Fume Hood Maintenance Plans to Minimize Downtime

- Fume Hood Maintenance Plans to Minimize Downtime

- Why a proactive Fume Hood maintenance plan matters

- Understanding the Fume Hood and its applications

- Core Fume Hood components that drive downtime

- Designing a Fume Hood maintenance plan: principles and priorities

- Maintenance schedule template for Fume Hood

- Planned vs. reactive maintenance: cost and downtime comparison

- Performance monitoring and testing to avoid surprises

- Spare parts, consumables and inventory strategy

- Service contracts: when to choose OEM vs. qualified third-party

- Training and SOPs to reduce operator-caused downtime

- Documentation, KPIs and continuous improvement

- Predictive maintenance: using data to preempt failures

- Emergency procedures and business continuity

- Brand advantages: why choose LabPro Fume Hood maintenance and products

- FAQ — Frequently Asked Questions about Fume Hood maintenance

- Contact us / View product

- Authoritative references and further reading

Fume Hood Maintenance Plans to Minimize Downtime

Why a proactive Fume Hood maintenance plan matters

Fume Hood systems are critical for protecting personnel and the surrounding environment from hazardous fumes, vapors, and airborne particulates. Unexpected failures — from a malfunctioning blower to a failed sash control — can halt experiments, delay production, and create safety and compliance risks. A planned maintenance program for your Fume Hood minimizes downtime, reduces emergency repair costs, extends equipment life, and preserves laboratory productivity and safety. This article outlines practical, actionable maintenance plans tailored for laboratories and manufacturers who use Fume Hood products. Even the best maintenance strategy depends on correct initial setup. Following a detailed fume hood installation checklist for procurement teams helps prevent early-stage issues and supports long-term reliability.

Understanding the Fume Hood and its applications

The Fume Hood provides safe ventilation to protect against exposure to hazardous or toxic fumes, vapors, or airborne particulate. It is primarily used in laboratory and manufacturing applications to protect the user or environment outside the hood, but can also be used to protect the materials or experiment under the hood.

APPLICATION

Chemistry Lab, physics Lab, biological analysis, pharmaceutical medicine analysis, biological pharmaceutical, plant culture, environmental testing and electronic instrumentation scientific research and so on.

Core Fume Hood components that drive downtime

To build an effective maintenance plan, you must know which components most often cause failures and delays. Typical trouble points include:

- Blowers and fans (motor wear, balance issues, bearings)

- Filters (HEPA/carbon saturation, seal leaks)

- Sash mechanisms and sensors (damaged glass, counterweights, controllers)

- Airflow controls and variable air volume (VAV) box actuators

- Ducting and exhaust stack (blockages, corrosion)

- Controls, alarm systems, and monitoring sensors

- Electrical connections and safety interlocks

Knowing these failure modes enables targeted inspections and spare-parts stocking to reduce mean time to repair (MTTR).

Designing a Fume Hood maintenance plan: principles and priorities

An effective maintenance plan balances safety, cost and operational uptime. Key principles are:

- Prioritize safety-critical inspections that can prevent exposures.

- Use risk-based scheduling: higher-use hoods get more frequent checks.

- Document everything to support compliance and continuous improvement.

- Blend predictive, preventive, and corrective maintenance for best cost-effectiveness.

Maintenance schedule template for Fume Hood

Below is a practical maintenance cadence to reduce downtime. Adjust frequencies to match your hazard level and usage intensity.

- Daily: Visual inspection of sash position, airflow alarm lights, audible alarms, and work-area cleanliness.

- Weekly: Check sash operation and counterbalances, clear obstructions from airflow paths, test basic alarms.

- Monthly: Measure face velocity or use a manometer to verify airflow parameters; inspect prefilters; check lighting and electrical outlets.

- Quarterly: Inspect blower belts and motors, check ducts for accumulation, perform smoke visualization tests and verify VAV operation.

- Annually: Full certification including calibrated face velocity testing, HEPA/charcoal filter integrity checks, duct cleaning as needed, control calibration, and detailed documentation for compliance.

Planned vs. reactive maintenance: cost and downtime comparison

Choosing planned maintenance over reactive fixes typically yields lower total cost and reduced downtime. The table below summarizes typical performance differences for a laboratory Fume Hood fleet.

| Metric | Planned Maintenance | Reactive Maintenance |

|---|---|---|

| Average annual downtime per hood | 8–24 hours | 48–120+ hours |

| Average annual maintenance cost | Low–Moderate (predictable) | High (unexpected emergency High Qualitys) |

| Safety/Compliance risk | Lower (regular checks) | Higher (missed indicators) |

| Equipment lifespan | Extended | Shortened |

Example cost rationale: a planned annual certification and filter change costing $800–$1,500 can prevent a single emergency repair or lost-week of lab productivity that costs thousands in staff downtime and delayed projects.

