Selecting Chemical-Resistant Worktops for Lab Benches

- Selecting Chemical-Resistant Worktops for Lab Benches

- Why Choosing the Right Worktop Matters for Lab Benches

- Common Lab Bench Worktop Materials and How They Perform

- Assessing Your Lab's Chemical Compatibility Needs

- Why Epoxy and Phenolic Are Popular for Lab Benches

- When Stainless Steel Worktops Make Sense for Lab Benches

- Design Considerations: Thickness, Edge Details, and Integration

- Maintenance and Cleaning: Preserving Chemical Resistance of Lab Benches

- Choosing a Worktop for Heavy Instrumentation and Vibration Concerns

- Floor Mounted Lab Bench: Product Overview and Advantages

- How to Select the Right Worktop for Your Floor Mounted Lab Bench

- Cost vs. Performance: Making a Value-Based Choice for Lab Benches

- Installation and Quality Assurance Best Practices

- Safety and Regulatory Considerations for Lab Worktops

- FAQ — Chemical-Resistant Worktops for Lab Benches

- Q: Which worktop material is best for general chemistry labs?

- Q: Can stainless steel be used in organic chemistry labs?

- Q: Are poured epoxy tops seamless?

- Q: How do I protect worktops from accidental spills of strong oxidizers?

- Q: How often should I inspect and maintain lab bench worktops?

- Q: Why choose a Floor Mounted Lab Bench over wall-mounted or island benches?

- Brand Advantages — Why Choose Our Floor Mounted Lab Bench

- Contact / View Product

- References and Further Reading

Selecting Chemical-Resistant Worktops for Lab Benches

Why Choosing the Right Worktop Matters for Lab Benches

Choosing an appropriate chemical-resistant worktop is one of the most important decisions when specifying lab benches. The worktop is the daily contact surface for experiments, instruments, and chemicals; its chemical resistance, physical durability, cleanability, and thermal properties directly affect safety, experiment integrity, and long-term costs. Poorly selected worktops can corrode, delaminate, or harbor contaminants, increasing downtime and repair costs and creating hazards for staff.

Common Lab Bench Worktop Materials and How They Perform

There are several widely used worktop materials for lab benches, each with strengths and limitations. Below is a concise comparison to help you match application needs with the right material.

| Material | Typical Chemical Resistance | Strengths | Limitations |

|---|---|---|---|

| Epoxy Resin | Excellent to broad-spectrum resistance to acids, bases, many solvents | Seamless tops possible, good heat tolerance, excellent mechanical resistance | Can yellow with UV, surface may be attacked by strong oxidizers over time |

| Phenolic Resin | Good resistance to water, many acids and solvents; less resistant to strong oxidizers | Cost-effective, impact-resistant, widely used for wet labs | Lower heat resistance than epoxy; edges can swell with prolonged solvent exposure |

| Stainless Steel (e.g., 304, 316) | Excellent to most inorganic chemicals; susceptible to pitting with chlorides for some grades | Hygienic, easy to clean, high heat resistance, durable | Can corrode with certain halogenated solvents or concentrated chlorides; noisy; may scratch |

| High-Density Polyethylene (HDPE) | Good to many solvents and acids; organic solvent resistance varies | Good for corrosive waste handling, affordable, chemical inert | Lower heat resistance and mechanical strength; may deform under heavy loads |

| Quartz/Granite/Ceramic | Excellent resistance to acids and solvents depending on glazing | High hardness, scratch resistance, aesthetic | Heavy; brittle; glazing can be attacked by strong alkalis or hydrofluoric acid |

| Glass (Tempered) | Good to many chemicals; attacked by hydroflouric acid and strong alkalies | Inert, easy to clean, attractive surface | Fragile, can break or chip; limited load capacity |

Assessing Your Lab's Chemical Compatibility Needs

To select the right worktop for a lab bench, start with a chemical compatibility assessment: compile a list of the reagents, concentrations, temperatures, and typical spill volumes used in the space. Pay attention to:

- Strong oxidizers (e.g., nitric acid, perchloric acid) and hydrofluoric acid — these limit many materials.

- Organic solvents and chlorinated solvents that can attack resins or cause swelling.

- Salt solutions and chloride exposure — important for stainless steel grade decisions (304 vs 316).

- Thermal loads — hot plates or autoclave adjacency requires heat-tolerant materials.

This data-driven approach reduces surprises and ensures laboratory safety and longevity of the lab benches.

Why Epoxy and Phenolic Are Popular for Lab Benches

Epoxy resin tops and phenolic resin tops are two of the most common choices for lab benches due to their blend of chemical resistance, affordability, and ease of fabrication. Epoxy typically offers broader solvent resistance and higher heat tolerance, making it suitable for chemical research labs. Phenolic tops provide excellent cost-performance for schools and teaching labs that handle water-based chemistry and moderate solvents.

