Installing Floor Mounted Lab Benches: What to Expect

- Installing Floor Mounted Lab Benches: What to Expect

- Introduction to floor-mounted lab benches and lab benches selection

- Why choose a Floor Mounted Lab Bench over other lab benches

- Quick comparison: floor-mounted vs island and mobile lab benches

- Pre-installation planning for lab benches

- Site survey and measurements

- Utility planning and integration

- Site preparation: what contractors will do before bench installation

- Floor work and anchoring points

- Utility stub-outs and service chase installation

- Delivery and staging of lab benches

- Step-by-step installation process for a Floor Mounted Lab Bench

- Unpacking and inspection

- Subframe assembly and alignment

- Anchoring and leveling

- Utility connection and integration

- Sealing and finishing

- Functional testing and commissioning

- Materials, corrosion resistance and durability of lab benches

- Choosing the right surface and frame materials

- Customization and storage options for laboratory efficiency

- Maintenance, hygiene and cleaning expectations

- Common installation challenges and troubleshooting

- Timeline and cost expectations for installing lab benches

- Brand advantages and why our Floor Mounted Lab Bench is a practical choice

- FAQ

- Q1: How long does installation of a floor-mounted bench typically take?

- Q2: Do floor-mounted benches require special floor reinforcement?

- Q3: Can I route services under a floor-mounted bench?

- Q4: Are stainless steel benches necessary for all labs?

- Q5: What maintenance is required after installation?

- Contact us / View product

- References

Installing Floor Mounted Lab Benches: What to Expect

Introduction to floor-mounted lab benches and lab benches selection

Choosing the right lab benches is a decision that affects safety, productivity, and long-term operational costs. A Floor Mounted Lab Bench provides a stable, low-vibration workspace ideal for many laboratory workflows. Below we explain what to expect during a typical installation, how to prepare, and how to ensure the best performance from your new floor-mounted systems.

