Fume Hood Vendor Selection Checklist for Procurement

- Fume Hood Vendor Selection Checklist for Procurement

- Why the right Fume Hood vendor selection matters

- Product overview: Fume Hood

- Checklist overview: procurement objectives and keywords

- Core vendor evaluation checklist (summary)

- Detailed technical specifications to verify with a Fume Hood vendor

- Compliance, testing and certification requirements

- Installation, site coordination and commissioning

- Warranty, maintenance and local service capability

- Energy efficiency and lifecycle cost comparison

- Vendor track record, references and sample installations

- Commercial terms, lead-time and procurement tips

- Brand advantages: why choose our Fume Hood offerings

- How to run an effective vendor selection process

- FAQ — Fume Hood Vendor Selection

- Q: What is the minimum face velocity for a general chemistry fume hood?

- Q: Can I use a recirculating Fume Hood for hazardous organic solvents?

- Q: What certifications should I require from the vendor?

- Q: How important is the vendor’s local service presence?

- Q: What should be included in commissioning?

- Contact sales / View product

- Authoritative references

Fume Hood Vendor Selection Checklist for Procurement

Why the right Fume Hood vendor selection matters

Choosing the correct fume hood and a reliable vendor is one of the most important decisions for laboratory safety, regulatory compliance and long-term operating cost control. A Fume Hood protects users from hazardous fumes, vapors and airborne particles; a poorly specified hood, inadequate installation, or weak after-sales support can expose people to risk, create regulatory headaches and increase lifecycle costs. Procurement teams must balance performance, compliance, lifecycle costs and vendor capability to ensure the installed equipment performs as intended for the lab’s use case.

Product overview: Fume Hood

<p><span style='font-family: Arial;'>The</span> fume hood provides safe ventilation to protect against exposure to hazardous or toxic fumes, vapors, or airborne particulate. <span style='font-family: Arial;'>It</span> is primarily used in laboratory and manufacturing applications to protect the user or environment outside the hood, but can also be used to protect the materials or experiment under the hood<span style='font-family: Arial;'>.</span></p>

<p class='MsoNormal'><strong><span style='font-family: Arial;'>APPLICATION</span></strong></p>

<p><span style='font-family: Arial;'>Chemistry Lab, physics Lab, biological analysis, pharmaceutical medicine analysis, biological pharmaceutical, plant culture, environmental testing and electronic instrumentation scientific research and so on.</span></p>

Checklist overview: procurement objectives and keywords

Procurement teams should document core objectives before contacting vendors: required protection level, intended applications (chemistry, biology, pharma), budget, timeline and sustainability goals. Use commercial-intent keywords such as 'buy Fume Hood', 'Fume Hood vendor', 'laboratory ventilation supplier', and 'Fume Hood procurement' when soliciting quotes to ensure responses target buying readiness.

Core vendor evaluation checklist (summary)

Below are the non-negotiable areas to verify with any potential Fume Hood vendor. Each item should be confirmed in writing and/or demonstrated with documentation and references:

- Standards & certifications: compliance with local and international standards (ANSI/AIHA Z9.5 where applicable, OSHA guidance, ASHRAE recommendations, CE if EU)

- Performance: face velocity ranges, containment testing results (e.g., smoke, tracer gas), airflow stability, sash design

- Safety features: alarm systems, automatic sash operation options, airflow interlocks, bypass designs

- Energy efficiency options: variable air volume (VAV), low-flow hoods, recirculating/filtered models when appropriate

- Installation and site services: ductwork, exhaust fan specification, commissioning, on-site testing (e.g., PGD or tracer gas containment testing)

- After-sales support: warranty terms, preventive maintenance plans, local field service, spare parts availability

- Customizations: size, materials (epoxy, stainless, phenolic), integration with utilities and casework

- References & past projects: similar installations and client contacts

Detailed technical specifications to verify with a Fume Hood vendor

Technical clarity prevents mismatches between lab needs and delivered equipment. Ask vendors to provide:

- Recommended face velocity and acceptable operating range (commonly 80–120 ft/min for general chemistry, but verify for your application)

- Sash type (vertical, horizontal, bypass) and sash opening dimensions along with sash velocity profile

- Exhaust requirements: static pressure, recommended duct diameter, fan capacity (CFM), and backdraft considerations

- Construction materials for the liner and work surface (chemical resistance, durability)

- Noise levels at typical operating points

- Filtration options (HEPA, carbon filters) for recirculating hoods and recommended change intervals

