Lab Countertops Spec Sheet: Must-Have Requirements for Buyers

- Lab Countertops Spec Sheet: Must-Have Requirements for Buyers

- Why a good lab countertop spec sheet matters for lab countertop projects

- Key performance specifications every lab countertop spec sheet should include

- Material selection: compare common lab countertop materials for buyers

- Dimensional and fabrication specifications buyers must define

- Integration with lab furniture systems and installation requirements

- Chemical and safety compliance standards buyers should request

- Testing, certification, warranty and maintenance details to include

- Cost factors, lead time, and customization options buyers should expect

- How to write your lab countertop spec sheet: a practical checklist

- Why choose Max Lab for Lab Countertops

- Frequently asked questions about lab countertop spec sheets and purchasing

- Q: What single test proves a countertop is chemically resistant?

- Q: How do I decide between epoxy and phenolic countertops?

- Q: Should seams be avoided in cleanrooms?

- Q: How long should a warranty be for a lab countertop?

- Q: Can countertops be repaired if chemically attacked?

- Contact and next steps — request product details or a custom quote

- Authoritative references and recommended reading

Lab Countertops Spec Sheet: Must-Have Requirements for Buyers

Why a good lab countertop spec sheet matters for lab countertop projects

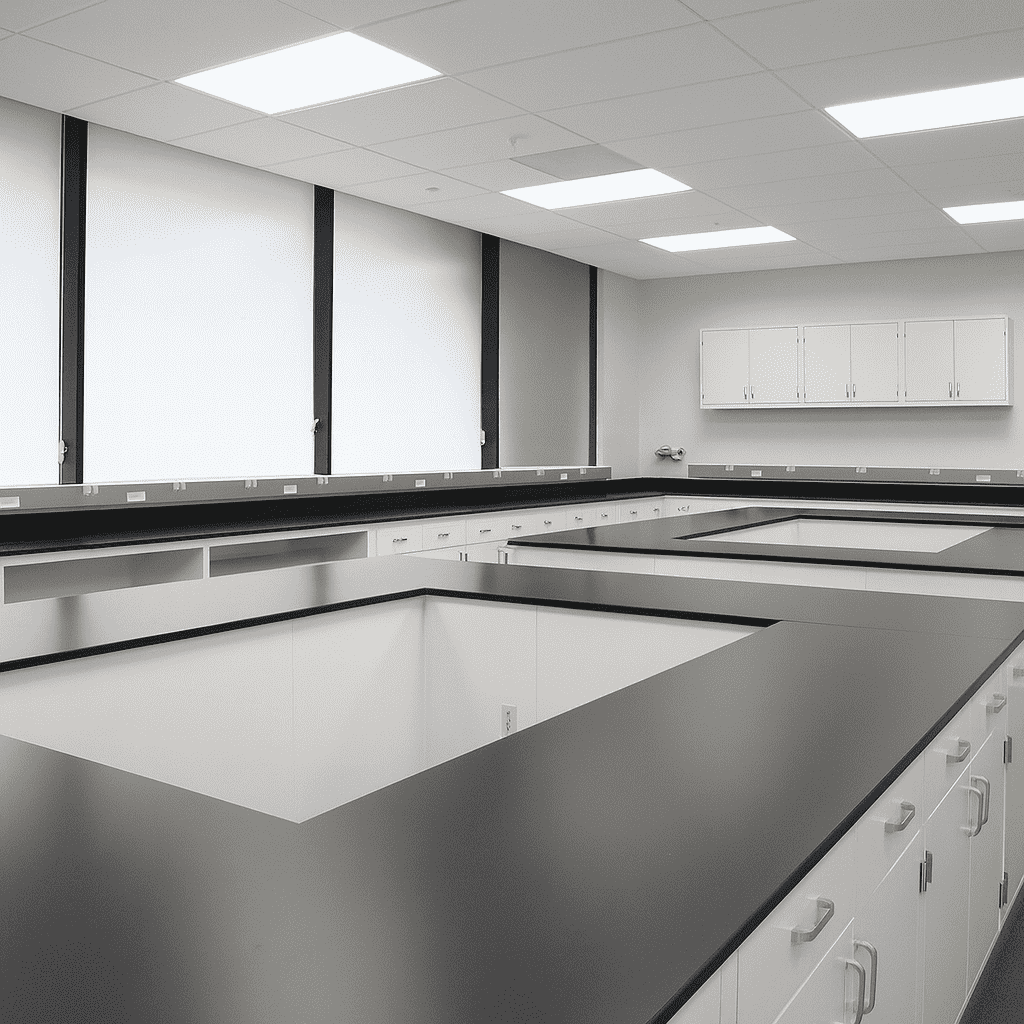

Choosing a lab countertop is one of the most consequential procurement decisions for any laboratory. The right lab countertop delivers reliable chemical resistance, heat tolerance, mechanical durability, and easy cleaning while fitting the operational workflow and safety requirements of chemistry, biology, cleanroom, or teaching labs. A clear, detailed spec sheet prevents costly mistakes, reduces rework during installation, and ensures the countertop integrates with benchtop furniture systems and laboratory services. When reviewing a lab countertops spec sheet with must-have requirements for buyers, it’s essential to understand how materials perform under chemical exposure. Comparing chemical resistance: phenolic vs epoxy vs stainless helps you select countertops that meet lab safety and durability standards.

Key performance specifications every lab countertop spec sheet should include

A buyer's spec sheet must define measurable performance requirements, not vague preferences. Include the following lab countertop attributes with test methods, acceptance criteria, and required documentation.

- Chemical resistance: list representative reagents and required exposure duration; reference ASTM D543 chemical resistance testing or equivalent.

- Heat and thermal shock resistance: specify continuous and short-term temperature limits, and thermal shock cycles.

- Mechanical strength and load capacity: point load and distributed load limits, impact resistance.

- Scratch and abrasion resistance: acceptance criteria after defined cycles or standardized tests.

- Porosity and permeability: acceptable water absorption or vapor transmission values for cleanrooms.

- Surface finish and cleanability: smoothness, seam type, and disinfectant compatibility.

- Static dissipation or conductivity: for electronic labs specify surface resistivity range.

