Inspection Checklist for New Lab Countertop Installations

- Inspection Checklist for New Lab Countertop Installations

- Why a formal inspection checklist matters for your lab countertop

- Pre-installation verification: confirm specifications and documentation (lab countertop)

- Material selection confirmation (Lab Countertops)

- On-site dimensional and level checks

- Cutouts, sinks, and integrated fixtures inspection

- Seams, joints, and edge treatment (: Lab Countertops)

- Anchoring and mechanical stabilization

- Plumbing and electrical integration

- Chemical and heat resistance verification (table included)

- Surface flatness, finish, and cleanability

- Leak and pressure testing

- Commissioning tests and documentation

- Post-installation safety and user training

- Maintenance and cleaning verification

- Common defects to look for on inspection day

- When to call for manufacturer or third-party testing

- Why choose Max Lab Lab Countertops for your installation

- FAQ — Inspection Checklist for New Lab Countertop Installations

- Q: How soon after installation can we use the countertops?

- Q: What is the single most important check to avoid future failures?

- Q: Do lab countertops require special cleaning agents?

- Q: How do I verify chemical resistance for uncommon reagents?

- Q: What warranties should I expect?

- Authoritative references and further reading

Inspection Checklist for New Lab Countertop Installations

Why a formal inspection checklist matters for your lab countertop

Installing a lab countertop is more than putting a surface in place — it directly affects safety, workflow, and long-term maintenance of your lab environment. A thorough inspection checklist ensures that the lab countertop meets functional needs (chemical resistance, heat tolerance, cleanability), complies with regulations, integrates correctly with casework and services, and is ready for safe use the moment installation is completed. Use this checklist to reduce rework, avoid hidden risks, and protect your lab personnel and assets. For labs requiring unique configurations, exploring custom fabrication options for lab countertops and specs allows you to meet specialized space, workflow, or experimental needs while adhering to quality standards.

Pre-installation verification: confirm specifications and documentation (lab countertop)

Before installers arrive, verify that the delivered Lab Countertops match the project specifications:

- Purchase order vs. delivery: confirm model, material, color, and finish.

- Drawings and cutlists: confirm dimensions, cutouts, sink locations, and edge profiles against the approved shop drawings.

- Material certificates: request chemical resistance data, fire rating, and manufacturer's installation instructions.

- Site readiness: confirm cabinets are level, walls and services are accessible, and the area is free of debris.

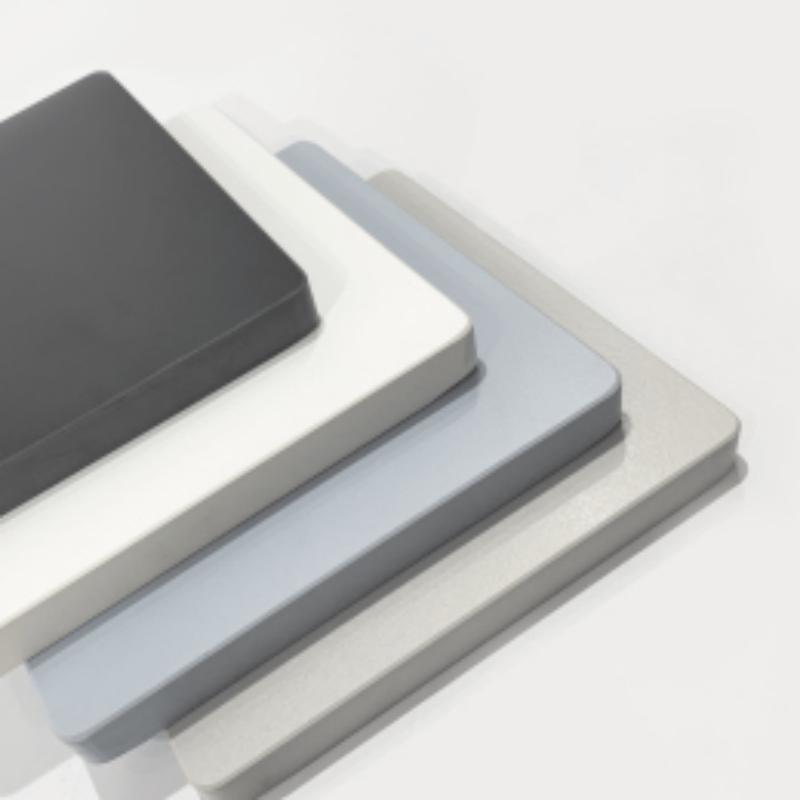

Material selection confirmation (Lab Countertops)