Performance monitoring and testing to avoid surprises

Regular testing identifies degradation before it becomes a failure. Key monitoring activities:

- Face velocity/airflow testing: Use calibrated anemometers or velocity hoods to ensure the Fume Hood meets target face velocity (commonly 80–120 fpm depending on standard and application).

- Smoke visualization: Confirms containment and reveals turbulence or leaks.

- Static pressure and differential monitoring: Track filter loading and blower performance trends with manometers or electronic transducers.

- Continuous monitoring/alarm systems: Remote alerts for low airflow, filter saturation, or fan faults reduce response time.

Implement simple dashboards for trending parameters; a rising trend in required static pressure or a falling face velocity are early warnings to schedule maintenance before operational impact.

Spare parts, consumables and inventory strategy

Downtime often increases because technicians wait for parts. A smart inventory strategy includes:

- Stocking critical spare items: blower motors, belts, fuses, VAV actuators, sash seals, common sensors, and filter housings.

- Consumables on hand: prefilters, HEPA filters (or contracts for quick filter delivery), and replacement sash glass.

- Vendor-managed inventory or consignment for high-value items to reduce capital lock-up while guaranteeing availability.

Pair inventory with a parts-replacement log so usage patterns drive reorder points, avoiding overstock and preventing stockouts that cause extended downtime.

Service contracts: when to choose OEM vs. qualified third-party

Service contracts reduce administrative burden and accelerate repairs. Consider the following:

- OEM service: Best for warranty support, proprietary control systems, and original-component expertise. OEMs often have guaranteed parts availability and specialized training.

- Qualified third-party service: Can be more cost-effective, offer faster local response, and provide flexible scheduling. Ensure technicians are certified for Fume Hood certification and understand local codes.

- Hybrid model: Use OEM for annual certification and warranty work and third-party providers for routine preventive maintenance and rapid response.

Whichever you choose, include guaranteed response times, clearly defined scopes of work, and penalty clauses for missed service levels in the contract to ensure accountability.

Training and SOPs to reduce operator-caused downtime

Human behavior is a major contributor to unnecessary Fume Hood downtime. Train users and create simple SOPs that cover:

- Correct sash positioning and work practices to maintain airflow.

- Allowed and forbidden equipment inside hoods (e.g., large obstructions that disturb airflow).

- How to recognize alarm indicators and who to contact first.

- Basic daily inspection checklist for lab personnel.

Well-trained users can prevent many common problems (e.g., blocked grilles, excessive clutter, improper use of portable devices that disrupt airflow) and report small issues before they escalate.

Documentation, KPIs and continuous improvement

Measure and document maintenance outcomes to demonstrate compliance and drive improvement. Useful KPIs include:

- Uptime percentage (target 98%+ for critical hoods)

- Mean time to repair (MTTR)

- Mean time between failures (MTBF)

- Number of emergency repairs per year

- Average time between filter changes

Maintain a digital log with test results, dates, parts replaced, technician notes and photos. This historical data supports warranty claims, audit compliance, and better budgeting.

Predictive maintenance: using data to preempt failures

Predictive maintenance strategies use trend data and sensors to forecast issues before they cause downtime. Examples:

- Trend analysis of static pressure rise to predict filter loading and schedule replacements just-in-time.

- Vibration and current monitoring of blowers to detect motor bearing wear before catastrophic failure.

- Remote alarm notifications for immediate action when airflow dips below safe thresholds.

Investing in inexpensive sensors and cloud-based alerts often pays for itself quickly through reduced emergency repairs and less lost productivity.

Emergency procedures and business continuity

Even with an excellent maintenance program, emergencies happen. Prepare with a clear response plan:

- Immediate steps for staff to secure experiments and isolate hazards when a Fume Hood becomes unsafe.

- Named emergency contacts with 24/7 availability (internal and vendor).

- Pre-identified backup workspaces or schedules to move critical activities if a hood is out of service.

- Pre-authorized purchase procedures for expedited parts replacement when necessary.

Well-rehearsed emergency protocols reduce time lost and keep personnel safe while repairs proceed.

Brand advantages: why choose LabPro Fume Hood maintenance and products

Our LabPro range of Fume Hood products is designed with maintenance and uptime in mind. Key advantages include:

- Modular components for quick access and replacement — blowers, sash assemblies and filters are designed for fast swap-out.

- Integrated monitoring options with remote alarm capability to accelerate response times.

- Comprehensive documentation and easy-to-follow maintenance checklists provided with each unit.

- Flexible service programs — OEM-certified annual certification plus optional rapid-response contracts to minimize downtime.

- Global spare-parts distribution network to reduce lead times for critical components.

Choosing equipment designed for maintainability reduces MTTR and total cost of ownership. If you already have LabPro Fume Hoods, our preventive programs are optimized for model-specific spare parts and calibration parameters.