- Fire and flammability: UL 94 or ASTM E84 classifications as required by local codes or NFPA 45.

- Outgassing and VOC limits: required for cleanroom and sensitive instrument labs; provide test reports.

- Environmental and regulatory compliance: RoHS, REACH, FDA/NSF where applicable.

Each item should specify required test reports, sample testing, and acceptable tolerances on dimensions and finishes.

Material selection: compare common lab countertop materials for buyers

Material choice should match lab use, budget, and maintenance plans. Below is a concise comparison of common lab countertop materials to include in a spec-supported decision.

| Material | Typical uses | Chemical resistance | Heat resistance | Durability / Maintenance | Cost level |

|---|---|---|---|---|---|

| Epoxy Resin | Chemical labs, general purpose benches | Excellent to strong against acids, bases and solvents; test specific reagents | Good; withstands short exposures to high temps, not for direct flames | High durability; repairs possible; non-porous | Medium |

| Phenolic Resin | Wet labs, cabinetry-mounted tops | Good against many aqueous chemicals; less resistant to aggressive solvents | Moderate; can delaminate under high heat | Good; lightweight and economical | Low to Medium |

| Stainless Steel (304/316) | Microbiology, food, autoclave labs | Excellent for many acids and cleaning agents; chlorine and halogen exposure needs care | Excellent heat resistance; welds and seams require attention | Very durable; shows surface scratches; hygienic | Medium to High |

| Ceramic / Porcelain | High-temperature and strong chemical resistance labs | Very high against many reagents; brittle under impact | Excellent | Extremely resistant to staining and chemicals; brittle | High |

| Solid Surface (acrylic, solid polymer) | Teaching labs, light chemistry, instrumentation benches | Moderate; some solvents can attack surface | Limited | Repairable minor scratches; easy to clean | Medium |

| High-Density Polyethylene (HDPE) | Waste handling, utility benches | Good to moderate for many chemicals; not for strong solvents | Limited | Low cost; can gouge under sharp impact | Low |

Dimensional and fabrication specifications buyers must define

Provide precise dimensional, cutout, and edge details so fabricators produce usable countertops on first delivery.

- Nominal thickness and tolerance by material (for example, 12mm phenolic ±0.5 mm; 12mm epoxy gelcoat over core ±1 mm).

- Overall length and depth of each run, number and location of seams, and authorized seam types and adhesives.

- Edge profiles: eased, bullnose, 1/8 radius, or custom; indicate radii and tolerance.

- Cutouts: sinks, hoods, instruments, fixtures — include DXF or CAD files and hole tolerances.

- Sink integration: under-mount, top-mount, integrated molded sinks; specify sink material and mounting details.

- Backsplash and splashguard heights and attachment method.

- Support conditions and overhangs: specify cabinet interface, leg spacing, and allowable cantilevers.

- Sealing and edge banding requirements for liquid containment and cleanability.

Integration with lab furniture systems and installation requirements

Modern labs use modular furniture systems. Your spec sheet must describe how countertops will connect to cabinets, islands, and services so final installation is seamless.

