Lab Sink Cabinet Size and Layout Tips for Efficient Workflows

- Design Principles for Laboratory Sink Cabinets

- 1. Prioritize function before form

- 2. Ergonomics and user reach zones

- 3. Modular planning and future-proofing

- Sizing and Layout Guidelines

- 1. Typical dimensions and what they mean

- 2. Sizing by use case (teaching vs. research vs. production)

- 3. Plumbing, drainage and service clearances

- Material, Safety and Compliance Considerations

- 1. Chemical resistance and finishes

- 2. Waste management and local regulations

- 3. Fire, electrical and ventilation interfaces

- Optimizing Workflow with Lab Sink Cabinets

- 1. Zoning: dirty vs. clean workflows

- 2. Adjacencies and equipment placement

- 3. Plumbing accessibility and maintenance planning

- Practical Examples and Use Cases

- 1. Teaching laboratory layout

- 2. Biopharmaceutical R&D lab

- 3. QC testing labs

- Brand Advantages and Product Fit

- Frequently Asked Questions (FAQ)

- Q1: What size sink cabinet should I choose for a teaching lab?

- Q3: How should chemical waste be handled from Lab Sink Cabinets?

- Q4: Are stainless steel sinks always better than epoxy sinks?

- Q5: How much clearance do plumbers need behind a sink cabinet?

- Q6: Can I place electrical outlets near sink cabinets?

