Fume Hood Lifecycle Costs: Total Cost of Ownership Guide

- Fume Hood Lifecycle Costs: How to Calculate Total Cost of Ownership

- What is a Fume Hood and why lifecycle costs matter

- Key Cost Components of a Fume Hood

- 1. Capital Cost (Purchase Price)

- 2. Installation and Commissioning

- 3. Energy and Utility Costs (Operating)

- 4. Maintenance, Filter Replacement and Consumables

- 5. Periodic Testing and Certification

- 6. Compliance, Training and Administrative Overhead

- 7. End-of-Life: Decommissioning and Disposal

- Typical Lifecycle Cost Breakdown (Percentages)

- Where money is spent over 10 years

- Example: 10-Year Cost Comparison — Ducted vs. Ductless (Illustrative)

- Assumptions and comparison table

- Factors That Significantly Affect TCO

- 1. Type of hood: Ducted vs Ductless

- 2. HVAC Strategy: VAV vs CAV

- 3. Usage Pattern and Sash Management

- 4. Local Climate and Energy Prices

- 5. Process Hazards and Chemical Compatibility

- Energy-Saving Strategies to Lower Operating Costs

- 1. Adopt VAV controls and sash management

- 2. Use low-flow hood designs and aerodynamic sashes

- 3. Schedule central HVAC with lab use patterns

- 4. Consider heat recovery where feasible

- Maintenance Best Practices to Reduce Lifecycle Costs

- 1. Planned preventive maintenance (PPM)

- 2. Filter management and validation for ductless hoods

- 3. Keep commissioning records and re-test after modifications

- Compliance, Standards and Testing Requirements

- Key standards and tests

- Decision Framework: Selecting the Lowest TCO Option

- Step-by-step approach

- Brand Advantages — Why Choose Our Fume Hood Solutions

- Expertise, Certification, and Service Network

- Frequently Asked Questions (FAQ)

- 1. How long does a typical fume hood last?

- 2. Are ductless hoods cheaper over the long term?

- 3. How often should a fume hood be tested?

- 4. What energy-saving retrofit options are available?

- 5. Will improving the sash behavior really save money?

- 6. What should I budget annually per hood?

- Contact us / View Product

- Authoritative References and Further Reading

Fume Hood Lifecycle Costs: How to Calculate Total Cost of Ownership

What is a Fume Hood and why lifecycle costs matter

The Fume Hood provides safe ventilation to protect against exposure to hazardous or toxic fumes, vapors, or airborne particulate. It is primarily used in laboratory and manufacturing applications to protect the user or environment outside the hood, but can also be used to protect the materials or experiment under the hood.

APPLICATION

Chemistry Lab, physics Lab, biological analysis, pharmaceutical medicine analysis, biological pharmaceutical, plant culture, environmental testing and electronic instrumentation scientific research and so on.

Buying a fume hood is not just a one-time capital expense. Over its lifetime, costs related to energy, maintenance, certification, filter replacement (for ductless hoods), and eventual disposal often exceed the initial purchase price. Understanding Total Cost of Ownership (TCO) ensures safety, regulatory compliance, and predictable budgeting. Assessing lifecycle costs naturally leads to questions about suppliers and service reliability. Using a structured fume hood vendor selection checklist for procurement helps buyers reduce risk and ensure consistent support.

Key Cost Components of a Fume Hood

1. Capital Cost (Purchase Price)

Capital cost includes the hood cabinet, work surface, sash, controls, and often ancillary items such as base cabinets, service fittings, and seismic restraints. Features such as VAV (variable air volume) controls, low-flow designs, and high-performance sash materials raise initial cost but can reduce operating expenses.

2. Installation and Commissioning

Installation costs include ductwork (for ducted hoods), HVAC adjustments, structural support, electrical connections, and commissioning tests (e.g., ASHRAE 110). Ducted systems require more costly installation than ductless units but may offer lower long-term filter costs. Commissioning is essential to confirm containment and airflow and is often mandated by institutions or regulations.

3. Energy and Utility Costs (Operating)

Energy is frequently the largest line item in fume hood TCO. HVAC systems must condition the makeup air exhausted through the hood—heating, cooling, and dehumidifying that air leads to high recurring costs. Key drivers include face velocity, sash height and usage patterns, and whether the hood is part of a VAV or CAV system.