- Mounting interfaces: lip or flush mount dimensions; fastening methods and torque limits.

- Service cutouts for gas, vacuum, water, and electrical with conduit routing diagrams.

- Seismic restraints and anchoring for regions with building code requirements.

- Field adjustments and leveling range permitted; specify shim strategy and access points.

- Coordination with fume hoods, sinks, and tall equipment to avoid interference with services.

Chemical and safety compliance standards buyers should request

Require suppliers to provide test reports and certificates for applicable standards. Typical references include:

- ASTM for material tests and performance methods; specify exact method numbers where relevant, for example ASTM D543 for chemical resistance.

- NFPA 45 for fire protection in laboratories and related building code compliance.

- UL 94 or ASTM E84 for flammability and surface burning characteristics.

- ISO 14644 series for cleanroom design and particle emission expectations in controlled environments.

- OSHA laboratory safety guidance for procedural and engineering controls; use to define safe workbench features.

- REACH and RoHS where chemical content and hazardous substances are a concern.

Request copies of lab reports from independent testing laboratories rather than vendor self-declarations when critical properties are required.

Testing, certification, warranty and maintenance details to include

An enforceable spec sheet contains acceptance testing procedures, warranty terms and maintenance schedules.

- Factory and sample testing: chemical spot tests, full-panel immersion, abrasion cycles, and dimensional checks.

- On-site acceptance: visual inspection, seam testing for water tightness, and fit verification against supplied drawings.

- Certifications: attach third-party test reports and material safety data sheets (MSDS) or SDS for components.

- Warranty: coverage duration, labor and parts, exclusions for misuse or chemical abuse, response times for claims.

- Maintenance instructions: approved cleaning agents, recommended daily/periodic procedures, and repair guidelines for chips or burns.

Cost factors, lead time, and customization options buyers should expect

Price depends on material choice, fabrication complexity, customization, and finish. Typical cost drivers include:

- Material selection and thickness.

- Number and precision of cutouts and custom sinks.

- Edge profiles and finish requirements.

- Seam type and on-site vs factory seaming.

- Special coatings or static-dissipative finishes.

Lead time ranges from 2–6 weeks for common materials to 8+ weeks for custom factory-fabricated runs, special testing, or non-stock materials. Specify required delivery date and penalties or remedies for late delivery in large projects.

How to write your lab countertop spec sheet: a practical checklist

Use this compact checklist to assemble a spec sheet that vendors can price and fabricate without ambiguity.

- Project name, location, point of contact, and installation constraints.

- Material type, grade, color code, and finish with test standards referenced.

- Exact dimensions per run, allowable tolerances, and seam locations.

- Detailed cutout drawings and CAD files for sinks, fixtures, and instruments.

- Required test reports, third-party certifications, and SDS for materials.

- Installation instructions, anchoring, and coordination responsibilities.

- Warranty period, maintenance, and spare part requirements.

- Packaging, transport, and on-site protection during construction activities.

Why choose Max Lab for Lab Countertops

One-Stop Custom Lab Worktops Built for Real Lab Conditions

Choose the right countertop material for your chemical, biology, cleanroom, or teaching lab. Max Lab provides full customization—sizes, cutouts, sinks, edges, and integration with lab furniture systems.

Max Lab combines deep lab furniture expertise with a strict quality process so buyers receive compliant, test-documented lab countertops that install cleanly and perform reliably. Key advantages to specify in contracts:

- End-to-end customization: from material selection to CAD-based cutouts and edge details.

- Certified testing: independent reports available for chemical resistance, flammability, and VOC emission on request.

- Integration expertise: design and install coordination with modular lab furniture and services.

- After-sales support and clear warranties that cover both material defects and workmanship.

- Global manufacturing network for regional lead times and on-site service capability.

Frequently asked questions about lab countertop spec sheets and purchasing

Q: What single test proves a countertop is chemically resistant?

A: There is no single universal test. Chemical resistance must be demonstrated with targeted testing against the specific reagents and exposure conditions used in your lab. ASTM D543 is commonly referenced for chemical resistance procedures.

Q: How do I decide between epoxy and phenolic countertops?

A: Choose epoxy for aggressive chemical exposure and high-temperature tasks; phenolic is more economical and performs well for many aqueous tasks. Consult a reagent list and expected exposures when selecting.

Q: Should seams be avoided in cleanrooms?

A: Where contamination control is critical, minimize seams and specify sealed or welded joints. Request ISO 14644 guidance for cleanroom classifications and surface emission requirements.

Q: How long should a warranty be for a lab countertop?