FAQ — Frequently Asked Questions about Fume Hood maintenance

Q: How often should I certify a Fume Hood?

A: Most regulations and industry best practices recommend annual certification for Fume Hoods used with hazardous materials. High-use or high-hazard hoods may need more frequent checks.

Q: What is the typical face velocity target?

A: Typical face velocity targets range from 80–120 feet per minute (fpm), but the exact target depends on local codes, standards, and the specific application.

Q: Can we perform maintenance in-house or should we use a contractor?

A: Routine visual checks and daily tasks can be handled in-house with proper training. Annual certifications, complex repairs, and compliance testing are usually best handled by trained, certified technicians or OEM service providers.

Q: How do I know when a filter needs replacement?

A: Monitor static pressure differentials and face velocity. A steady rise in static pressure or a measurable fall in face velocity indicates filter loading. Many facilities also use a calendar-based replacement tied to usage.

Q: What spare parts should I keep on hand to minimize downtime?

A: Keep blower belts, common sensors, blower motors (if space and budget allow), prefilters, sash seals, fuses, and actuator motors for VAV systems. High-value parts like HEPA filters can be on a short lead-time contract or consignment.

Q: Will predictive monitoring require expensive upgrades?

A: Not necessarily. Start with basic differential pressure sensors and vibration/current monitoring for blowers. These inexpensive sensors can be integrated into a simple alert system and provide significant uptime benefits.

Contact us / View product

To discuss a tailored Fume Hood maintenance plan or to view the LabPro Fume Hood product line, contact our service team today. We offer preventive maintenance contracts, rapid-response service, and OEM-certified annual certifications to keep your facility running. Email: service@labpro-example.com | Phone: +1-800-555-0123

Authoritative references and further reading

- Occupational Safety and Health Administration (OSHA) laboratory safety guidance: https://www.osha.gov/laboratory

- NIOSH resources on laboratory safety and ventilation: https://www.cdc.gov/niosh

- American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE): https://www.ashrae.org

- National Sanitation Foundation (NSF) standards and laboratory equipment references: https://www.nsf.org

- Wikipedia: Fume hood: https://en.wikipedia.org/wiki/Fume_hood

Implementing a risk-based, documented Fume Hood maintenance plan preserves safety, minimizes downtime, reduces lifecycle cost, and supports regulatory compliance. Use the templates and strategies above to create a program that fits your facility’s hazard profile and operational needs.

Choosing a laboratory table for precision balances: BT-03 insights

What are the different types of Laboratory?

Lab Bench Design Ideas for Maximizing Work Surface Efficiency

Installing Floor Mounted Lab Benches: What to Expect

Customization

How long does it take to customize the product?

The delivery time of the custom equipment depends on the specific customization program and production cycle, which generally takes 4 to 8 weeks. We will keep you updated during the production process.

About Solution

What is the corrosion resistance of the laboratory furniture?

Our products are made of high quality corrosion-resistant materials, such as epoxy resin, PP board and stainless steel, which can resist the erosion of various chemicals and prolong the service life of the products.

For Company

How long has your company been in business?

Our company has been in the laboratory furniture and equipment business for over 15 years, during which we have gained extensive experience and built a solid reputation in the industry. We specialize in serving a variety of industries, including academic research labs, pharmaceutical labs, healthcare, manufacturing, and more.

For Logistics

What is the lead time?

We usually will start to work after receiving 50% deposit, and as for the exact lead time, it depends on quantity and detailed requirement. We can promise it will be shipped on time as we negotiated.

For Customization

What is the process for requesting a custom quote?

To request a custom quote, please provide us with details about your lab’s size, needs, and desired specifications.

Fume Hood

The fume hood provides safe ventilation to protect against exposure to hazardous or toxic fumes, vapors, or airborne particulate. It is primarily used in laboratory and manufacturing applications to protect the user or environment outside the hood, but can also be used to protect the materials or experiment under the hood.

APPLICATION

Chemistry Lab, physics Lab, biological analysis, pharmaceutical medicine analysis, biological pharmaceutical, plant culture, environmental testing and electronic instrumentation scientific research and so on.