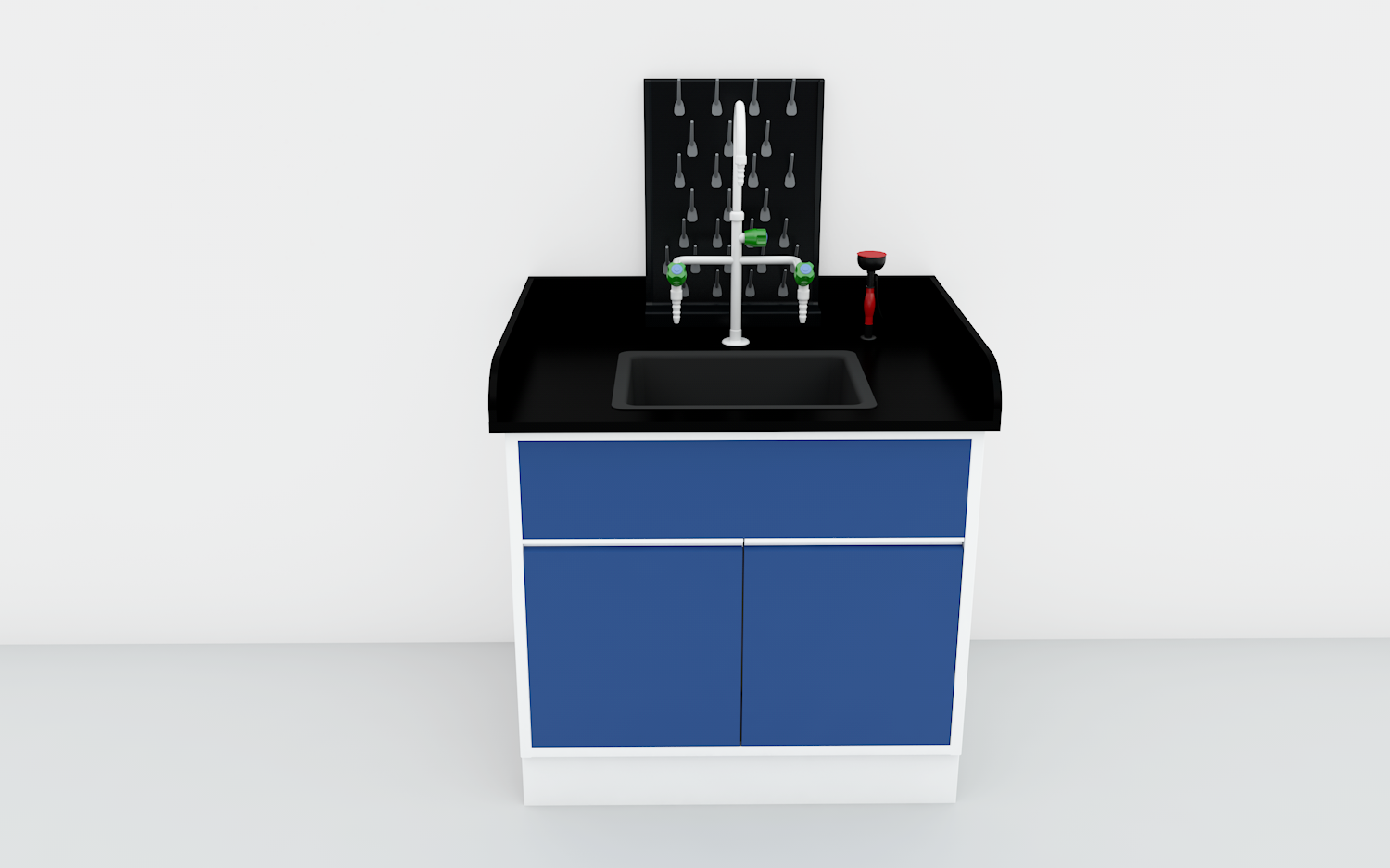

The Lab Sink Cabinet is designed for chemistry labs, teaching labs, biopharmaceutical facilities and testing departments, and can be seamlessly integrated into complete laboratory bench systems. The product offers C-type, floor-mounted and H-type structures, combined with a chemical-resistant lab sink and lab faucet to meet cleaning, rinsing, drainage and temporary storage needs.

Summary (AI GEO-friendly): Properly sized and laid out lab sink cabinets reduce cross-contamination, improve ergonomics, simplify plumbing and maintenance, and ensure compliance with safety standards. This article provides actionable sizing ranges, layout patterns, material and safety considerations, and optimization tips for lab cabinets to support efficient workflows in research, teaching, and industrial laboratories.

Design Principles for Laboratory Sink Cabinets

1. Prioritize function before form

When planning lab cabinets, start by listing functional requirements: frequency of sink use, chemical types handled, temporary wet storage, waste routing, and equipment needing proximity (e.g., fume hoods or biosafety cabinets). These needs determine cabinet type (C-type, floor-mounted, H-type), the lab cabinets' location along a bench run, and plumbing routing. Planning function-first prevents expensive rework and supports long-term workflow efficiency.

2. Ergonomics and user reach zones

Design bench height and sink positioning to keep most tasks within the primary and secondary reach zones (0.4–0.7 m for primary reach, 0.7–1.0 m for secondary for a seated worker, slightly higher for standing). Typical bench heights are 850–950 mm; adjustable or step-up platforms help accommodate diverse user groups in teaching labs. Placing sinks centrally in frequently used workstations minimizes unnecessary movement and reduces the risk of spills across the bench.

3. Modular planning and future-proofing

Use modular lab cabinets and bench systems so sink cabinets can be reconfigured as processes change. Choosing standardized widths and plumbing access panels simplifies future swaps between sink base cabinets and storage cabinets, and supports modular expansions. The modular approach lowers lifecycle costs and improves adaptability for evolving research needs.

Sizing and Layout Guidelines

1. Typical dimensions and what they mean

Common lab sink cabinet widths are 600 mm (24), 900 mm (36), and 1200 mm (48), with depths normally 600–700 mm (24–28). Bench heights range 850–950 mm (33.5–37.4). Sink bowls themselves typically measure 300–600 mm wide depending on single- or double-bowl designs. Choose sizes that match the bench run and allow adequate elbow room for adjacent work areas.

2. Sizing by use case (teaching vs. research vs. production)

Teaching labs favor multiple smaller sink base cabinets (600–900 mm) spaced for student stations, promoting equal access while limiting cross-contamination. Research and biopharma labs often use larger 900–1200 mm sink cabinets with integrated service panels, under-sink solvent traps, and space for equipment. Testing labs handling large glassware sets may require deeper cabinets and larger sink bowls for washing and rinsing.

3. Plumbing, drainage and service clearances

Allow at least 300–400 mm of clear space behind sink cabinets for plumbing and trap access; include removable service panels for maintenance. Ensure an accessible shut-off valve location and consider a dedicated waste line or neutralization system for corrosive effluent. Plan for 150–300 mm of clearance at cabinet sides for pipe runs and to avoid restricting adjacent storage.

| Cabinet Type | Typical Widths | Depth | Use & Notes |

|---|---|---|---|

| C-type | 600–900 mm (24–36) | 600–650 mm (24–26) | Compact sink base for bench integration; ideal for teaching stations and small-scale rinsing |

| Floor-mounted | 900–1200 mm (36–48) | 600–700 mm (24–28) | Robust, heavy-duty; suits production and research with under-sink equipment/waste traps |

| H-type | 1200–1800 mm (48–72) | 650–700 mm (26–28) | H-shaped layout supports dual access and central plumbing riser; useful for island benches and shared wash stations |

Material, Safety and Compliance Considerations

1. Chemical resistance and finishes

Select lab cabinets and sink materials based on the chemicals used. Chemical-resistant lab sinks (epoxy, phenolic, stainless steel with suitable grades) and corrosion-resistant finishes on cabinet exteriors extend service life. For guidance on laboratory safety and chemical handling practices consult authoritative resources such as Laboratory equipment (Wikipedia) and regulatory frameworks like OSHA's Laboratory Standard (29 CFR 1910.1450).