- Instrumentation and controls: display of face velocity, alarms, integration with building management systems

Compliance, testing and certification requirements

Regulatory compliance is critical. Ask vendors to provide proof of compliance and testing, including:

- Containment test reports (smoke test videos/photos, tracer gas test where required)

- Manufacturing and quality certifications (ISO 9001 is a common quality baseline)

- Compliance with national workplace safety guidance (OSHA laboratory guidance, local health & safety codes)

- Electrical safety approvals if applicable (CE/UL/CSA as relevant to your region)

Installation, site coordination and commissioning

A vendor should supply an installation scope that includes site surveys, mechanical interface drawings, electrical requirements, ductwork routing and commissioning (airflow balancing, alarm setpoints). Procurement must confirm:

- Who supplies and installs the exhaust fan and ducting: vendor, contractor, or owner responsibility?

- Site readiness requirements: slab leveling, services locations, clearances and utilities

- Commissioning scope: who performs final face velocity checks, alarm calibration and acceptance testing

- Documentation delivery: O&M manuals, as-built drawings and commissioning records

Warranty, maintenance and local service capability

Short initial warranties may be insufficient for high-use laboratory environments. Negotiate service terms that include:

- Minimum one-year warranty on workmanship and a defined parts warranty period

- Preventive maintenance plans and recommended service intervals

- Local field service coverage and guaranteed response times for critical failures

- Availability and lead-time for consumables and spare parts (sash seals, filters, sensors)

Energy efficiency and lifecycle cost comparison

Procurement should evaluate total cost of ownership beyond the purchase price. Consider fan energy, makeup air costs, filter replacements and service. Use lifecycle cost modelling to compare options. The table below compares typical choices:

| Characteristic | Ducted Constant Volume | Ducted VAV (Low-flow) | Recirculating/Filtered |

|---|---|---|---|

| Initial Cost | Medium | High | Low–Medium |

| Operating Energy | High | Lower (variable) | Low (no exhaust makeup air) |

| Containment Reliability | High | High | Application-dependent (not suitable for all chemistries) |

| Maintenance | Moderate | Higher (controls + sensors) | Higher (filter changes) |

Vendor track record, references and sample installations

Request case studies and reference contacts for installations similar to your use case. Verify the vendor’s experience with the required scale, chemical classes and any hazardous classifications (e.g., perchloric acid, radionuclides, BSL labs). Ask to visit a local installation or request virtual walkthroughs. A strong vendor will supply measurable performance data from in-service installations.

Commercial terms, lead-time and procurement tips

Negotiate clear commercial terms that reduce schedule risk and hidden costs. Points to cover:

- Firm delivery and installation timelines tied to penalties or milestones

- Clear delineation of scope for site works, ducting and electrical

- Options for modular or pre-assembled units to reduce on-site time

- Acceptance criteria and final sign-off process

Brand advantages: why choose our Fume Hood offerings

When evaluating vendors, consider attributes beyond product specifications. Our brand advantages include:

- Demonstrated expertise in lab furniture and ventilation systems with multiple successful installations across chemistry, biology and pharmaceutical labs

- Comprehensive documentation and in-house commissioning teams to reduce integration risk

- Local service network for faster response times and stocked spare parts to minimize downtime

- Energy-efficient design options (VAV controls, low-flow hoods) to reduce operating costs and meet sustainability targets

- Custom fabrication capabilities (stainless, epoxy, special liners) for unique experimental needs

How to run an effective vendor selection process

Follow a structured procurement workflow:

- Define technical and commercial must-haves and pass/fail criteria

- Issue an RFQ/RFP including required documentation and acceptance tests

- Shortlist vendors based on documentation then request demonstrations or site visits

- Evaluate total cost of ownership, not just capital price

- Negotiate clear commissioning and warranty clauses, then finalize purchase order

FAQ — Fume Hood Vendor Selection

Q: What is the minimum face velocity for a general chemistry fume hood?

A: A common target is 80–120 feet per minute (fpm) at the sash opening for general chemistry, but the exact setpoint should be determined based on the hood design, sash configuration and the lab’s specific hazards. Always confirm acceptable operating ranges with the vendor and adjust during commissioning.

Q: Can I use a recirculating Fume Hood for hazardous organic solvents?

A: Recirculating (filtered) hoods are appropriate for many applications but are not suitable for all hazardous solvents or high-toxicity operations. They rely on filters (e.g., activated carbon, HEPA) and require validated filter change intervals and appropriate capture efficiency. For highly toxic or regulated emissions, ducted exhaust is usually required.

