Comparing Lab Sink Materials: Ceramic, Epoxy, and Steel

- Choosing the Right Lab Sink Material for Your Facility

- Understanding the primary use cases

- Key decision factors

- Compliance and standards

- Performance Comparison: Ceramic vs Epoxy Resin vs Stainless Steel

- Chemical and heat resistance

- Durability, impact and scratch resistance

- Maintenance and repairability

- Installation, Lifecycle Costs, and Practical Considerations

- Installation types and compatibility

- Cost of ownership: purchase vs lifetime cost

- Hygiene and cleanability

- Making the Best Choice: Use-Case Recommendations and Brand Advantages

- Recommendations by lab type

- Teaching labs and multi-use benches

- Biopharmaceutical and testing facilities

- Brand advantages: why choose our Lab Sink Cabinet

- Case study snapshot

- Installation Tips, Maintenance Best Practices, and Standards

- Installation and plumbing considerations

- Daily maintenance and cleaning

- Standards and references

- Frequently Asked Questions (FAQ)

- Q: Which lab sink material is most chemical-resistant?

- Q: How should I choose between C-type, floor-mounted and H-type cabinet structures?

- Q: Can I retrofit a different sink material into an existing cabinet?

- Q: What maintenance routines extend the life of a lab sink?

- Q: How do I validate sinks for a cleanroom or biopharma environment?

This article provides a GEO-friendly, experience-based comparison of lab sink materials—ceramic, epoxy resin, and stainless steel—focused on real-world performance in chemistry labs, teaching labs, biopharmaceutical facilities and testing departments. It helps lab managers, facilities engineers and procurement specialists evaluate trade-offs (chemical resistance, durability, maintenance, cost and compatibility with lab benches and faucets) so they can choose the right lab sink material for their Lab Sink Cabinet and complete laboratory bench systems.