Not every material is suitable for every lab. Confirm the chosen lab countertop material is appropriate for your lab type—chemical, biology, cleanroom, or teaching—and for specific processes. Check:

- Chemical resistance profile vs. expected reagents.

- Heat tolerance for hot plates or direct contact with heated equipment.

- Cleanroom compatibility and particulate shedding for controlled environments.

- Mechanical durability for heavy equipment or frequent impacts.

On-site dimensional and level checks

Accurate dimensions prevent fitment issues and subsequent downtime. On arrival:

- Measure overall length, depth, and thickness at multiple points; verify against shop drawings.

- Check squareness and alignment at walls and corners.

- Confirm cabinets and support structures are level within specified tolerance (typically ±3 mm over 3 m, but confirm project standard).

- Verify overhangs and knee clearance for ergonomic compliance.

Cutouts, sinks, and integrated fixtures inspection

Cutouts are common failure points if not inspected carefully. For each cutout and sink:

- Verify cutout dimensions and locations against equipment and plumbing rough-ins.

- Check edge finishing around cutouts for smoothness and proper sealing.

- Confirm sink drop-in or undermount type is compatible and installed per manufacturer guidance.

- Inspect fasteners and mounting clips for corrosion resistance and correct torque.

Seams, joints, and edge treatment (: Lab Countertops)

Seams and edges must be sealed and finished to prevent chemical ingress and microbial harboring:

- Inspect seam gaps and confirm epoxy or adhesive used is approved for the material and lab application.

- Check joint surface flatness (no high/low points that trap liquids).

- Verify edge profiles (eased, bullnose, or drip) match ergonomic and safety requirements.

- Confirm radiused corners where required for cleanability.

Anchoring and mechanical stabilization

Proper anchoring prevents movement, reduces stress on plumbing fixtures, and maintains alignment:

- Check anchoring points to cabinets, walls, or support frames. Fastener types and spacing should match installation instructions.

- Verify expansion gaps are present where thermal expansion is expected (e.g., long runs of solid surface or stone).

- Confirm load-bearing capacity if heavy equipment will be placed on the countertops.

Plumbing and electrical integration

Lab countertops often carry sinks, eyewash stations, gas lines, and power outlets. Inspect:

- Water supply and drainage align with sink locations and slope correctly to prevent standing water.

- P-traps and cleanouts are accessible and properly supported.

- Electrical outlets and data ports flush-mount or recesses are sealed and positioned per ergonomic standards.

- Gas and vacuum line terminations are correctly installed, labeled, and tested for leaks.

Chemical and heat resistance verification (table included)

Material selection should be validated with known exposures. Use manufacturer data and, if necessary, test coupons. The table below gives a high-level comparison of common lab countertop materials to guide inspection focus.

| Material | Chemical Resistance | Heat Resistance | Cleanroom Suitability | Typical Relative Cost |

|---|---|---|---|---|

| Epoxy Resin | Excellent (many acids/bases; check specifics) | Good to 250°C (spot heat varies) | Good (low particulate if finished) | Mid |

| Phenolic Resin | Good for biological/teaching labs; weaker vs. strong solvents | Moderate (not for high temp contact) | Moderate | Low–Mid |

| Stainless Steel (304/316) | Excellent vs. many solvents; strong acids may pit | Excellent | Excellent (non-porous) | Mid–High |

| Sintered/Quartz Stone | Very good; some chemical vulnerability | Good; thermal shock can be issue | Good | High |

| High-Density Polyethylene (HDPE) | Good for many chemicals; organic solvents vary | Poor to Moderate | Moderate | Low |

Surface flatness, finish, and cleanability

Inspect the installed surface for flatness and finish quality:

- Run a straightedge across long runs to check for warping or dips.

