories

Fume Hood Vendor Selection Checklist for Procurement

For After-Sales Support

How can I get technical support for my equipment?

You can contact our technical support team via email or phone for assistance with installation, troubleshooting, or any issues you encounter with your laboratory equipment.

For Logistics

What is the lead time?

We usually will start to work after receiving 50% deposit, and as for the exact lead time, it depends on quantity and detailed requirement. We can promise it will be shipped on time as we negotiated.

Customization

Do you offer free design consultation?

Yes, we provide our clients with free preliminary design consulting services. Our design team will provide advice based on your needs and budget, and help you develop a laboratory layout and equipment plan that meets your requirements.

About Solution

How about your after sale service?

We will reply to you within 24 hours by email or phone.

If we have a local agent, we will arrange for him to be at your site within 24 hours to assist you in shooting the problem.

For Customization

Can you create furniture for labs with special requirements?

Yes, we specialize in designing and manufacturing lab furniture for specialized environments, including clean rooms, bio labs, and industrial labs.

Floor Mounted Lab Bench

Our Floor Mounted Lab Bench is an essential, high-efficiency workspace for laboratories, made from high-quality steel-wood or corrosion-resistant stainless steel materials to ensure exceptional durability and stability. The unique floor-mounted design effectively reduces vibration, optimizes space usage, and provides a safe and tidy laboratory environment.

Customizable storage solutions help organize lab equipment efficiently, while the easy-to-clean surface maintains laboratory hygiene. It is widely suitable for research institutions, educational laboratories, and the chemical and pharmaceutical industries.

Fume Hood

The fume hood provides safe ventilation to protect against exposure to hazardous or toxic fumes, vapors, or airborne particulate. It is primarily used in laboratory and manufacturing applications to protect the user or environment outside the hood, but can also be used to protect the materials or experiment under the hood.

APPLICATION

Chemistry Lab, physics Lab, biological analysis, pharmaceutical medicine analysis, biological pharmaceutical, plant culture, environmental testing and electronic instrumentation scientific research and so on.

Flammable Storage Cabinet

Safety Cabinets store flammable liquids, corrosives, pesticides and other hazardous materials. All fire-resistant safety cabinets by meet fire codes and regulations for safety storage.

To help protect your people and facility from a potential fire, safety cabinets are engineered to safely contain flammable fuels, solvents, and chemicals. Safety cabinets can not only help everyone store chemicals reasonably, save chemical supplies, but also save human resources, and avoid fires caused by chemicals with the greatest strength.

Class II Type A2 Biological Safety Cabinet for Laboratory

The Class II A2 Biological Safety Cabinet is designed to provide superior biosafety and contamination control for laboratories, research facilities, and clinical settings. With 70% air recirculation and 30% air exhaust, this cabinet ensures a safe and efficient work environment while protecting both the user and the samples.

Equipped with advanced features like a HEPA filtration system, motorized front window, and ergonomic design, this cabinet is a must-have for safe and reliable biological research.

Scan QR Code

Scan QR Code

MaxLabFurniture

MaxLab Furniture

daihongada

Max Laboratory