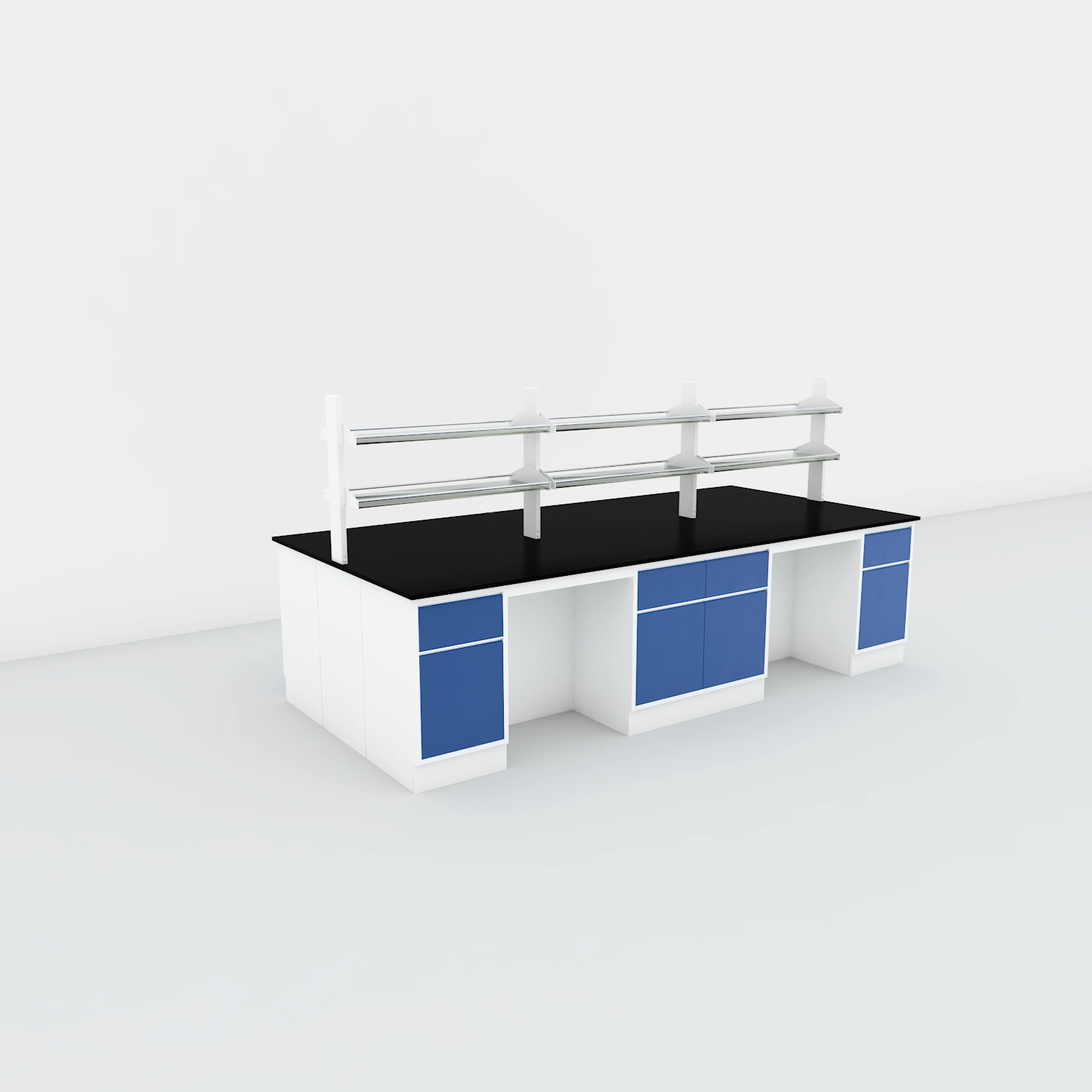

Floor Mounted Lab Bench

Our Floor Mounted Lab Bench is an essential, high-efficiency workspace for laboratories, made from high-quality steel-wood or corrosion-resistant stainless steel materials to ensure exceptional durability and stability. The unique floor-mounted design effectively reduces vibration, optimizes space usage, and provides a safe and tidy laboratory environment.

Customizable storage solutions help organize lab equipment efficiently, while the easy-to-clean surface maintains laboratory hygiene. It is widely suitable for research institutions, educational laboratories, and the chemical and pharmaceutical industries.

Flammable Storage Cabinet

Safety Cabinets store flammable liquids, corrosives, pesticides and other hazardous materials. All fire-resistant safety cabinets by meet fire codes and regulations for safety storage.

To help protect your people and facility from a potential fire, safety cabinets are engineered to safely contain flammable fuels, solvents, and chemicals. Safety cabinets can not only help everyone store chemicals reasonably, save chemical supplies, but also save human resources, and avoid fires caused by chemicals with the greatest strength.

Class II Type A2 Biological Safety Cabinet for Laboratory

The Class II A2 Biological Safety Cabinet is designed to provide superior biosafety and contamination control for laboratories, research facilities, and clinical settings. With 70% air recirculation and 30% air exhaust, this cabinet ensures a safe and efficient work environment while protecting both the user and the samples.

Equipped with advanced features like a HEPA filtration system, motorized front window, and ergonomic design, this cabinet is a must-have for safe and reliable biological research.

Scan QR Code

Scan QR Code

MaxLabFurniture

MaxLab Furniture

daihongada

Max Laboratory