How to Choose Lab Sink Cabinets: A Buyer's Practical Checklist

- How to Choose Lab Sink Cabinets: A Buyer's Practical Checklist

- Introduction to Lab Sink Cabinets and lab cabinets

- Product overview: Lab Sink Cabinet

- 1. Understand Your Lab's Needs: Use Case Determines lab cabinets Specifications

- 2. Cabinet Structure: Choosing Between C-type, Floor-mounted and H-type lab cabinets

- 3. Materials & Chemical Resistance: The Most Critical lab cabinets Factor

- 4. Plumbing, Drainage and Lab Faucet Selection for lab cabinets

- Plumbing quick checklist

- 5. Safety Features and Compliance: Meet Standards When Choosing lab cabinets

- 6. Ergonomics, Dimensions and Integration with Lab Furniture (lab cabinets)

- 7. Storage and Organization Options in lab cabinets

- 8. Durability, Maintenance and Cleaning for lab cabinets

- 9. Budgeting and Total Cost of Ownership for lab cabinets

- 10. Procurement Checklist: Step-by-step Buying Guide for lab sink cabinets

- 11. Example Comparison Table: Common Sink & Cabinet Options

- 12. Real-World Scenarios: Choosing lab cabinets for Specific Lab Types

- 13. Brand Considerations and How Our Lab Sink Cabinet Stands Out Among lab cabinets

- 14. Maintenance Schedule and Best Practices for lab cabinets

- FAQ — Frequently Asked Questions about lab cabinets and Lab Sink Cabinet

- Q1: Which sink material is best for handling strong acids?

- Q2: Can I install a Lab Sink Cabinet in a cleanroom or biopharma environment?

- Q3: How do I prevent chemical odors and drain blockages?

- Q4: Are legs or floor-mounted cabinets better for plumbing access?

- Q5: What warranties should I expect for Lab Sink Cabinet purchases?

- Contact Us / View Product CTA

- Authoritative References and Further Reading

How to Choose Lab Sink Cabinets: A Buyer's Practical Checklist

Introduction to Lab Sink Cabinets and lab cabinets

Selecting the right lab sink cabinet is a critical decision for lab managers, facility engineers, and purchasing teams. A well-chosen Lab Sink Cabinet supports daily cleaning and decontamination routines, ensures safe drainage and temporary storage, and integrates seamlessly with bench systems. This guide gives practical, actionable advice and a concise buyer's checklist to help you choose lab cabinets that meet performance, safety, and budget requirements. Once you understand the fundamentals in how to choose lab sink cabinets using a buyer’s practical checklist, the next step is evaluating the best materials for lab sink cabinets with chemical resistance.