When Stainless Steel Worktops Make Sense for Lab Benches

Stainless steel worktops are favored for cleanrooms, biological laboratories, and situations that demand sterilization and hard-surface cleaning. They are ideal when hygiene and ease of decontamination are top priorities. Choose higher grades (316) if chlorides or halogenated solvents are present frequently; otherwise 304 is acceptable for many uses.

Design Considerations: Thickness, Edge Details, and Integration

Beyond material chemistry, the design of the lab bench worktop matters. Key factors:

- Thickness: Thicker tops offer better load-carrying capacity and reduce warping. Epoxy and phenolic typically range 12–25 mm; stainless steel sheets are often 1.2–3 mm over supporting structure.

- Edge treatment: Chemically-resistant coved edges prevent liquid ingress and simplify cleaning. Integrated upstands (backsplashes) protect vertical surfaces.

- Seams and joints: Seamless or welded finishes minimize contamination points. For resin tops, poured or laminated seams are preferable.

- Integration: Consider sinks, fume hoods, and utilities routing (gas, vacuum, electrical) when selecting the top material and layout.

Maintenance and Cleaning: Preserving Chemical Resistance of Lab Benches

Proper maintenance significantly extends worktop life. Guidelines:

- Follow manufacturer cleaning instructions; many lab tops tolerate mild detergent and water, with alcohol-based disinfectants for biological labs.

- Avoid abrasive cleaners on resin surfaces to prevent micro-scratches that trap contaminants.

- Neutralize and remove spills quickly; keep a spill response plan and appropriate neutralizing agents accessible.

- Inspect seams, edge joints, and fastenings periodically to ensure integrity and reseal if necessary.

Choosing a Worktop for Heavy Instrumentation and Vibration Concerns

Heavy equipment such as centrifuges, mass spectrometers, or mechanical shakers demands a sturdy bench construction. A Floor Mounted Lab Bench provides a solid foundation that reduces vibration and improves instrument stability. If your lab houses vibration-sensitive instrumentation, prioritize thicker top materials and a robust floor-mounted support system rather than suspended or mobile benches.