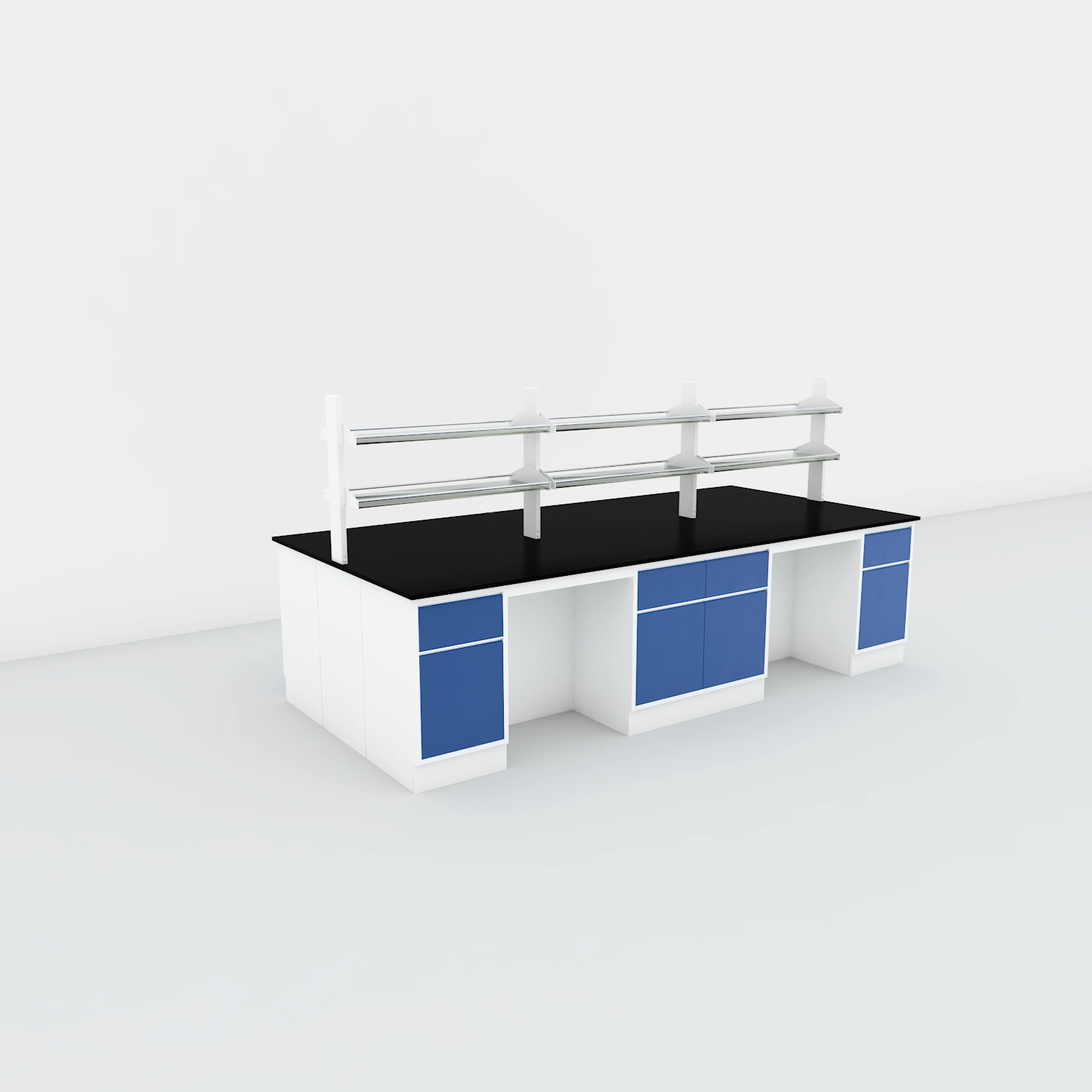

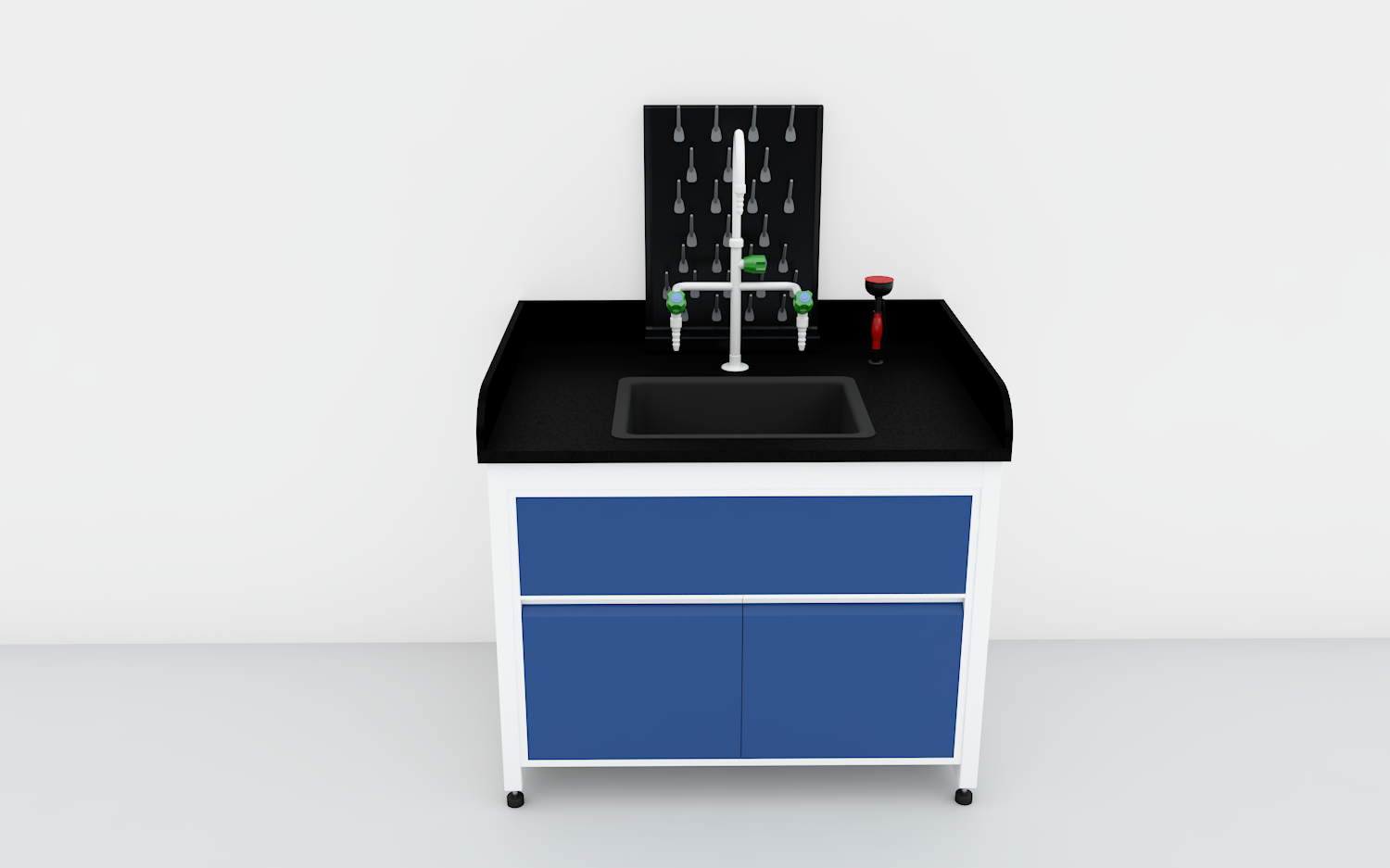

The Lab Sink Cabinet is designed for chemistry labs, teaching labs, biopharmaceutical facilities and testing departments, and can be seamlessly integrated into complete laboratory bench systems. The product offers C-type, floor-mounted and H-type structures, combined with a chemical-resistant lab sink and lab faucet to meet cleaning, rinsing, drainage and temporary storage needs.

After comparing material options, decision-makers typically return to how to choose the right lab sink for your facility to finalize specifications or plan future upgrades.

Choosing the Right Lab Sink Material for Your Facility

Understanding the primary use cases

Before selecting a lab sink, identify the dominant activities at the workstation. Teaching labs typically prioritize resilience to wear and easy maintenance; research chemistry labs need high chemical and heat resistance; biopharmaceutical facilities emphasize cleanability and validated surfaces for contamination control. The right material aligns with these use cases and ensures the Lab Sink Cabinet serves both everyday and exceptional needs.

Key decision factors

Choose a lab sink material based on: chemical resistance, heat tolerance, mechanical durability (scratch and impact resistance), ease of repair, long-term cost of ownership (including downtime and replacement), aesthetics, and compatibility with lab faucets and drainage systems. Consider integration: sinks in our Lab Sink Cabinet support C-type, floor-mounted and H-type installations, so material thickness and mounting details matter.

Compliance and standards

Laboratory furniture and fixtures should meet applicable local regulations and industry standards for safety and hygiene. Refer to standards and guidance from recognized bodies such as ASTM for material testing and general laboratory safety guidance from organizations like OSHA and NIOSH. For material science background, authoritative references like the Wikipedia pages for ceramic, epoxy and stainless steel provide useful technical summaries.

Performance Comparison: Ceramic vs Epoxy Resin vs Stainless Steel

Chemical and heat resistance