- Confirm finish meets slip-resistance and cleanability requirements (no micro-grooves that hold contaminants).

- Test a small area with intended cleaning agents to confirm finish compatibility.

Leak and pressure testing

For sinks, eyewash, and gas/vacuum services:

- Perform water pressure tests and inspect for leaks at seals and joints.

- Gas lines should be leak-tested using an approved method (soap test, electronic detector) to project standards.

- Verify drainage flow and absence of siphon/vacuum issues.

Commissioning tests and documentation

Complete a formal commissioning protocol and capture documentation:

- Installation checklist sign-off by installer and lab manager.

- Material certificates, warranties, and maintenance instructions stored in project records.

- Test reports for chemical resistance, leak tests, and level/flatness measurements.

- Photos of critical details (seams, cutouts, anchoring) for future maintenance reference.

Post-installation safety and user training

Once installed, ensure lab personnel know proper use and limitations of the Lab Countertops:

- Provide quick training on chemical handling practices specific to the countertop material.

- Label safe working procedures near benches if required (heat limits, incompatible reagents, cleaning agents).

- Schedule first-maintenance inspection after initial use (30–90 days) to check for unforeseen issues.

Maintenance and cleaning verification

Confirm maintenance plans align with manufacturer guidance:

- Establish approved cleaning agents and concentrations—avoid abrasive cleaners if not recommended.

- Define routine sealing or surface maintenance intervals if required (e.g., for some stone surfaces).

- Keep an incident log for spills or damage to track wear patterns and inform future purchases.

Common defects to look for on inspection day

Be alert to:

- Visible cracks or chips around cutouts.

- Improperly cured or tacky adhesives at seams.

- Misaligned sinks, overhangs, or edge treatments causing drip issues.

- Loose fasteners or gaps between countertop and casework.

When to call for manufacturer or third-party testing

If your inspection reveals material questions (e.g., unexpected staining, rapid degradation, or concerns about chemical resistance), consider:

- Requesting manufacturer material test results or in-situ coupons.

- Contracting a materials lab for chemical exposure testing per ASTM methods (for example, ASTM D543 for chemical resistance).

- Consulting an independent lab safety or ergonomics assessor for high-risk installations.