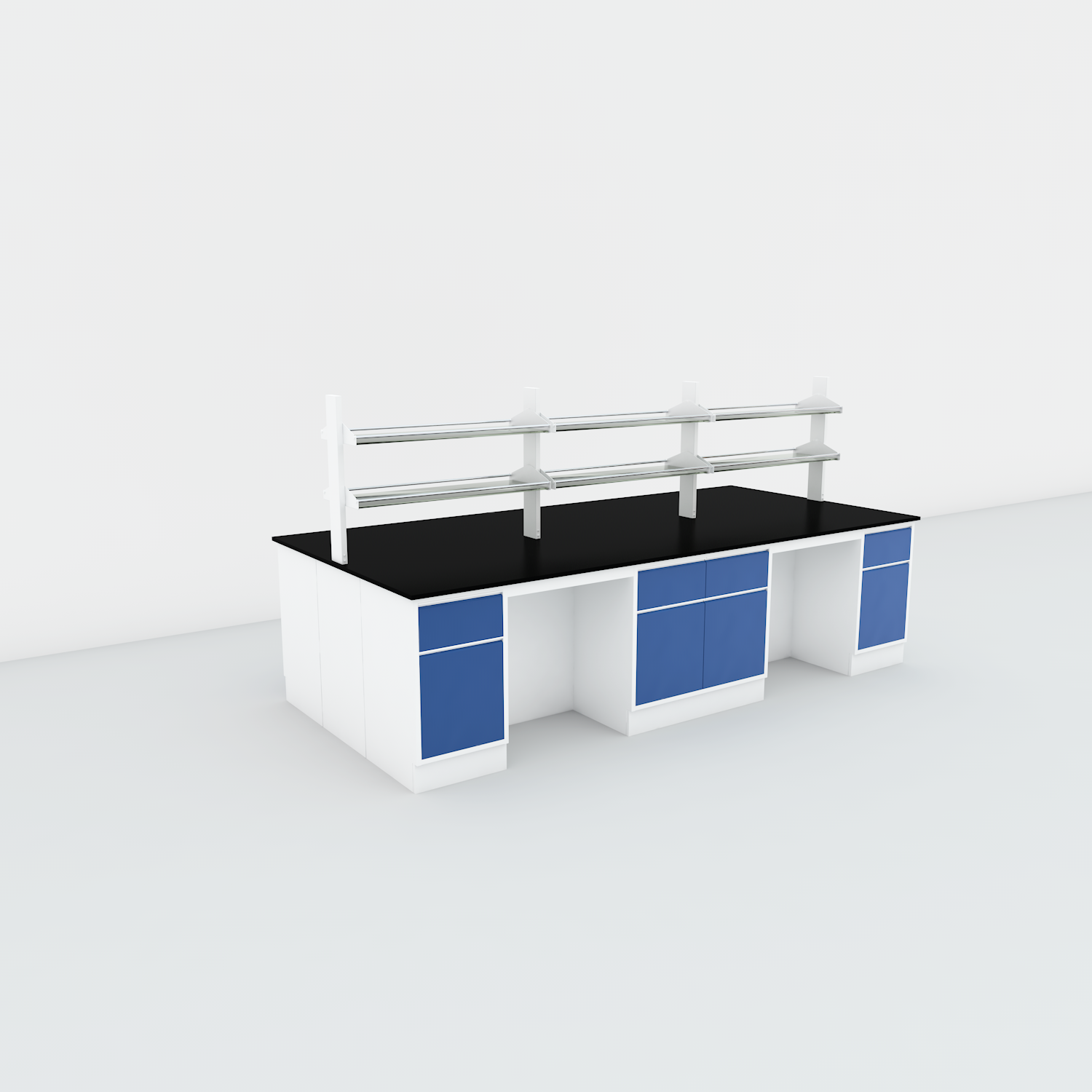

Floor Mounted Lab Bench: Product Overview and Advantages

Our Floor Mounted Lab Bench is an essential, high-efficiency workspace for laboratories, made from high-quality steel-wood or corrosion-resistant stainless steel materials to ensure exceptional durability and stability. The unique floor-mounted design effectively reduces vibration, optimizes space usage, and provides a safe and tidy laboratory environment.

Customizable storage solutions help organize lab equipment efficiently, while the easy-to-clean surface maintains laboratory hygiene. It is widely suitable for research institutions, educational laboratories, and the chemical and pharmaceutical industries.

How to Select the Right Worktop for Your Floor Mounted Lab Bench

When specifying a worktop for a Floor Mounted Lab Bench, match the material to your chemical list, temperature exposure, and loading requirements. Use the following checklist:

- List all chemicals used (name, concentration, volume, temperature).

- Identify the most aggressive substances — select a material that resists those.

- Determine mechanical load and vibration requirements for heavy instruments.

- Consider cleaning and decontamination protocols to choose a compatible surface.

- Plan for service access (utility routing under the bench) and storage integration.

Cost vs. Performance: Making a Value-Based Choice for Lab Benches

Budget is always a factor. High upfront cost materials like stainless steel or engineered stone may pay off through reduced replacement, lower maintenance, and better longevity. Resin tops often provide the best balance of chemical resistance and cost for many chemistry labs. Always calculate lifecycle costs — initial price, maintenance, downtime for repairs, and expected service life — rather than selecting solely on purchase price.

Installation and Quality Assurance Best Practices

Proper installation ensures the expected performance of worktops on lab benches. Best practices include:

- Professional measurement and templating to avoid field modifications that can compromise chemical resistance.

- Sealing joints and fixing anchors as recommended by the manufacturer.

- Validation checks after installation: flatness, seam integrity, and utility connections.

- Documenting maintenance and calibration schedules for equipment mounted to or near worktops.

Safety and Regulatory Considerations for Lab Worktops

Ensure the selected worktop complies with local health and safety codes. Some labs may require anti-static surfaces, ESD protection, or compliance with biosafety level requirements. For labs handling radioactive materials or controlled substances, follow national guidance and institutional policies for containment and decontamination. Consult your safety officer when in doubt.

FAQ — Chemical-Resistant Worktops for Lab Benches

Q: Which worktop material is best for general chemistry labs?

A: Epoxy resin tops are often best for general chemistry due to broad chemical resistance and heat tolerance. Phenolic resin can be a cost-effective alternative for teaching labs with lighter solvent usage.

Q: Can stainless steel be used in organic chemistry labs?

A: Stainless steel is suitable for many applications, especially where hygiene is required. However, be cautious with halogenated solvents and chloride exposure; using 316 grade where needed reduces pitting risk.

Q: Are poured epoxy tops seamless?

A: Yes, poured epoxy can be formed with continuous, seamless surfaces which reduce contamination points and simplify cleaning.

Q: How do I protect worktops from accidental spills of strong oxidizers?

A: Select materials rated for resistant to those oxidizers, use secondary containment (tray or lip), implement spill kits, and ensure rapid neutralization and cleanup procedures.

Q: How often should I inspect and maintain lab bench worktops?

A: Inspect high-use areas monthly and perform a more thorough check quarterly. Immediately address any visible damage, seam failures, or discoloration.

Q: Why choose a Floor Mounted Lab Bench over wall-mounted or island benches?

A: Floor mounted benches provide superior load capacity and vibration damping, ideal for heavy instruments and long-term durability. They also allow more flexible storage and utility routing.

