Fume Hood Energy Efficiency: Savings and Performance for Labs

- Fume Hood Energy Efficiency: Savings and Performance for Labs

- What a Fume Hood Is and Why Energy Matters

- How Fume Hood Design Affects Energy Use

- Constant Air Volume (CAV) vs Variable Air Volume (VAV): Key Differences

- Why Face Velocity and Containment Testing Matter

- Sash Management: Low-cost Savings with Big Impact

- Smart Controls and Monitoring for Ongoing Savings

- Retrofit Strategies: From Simple to Comprehensive

- Energy and Cost Comparison: Typical Scenarios

- Calculating ROI for a VAV Retrofit

- Maintaining Safety When Optimizing Energy

- Standards, Codes, and Best Practices

- When to Replace vs Retrofit

- Brand Advantage: Why Choose Our Fume Hood Solutions

- Implementation Checklist for Lab Managers

- Frequently Asked Questions (FAQ)

- How much energy can a lab save by switching from CAV to VAV fume hoods?

- Does VAV affect fume hood safety?

- Are there quick wins for reducing fume hood energy use?

- What maintenance is required to keep savings and containment?

- How do I estimate payback for a retrofit?

- Contact Us / View Product

- Authoritative References

Fume Hood Energy Efficiency: Savings and Performance for Labs

What a Fume Hood Is and Why Energy Matters

The fume hood provides safe ventilation to protect against exposure to hazardous or toxic fumes, vapors, or airborne particulate. It is primarily used in laboratory and manufacturing applications to protect the user or environment outside the hood, but can also be used to protect the materials or experiment under the hood.

APPLICATION

Chemistry Lab, physics Lab, biological analysis, pharmaceutical medicine analysis, biological pharmaceutical, plant culture, environmental testing and electronic instrumentation scientific research and so on.

Fume hoods are essential for safety, but they are also among the largest single energy consumers in a laboratory. Understanding how to balance containment performance with ventilation efficiency is critical for lab managers seeking to reduce utility bills and environmental footprint without compromising safety or compliance.

How Fume Hood Design Affects Energy Use

Fume Hood design choices (CAV vs VAV), sash configuration, and ducting directly affect the volume of conditioned air exhausted from the building. Constant Air Volume (CAV) hoods run at a fixed exhaust rate whether in use or not; Variable Air Volume (VAV) hoods adjust exhaust based on sash position or face velocity. Choosing the right system can cut heating, ventilation and air conditioning (HVAC) energy use dramatically.

Constant Air Volume (CAV) vs Variable Air Volume (VAV): Key Differences

CAV systems are simple and reliable but wasteful: they maintain a fixed airflow (e.g., 800–1200 CFM per hood) regardless of sash position. VAV systems use sensors and controls to lower exhaust as the sash is lowered or when hoods are idle, often reducing average exhaust volumes by 30%–70% and producing significant energy savings without undermining containment when properly commissioned.

Why Face Velocity and Containment Testing Matter

Face velocity (usually measured in feet per minute, fpm) is a commonly referenced metric, but containment is the goal. ASHRAE Standard 110 addresses laboratory fume hood performance testing and emphasizes tracer gas containment tests. Correct commissioning and periodic performance testing ensure a hood delivers required containment at the operating sash height while minimizing unnecessary airflow.

Sash Management: Low-cost Savings with Big Impact

Sash position is the single easiest operational control to reduce energy use. Closing the sash when the hood is not actively being accessed reduces exhaust and can be combined with automatic sash closers or reminders to maximize compliance. Behavioral programs plus physical sash controls often yield immediate savings at very low capital cost.

Smart Controls and Monitoring for Ongoing Savings

Modern VAV fume hoods use pressure sensors, optical sash sensors, and building automation integration to optimize exhaust rates. Intelligent control sequences can incorporate occupancy sensing, setpoint deadbands, and scheduled setbacks for nights/weekends, and allow real-time monitoring to detect anomalies (e.g., blocked ducts or fan degradation) that can degrade efficiency or safety.

Retrofit Strategies: From Simple to Comprehensive

Retrofitting can range from inexpensive sash seals and monitors to full VAV conversion. Common retrofit options include: sash airflow monitors, automatic sash closers, VAV controllers and control valves, and ductwork balancing. Selecting the appropriate retrofit depends on existing infrastructure, capital budget, and expected payback period.