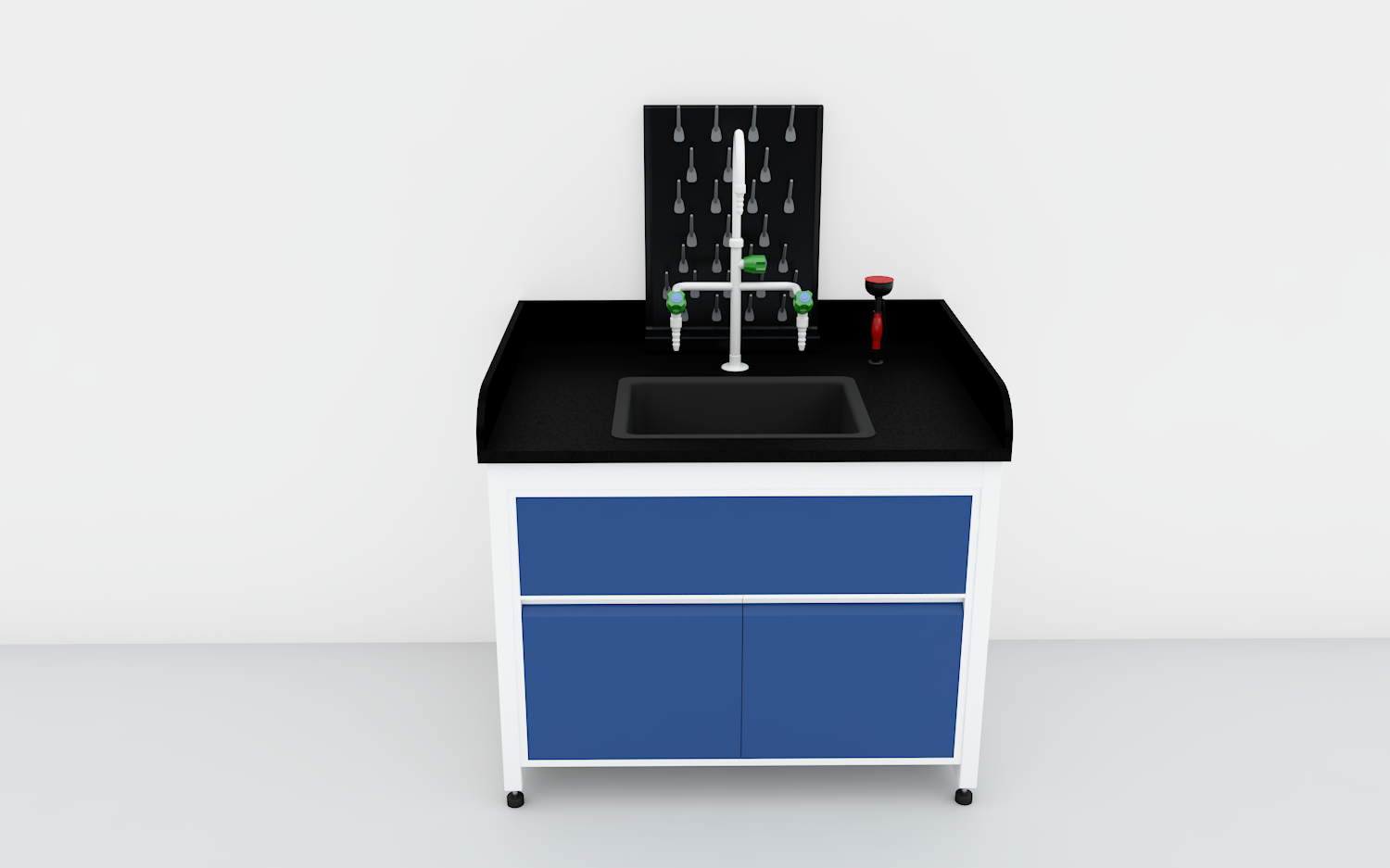

Product overview: Lab Sink Cabinet

The Lab Sink Cabinet is designed for chemistry labs, teaching labs, biopharmaceutical facilities and testing departments, and can be seamlessly integrated into complete laboratory bench systems. The product offers C-type, floor-mounted and H-type structures, combined with a chemical-resistant lab sink and lab faucet to meet cleaning, rinsing, drainage and temporary storage needs.

1. Understand Your Lab's Needs: Use Case Determines lab cabinets Specifications

Before you evaluate specific Lab Sink Cabinet models, map out how the sink cabinet will be used. Typical use cases drive different priorities:

- Chemistry labs: strong chemical resistance, acid/solvent compatibility, spill containment and easy decontamination.

- Teaching labs: durability, vandal-resistant fixtures, easy maintenance and cost-effectiveness.

- Biopharmaceutical facilities: contamination control, stainless interiors, sanitary drains and compatibility with cleanroom protocols.

- Testing departments: flexibility for different sample types and integrated storage for reagents and waste handling.

Knowing the primary use case helps narrow choices on materials, sink shapes, faucet types, and cabinet structures (C-type, floor-mounted, H-type) to best support operations.

2. Cabinet Structure: Choosing Between C-type, Floor-mounted and H-type lab cabinets

Cabinet structure affects installation, under-sink storage, and plumbing routing. The three common structures are:

- C-type: Typically supported by adjacent benches or a central frame. Good for continuous bench runs and integrated systems.

- Floor-mounted: Free-standing cabinets that rest directly on the floor. Offer robust storage and are easy to plumb; ideal where independent units are preferred.

- H-type: Designed for islands or dual-access benches (work from both sides). Often used in teaching or collaborative labs.

Choose the structure that matches your workflow, bench layout, and plumbing access. If you plan modular reconfigurations, floor-mounted units usually offer the greatest flexibility.