Q: What certifications should I require from the vendor?

A: Require evidence of compliance with applicable national standards and industry guidance (OSHA laboratory safety guidance, ANSI/AIHA Z9.5 where applicable), manufacturing quality systems (ISO 9001) and electrical safety approvals relevant to your region (UL/CE/CSA). Also request recent containment test reports for the specific model.

Q: How important is the vendor’s local service presence?

A: Very important. Local technical service reduces downtime and simplifies spare parts logistics. Confirm guaranteed response times and whether parts are stocked locally or shipped from a central warehouse.

Q: What should be included in commissioning?

A: Commissioning should include airflow verification (face velocity), alarm functionality checks, sash setpoint calibration, documentation handover (as-built drawings, test reports) and operator training. Ensure commissioning acceptance criteria are in the contract.

Contact sales / View product

After comparing vendors and capabilities, many buyers revisit their original requirements to validate decisions. Returning to the fume hood procurement guide with key specs B2B buyers need helps confirm alignment between technical needs and supplier offerings.Ready to evaluate Fume Hood options for your lab? Contact our sales team for a tailored quotation, site survey and live demonstration. Visit our product page or email sales@example.com. For urgent inquiries call +1-800-555-0123.

Authoritative references

- OSHA Laboratory Safety Guidance: https://www.osha.gov/laboratory-safety

- Wikipedia: Fume hood: https://en.wikipedia.org/wiki/Fume_hood

- CDC/NIOSH: https://www.cdc.gov/niosh/index.htm

- ANSI/AIHA Z9.5 (overview page): https://www.aiha.org

- ASHRAE: https://www.ashrae.org

We recommend saving this checklist and sharing it with your facility manager, EHS team and lab supervisors to ensure the selected Fume Hood meets protection, compliance and operational goals.

Cleaning and Decontamination Best Practices for Lab Benches

Space-Saving Lab Sink Cabinet Designs for Modern Laboratories

Fume Hood Procurement Guide: Key Specs B2B Buyers Need

Top Lab Furniture Manufacturers and Suppliers in 2026

For Company

What sets your company apart from other lab furniture providers?

Our commitment to quality, innovation, and customer satisfaction sets us apart. We offer customized solutions, high-quality materials, and a full range of laboratory furniture and equipment to ensure optimal functionality and safety for every lab.

For After-Sales Support

Do you offer training for using your products?

Yes, we offer training for your staff on how to properly use and maintain the laboratory equipment we provide. Contact us to schedule a training session.

Why choose your company?

We have been engaged in the manufacturing of various packing machines professionally over 15 years, and we can provide better after-sales service.

For Products

What materials do you use for your furniture?

We use a variety of durable materials such as stainless steel, steel wood, PP and wood composites. Our countertop materials are phenolic resin, epoxy resin, ceramic, trespa and granite, depending on your lab’s needs.

FAQS

Do you export internationally?

Yes, we have over 15 years of export experience and have served clients in more than 60 countries and regions.

Fume Hood

The fume hood provides safe ventilation to protect against exposure to hazardous or toxic fumes, vapors, or airborne particulate. It is primarily used in laboratory and manufacturing applications to protect the user or environment outside the hood, but can also be used to protect the materials or experiment under the hood.

APPLICATION

Chemistry Lab, physics Lab, biological analysis, pharmaceutical medicine analysis, biological pharmaceutical, plant culture, environmental testing and electronic instrumentation scientific research and so on.