Energy and Cost Comparison: Typical Scenarios

Below is a representative comparison showing annual energy and cost implications for one typical 6-foot fume hood operated in three configurations. Numbers are illustrative but based on typical lab exhaust volumes and energy factors; use your facility's data for precise analysis.

| Scenario | Average Exhaust (CFM) | Annual Exhaust Air Volume (million ft³) | Estimated Annual HVAC Energy (kWh) | Estimated Annual Energy Cost (USD, $0.12/kWh) |

|---|---|---|---|---|

| CAV, sash open full-time (baseline) | 900 | 472 | 21,000 | $2,520 |

| CAV, sash closed when idle (behavior change) | 650 | 341 | 15,200 | $1,824 |

| VAV with sash management & setbacks | 300 | 157 | 7,000 | $840 |

Note: HVAC energy includes heating, cooling, and fan energy associated with conditioned supply air required to replace exhausted air. Savings can be higher in cold or hot climates with significant conditioning needs.

Calculating ROI for a VAV Retrofit

To decide on a retrofit, calculate simple payback: (project cost) ÷ (annual energy + maintenance savings). Example: if a VAV retrofit costs $6,000 and annual savings are $1,700 (energy + utility demand reductions), payback is ~3.5 years. Incentives and utility rebates can shorten payback. Include commissioning costs to guarantee performance.

Maintaining Safety When Optimizing Energy

Energy efficiency must not compromise safety. VAV systems must be properly commissioned to maintain minimum face velocities and containment at all expected sash positions. Regular maintenance—filter changes, fan and damper calibration, tracer gas or smoke testing—ensures safe operation and preserves energy performance.

Standards, Codes, and Best Practices

Key references include ASHRAE 110 (performance testing), local building codes for exhaust stacks, and occupational safety guidance (OSHA, NIOSH). Lab design guides (e.g., U.S. DOE/Labs21 resources) provide best practices for energy-efficient laboratory design. Following standards and documenting testing supports regulatory compliance and risk management.

When to Replace vs Retrofit

Consider full replacement when hoods are older than 15–20 years, have poor containment despite repairs, or when building HVAC systems are being upgraded. New hoods with integrated VAV controls, ergonomic sashes, and low-leak construction can offer superior long-term energy performance and reduced maintenance costs compared to repeated retrofits.

Brand Advantage: Why Choose Our Fume Hood Solutions

Our Fume Hood product line combines proven containment performance with energy-efficient engineering. Advantages include precision VAV controls, low-leak sash design, easy-to-clean interiors, and compatibility with building automation systems. We provide commissioning support, training for lab staff on sash management, and ongoing service plans to maintain both safety and efficiency.

Implementation Checklist for Lab Managers

To begin saving energy without sacrificing safety, follow this practical checklist:

- Audit current hood inventory and operation hours.

- Measure typical sash positions and face velocities.

- Identify simple behavioral improvements (e.g., sash-closing campaigns).

- Evaluate retrofit options and calculate payback including rebates.

- Plan commissioning and periodic performance testing (ASHRAE 110).

- Install monitoring and alarms to ensure continuous compliance.

Frequently Asked Questions (FAQ)

How much energy can a lab save by switching from CAV to VAV fume hoods?

Savings vary, but many facilities report 30%–70% reductions in exhaust-related energy use per hood depending on usage patterns, climate, and controls. Actual savings require measured baseline data and proper commissioning.

Does VAV affect fume hood safety?

No—if correctly commissioned and maintained. VAV systems are designed to maintain required face velocities and containment at all operating sash positions. Commissioning and periodic performance tests (e.g., ASHRAE 110) are essential.

Are there quick wins for reducing fume hood energy use?

Yes: enforce sash-closed policies, install automatic sash closers, add sash position alarms, and schedule setbacks for nights/weekends. These low-cost measures often produce immediate savings.

What maintenance is required to keep savings and containment?

Regular filter checks, fan and damper calibration, sash inspection, and annual containment tests are recommended. Monitoring systems can flag problems early to avoid safety or efficiency degradation.

How do I estimate payback for a retrofit?