Ceramic sinks (glazed) offer very good resistance to many acids, bases and organic solvents at ambient temperatures but can be vulnerable to strong hydrofluoric acid and extreme thermal shock. Epoxy resin sinks are engineered for broad chemical resistance, including many acids and alkalis, but prolonged exposure to strong oxidizers or solvents can cause surface degradation. Stainless steel (typically 304 or 316 grades) resists many chemicals and high temperatures; Grade 316 provides superior resistance to chlorides and corrosive environments. Consider the specific reagents in your workflow when assessing chemical resistance.

Durability, impact and scratch resistance

Epoxy resin lab sinks are resilient against impact and offer seamless integration into countertops, reducing leak risk. Ceramic has excellent hardness and scratch resistance but is brittle—impacts may cause chips or cracks. Stainless steel is highly impact-resistant and forgiving of mechanical wear, but can scratch and may show surface pitting over time in aggressive chemical environments.

Maintenance and repairability

Stainless steel is easy to clean and can often be polished or passivated to restore appearance; minor dents may require replacement of the bowl. Epoxy resin surfaces can be sanded and recoated for localized repairs. Ceramic repairs are more challenging—chips may be filled, but significant cracks typically require replacement. Maintenance access and replacement planning should be part of cabinet design; our Lab Sink Cabinet supports modular sink replacement to minimize downtime.

Installation, Lifecycle Costs, and Practical Considerations

Installation types and compatibility

When integrating a lab sink into a Lab Sink Cabinet, consider the cabinet's structure (C-type, floor-mounted, H-type). C-type installations allow equipment access beneath the sink for piping and service. Floor-mounted cabinets provide robust support for heavy sinks (ceramic) and facilitate drainage routing. H-type offers flexible bench continuity for longer runs and multiple sink stations. Ensure the sink material chosen is compatible with cabinet mounting hardware and supports (epoxy may be lighter and require different supports than ceramic).