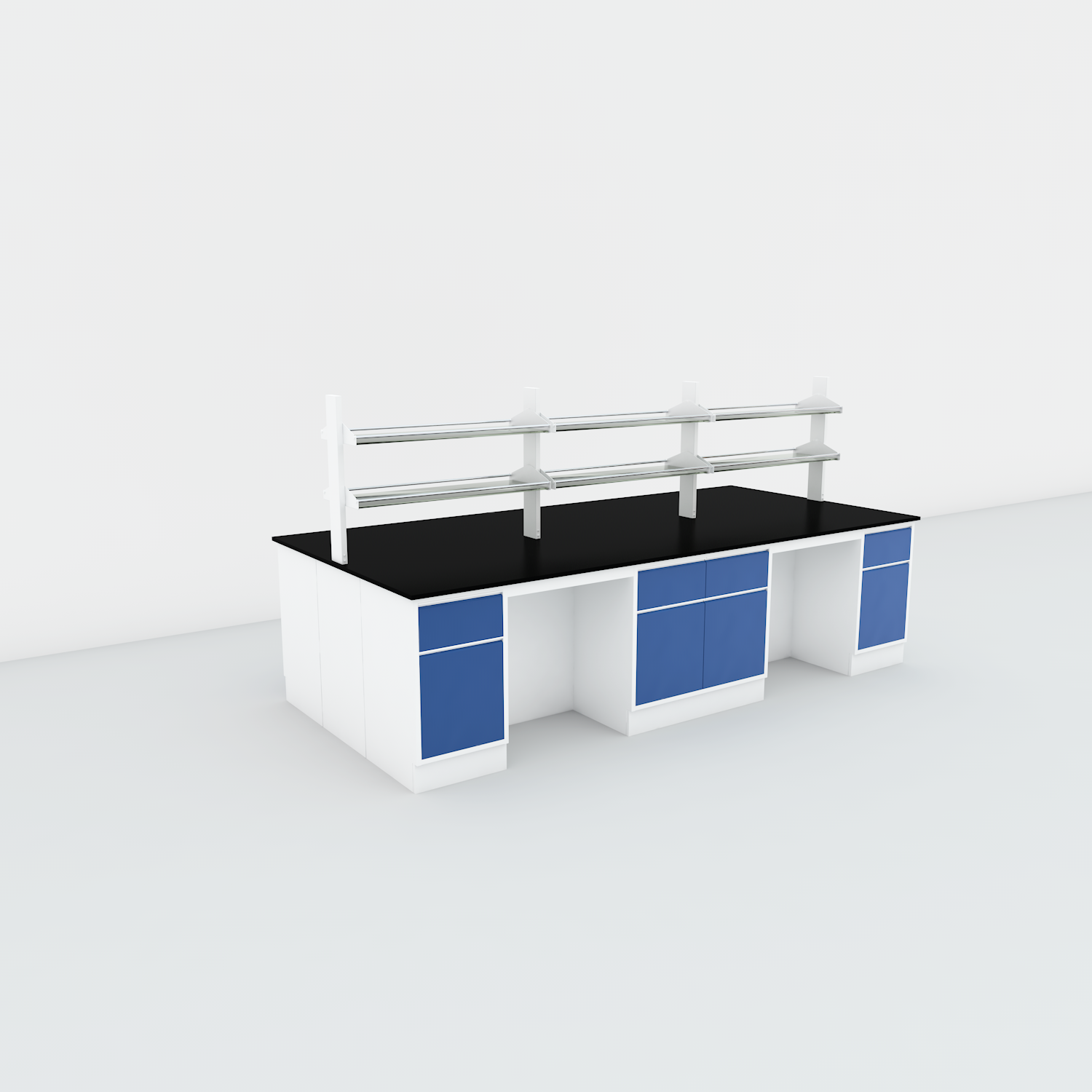

Our Floor Mounted Lab Bench is an essential, high-efficiency workspace for laboratories, made from high-quality steel-wood or corrosion-resistant stainless steel materials to ensure exceptional durability and stability. The unique floor-mounted design effectively reduces vibration, optimizes space usage, and provides a safe and tidy laboratory environment.

Customizable storage solutions help organize lab equipment efficiently, while the easy-to-clean surface maintains laboratory hygiene. It is widely suitable for research institutions, educational laboratories, and the chemical and pharmaceutical industries.

Why choose a Floor Mounted Lab Bench over other lab benches

Floor mounted lab benches anchor directly to the building structure, offering stability that freestanding or bench-mounted systems cannot match. You can expect reduced tabletop vibration, higher load capacity, and improved alignment for sensitive instruments. The floor-mounted design also allows for better cable routing and utility integration under benches while maintaining a clean perimeter and evacuation paths.

Quick comparison: floor-mounted vs island and mobile lab benches

| Feature | Floor Mounted Lab Bench | Island Lab Bench | Mobile/Bench-mounted |

|---|---|---|---|

| Stability | High | High (if anchored) | Low to Medium |

| Vibration control | Excellent | Good | Poor |

| Service routing | Under-bench routing possible | Accessible on both sides | Limited |

| Installation complexity | Moderate to High | Moderate | Low |

Sources: OSHA laboratory safety guidance and standard laboratory design references. See References at the end for details.

Pre-installation planning for lab benches

Good planning shortens installation time and avoids costly rework. Expect to coordinate the following before equipment arrives: floor strength and flatness survey, utility service locations and types, workflow and bench layout, safety and regulatory constraints, and delivery and staging logistics.

Site survey and measurements

Perform a full site survey that checks floor flatness, slab thickness, presence of raised floors, and locations of structural columns. Floor-mounted benches require anchor points on a sound substrate. Document elevations and use a laser level for run alignment. Accurate measurements reduce alignment issues during anchoring.

Utility planning and integration

Plan where gas, vacuum, electrical, data, and plumbing will enter and exit benches. Because floor-mounted systems often route services beneath the bench or through floor penetrations, coordinate with your facilities and utilities teams. Confirm required service pressures, electrical load, conduit sizes, and whether shutoff valves or isolation panels are needed in the bench footprint.

Site preparation: what contractors will do before bench installation

Before the delivery of lab benches, the site must be prepared. This reduces delays and ensures safety. Expect the following preparatory work from contractors or facilities staff.

Floor work and anchoring points

Floor-mounted benches need secure anchoring. Contractors may core-drill anchors into concrete, install embedded plates, or verify threaded inserts are present. Ensure the floor finish type is compatible with anchoring methods and that penetration into the slab follows building rules and fire/safety codes.

Utility stub-outs and service chase installation

Install utility stub-outs at planned locations and run chases or conduits for electrical and data. If services must be installed after bench placement, coordinate so openings and access panels align with bench service modules.

Delivery and staging of lab benches

Handling and staging are important for large units. Expect protective packaging and crates. Schedule an area for staging close to the installation site, keeping aisles clear for forklifts and technicians. Ensure load-bearing doors and elevators can accommodate bench modules. For multi-piece benches, label modules clearly to match the layout plan.