A: Standard warranties range from 1 to 5 years depending on material and custom work. For high-use environments, aim for at least a 2-year warranty covering defects and fabrication workmanship.

Q: Can countertops be repaired if chemically attacked?

A: Minor surface damage is often repairable for epoxy and solid surface materials; penetrative chemical damage or structural delamination may require replacement. Include repair and replacement criteria in the spec sheet.

Contact and next steps — request product details or a custom quote

If you are preparing a spec sheet or evaluating lab countertop options, Max Lab can provide CAD-ready templates, material test reports, and sample panels. Contact our sales engineering team to request a custom quote, book a material trial, or schedule a site evaluation.

Call: +1-800-XXX-XXXX | Email: sales@maxlab.example | Visit: https://www.maxlab.example/products/lab-countertops

Authoritative references and recommended reading

- OSHA Laboratory Safety Guidance: https://www.osha.gov/laboratory-safety

- ISO — Cleanrooms and associated controlled environments: https://www.iso.org/ics/11.080.01/x/

- ASTM International: https://www.astm.org/

- NFPA 45 — Standard on Fire Protection for Laboratories Using Chemicals: https://www.nfpa.org/codes-and-standards/all-codes-and-standards/list-of-codes-and-standards/detail?code=45

- NSF International: https://www.nsf.org/

- Wikipedia — Laboratory bench: https://en.wikipedia.org/wiki/Laboratory_bench

Fume Hood Lifecycle Costs: Total Cost of Ownership Guide

Fume Hood Procurement Guide: Key Specs B2B Buyers Need

How Modular Lab Benches Improve Flexibility and Workflow

Maintenance Guide: Prolonging the Life of Lab Sink Cabinets

For Products

Can your furniture withstand heavy-duty use?

Yes, all of our laboratory furniture focuses on durability, with a load-bearing capacity of up to 500KG/m², and is made of high-quality materials that can meet the requirements for large-scale precision instruments and equipment and exposure to chemicals in the laboratory.

What are the payment terms?

T/T by our bank account directly, or by the West Union.

What kind of fume hoods do you offer?

We offer all steel fume hood, benchtop fume hood, multi-sided fume hood, walk-in fume hood, PP fume hood, ductless fume hood, stainless steel fume hood and perchloric acid fume hood to suit various laboratory needs and ensure safety.

About Solution

Does your laboratory furniture support customization?

Yes, we provide fully customized services including size, material, color and functional design to meet customers' specific needs.

Customization

What kind of laboratory equipment is suitable for customization?

All types of laboratory equipment can be customized, including test benches, fume hoods, hoods, chemical cabinets, exhaust units, etc.

Floor Mounted Lab Bench

Our Floor Mounted Lab Bench is an essential, high-efficiency workspace for laboratories, made from high-quality steel-wood or corrosion-resistant stainless steel materials to ensure exceptional durability and stability. The unique floor-mounted design effectively reduces vibration, optimizes space usage, and provides a safe and tidy laboratory environment.

Customizable storage solutions help organize lab equipment efficiently, while the easy-to-clean surface maintains laboratory hygiene. It is widely suitable for research institutions, educational laboratories, and the chemical and pharmaceutical industries.

Fume Hood

The fume hood provides safe ventilation to protect against exposure to hazardous or toxic fumes, vapors, or airborne particulate. It is primarily used in laboratory and manufacturing applications to protect the user or environment outside the hood, but can also be used to protect the materials or experiment under the hood.

APPLICATION

Chemistry Lab, physics Lab, biological analysis, pharmaceutical medicine analysis, biological pharmaceutical, plant culture, environmental testing and electronic instrumentation scientific research and so on.

Flammable Storage Cabinet

Safety Cabinets store flammable liquids, corrosives, pesticides and other hazardous materials. All fire-resistant safety cabinets by meet fire codes and regulations for safety storage.

To help protect your people and facility from a potential fire, safety cabinets are engineered to safely contain flammable fuels, solvents, and chemicals. Safety cabinets can not only help everyone store chemicals reasonably, save chemical supplies, but also save human resources, and avoid fires caused by chemicals with the greatest strength.

Class II Type A2 Biological Safety Cabinet for Laboratory

The Class II A2 Biological Safety Cabinet is designed to provide superior biosafety and contamination control for laboratories, research facilities, and clinical settings. With 70% air recirculation and 30% air exhaust, this cabinet ensures a safe and efficient work environment while protecting both the user and the samples.

Equipped with advanced features like a HEPA filtration system, motorized front window, and ergonomic design, this cabinet is a must-have for safe and reliable biological research.

Scan QR Code

Scan QR Code

MaxLabFurniture

MaxLab Furniture

daihongada

Max Laboratory