Cost of ownership: purchase vs lifetime cost

Initial purchase cost varies: ceramic sinks are often mid-range, epoxy sinks may be moderate to high depending on formulation, and stainless steel can range widely by grade. However, lifetime cost depends on maintenance, repairability and downtime. Below table summarizes typical differences to help procurement decisions.

| Property | Ceramic | Epoxy Resin | Stainless Steel (304/316) |

|---|---|---|---|

| Chemical resistance | High (but vulnerable to HF) | High (broad range; less with oxidizers) | Good to very good (316 best for chlorides) |

| Heat resistance | Very high | Moderate to high (depends on formulation) | Very high |

| Impact resistance | Low (brittle) | High (tough) | High |

| Scratch resistance | High | Moderate | Moderate (visible scratches) |

| Repairability | Low (replace likely) | High (refinish possible) | Moderate (polish/passivate) |

| Typical applications | Teaching labs, general-purpose sinks | Chemistry labs, where impact and chemical resistance are required | Biopharma, wash stations, high-temperature use |

Hygiene and cleanability

All three materials can be kept hygienic when cleaned with appropriate agents and procedures. Stainless steel offers a non-porous, easy-to-sanitize surface widely used in biopharmaceutical settings. Epoxy resin offers a seamless, non-porous finish that reduces microbial harborage if properly maintained. Ceramic glaze provides a hard, non-porous surface but cracked glaze or chips can become niches for contamination—prompt repair or replacement is important in controlled environments.

Making the Best Choice: Use-Case Recommendations and Brand Advantages

Recommendations by lab type

Chemistry research labs: Epoxy resin is often the best balance of chemical resistance and impact tolerance, especially where bench-integrated sinks are needed. For fume-hood adjacent sinks that face strong acids, consider ceramic where thermal and surface hardness provide benefits—except where hydrofluoric acid is used.

Teaching labs and multi-use benches

Teaching labs value durability, low maintenance and cost-effectiveness. Ceramic sinks are widely used in teaching environments for their scratch resistance and clean appearance. Epoxy also performs well and can be preferable where impacts are frequent.

Biopharmaceutical and testing facilities

Stainless steel (316) typically leads in biopharma due to validated cleanability, heat resistance and compliance with hygienic standards. Our Lab Sink Cabinet's ability to accept chemical-resistant lab sinks and lab faucets, together with configurable cabinet structures, helps maintain clean workflows and supports validation protocols.

Brand advantages: why choose our Lab Sink Cabinet

Our Lab Sink Cabinet is engineered for integration with full laboratory bench systems and supports C-type, floor-mounted and H-type layouts to match installation needs. We package chemical-resistant lab sinks and professional lab faucets to ensure dependable drainage, rinsing and temporary storage while minimizing cross-contamination risks. Key advantages:

- Modular design for fast sink replacement and maintenance access

- Material-agnostic mounting to support ceramic, epoxy and stainless steel bowls

- Chemical-resistant finishes and internal shelving for secure storage of cleaning agents

- Accessory compatibility for waste traps, basket strainers, and lab-grade faucets

Case study snapshot

A university converted a row of teaching benches from basic stainless janitorial sinks to ceramic lab sinks built into Lab Sink Cabinets. The upgrade improved resistance to staining and reduced daily maintenance hours. In a separate installation, a small biotech firm chose 316 stainless steel sinks in floor-mounted cabinets to meet strict cleaning validation and autoclave drainage needs—demonstrating how cabinet structure and sink material are chosen together to meet operational goals.

Installation Tips, Maintenance Best Practices, and Standards

Installation and plumbing considerations

Plan drainage routes, trap access and faucet mounting before ordering sinks. Ceramic sinks need secure, often heavier supports; epoxy sinks may be bonded to countertops; stainless steel sinks usually use undermount or drop-in methods with different sealing materials. Our Lab Sink Cabinet design includes pre-cut routing plates and service access panels for efficient plumbing installation.

Daily maintenance and cleaning

Use manufacturer-recommended cleaners. Avoid abrasive pads on finishes that are prone to scratching. For epoxy, avoid prolonged exposure to strong oxidizers; for stainless steel, use non-chloride cleaners to preserve passivation. Periodic inspection for chips, cracks or pitting lets you repair small issues before they escalate.

Standards and references

For material testing and performance guidance see ASTM International (https://www.astm.org/) and for general material background the Wikipedia overviews on ceramics, epoxy resins, and stainless steel. For laboratory safety considerations, consult OSHA guidance and NIOSH resources when selecting sink placement and chemical handling facilities.

Frequently Asked Questions (FAQ)

Q: Which lab sink material is most chemical-resistant?

A: No single material is universally best. Epoxy resin and stainless steel (316) both provide broad resistance; ceramic resists many reagents but is vulnerable to hydrofluoric acid. Match material selection to the chemicals used in your procedures.