Estimate current energy costs associated with hood exhaust (using CFM, hours of operation, and local energy rates). Compare to projected energy use after retrofit. Include project cost, commissioning, and expected incentives to calculate simple payback.

Contact Us / View Product

Energy performance is important, but many laboratories have unique workflows that standard units cannot support. In these cases, custom fume hood configurations for specialized laboratory needs offer greater flexibility without compromising efficiency.To evaluate your lab's fume hood energy performance or to request specifications and a quote for our Fume Hood line, please contact our sales team or view the product page. Our experts will provide site assessment recommendations, ROI calculations, and commissioning support to ensure safe, efficient operation.

Authoritative References

Sources used for best practices and performance standards (links):

- ASHRAE - Standard 110: Method of Testing Performance of Laboratory Fume Hoods: https://www.ashrae.org

- OSHA - Chemical Hygiene and Laboratory Safety: https://www.osha.gov/chemical-hazards

- CDC / NIOSH - Laboratory Safety: https://www.cdc.gov/niosh

- U.S. EPA - Labs for the 21st Century (Labs21): https://www.epa.gov/labs21century

- U.S. Department of Energy - Energy-efficient Laboratories: https://www.energy.gov/eere/femp/energy-efficient-laboratories

- Wikipedia - Chemical fume hood (overview): https://en.wikipedia.org/wiki/Chemical_fume_hood

For a personalized assessment, contact our technical sales team to schedule a lab audit and learn how our Fume Hood solutions can improve safety and reduce operating costs.

Comparing Lab Sink Materials: Ceramic, Epoxy, and Steel

Cleaning and Decontamination Best Practices for Lab Benches

Maintenance Guide: Prolonging the Life of Lab Sink Cabinets

Stainless Steel Lab Sink Options: Pros and Cons

For Products

Do you offer ergonomic solutions for lab furniture?

Yes, our laboratory furniture includes ergonomic designs such as height-adjustable lab benches and chairs that reduce strain during long hours of work.

For Logistics

What is the lead time?

We usually will start to work after receiving 50% deposit, and as for the exact lead time, it depends on quantity and detailed requirement. We can promise it will be shipped on time as we negotiated.

About Solution

Do you provide laboratory layout design service?

Yes, we provide professional laboratory layout design service to optimize space utilization and workflow according to customer's site and usage requirements.

Customization

What is the after-sales support for customized services?

We provide a full range of after-sales service, including equipment installation guidance, regular maintenance, troubleshooting, operation training, etc., to ensure the safe and efficient operation of equipment.

For Company

Do you provide installation services?

Yes, we offer professional installation services to ensure your laboratory furniture and equipment are set up properly and safely.

Fume Hood

The fume hood provides safe ventilation to protect against exposure to hazardous or toxic fumes, vapors, or airborne particulate. It is primarily used in laboratory and manufacturing applications to protect the user or environment outside the hood, but can also be used to protect the materials or experiment under the hood.

APPLICATION

Chemistry Lab, physics Lab, biological analysis, pharmaceutical medicine analysis, biological pharmaceutical, plant culture, environmental testing and electronic instrumentation scientific research and so on.