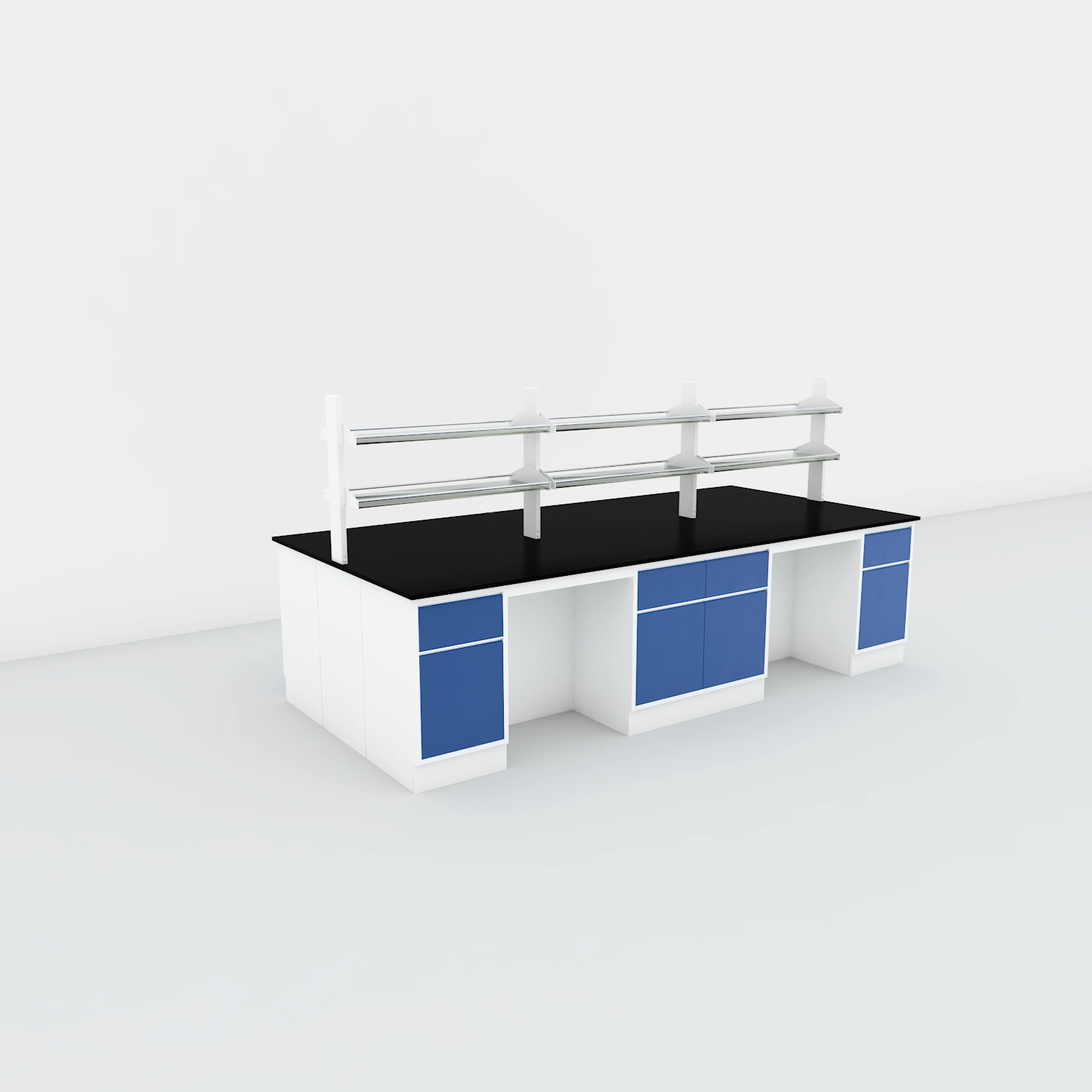

Floor Mounted Lab Bench

Our Floor Mounted Lab Bench is an essential, high-efficiency workspace for laboratories, made from high-quality steel-wood or corrosion-resistant stainless steel materials to ensure exceptional durability and stability. The unique floor-mounted design effectively reduces vibration, optimizes space usage, and provides a safe and tidy laboratory environment.

Customizable storage solutions help organize lab equipment efficiently, while the easy-to-clean surface maintains laboratory hygiene. It is widely suitable for research institutions, educational laboratories, and the chemical and pharmaceutical industries.

Flammable Storage Cabinet

Safety Cabinets store flammable liquids, corrosives, pesticides and other hazardous materials. All fire-resistant safety cabinets by meet fire codes and regulations for safety storage.

To help protect your people and facility from a potential fire, safety cabinets are engineered to safely contain flammable fuels, solvents, and chemicals. Safety cabinets can not only help everyone store chemicals reasonably, save chemical supplies, but also save human resources, and avoid fires caused by chemicals with the greatest strength.

Class II Type A2 Biological Safety Cabinet for Laboratory

The Class II A2 Biological Safety Cabinet is designed to provide superior biosafety and contamination control for laboratories, research facilities, and clinical settings. With 70% air recirculation and 30% air exhaust, this cabinet ensures a safe and efficient work environment while protecting both the user and the samples.

Equipped with advanced features like a HEPA filtration system, motorized front window, and ergonomic design, this cabinet is a must-have for safe and reliable biological research.

Scan QR Code

Scan QR Code

MaxLabFurniture

MaxLab Furniture

daihongada

Max Laboratory