3. Materials & Chemical Resistance: The Most Critical lab cabinets Factor

Material selection for both the sink and cabinet body determines longevity and safety. Consider these options:

- Sinks: Epoxy resin sinks (excellent chemical resistance to acids and solvents), polypropylene (good for many chemicals and low cost), stainless steel (durable and sanitary but can corrode with strong acids), and ceramic (scratch- and heat-resistant but brittle).

- Cabinet bodies: Powder-coated metal (economical but susceptible to coating damage), stainless steel (preferred for corrosive environments and cleanrooms), and chemical-resistant laminates over plywood (common in teaching labs for cost balance).

Checklist point: Request chemical-resistance charts from the vendor showing compatibility with the specific reagents used in your lab.

4. Plumbing, Drainage and Lab Faucet Selection for lab cabinets

Plumbing design affects utility, safety, and maintenance:

- Ensure drain location and size match your waste routing and local plumbing code.

- Consider traps and vents for odor control and to meet sanitary code.

- Choose faucets engineered for lab use—gooseneck for general cleaning, pre-rinse spray for glassware, and foot/touchless valves for contamination control.

- Corrosion-resistant fittings (PTFE-lined, stainless steel, plastic) are essential when handling aggressive chemicals.

Plumbing quick checklist

| Item | Recommended |

|---|---|

| Drain material | CPVC/HDPE or stainless steel with chemical-resistant seals |

| Trap | Accessible, corrosion-resistant trap with clean-out |

| Faucet controls | Hands-free or knee/foot controls for bio/aseptic labs |

5. Safety Features and Compliance: Meet Standards When Choosing lab cabinets

Safety considerations are non-negotiable. Key items to check:

- Containment: Continuous sump or sloped sink to prevent spills escaping cabinet areas.

- Ventilation: Some cabinets need local exhaust or connection to fume capture systems—especially for acid rinses or solvent washouts.

- Grounding and bonding: For flammable solvent areas, ensure the sink/faucet and cabinet metalwork can be grounded to prevent static buildup.

- Labeling and signs: Chemical-resistant labels for hazardous waste and cleaning instructions.

- Regulatory compliance: Confirm the product supports compliance with relevant guidelines (local plumbing codes, OSHA Laboratory Standard 29 CFR 1910.1450, and biosafety guidance where applicable).

6. Ergonomics, Dimensions and Integration with Lab Furniture (lab cabinets)

Proper height, knee clearance, and reach zones improve safety and productivity:

- Standard bench heights (typically 34–36 inches/86–91 cm) may be adjusted for sit-stand tasks or ADA access.

- Ensure adequate knee clearance where users need to work from the sink side.

- Confirm that cabinet depth and width align with bench runs and allow space for under-sink plumbing and waste containers.

7. Storage and Organization Options in lab cabinets

Good under-sink storage balances accessibility and safety:

- Removable shelves or corrosion-resistant pull-out trays simplify cleaning and maintenance.

- Dedicated waste compartments with sealed liners for hazardous waste containers.

- Lockable doors for reagent or hazardous material storage in teaching labs.

- Integrated drip trays, secondary containment or bunded compartments for reactive or corrosive liquids.

8. Durability, Maintenance and Cleaning for lab cabinets

To minimize lifecycle costs, evaluate maintenance requirements:

- Surface resilience: Choose finishes that stand up to daily disinfectants and chemical spills.

- Replaceable parts: Are sink inserts, seals, and hardware readily replaceable?

- Ease of cleaning: Smooth, seamless sinks and well-sealed cabinet joints prevent contamination harborage.

- Warranty and service: Check manufacturer warranties, spare parts availability, and local service support.

9. Budgeting and Total Cost of Ownership for lab cabinets

Purchase price is only part of the cost equation. Consider:

- Installation — plumbing, electrical and any custom bench integration.

- Lifetime maintenance — replacement seals, faucets, coatings and parts.

- Downtime cost — how often units need repair or retouching.

- Resale or refurbishment value—stainless options often retain value longer.

10. Procurement Checklist: Step-by-step Buying Guide for lab sink cabinets

Use this checklist during procurement and vendor evaluation:

- Define use case(s) and chemical list.

- Specify sink material and cabinet body material based on chemical compatibility.