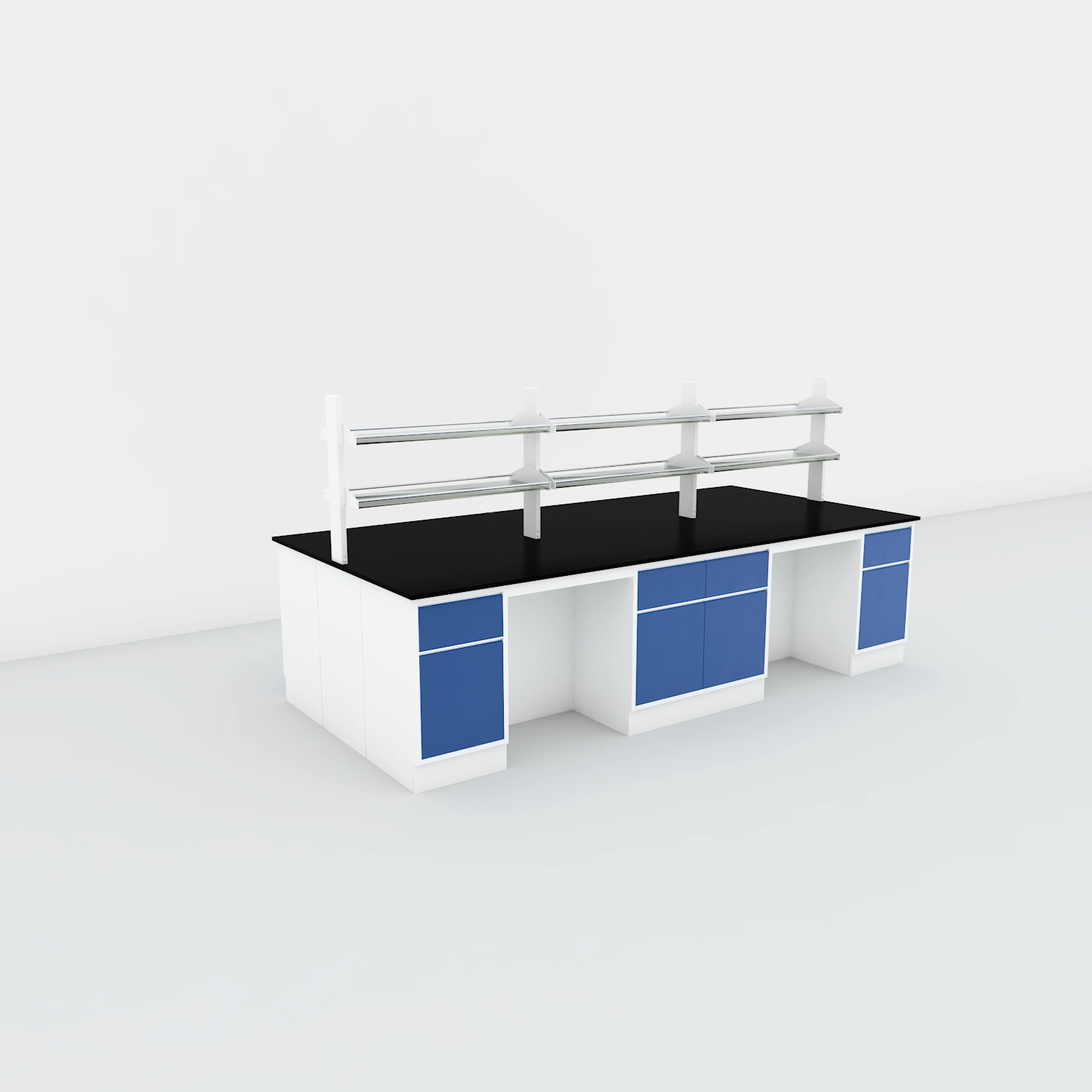

Why choose Max Lab Lab Countertops for your installation

One-Stop Custom Lab Worktops Built for Real Lab Conditions

Choose the right countertop material for your chemical, biology, cleanroom, or teaching lab. Max Lab provides full customization—sizes, cutouts, sinks, edges, and integration with lab furniture systems.

Key brand advantages to highlight during inspection and commissioning:

- Full customization to exact shop drawings reduces on-site modifications and fitment issues.

- Material selection support and published chemical resistance guides to help specifiers and end users.

- Pre-fabricated cutouts and finished seams for faster, higher-quality installations.

- Dedicated technical support for commissioning and maintenance with warranty-backed service.

FAQ — Inspection Checklist for New Lab Countertop Installations

Q: How soon after installation can we use the countertops?

A: Use depends on material and service installations. Most Lab Countertops (epoxy, phenolic, stainless) are usable immediately after installation once adhesives and sealants cure per manufacturer instructions. Verify no pending pressure tests or leak repairs remain.

Q: What is the single most important check to avoid future failures?

A: Ensuring cabinets and supports are level before countertop installation. Improper support leads to stress, seam failure, and premature surface damage.

Q: Do lab countertops require special cleaning agents?

A: Yes. Manufacturer guidance should list approved cleaners. Avoid strong solvents on materials not rated for them, and avoid abrasive pads on polished surfaces. For sensitive applications, use neutral pH cleaners and disinfectants recommended for the material.

Q: How do I verify chemical resistance for uncommon reagents?

A: Request material compatibility data from the manufacturer and, if necessary, run a small exposure test on a spare coupon or discreet area following ASTM D543 procedures.

Q: What warranties should I expect?

A: Standard warranties cover manufacturing defects and installation workmanship for a defined period; ensure warranties include explicit coverage for seams and adhesive performance. Keep warranty certificates and maintenance records in project files.