4. Maintenance, Filter Replacement and Consumables

Regular maintenance—fan service, sash hardware, airflow sensors, and replacing filters—adds to lifecycle costs. For ductless hoods, filter media (HEPA, activated carbon, specialty adsorbents) can be a significant recurring expense and may require disposal as hazardous waste depending on captured contaminants.

5. Periodic Testing and Certification

Laboratory hoods require periodic performance testing (e.g., annual face velocity checks and containment tests like ASHRAE 110) and documentation for compliance and insurance. These tests contribute to ongoing costs and must be budgeted.

6. Compliance, Training and Administrative Overhead

Costs associated with ensuring compliance with local regulations, user training (proper sash use, work practices), signage, and record-keeping are part of TCO. Poor user behavior can increase energy and maintenance costs, so training is a cost-avoidance investment.

7. End-of-Life: Decommissioning and Disposal

Disposal costs include safe decontamination, removal of hazardous filters or materials, recycling, and potential refurbishment. Planning for disposal avoids unexpected liabilities and costs.

Typical Lifecycle Cost Breakdown (Percentages)

Where money is spent over 10 years

As a rule of thumb over a 10-year lifecycle for a typical ducted laboratory fume hood:

- Capital cost: 15–25%

- Installation/commissioning: 10–20%

- Energy/utility costs: 45–60%

- Maintenance & filters: 5–10%

- Testing/administration/disposal: 5–10%

Example: 10-Year Cost Comparison — Ducted vs. Ductless (Illustrative)

Assumptions and comparison table

Assumptions (illustrative): purchase price ducted $12,000, ductless $8,500; installation ducted $6,000, ductless $2,000; annual energy cost ducted $3,500, ductless $800; annual maintenance & filters ducted $400, ductless $1,200 (includes major filter replacements every 2–3 years). 10-year horizon, no discounting for simplicity.

| Item | Ducted (10 yrs) | Ductless (10 yrs) |

|---|---|---|

| Purchase | $12,000 | $8,500 |

| Installation & commissioning | $6,000 | $2,000 |

| Energy (10 yrs) | $35,000 | $8,000 |

| Maintenance & filters (10 yrs) | $4,000 | $12,000 |

| Testing, disposal, admin | $2,000 | $2,500 |

| Total | $59,000 | $33,000 |

Interpretation: ductless hoods may show lower total cost only where compatible (non-hazardous, well-characterized chemistries) and when filter replacement and disposal are manageable. Ducted hoods often cost more to operate but are required for many hazardous processes.

Factors That Significantly Affect TCO

1. Type of hood: Ducted vs Ductless

Ducted hoods exhaust to the building HVAC and require makeup air, increasing energy costs but avoid filter replacement. Ductless hoods recirculate air through filters and reduce building HVAC load but require regular, often expensive filter changes and strict process limitations.

2. HVAC Strategy: VAV vs CAV

Variable Air Volume (VAV) systems reduce face velocity when the hood is not in use, saving substantial heating/cooling energy compared to Constant Air Volume (CAV). Upgrading to VAV or integrating sash-sensor controls can reduce energy costs by 30–60% for frequently used hoods.

3. Usage Pattern and Sash Management

Open sashes and frequent use increase exhausted air volumes. Promoting best practices (lowering sashes when not in active use, using high-visibility sash stops, and training users) delivers quick energy savings with minimal capital expense.

4. Local Climate and Energy Prices

In extreme climates, conditioning makeup air is more expensive, raising energy costs for ducted systems. High electricity or gas prices shorten payback for energy-saving investments.

5. Process Hazards and Chemical Compatibility

Some processes require ducted hoods by code or because contaminants are not removable by adsorbents. Ductless systems need validated filters rated for the specific chemical challenges; otherwise they increase safety and liability risks.

Energy-Saving Strategies to Lower Operating Costs

1. Adopt VAV controls and sash management

Installing VAV controllers and automated sash-closing systems reduces volumetric airflow during idle periods. Retrofits are cost-effective for banks of hoods and have clear payback periods in energy-intensive facilities.