- Choose cabinet structure (C-type, floor-mounted, H-type) per bench layout.

- Confirm plumbing requirements and local code compliance.

- List required faucets, control types and accessories (hands-free, gooseneck, spray).

- Request chemical resistance charts and maintenance instructions from vendor.

- Evaluate ergonomics, dimensions and integration needs.

- Ask for warranty, service response times and spare parts availability.

- Get three competitive bids including installation scope and timelines.

- Plan for commissioning, user training and routine maintenance schedule.

11. Example Comparison Table: Common Sink & Cabinet Options

| Feature | Epoxy Sink + Stainless Cabinet | Polypropylene Sink + Powder-coated Metal Cabinet | Stainless Sink + Stainless Cabinet |

|---|---|---|---|

| Chemical resistance | Excellent | Good for many chemicals | Good, but vulnerable to strong acids |

| Durability | Very high | Medium | Very high |

| Cost | Higher | Lower–Medium | Higher |

| Best for | Chemistry and mixed-use labs | Teaching labs, budget-limited installs | Biopharma, sanitary environments |

12. Real-World Scenarios: Choosing lab cabinets for Specific Lab Types

Scenario A — High-school teaching lab: Choose a floor-mounted polypropylene sink with powder-coated cabinet. Prioritize cost, vandal resistance, and simple maintenance. Include lockable storage and easy-to-clean surfaces.

Scenario B — Analytical chemistry lab: Epoxy resin sink with stainless steel cabinet. Add chemical-resistant plumbing, foot-operated valves, and secondary containment for acid baths.

Scenario C — Biopharmaceutical lab: Seamless stainless sink, stainless cabinet, sanitary drains, touchless faucets and integration with cleanroom bench modules (H-type for island benches if needed).

13. Brand Considerations and How Our Lab Sink Cabinet Stands Out Among lab cabinets

When comparing brands, evaluate these differentiators:

- Proven chemical compatibility documentation and transparent testing data.

- Customization options (sizes, sink shapes, door configurations) that match bench systems.

- Local support, installation services and spare parts availability.

- Certifications and references from similar facilities (teaching labs, biopharma, testing centers).

Our Lab Sink Cabinet brings together these strengths: multiple structural options (C-type, floor-mounted and H-type) to fit diverse layouts; chemical-resistant sinks paired with lab faucets designed for rigorous use; and integration capability with full laboratory bench systems. We provide detailed chemical compatibility charts, on-site installation support, and a warranty that covers both materials and finishes—minimizing lifetime cost and downtime.

14. Maintenance Schedule and Best Practices for lab cabinets

To extend service life and keep your lab cabinets compliant and safe:

- Daily: Wipe sinks and surrounding counters with compatible cleaners; empty drip trays and inspect for leaks.

- Weekly: Inspect seals, drains and trap for build-up; check for corrosion or coating damage.

- Quarterly: Lubricate hinges if needed, test hands-free valves, and verify grounding/bonding where relevant.

- Annually: Vendor inspection for wear items, replace seals and review chemical compatibility if processes changed.

FAQ — Frequently Asked Questions about lab cabinets and Lab Sink Cabinet

Q1: Which sink material is best for handling strong acids?

A1: Epoxy resin sinks are generally the best choice for strong acids and solvents due to their broad chemical resistance. Stainless steel may corrode with some acids; polypropylene is resistant to many chemicals but less heat resistant.

Q2: Can I install a Lab Sink Cabinet in a cleanroom or biopharma environment?

A2: Yes—choose stainless steel sinks and cabinets with sanitary drains, smooth welds, and cleanroom-compatible finishes. Coordinate with your contamination control team for integration and validation.

Q3: How do I prevent chemical odors and drain blockages?

A3: Use accessible corrosion-resistant traps, maintain regular cleaning schedules, and consider inline neutralizers or local exhaust for volatile chemicals. Ensure proper waste segregation and use appropriate waste containers rather than pouring incompatible wastes down sinks.

Q4: Are legs or floor-mounted cabinets better for plumbing access?

A4: Floor-mounted cabinets typically offer easier plumbing access and more storage capacity. Legged cabinets integrated into bench modules (C-type) can be better for continuous bench aesthetics and workflows.