Need help with inspection or selecting the right Lab Countertops? Contact our technical team for on-site or remote commissioning support, sample coupons, and installation guides. View product options or request a quote: https://www.maxlab.example/contact

Authoritative references and further reading

- OSHA Laboratory Safety Guidance: https://www.osha.gov/laboratory

- CDC/NIOSH Laboratory Safety: https://www.cdc.gov/niosh/topics/labsafety/default.

- Wikipedia — Laboratory: https://en.wikipedia.org/wiki/Laboratory

- ASTM D543 — Standard Practices for Evaluating the Resistance of Plastics to Chemical Reagents: https://www.astm.org/d543-14.

- ISO 14644 (Cleanrooms and associated controlled environments): https://www.iso.org/standard/53394.

How to Choose the Right Lab Sink for Your Facility

Fume Hood Vendor Selection Checklist for Procurement

Lab Sink Cabinet Size and Layout Tips for Efficient Workflows

Floor Mounted Lab Bench vs. Freestanding Benches: Pros & Cons

For Customization

Do you offer custom branding for laboratory furniture?

Yes, we can incorporate custom logos, colors, and branding into your lab furniture to make it unique to your organization.

About Solution

Does your laboratory furniture support customization?

Yes, we provide fully customized services including size, material, color and functional design to meet customers' specific needs.

For Company

How do I get in touch with your sales team?

You can reach our sales team via email at ada@maxlabfurniture.com, by phone at +86 132 4232 3168, WhatsApp:+86 132 4232 3168, or through the contact form on our Facebook: https://www.facebook.com/MaxLabFurniture

For Products

Are your products customizable?

Absolutely! We offer customized solutions for laboratory benches, lab tables, and furniture systems to meet the specific requirements of your workspace.

FAQS

What quality standards do your products meet?

We conduct strict quality inspections before products leave the factory to ensure they meet international standards and customer expectations.

Floor Mounted Lab Bench

Our Floor Mounted Lab Bench is an essential, high-efficiency workspace for laboratories, made from high-quality steel-wood or corrosion-resistant stainless steel materials to ensure exceptional durability and stability. The unique floor-mounted design effectively reduces vibration, optimizes space usage, and provides a safe and tidy laboratory environment.

Customizable storage solutions help organize lab equipment efficiently, while the easy-to-clean surface maintains laboratory hygiene. It is widely suitable for research institutions, educational laboratories, and the chemical and pharmaceutical industries.

Fume Hood

The fume hood provides safe ventilation to protect against exposure to hazardous or toxic fumes, vapors, or airborne particulate. It is primarily used in laboratory and manufacturing applications to protect the user or environment outside the hood, but can also be used to protect the materials or experiment under the hood.

APPLICATION

Chemistry Lab, physics Lab, biological analysis, pharmaceutical medicine analysis, biological pharmaceutical, plant culture, environmental testing and electronic instrumentation scientific research and so on.

Flammable Storage Cabinet

Safety Cabinets store flammable liquids, corrosives, pesticides and other hazardous materials. All fire-resistant safety cabinets by meet fire codes and regulations for safety storage.

To help protect your people and facility from a potential fire, safety cabinets are engineered to safely contain flammable fuels, solvents, and chemicals. Safety cabinets can not only help everyone store chemicals reasonably, save chemical supplies, but also save human resources, and avoid fires caused by chemicals with the greatest strength.

Class II Type A2 Biological Safety Cabinet for Laboratory

The Class II A2 Biological Safety Cabinet is designed to provide superior biosafety and contamination control for laboratories, research facilities, and clinical settings. With 70% air recirculation and 30% air exhaust, this cabinet ensures a safe and efficient work environment while protecting both the user and the samples.

Equipped with advanced features like a HEPA filtration system, motorized front window, and ergonomic design, this cabinet is a must-have for safe and reliable biological research.

Scan QR Code

Scan QR Code

MaxLabFurniture

MaxLab Furniture

daihongada

Max Laboratory