Brand Advantages — Why Choose Our Floor Mounted Lab Bench

Our Floor Mounted Lab Bench combines industry experience and quality materials to deliver a reliable platform for modern laboratories. Key advantages:

- Durable materials: available in corrosion-resistant stainless steel or high-quality steel-wood constructions matched to lab needs.

- Stable floor-mounted design: reduces vibration and increases instrument accuracy and life.

- Customizable storage and utilities: configurable drawers, cabinets, and integrated service modules simplify workflows.

- Hygienic, easy-to-clean surfaces: supports laboratory compliance with cleaning protocols.

- Lifecycle support: guidance on material selection, installation, and maintenance from experienced lab furniture specialists.

Contact / View Product

To support evolving research needs, many facilities turn to adaptability—how modular lab benches improve flexibility and workflow explains why modular systems are increasingly preferred.If you are planning a new laboratory or upgrading existing lab benches and want expert guidance on chemical-resistant worktops, contact our sales and technical team. We can provide material compatibility assessments, layout advice, and custom configurations for the Floor Mounted Lab Bench. Reach out to request a quote, technical datasheets, or an on-site consultation.

References and Further Reading

Authoritative sources for material properties and laboratory safety:

- OSHA — Occupational Safety and Health Administration: https://www.osha.gov

- NIH — Guide for Laboratory Safety: https://www.nih.gov

- ASTM International — Standards for materials: https://www.astm.org

- Wikipedia — Epoxy resin: https://en.wikipedia.org/wiki/Epoxy

- Wikipedia — Phenolic resin: https://en.wikipedia.org/wiki/Phenol-formaldehyde_resin

Top Lab Furniture Design Trends for Modern Laboratories

Comparing Lab Sink Materials: Ceramic, Epoxy, and Steel

Fume Hood Procurement Guide: Key Specs B2B Buyers Need

Corrosion-Resistant Coatings for Lab Sink Cabinets

For Customization

Do you offer custom branding for laboratory furniture?

Yes, we can incorporate custom logos, colors, and branding into your lab furniture to make it unique to your organization.

Can I make changes to my order once it has been placed?

We offer limited flexibility to make changes to your order after it has been placed. Contact our sales team as soon as possible if you need to make modifications.

About Solution

Do you provide laboratory layout design service?

Yes, we provide professional laboratory layout design service to optimize space utilization and workflow according to customer's site and usage requirements.

What is the warranty policy of the product?

We provide 1-3 years warranty service, depending on the product type. Meanwhile, comprehensive after-sales support is provided, including repair and replacement services.

For Company

What types of companies do you work with?

We have worked with a wide range of companies, from small startups to large, multinational corporations. Our expertise in the laboratory furniture industry enables us to meet the needs of various sectors, including healthcare, research, education, pharmaceuticals, and industrial labs.

Floor Mounted Lab Bench

Our Floor Mounted Lab Bench is an essential, high-efficiency workspace for laboratories, made from high-quality steel-wood or corrosion-resistant stainless steel materials to ensure exceptional durability and stability. The unique floor-mounted design effectively reduces vibration, optimizes space usage, and provides a safe and tidy laboratory environment.

Customizable storage solutions help organize lab equipment efficiently, while the easy-to-clean surface maintains laboratory hygiene. It is widely suitable for research institutions, educational laboratories, and the chemical and pharmaceutical industries.

Fume Hood

The fume hood provides safe ventilation to protect against exposure to hazardous or toxic fumes, vapors, or airborne particulate. It is primarily used in laboratory and manufacturing applications to protect the user or environment outside the hood, but can also be used to protect the materials or experiment under the hood.

APPLICATION

Chemistry Lab, physics Lab, biological analysis, pharmaceutical medicine analysis, biological pharmaceutical, plant culture, environmental testing and electronic instrumentation scientific research and so on.

Flammable Storage Cabinet

Safety Cabinets store flammable liquids, corrosives, pesticides and other hazardous materials. All fire-resistant safety cabinets by meet fire codes and regulations for safety storage.

To help protect your people and facility from a potential fire, safety cabinets are engineered to safely contain flammable fuels, solvents, and chemicals. Safety cabinets can not only help everyone store chemicals reasonably, save chemical supplies, but also save human resources, and avoid fires caused by chemicals with the greatest strength.

Class II Type A2 Biological Safety Cabinet for Laboratory

The Class II A2 Biological Safety Cabinet is designed to provide superior biosafety and contamination control for laboratories, research facilities, and clinical settings. With 70% air recirculation and 30% air exhaust, this cabinet ensures a safe and efficient work environment while protecting both the user and the samples.

Equipped with advanced features like a HEPA filtration system, motorized front window, and ergonomic design, this cabinet is a must-have for safe and reliable biological research.

Scan QR Code

Scan QR Code

MaxLabFurniture

MaxLab Furniture

daihongada

Max Laboratory