2. Use low-flow hood designs and aerodynamic sashes

Modern low-flow hoods maintain containment at lower face velocities and reduce makeup air. Sash design that minimizes turbulence also improves containment and lowers required airflow.

3. Schedule central HVAC with lab use patterns

Coordinating HVAC setback and demand-control ventilation with laboratory occupancy can reduce wasted conditioning of makeup air.

4. Consider heat recovery where feasible

Heat recovery systems on exhaust can recapture energy from hood exhaust, reducing net HVAC load; applicable mostly where exhausted air isn't heavily contaminated with hazardous vapors that preclude heat exchangers.

Maintenance Best Practices to Reduce Lifecycle Costs

1. Planned preventive maintenance (PPM)

Schedule regular inspections for sash function, airflow sensors, fans, belts, and electrical systems. Timely small repairs prevent expensive breakdowns and downtime.

2. Filter management and validation for ductless hoods

Document filter service life with capture-efficiency testing. Use sensor systems or scheduled replacement intervals rather than waiting for performance failures. Track disposal costs and hazardous-waste handling requirements.

3. Keep commissioning records and re-test after modifications

Any changes to HVAC, hood configuration, or room layout require re-commissioning to ensure containment performance remains acceptable and that safety isn’t compromised.

Compliance, Standards and Testing Requirements

Key standards and tests

Common references used for hood testing and acceptance include ASHRAE 110 (Test Standard for Performance of Laboratory Fume Hoods) and local regulations. Regular airflow checks, smoke visualization, and containment tests are widely required to demonstrate safe performance and support liability protection.

Decision Framework: Selecting the Lowest TCO Option

Step-by-step approach

- Define the chemical processes, worst-case exposures, and safety requirements.

- Assess suitability: ductless only for known, compatible chemistries with manageable filter replacement.

- Estimate usage patterns and HVAC impacts (hours/day, sash open fraction).

- Model 5–10 year costs: purchase, installation, energy, maintenance, testing, disposal.

- Evaluate non-monetary factors: safety margin, regulatory acceptance, flexibility.

- Calculate payback for energy-saving upgrades (VAV, improved sash) and include them in procurement decisions.

Brand Advantages — Why Choose Our Fume Hood Solutions

Expertise, Certification, and Service Network

We design and manufacture certified fume hoods that comply with international standards and local codes. Our product offering includes both ducted and ductless models optimized for low energy use and easy maintenance. Key advantages:

- Proven designs that meet ASHRAE 110 performance criteria.

- Modular construction for straightforward installation and retrofit.

- Comprehensive commissioning and validation services.

- Nationwide service network for preventive maintenance and emergency repairs.

- Transparent lifecycle cost modeling during procurement to ensure lowest TCO for your application.

We provide detailed energy and maintenance forecasts tailored to your climate, lab schedule, and chemical profile to help you make an informed decision with measurable ROI.

Frequently Asked Questions (FAQ)

1. How long does a typical fume hood last?

With regular maintenance and proper use, a well-built fume hood can reliably serve 15–25 years. Components like fans, controls, and filters have shorter lifespans and must be maintained or replaced periodically.

2. Are ductless hoods cheaper over the long term?

Not always. Ductless hoods lower HVAC costs but incur ongoing filter costs and potential disposal expenses. They are best for labs with known, non-hazardous chemistries where filters are effective and affordable.

3. How often should a fume hood be tested?

Most institutions perform basic airflow checks annually and full containment testing after installation, major changes, or when performance is suspect. High-risk operations may require more frequent testing.

4. What energy-saving retrofit options are available?

Common retrofits include VAV controllers, sash automatic closers, low-flow hood inserts, and improved sash seals. Each retrofit should be evaluated for payback based on local energy prices and usage.

5. Will improving the sash behavior really save money?

Yes. Sashes control the opening through which air is exhausted. Closing the sash when not actively working can dramatically reduce exhausted makeup air and cut energy costs with no capital cost aside from training or minor hardware.

6. What should I budget annually per hood?

Budgeting varies by location and type: a conservative estimate for a ducted hood might be 6–8% of purchase price annually (largely energy), while ductless units may see 3–6% for energy but higher filter costs depending on usage. Use a facility-specific model for accuracy.