Q5: What warranties should I expect for Lab Sink Cabinet purchases?

A5: Expect warranties covering manufacturing defects, finish degradation under normal use, and limited guarantees on sink materials. Verify coverage timeframe, exclusions for chemical damage, and availability of service centers.

Contact Us / View Product CTA

If you’re ready to evaluate Lab Sink Cabinet options for your facility, contact our technical sales team for a free site assessment, chemical-compatibility review and customised quote. View the Lab Sink Cabinet product page or get in touch for a specification sheet and installation planning.

Authoritative References and Further Reading

- OSHA — Laboratory Safety Guidance: https://www.osha.gov/laboratory

- CDC — Biosafety in Microbiological and Biomedical Laboratories (BMBL): https://www.cdc.gov/labs/BMBL.

- NSF International — Standards & Certifications: https://www.nsf.org

- Wikipedia — Laboratory furniture: https://en.wikipedia.org/wiki/Laboratory_furniture

Note: For best results, always share your chemical inventory and bench layout with vendors when requesting quotes and compatibility documentation.

Fume Hood Integration with HVAC and Laboratory Design

Compliance and Standards to Consider for Lab Sink Installations

Best Materials for Lab Sink Cabinets: Chemical Resistance

Maintenance Tips to Extend the Life of Your Lab Sink

For Products

Is available to buy your original design?

Yes, all the products are designed professionally by our designers. Please feel free to inform us which item you are interested in.

For Company

What sets your company apart from other lab furniture providers?

Our commitment to quality, innovation, and customer satisfaction sets us apart. We offer customized solutions, high-quality materials, and a full range of laboratory furniture and equipment to ensure optimal functionality and safety for every lab.

Do you offer our design service from scratch?

Yes, we provide full design support tailored to your lab’s specific needs, including layout planning and furniture customization.

For After-Sales Support

Do you offer training for using your products?

Yes, we offer training for your staff on how to properly use and maintain the laboratory equipment we provide. Contact us to schedule a training session.

Customization

How to calculate the cost of customized services?

Customization services incur additional costs depending on the complexity of the design, material selection and production requirements. We will clearly list all costs at the quote stage to ensure that the client understands all costs.

Floor Mounted Lab Bench

Our Floor Mounted Lab Bench is an essential, high-efficiency workspace for laboratories, made from high-quality steel-wood or corrosion-resistant stainless steel materials to ensure exceptional durability and stability. The unique floor-mounted design effectively reduces vibration, optimizes space usage, and provides a safe and tidy laboratory environment.

Customizable storage solutions help organize lab equipment efficiently, while the easy-to-clean surface maintains laboratory hygiene. It is widely suitable for research institutions, educational laboratories, and the chemical and pharmaceutical industries.

Fume Hood

The fume hood provides safe ventilation to protect against exposure to hazardous or toxic fumes, vapors, or airborne particulate. It is primarily used in laboratory and manufacturing applications to protect the user or environment outside the hood, but can also be used to protect the materials or experiment under the hood.

APPLICATION

Chemistry Lab, physics Lab, biological analysis, pharmaceutical medicine analysis, biological pharmaceutical, plant culture, environmental testing and electronic instrumentation scientific research and so on.

Flammable Storage Cabinet

Safety Cabinets store flammable liquids, corrosives, pesticides and other hazardous materials. All fire-resistant safety cabinets by meet fire codes and regulations for safety storage.

To help protect your people and facility from a potential fire, safety cabinets are engineered to safely contain flammable fuels, solvents, and chemicals. Safety cabinets can not only help everyone store chemicals reasonably, save chemical supplies, but also save human resources, and avoid fires caused by chemicals with the greatest strength.

Class II Type A2 Biological Safety Cabinet for Laboratory

The Class II A2 Biological Safety Cabinet is designed to provide superior biosafety and contamination control for laboratories, research facilities, and clinical settings. With 70% air recirculation and 30% air exhaust, this cabinet ensures a safe and efficient work environment while protecting both the user and the samples.

Equipped with advanced features like a HEPA filtration system, motorized front window, and ergonomic design, this cabinet is a must-have for safe and reliable biological research.

Scan QR Code

Scan QR Code

MaxLabFurniture

MaxLab Furniture

daihongada

Max Laboratory