Step-by-step installation process for a Floor Mounted Lab Bench

The installation sequence reduces rework and ensures correct alignment. A typical procedure includes unpacking and inspection, subframe assembly, leveling, anchoring, service integration, and commissioning tests. During installation planning, many labs reassess bench styles, so comparing floor mounted lab bench vs. freestanding benches: pros & cons helps ensure the structure matches operational demands.

Unpacking and inspection

Inspect all components for transport damage before installation. Confirm inventory against packing lists and photographs. Report missing or damaged items immediately to avoid schedule impacts.

Subframe assembly and alignment

Assemble the bench subframe on site. Use a laser level and string lines to align modules. Temporary shims help during alignment. Precise alignment before anchoring prevents gaps between modules and avoids stress on tabletop surfaces.

Anchoring and leveling

Anchor the bench frame to the floor using specified anchors or embedded plates. Leveling is critical for vibration-sensitive instruments. Use precision leveling feet or grout pads where required. Check that anchoring hardware does not overstress the floor or bench frame.

Utility connection and integration

Connect electrical, gas, vacuum, and plumbing following local codes. Use qualified trades for final connections. Label all shutoffs and ensure isolation valves are accessible from the front of the bench where appropriate.

Sealing and finishing

Seal joints where benches meet the floor to maintain hygiene and containment requirements. Install toe kicks, access panels, and service risers. Clean protective films from surfaces only after installation to prevent adhesive residue on countertops.

Functional testing and commissioning

Test all installed utilities and verify they meet specification. Confirm that vibration-sensitive equipment is within acceptable limits. Perform a walkthrough with stakeholders and document any punch-list items for resolution.

Materials, corrosion resistance and durability of lab benches

Floor Mounted Lab Benches commonly use steel-wood constructions or stainless steel. Stainless steel offers superior corrosion resistance, especially in chemical and wet labs, while high-quality steel-wood with protective finishes can be cost-effective for teaching or dry labs.

Choosing the right surface and frame materials

Choose worktops and frames based on chemical exposure, heat resistance, and cleaning regimes. Epoxy resin or phenolic resin tops resist many chemicals and are often paired with stainless subframes. For corrosive environments, full stainless steel benches reduce long-term maintenance and contamination risks.

Customization and storage options for laboratory efficiency

Floor mounted benches offer flexible storage options: under-bench cabinets, drawers, reagent cabinets with ventilation, and integrated shelving. Consider modular cabinetry with adjustable shelving and lockable storage to improve workflow and security.

Maintenance, hygiene and cleaning expectations

Easy-to-clean surfaces reduce contamination risk and simplify daily maintenance. Establish a cleaning schedule and use compatible cleaning agents to avoid damaging surfaces. Periodic inspections of anchors, seals, and utility connections prevent leaks and structural issues.

Common installation challenges and troubleshooting

Typical issues include uneven floors, misaligned utility stub-outs, and transport damage. Troubleshooting steps: re-measure and re-level using shims and precision tools, reroute utilities when feasible, and replace or repair damaged components before commissioning.

Timeline and cost expectations for installing lab benches

Installation timelines vary by project size and site readiness. Small installations (single bench run) can often be completed in 1-3 days once site-ready. Larger projects or complex service integrations can take several weeks. Cost drivers include materials, custom finishes, utility tie-ins, and anchoring methods.

Brand advantages and why our Floor Mounted Lab Bench is a practical choice

When selecting lab benches, choose a product backed by reliable manufacturing, customizable options, and comprehensive installation support. Our Floor Mounted Lab Bench offers:

- High stability and low vibration for sensitive instrumentation

- Durable materials choices, including corrosion-resistant stainless steel

- Flexible under-bench utility routing and modular storage options

- Professional installation guidance and on-site support to minimize downtime

- Designed for easy cleaning and long service life in research, education, and industry labs

FAQ

Q1: How long does installation of a floor-mounted bench typically take?

A1: For a single run with site-ready conditions, expect 1 to 3 days. Complex or multi-bench installations with utility tie-ins usually take several days to weeks depending on scope.

Q2: Do floor-mounted benches require special floor reinforcement?

A2: Not usually for standard lab loads. However, heavy equipment or dense instrument clusters may require a structural review. A site survey will determine whether reinforcement is required.

Q3: Can I route services under a floor-mounted bench?