Contact us / View Product

If you need a lifecycle cost analysis or help selecting the right fume hood for your application, contact our sales and engineering team. We offer site surveys, energy and maintenance modeling, and customized proposals.

View Fume Hood Products | Contact sales: sales@example.com | Phone: +1-800-000-0000

Authoritative References and Further Reading

Sources used for industry best practices and standards:

- Wikipedia — Fume hood: https://en.wikipedia.org/wiki/Fume_hood

- ASHRAE — Standards & guidelines (including ASHRAE 110 references): https://www.ashrae.org/technical-resources

- OSHA — Laboratory safety and chemical hazards: https://www.osha.gov/laboratory-hazards

- CDC/NIOSH — Laboratory safety guidance: https://www.cdc.gov/niosh/topics/lab/

- European Committee for Standardization (CEN) — EN standards for fume cupboards: https://standards.cen.eu

- Lab Manager — Practical articles on fume hood energy and safety (example): https://www.labmanager.com

For a customized TCO model or to arrange a demonstration, reach out to our team. We will provide a detailed lifecycle analysis aligned to your lab processes and compliance obligations.

Modular Lab Sink Cabinets: Flexibility for Evolving Labs

Comparing Chemical Resistance: Phenolic vs Epoxy vs Stainless

Fume Hood Selection for Lab Safety and Regulatory Compliance

Selecting Chemical-Resistant Worktops for Lab Benches

For After-Sales Support

What do I do if I am not satisfied with my purchase?

We strive to ensure customer satisfaction. If you are not happy with your purchase, please contact us, and we will do our best to resolve any concerns.

Customization

How to calculate the cost of customized services?

Customization services incur additional costs depending on the complexity of the design, material selection and production requirements. We will clearly list all costs at the quote stage to ensure that the client understands all costs.

For Company

How do I get in touch with your sales team?

You can reach our sales team via email at ada@maxlabfurniture.com, by phone at +86 132 4232 3168, WhatsApp:+86 132 4232 3168, or through the contact form on our Facebook: https://www.facebook.com/MaxLabFurniture

Do you offer services internationally?

Yes, we serve clients around the world, including Europe, North America, and Asia. Our international experience enables us to provide solutions that meet local regulations and standards.

For Customization

Can I customize the size and configuration of my lab furniture?

Yes, we offer full customization for laboratory benches, modular systems, and storage units to meet your specific space and functional needs.

Fume Hood

The fume hood provides safe ventilation to protect against exposure to hazardous or toxic fumes, vapors, or airborne particulate. It is primarily used in laboratory and manufacturing applications to protect the user or environment outside the hood, but can also be used to protect the materials or experiment under the hood.

APPLICATION

Chemistry Lab, physics Lab, biological analysis, pharmaceutical medicine analysis, biological pharmaceutical, plant culture, environmental testing and electronic instrumentation scientific research and so on.