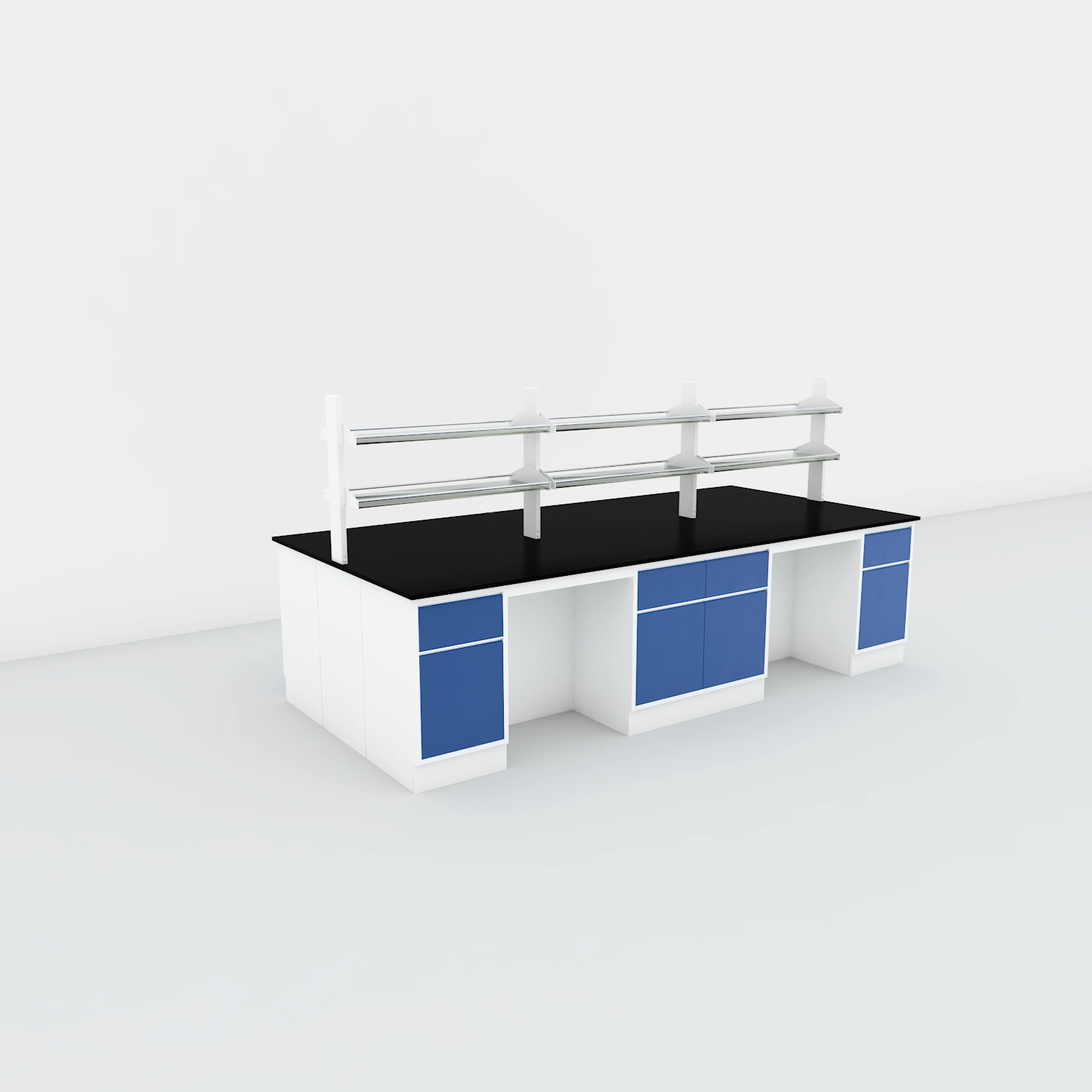

Floor Mounted Lab Bench

Our Floor Mounted Lab Bench is an essential, high-efficiency workspace for laboratories, made from high-quality steel-wood or corrosion-resistant stainless steel materials to ensure exceptional durability and stability. The unique floor-mounted design effectively reduces vibration, optimizes space usage, and provides a safe and tidy laboratory environment.

Customizable storage solutions help organize lab equipment efficiently, while the easy-to-clean surface maintains laboratory hygiene. It is widely suitable for research institutions, educational laboratories, and the chemical and pharmaceutical industries.

Flammable Storage Cabinet

Safety Cabinets store flammable liquids, corrosives, pesticides and other hazardous materials. All fire-resistant safety cabinets by meet fire codes and regulations for safety storage.

To help protect your people and facility from a potential fire, safety cabinets are engineered to safely contain flammable fuels, solvents, and chemicals. Safety cabinets can not only help everyone store chemicals reasonably, save chemical supplies, but also save human resources, and avoid fires caused by chemicals with the greatest strength.

Class II Type A2 Biological Safety Cabinet for Laboratory

The Class II A2 Biological Safety Cabinet is designed to provide superior biosafety and contamination control for laboratories, research facilities, and clinical settings. With 70% air recirculation and 30% air exhaust, this cabinet ensures a safe and efficient work environment while protecting both the user and the samples.

Equipped with advanced features like a HEPA filtration system, motorized front window, and ergonomic design, this cabinet is a must-have for safe and reliable biological research.

Scan QR Code

Scan QR Code

MaxLabFurniture

MaxLab Furniture

daihongada

Max Laboratory