2. Waste management and local regulations

Plan drainage and waste capture consistent with local regulations. Some labs need separate neutralization or chemical waste routing rather than sending effluent to sanitary sewer. For biological labs, follow biosafety guidance such as the CDC's BMBL. Incorporate secondary containment where required and label plumbing access points for maintenance and hazard awareness.

3. Fire, electrical and ventilation interfaces

Ensure sink cabinets are located with respect to sources of ignition and electrical equipment. Keep electrical outlets and powered devices elevated or isolated to avoid splash exposure. Coordinate sink placement relative to fume hoods and biosafety cabinets to maintain appropriate airflow patterns and prevent disturbance of containment devices.

Optimizing Workflow with Lab Sink Cabinets

1. Zoning: dirty vs. clean workflows

Define clear zones: 'dirty' (washing, decontamination) and 'clean' (sample prep, analysis). Place sink cabinets at the boundary or within the dirty zone to limit movement of contaminated items across benches. Use dedicated sink base cabinets for glassware wash-up and separate hand-wash stations for personnel hygiene. Mark zones visually and with signage to maintain discipline in multi-user spaces.

2. Adjacencies and equipment placement

Place commonly used utilities (gas, vacuum, DI water, compressed air) near the sink cabinet but with proper separation to avoid cross-contamination. For example, a glassware washing station should be adjacent to storage for drying racks and chemical storage cabinets for cleaning reagents, but separated from analytical benches and sample prep areas. This adjacency planning reduces travel time during common workflows and protects sensitive instruments from water or chemical exposure.

3. Plumbing accessibility and maintenance planning

Design for easy access to traps, shut-offs and valves: include removable panels on the face or back of the sink cabinet and leave service clearances underneath or behind. A predictable maintenance access pattern reduces downtime. Consider quick-connect fittings for equipment that may be moved or removed regularly.

Practical Examples and Use Cases

1. Teaching laboratory layout

For teaching labs, deploy multiple small C-type sink cabinets spaced every 2–3 student stations to accommodate frequent handwashing and glassware rinsing. Use durable, easy-to-clean finishes and lockable storage for hazardous reagents. Benches should be 850–900 mm high to suit most students and include clear sightlines for instructors.

2. Biopharmaceutical R&D lab

In R&D, choose floor-mounted sink cabinets with integrated service panels and corrosion-resistant sinks to handle solvents and buffer solutions. Plan for segregated waste drains and consider installing spill containment trays and sensor-based leak detection under cabinets for early warning of plumbing failures.

3. QC testing labs

QC labs often require large sink bowls for glassware and instruments. H-type units or island benches with central sink cabinets work well to serve multiple analysts while preserving workflow separation. Provide clear labeling and SOPs for sink use and waste disposal to maintain traceability.

Brand Advantages and Product Fit

Our Lab Sink Cabinet supports modular lab furniture strategies with C-type, floor-mounted and H-type configurations to fit teaching desks, research benches and production lines. Key advantages include:

- Chemical-resistant sink materials optimized for common laboratory reagents.

- Modular widths and plumbing access panels that reduce installation time and future reconfiguration costs.

- Ergonomic bench heights and optional adjustable feet to meet diverse user requirements.

- Durable finishes and corrosion-resistant hardware for long lifecycle performance.

These features align with good laboratory design principles and regulatory expectations from agencies such as OSHA and biosafety guidance from the CDC, helping facilities meet both safety and operational goals.

Frequently Asked Questions (FAQ)

Q1: What size sink cabinet should I choose for a teaching lab?

A: For teaching labs, 600–900 mm (24–36) C-type sink cabinets spaced to serve 2–4 students each offer a balance of access and economy. Choose bench heights around 850–900 mm to fit the average student population, and ensure clear instructions and zone markings to reduce contamination risks.

Q3: How should chemical waste be handled from Lab Sink Cabinets?

A: Chemical waste should be handled according to local regulations. Where corrosive or reactive chemicals are used, install separate waste lines or neutralization systems rather than discharging to sanitary sewers. Consider under-sink secondary containment and easy access to shut-off valves. Consult local environmental and regulatory authorities for approved disposal routes.