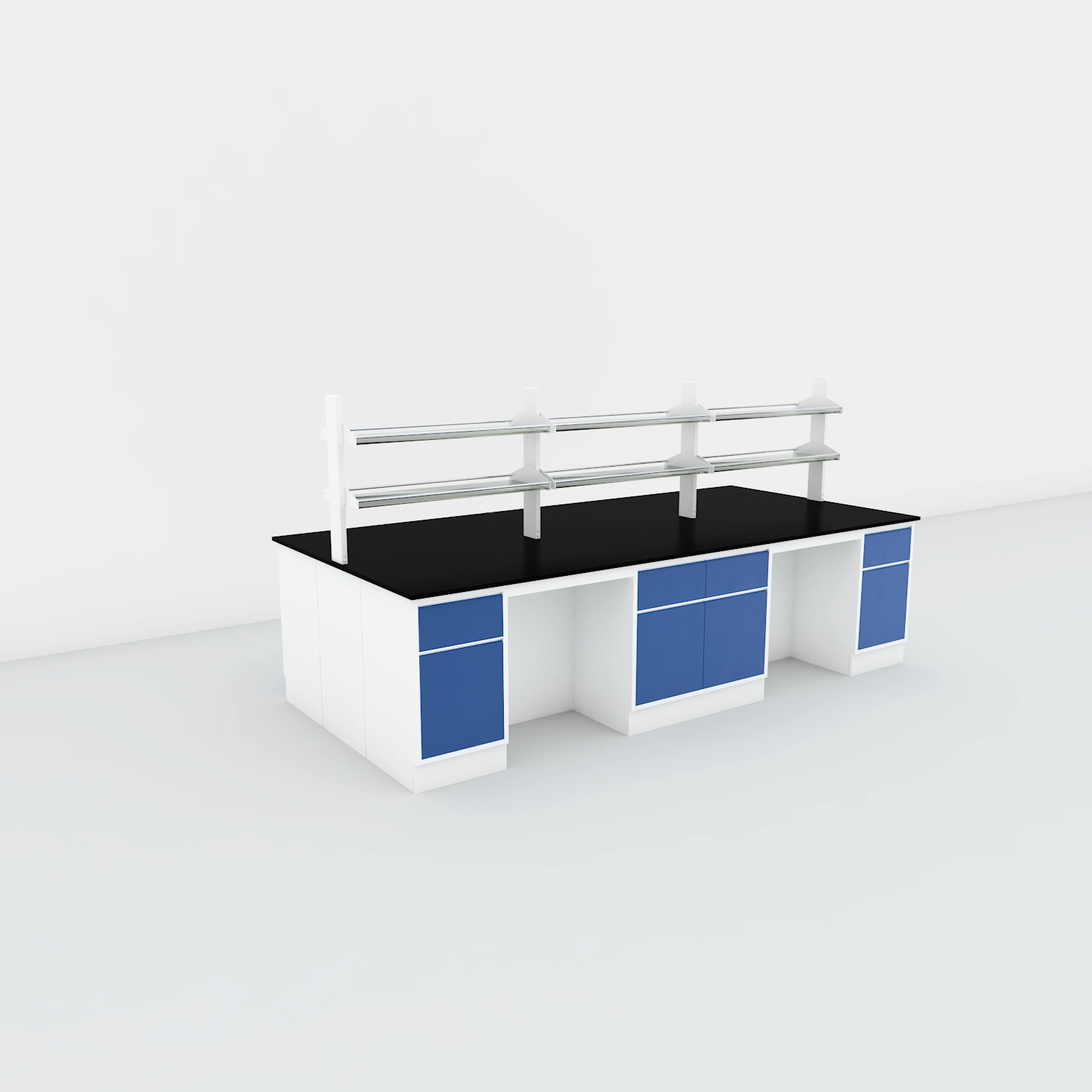

Floor Mounted Lab Bench

Our Floor Mounted Lab Bench is an essential, high-efficiency workspace for laboratories, made from high-quality steel-wood or corrosion-resistant stainless steel materials to ensure exceptional durability and stability. The unique floor-mounted design effectively reduces vibration, optimizes space usage, and provides a safe and tidy laboratory environment.

Customizable storage solutions help organize lab equipment efficiently, while the easy-to-clean surface maintains laboratory hygiene. It is widely suitable for research institutions, educational laboratories, and the chemical and pharmaceutical industries.

Flammable Storage Cabinet

Safety Cabinets store flammable liquids, corrosives, pesticides and other hazardous materials. All fire-resistant safety cabinets by meet fire codes and regulations for safety storage.

To help protect your people and facility from a potential fire, safety cabinets are engineered to safely contain flammable fuels, solvents, and chemicals. Safety cabinets can not only help everyone store chemicals reasonably, save chemical supplies, but also save human resources, and avoid fires caused by chemicals with the greatest strength.

Class II Type A2 Biological Safety Cabinet for Laboratory

The Class II A2 Biological Safety Cabinet is designed to provide superior biosafety and contamination control for laboratories, research facilities, and clinical settings. With 70% air recirculation and 30% air exhaust, this cabinet ensures a safe and efficient work environment while protecting both the user and the samples.

Equipped with advanced features like a HEPA filtration system, motorized front window, and ergonomic design, this cabinet is a must-have for safe and reliable biological research.

Scan QR Code

Scan QR Code

MaxLabFurniture

MaxLab Furniture

daihongada

Max Laboratory