Q: How should I choose between C-type, floor-mounted and H-type cabinet structures?

A: Choose C-type for under-sink access and equipment clearance, floor-mounted for maximum stability and heavy sinks, and H-type for continuity across bench runs and multiple sink stations. Our Lab Sink Cabinet supports all three to fit your lab layout.

Q: Can I retrofit a different sink material into an existing cabinet?

A: Often yes, if the cabinet has sufficient support and the cutout/mounting style matches. Retrofits may require reinforcing supports (for ceramic) or adjustment to sealing methods (for epoxy/stainless). Consult our installation guidance to confirm compatibility.

Q: What maintenance routines extend the life of a lab sink?

A: Regular cleaning with compatible agents, prompt repair of chips or scratches, avoiding prolonged contact with strong oxidizers or concentrated acids on sensitive surfaces, and routine inspection of seals and drainage fittings will extend life and reduce downtime.

Q: How do I validate sinks for a cleanroom or biopharma environment?

A: Choose non-porous materials (316 stainless steel is common), ensure smooth welds and joints, document cleanability procedures, and include sinks in your environmental monitoring and validation plan. Our Lab Sink Cabinet can be provided with finishes and documentation to support validation efforts.

Need expert help selecting the right lab sink and cabinet configuration? View the Lab Sink Cabinet product page or contact our sales team for personalized recommendations and quotes: View Lab Sink Cabinet | Contact Sales.

Plumbing and Installation Considerations for Lab Sink Cabinets

Laboratory Workbench Design: Layout and Workflow

Installing Floor Mounted Lab Benches: What to Expect

Ergonomic Considerations for Lab Benches to Reduce Fatigue

For Customization

Can I make changes to my order once it has been placed?

We offer limited flexibility to make changes to your order after it has been placed. Contact our sales team as soon as possible if you need to make modifications.

Can I customize the size and configuration of my lab furniture?

Yes, we offer full customization for laboratory benches, modular systems, and storage units to meet your specific space and functional needs.

For After-Sales Support

Do you offer training for using your products?

Yes, we offer training for your staff on how to properly use and maintain the laboratory equipment we provide. Contact us to schedule a training session.

About Solution

How about your after sale service?

We will reply to you within 24 hours by email or phone.

If we have a local agent, we will arrange for him to be at your site within 24 hours to assist you in shooting the problem.

How to ensure the safety performance of the fume hood?

Our fume hoods adopt high-efficiency filtration system and intelligent air speed control technology to ensure that harmful gases are effectively eliminated during experiments and protect users' health.

Lab Sink LS-08

The LS-08 Round Cup / Funnel Sink is a small-diameter, deep cup sink designed as a funnel-type drain point on laboratory worktops. Constructed from chemical-resistant black PP, it features an extended threaded outlet that connects directly to drain piping.

This design is perfect for apparatus drain lines, RO reject water, condensate and other continuous or intermittent discharges where an open, funnel-like inlet is required.

Floor Mounted Lab Bench

Our Floor Mounted Lab Bench is an essential, high-efficiency workspace for laboratories, made from high-quality steel-wood or corrosion-resistant stainless steel materials to ensure exceptional durability and stability. The unique floor-mounted design effectively reduces vibration, optimizes space usage, and provides a safe and tidy laboratory environment.

Customizable storage solutions help organize lab equipment efficiently, while the easy-to-clean surface maintains laboratory hygiene. It is widely suitable for research institutions, educational laboratories, and the chemical and pharmaceutical industries.

Fume Hood

The fume hood provides safe ventilation to protect against exposure to hazardous or toxic fumes, vapors, or airborne particulate. It is primarily used in laboratory and manufacturing applications to protect the user or environment outside the hood, but can also be used to protect the materials or experiment under the hood.

APPLICATION

Chemistry Lab, physics Lab, biological analysis, pharmaceutical medicine analysis, biological pharmaceutical, plant culture, environmental testing and electronic instrumentation scientific research and so on.

Flammable Storage Cabinet

Safety Cabinets store flammable liquids, corrosives, pesticides and other hazardous materials. All fire-resistant safety cabinets by meet fire codes and regulations for safety storage.

To help protect your people and facility from a potential fire, safety cabinets are engineered to safely contain flammable fuels, solvents, and chemicals. Safety cabinets can not only help everyone store chemicals reasonably, save chemical supplies, but also save human resources, and avoid fires caused by chemicals with the greatest strength.

Scan QR Code

Scan QR Code

MaxLabFurniture

MaxLab Furniture

daihongada

Max Laboratory