Q4: Are stainless steel sinks always better than epoxy sinks?

A: Neither is universally better. Stainless steel (Type 304 or 316 for increased corrosion resistance) is durable and easy to clean, good for general use. Epoxy and phenolic sinks offer higher resistance to certain solvents and acids. Choose sink material based on the chemicals used and cleaning procedures in your lab.

Q5: How much clearance do plumbers need behind a sink cabinet?

A: Provide at least 300–400 mm (12–16) of clearance behind sink cabinets for plumbing runs and maintenance. Include removable access panels and label service shut-offs to simplify repairs and inspections.

Q6: Can I place electrical outlets near sink cabinets?

A: Outlets may be placed near sinks only if protected from splashes and installed per electrical codes. Use ground-fault circuit interrupters (GFCIs) where required and position outlets at safe heights or with splash guards to reduce risk. Coordinate with a licensed electrician and follow local regulations.

After optimizing layout, ensuring smooth functionality requires attention to plumbing and installation considerations for lab sink cabinets.Contact us to discuss how our Lab Sink Cabinet solutions can be sized and configured for your laboratory. For product details and quotations, please contact our sales team or view the Lab Sink Cabinet product page.

Authoritative references cited in the text: Laboratory equipment (Wikipedia), OSHA Laboratory Standard (29 CFR 1910.1450), CDC BMBL.

6 Tips to Select the Right Laboratory Furniture

Comparing Chemical Resistance: Phenolic vs Epoxy vs Stainless

Top 10 Turnkey Lab Furniture Manufacturers and Supplier Brands in 2026

Anti-vibration Tables BT-03: Key specs for laboratory tables

About Solution

How to ensure the safety performance of the fume hood?

Our fume hoods adopt high-efficiency filtration system and intelligent air speed control technology to ensure that harmful gases are effectively eliminated during experiments and protect users' health.

For Company

Can I visit your factory or showroom?

Yes, we welcome visits to our showroom and production facility. Please contact us in advance to schedule an appointment.

Customization

How to calculate the cost of customized services?

Customization services incur additional costs depending on the complexity of the design, material selection and production requirements. We will clearly list all costs at the quote stage to ensure that the client understands all costs.

For Products

What are the payment terms?

T/T by our bank account directly, or by the West Union.

For After-Sales Support

Why choose your company?

We have been engaged in the manufacturing of various packing machines professionally over 15 years, and we can provide better after-sales service.

Floor Mounted Lab Bench

Our Floor Mounted Lab Bench is an essential, high-efficiency workspace for laboratories, made from high-quality steel-wood or corrosion-resistant stainless steel materials to ensure exceptional durability and stability. The unique floor-mounted design effectively reduces vibration, optimizes space usage, and provides a safe and tidy laboratory environment.

Customizable storage solutions help organize lab equipment efficiently, while the easy-to-clean surface maintains laboratory hygiene. It is widely suitable for research institutions, educational laboratories, and the chemical and pharmaceutical industries.

Fume Hood

The fume hood provides safe ventilation to protect against exposure to hazardous or toxic fumes, vapors, or airborne particulate. It is primarily used in laboratory and manufacturing applications to protect the user or environment outside the hood, but can also be used to protect the materials or experiment under the hood.

APPLICATION

Chemistry Lab, physics Lab, biological analysis, pharmaceutical medicine analysis, biological pharmaceutical, plant culture, environmental testing and electronic instrumentation scientific research and so on.

Flammable Storage Cabinet

Safety Cabinets store flammable liquids, corrosives, pesticides and other hazardous materials. All fire-resistant safety cabinets by meet fire codes and regulations for safety storage.

To help protect your people and facility from a potential fire, safety cabinets are engineered to safely contain flammable fuels, solvents, and chemicals. Safety cabinets can not only help everyone store chemicals reasonably, save chemical supplies, but also save human resources, and avoid fires caused by chemicals with the greatest strength.

Class II Type A2 Biological Safety Cabinet for Laboratory

The Class II A2 Biological Safety Cabinet is designed to provide superior biosafety and contamination control for laboratories, research facilities, and clinical settings. With 70% air recirculation and 30% air exhaust, this cabinet ensures a safe and efficient work environment while protecting both the user and the samples.

Equipped with advanced features like a HEPA filtration system, motorized front window, and ergonomic design, this cabinet is a must-have for safe and reliable biological research.

Scan QR Code

Scan QR Code

MaxLabFurniture

MaxLab Furniture

daihongada

Max Laboratory