A3: Yes. One of the advantages of floor-mounted lab benches is under-bench service routing. Plan these in advance to align stub-outs and access panels.

Q4: Are stainless steel benches necessary for all labs?

A4: No. Stainless steel is preferred in corrosive or wet labs. High-quality steel-wood with chemical-resistant tops may be appropriate for teaching labs or low-exposure environments.

Q5: What maintenance is required after installation?

A5: Regular cleaning with compatible agents, periodic checks of anchors and seals, and annual inspection of utility connections. Addressing small issues early prevents major repairs.

Contact us / View product

If you are planning a lab upgrade or need support with installation, contact our technical sales team to get a site assessment, installation quote, and product demo. View the Floor Mounted Lab Bench product details and request a quote to start your project.

References

- OSHA Laboratory Safety Guidance and Standards. United States Department of Labor Occupational Safety and Health Administration. https://www.osha.gov/laboratory

- CDC Laboratory Design and Construction Guidance. Centers for Disease Control and Prevention. https://www.cdc.gov/labs/

- BIFMA Industry Standards for Laboratory Furniture Performance. Business and Institutional Furniture Manufacturers Association. https://www.bifma.org

- NIH Design Requirements Manual and Laboratory Design References. National Institutes of Health.

Space-Saving Lab Sink Cabinet Designs for Modern Laboratories

Lab Sink Cabinet Size and Layout Tips for Efficient Workflows

Ergonomic Principles in Lab Furniture Design

Sustainability and Certifications to Require for Lab Countertops

For Products

Do you provide laboratory tables with built-in power outlets?

Yes, we offer lab tables with integrated electrical outlets, power strips, and other features to support your laboratory's equipment needs.

FAQS

How can I request a quote?

Simply contact us or fill out our online form with your project details. Our team will respond promptly with a free quote.

For Company

Do you offer services internationally?

Yes, we serve clients around the world, including Europe, North America, and Asia. Our international experience enables us to provide solutions that meet local regulations and standards.

Customization

What information do I need to provide to start a custom project?

In order to start a custom project, you need to provide information about the spatial layout of the laboratory, functional requirements, equipment quantity and specifications, budget, etc. If possible, you can also provide reference drawings or patterns so that we can better understand your needs.

What kind of laboratory equipment is suitable for customization?

All types of laboratory equipment can be customized, including test benches, fume hoods, hoods, chemical cabinets, exhaust units, etc.

Floor Mounted Lab Bench

Our Floor Mounted Lab Bench is an essential, high-efficiency workspace for laboratories, made from high-quality steel-wood or corrosion-resistant stainless steel materials to ensure exceptional durability and stability. The unique floor-mounted design effectively reduces vibration, optimizes space usage, and provides a safe and tidy laboratory environment.

Customizable storage solutions help organize lab equipment efficiently, while the easy-to-clean surface maintains laboratory hygiene. It is widely suitable for research institutions, educational laboratories, and the chemical and pharmaceutical industries.

Fume Hood

The fume hood provides safe ventilation to protect against exposure to hazardous or toxic fumes, vapors, or airborne particulate. It is primarily used in laboratory and manufacturing applications to protect the user or environment outside the hood, but can also be used to protect the materials or experiment under the hood.

APPLICATION

Chemistry Lab, physics Lab, biological analysis, pharmaceutical medicine analysis, biological pharmaceutical, plant culture, environmental testing and electronic instrumentation scientific research and so on.

Flammable Storage Cabinet

Safety Cabinets store flammable liquids, corrosives, pesticides and other hazardous materials. All fire-resistant safety cabinets by meet fire codes and regulations for safety storage.

To help protect your people and facility from a potential fire, safety cabinets are engineered to safely contain flammable fuels, solvents, and chemicals. Safety cabinets can not only help everyone store chemicals reasonably, save chemical supplies, but also save human resources, and avoid fires caused by chemicals with the greatest strength.

Class II Type A2 Biological Safety Cabinet for Laboratory

The Class II A2 Biological Safety Cabinet is designed to provide superior biosafety and contamination control for laboratories, research facilities, and clinical settings. With 70% air recirculation and 30% air exhaust, this cabinet ensures a safe and efficient work environment while protecting both the user and the samples.

Equipped with advanced features like a HEPA filtration system, motorized front window, and ergonomic design, this cabinet is a must-have for safe and reliable biological research.

Scan QR Code

Scan QR Code

MaxLabFurniture

MaxLab Furniture

daihongada

Max Laboratory